HELP WITH HEIGHT MAP HAS SUBSTANTIAL Z OFFSET WARNING

-

I just updated from 2.05 to 3.2 firmware and have changed out springs on my heated bed for a silicone solution.

I am trying to do a Mesh Bed Leveling with just 4 points to just get the mounts in the exact position. (I use the DC42 IR Probe)

I keep receiving the error:

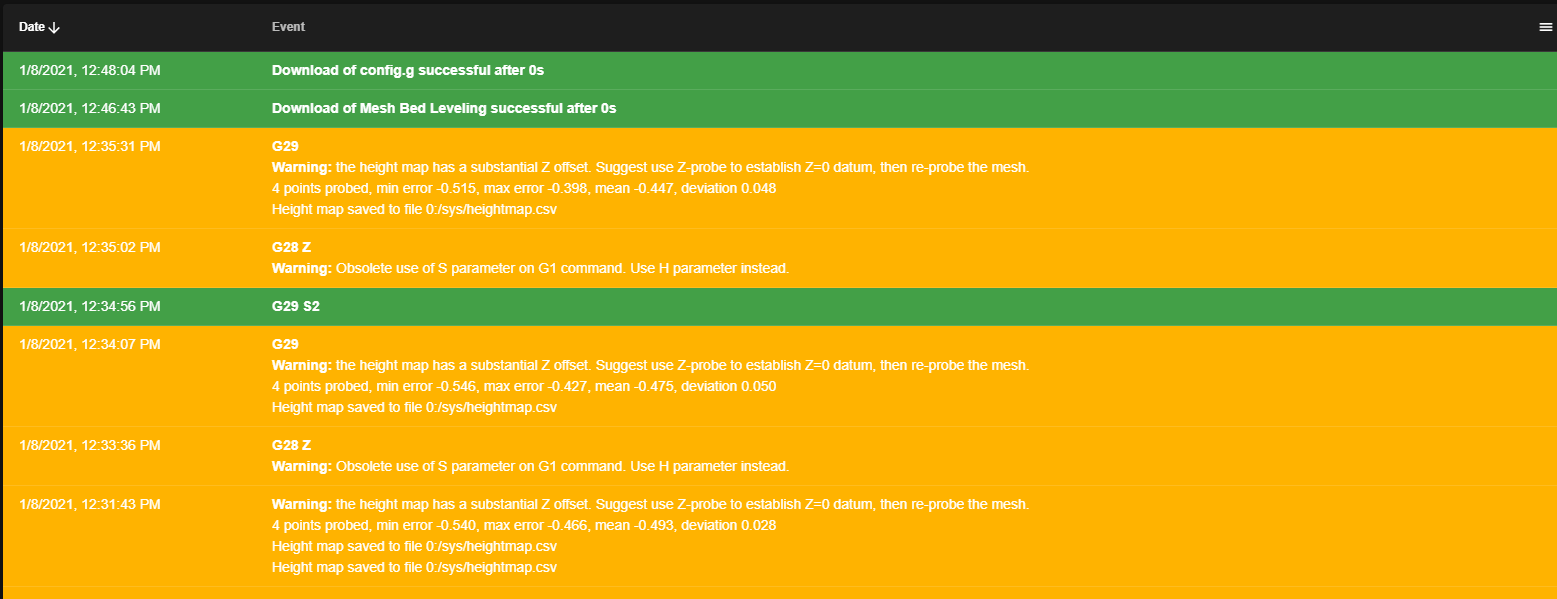

1/8/2021, 12:35:31 PM G29

Warning: the height map has a substantial Z offset. Suggest use Z-probe to establish Z=0 datum, then re-probe the mesh.

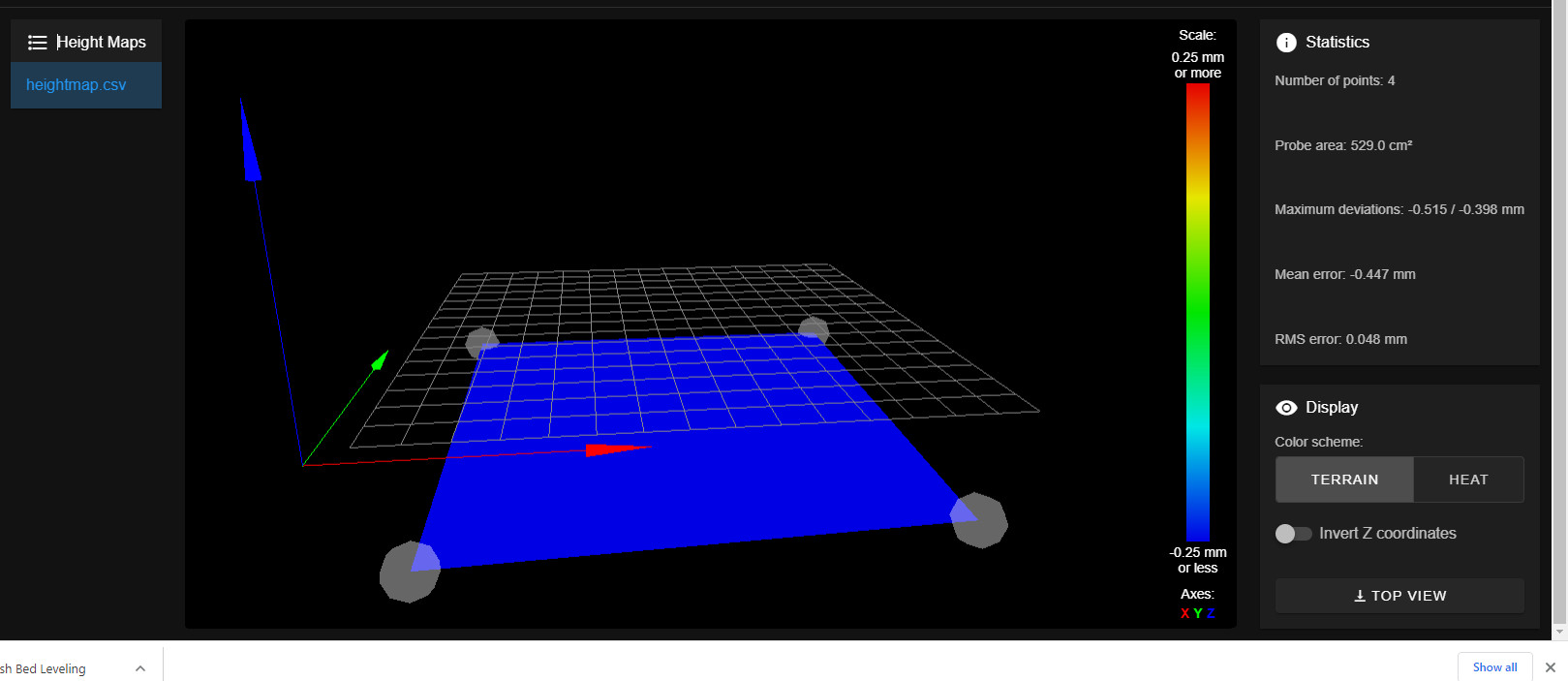

4 points probed, min error -0.515, max error -0.398, mean -0.447, deviation 0.048

Height map saved to file 0:/sys/heightmap.csvI have tried to write a Macro to do the leveling and am not sure where I got crossed up. ANYONE THAT CAN HELP, I'm sure it's something simple.

-

This post is deleted! -

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 ; configure sensor 1 as thermistor on pin e0temp

you are missing the c parameter for your thermistors.

after you changed that you need to pid tune both bed and hotend again.

you really need to keep your files seperate.

homing should only do homing.

what you want to do is write a macro that does the things in sequence

the problem could be that you are using z screw leveling without another z=0 determination.

-

I did PID tune both hotend and bed thermistors and copied results into my config.g. I'm working on separating out the homing scripts. How do I get a another z=0 determination that is where I've been struggling. Attached are my cleaned up home scripts

[0_1610138085213_bed.g](Uploading 100%)

[0_1610138095546_homez.g](Uploading 100%)

[0_1610138138115_Mesh Bed Leveling update.txt](Uploading 100%) -

@Jaw8850 said in HELP WITH HEIGHT MAP HAS SUBSTANTIAL Z OFFSET WARNING:

I did PID tune both hotend and bed thermistors and copied results into my config.g

you tuned with the wrong thermistor settings.

How do I get a another z=0 determination that is where I've been struggling.

G28 Z

the files did not upload

-

-

i would recommend you remove G29 S1 ; load heightmap

from the homing. -

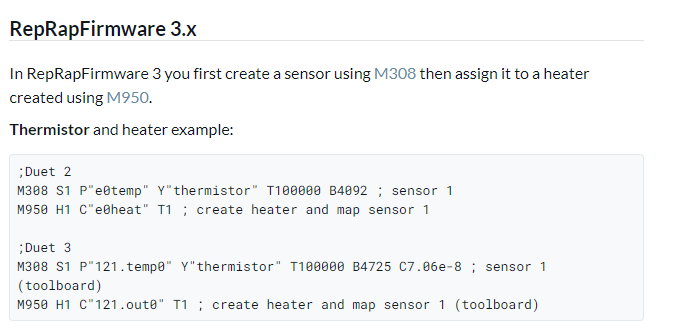

I'm still confused on the Thermistor settings

here is my Bed Thermistor (E3D mains powered heat bed with E3D thermistor (B4725 from E3D documentation)

M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" Q10 T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 R1.115 C329.1 D4.73 S1.00 V24.2 ; disable bang-bang mode for the bed heater and set PWM limit

and my E3D Hotend

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 R1.415 C284.6 D6.03 S1.00 V24.2 ; disable bang-bang mode for heater and set PWM limit -

@Jaw8850 said in HELP WITH HEIGHT MAP HAS SUBSTANTIAL Z OFFSET WARNING:

here is my Bed Thermistor (E3D mains powered heat bed with E3D thermistor (B4725 from E3D documentation)

can you link that, because its wrong. its missing the C parameter

-

@Veti here is link to Wiki for Duet (I'm running Duet 2 Ethernet board) says Duet 3 needs C but Duet 2 doesnt?

https://duet3d.dozuki.com/Wiki/Connecting_thermistors_or_PT1000_temperature_sensors

-

@Jaw8850 said in HELP WITH HEIGHT MAP HAS SUBSTANTIAL Z OFFSET WARNING:

here is link to Wiki for Duet (I'm running Duet 2 Ethernet board) says Duet 3 needs C but Duet 2 doesnt?

it doesnt say that at all.

the duet 2 example is for a completely different thermistor. -

@Veti

I see it now. I used the configurator then did PID and thought I was good. How does this look?; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C7.060000e-8 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" Q10 T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 R1.115 C329.1 D4.73 S1.00 V24.2 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S200 ; set temperature limit for heater 0 to 200C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.060000e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 R1.415 C284.6 D6.03 S1.00 V24.2 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S300 ; set temperature limit for heater 1 to 300CM570 S360 ; Heater fault detections allow 1 minute

-

dont forget to pid tune again. because you were operating at the wrong temperature

-

@Veti

I will definitely do that. I'm just fighting this homing mess. G28 Z throws an error and says insufficient axes homed. this is after I did G28 Y and G28 X it won't let me use G28 Z -

thats because you modified the homez and removed the H2 part

-

@Veti

Thank You!!!!!!!!! I truly appreciate your help. Now I have a baseline I can build from. PID tune in progress -

@Veti

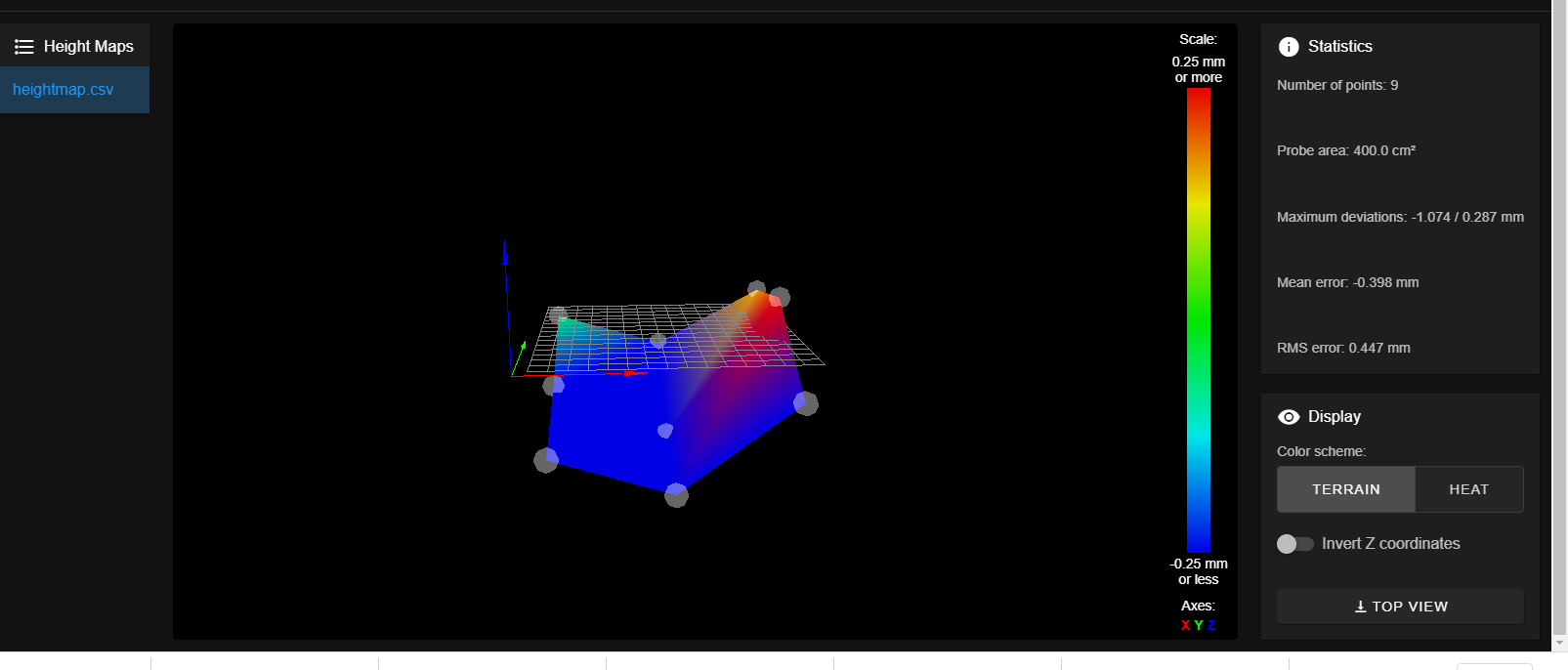

OK, I have re-run PID tuning on bed 1st then hotend. I have trimmed down my config files I believe. I am running G32 which homes all then probes center then probes each side lead screws. I then run G1 X137 Y156 Z5 to move the print head to the center of the bed. I then run G30 to get a zero value followed by G29. When done my mesh is a mess and the original z in the center of the bed is WAY BELOW 0, like -.962. any ideas what may cause this? I am running a mini IR probe and probing each spot 5 times with an S value of 0. I am probing a black textured pei sheet.

-

Can you show a photo of your bed surface?

Was it working at all before you updated from 2.05?

Taking a look at your latest files now.

-

I notice you have S0 in your M558. Delete that. The default is 0.03 and I don't think 0 is a valid way to use it.

Can you also post the results of M122 and M98 P"config.g"?

-

By the way, if you're using stall detection for X and Y you really only need to make a single pass. A slower second pass makes no sense in this context since a good stall needs a short sharp shock.

M913 X50 Y50 Z50 ; drop motor currents to 50% M915 X Y S3 R0 ; set sensitivity to +3 unfiltered G1 H1 X-305 F4800 ; move X all the way left and stop at end G4 P250 ; wait 250msec G1 X10 F12000 ; go back a few mm G4 P250 ; wait 250msec G1 H1 X-305 F4800 ; move slowly to X axis endstop once more (second pass) G1 X10 F12000 ; go back a few mm G4 P500 ; wait 500msec G1 H1 Y-305 F4800 ; move Y all the way forward and stop at end G1 Y10 F12000 ; go back a few mm G1 H1 Y-305 F4800 ; move slowly to Y axis endstop once more (second pass) G4 P500 ; wait 500msec G0 X127 Y142 F12000 ; go to back center of bed for measurement G4 P500 ; wait 500msec