Chamber heater plan

-

I have a plan to build a chamber heater for my anycubic predator. I just want to run that plan by some folks that are smarter than me before I go and do something stupid.

I have an anycubic predator running a duet maestro and a smart effector. I have a fan on E1, so I can't use that pin. But I figured I could use output EXP_0 from the expansion header to control a 25 Amp SSR in bang-bang mode, with a 110V heat gun in the enclosure as the heating element. I picked a heat gun because its got heating element an fan and that seems like the best way to do a chamber heater.

Is this a terrible idea? If so, why, and do you have an alternative suggestion? -

@oryhara I don't know if I'd trust the motor to last for very long- heat guns are normally used intermittently for a minute or two at a time. They may not hold up well under continuous use. They tend to make a lot of noise, too...

-

I had not considered the longevity of the heat gun, but it was only $10 so replacing it will not be a burden. If heat guns burn out quickly I'll see about getting something else.

The noise will not be a problem. The enclosure dampens most sound and the room is not used for anything but the printer so no one will be bothered.

-

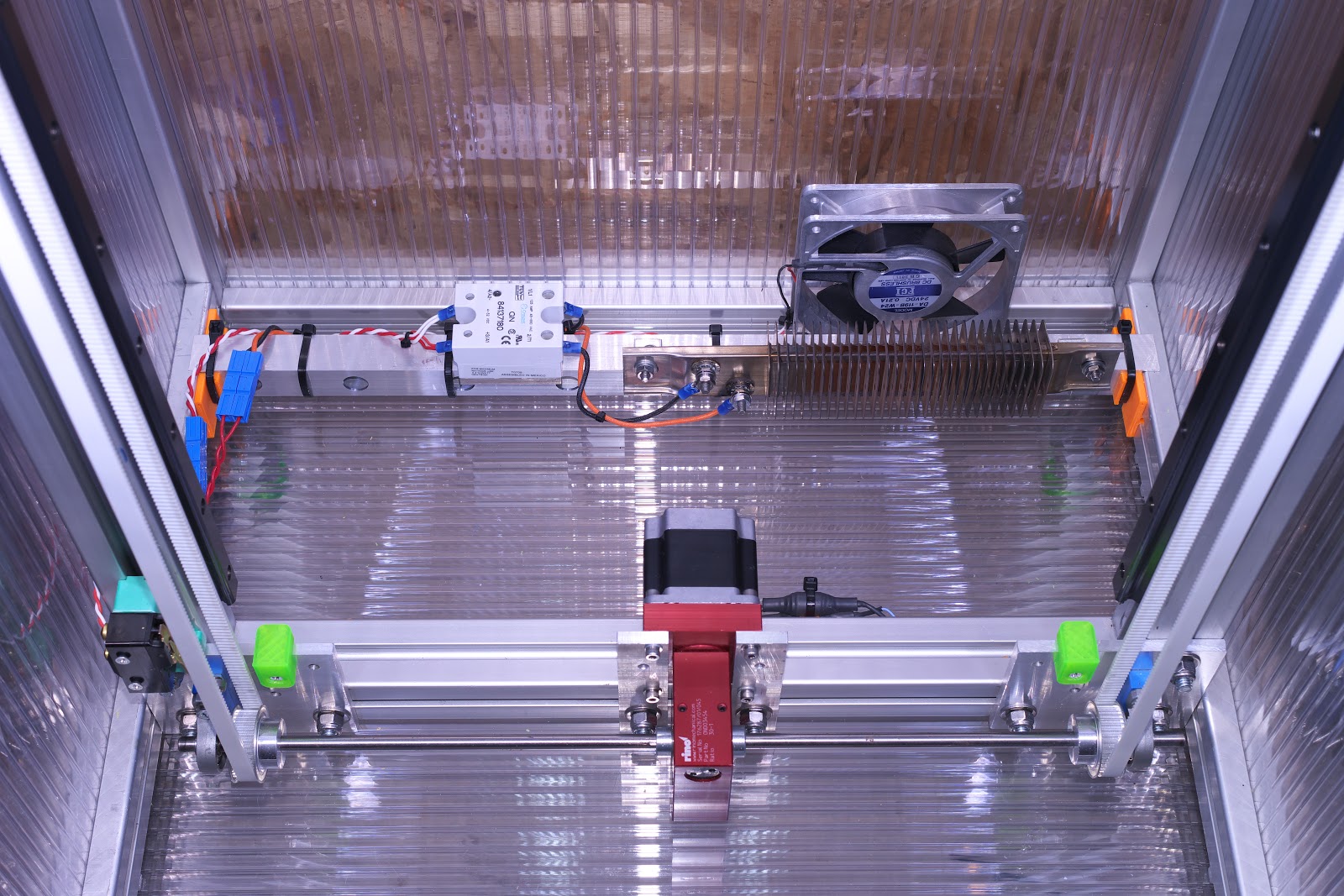

@oryhara I use this setup in my printer- it's a 500W heater switched by an SSR, with a 220V fan wired in parallel with the heater. Power is 117VAC so the fan turns slowly and quietly without creating too much air movement- just enough to keep the heater from getting too hot. The 420 liter enclosure gets to 50C in about 20 minutes. I fitted a sheet metal heat shield (not in this photo) over the Z axis motor to keep it from cooking.

I have found 50C works fine for preventing warping and delamination in ABS prints. I prefer the warm air to be still, but others may have other opinions on that.

I let the printer cool down (about 30 minutes or so) before I take large ABS prints out of the machine.

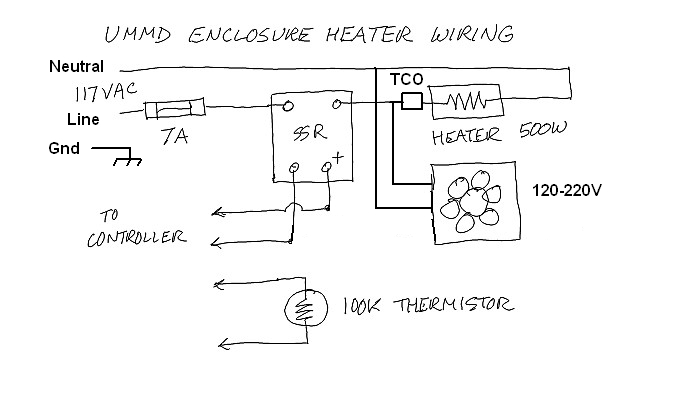

Wiring:

I do not have the TCO installed yet, but it should be there...

-

Where did you find that heating element ?

-

What is a TCO?

-

TCO = Thermal cut off (ie a thermal fuse)

https://fermio.xyz/en/electronics/thermal-fuses/151/thermal-fuse-sk150 -

@CaLviNx Someone at the makerspace scrapped an old stratasys 3D printer. It was one of two 500W heaters that were in the machine. I don't recall the manufacturer, but they can be purchased for about $60 new, and I have seen them on the surplus market for $15.

I think you can buy PTC heaters from China cheaply. Theoretically the PTC will limit the maximum temperature they will hit, but you probably still need a TCO.

When selecting a chamber heater, consider the bed heater power- I have a 750W bed heater so between the two heaters the machine uses 1250W when both heaters are on. That's approaching the limit of a household power outlet.

-

@mrehorstdmd said in Chamber heater plan:

I have a 750W bed heater so between the two heaters the machine uses 1250W when both heaters are on. That's approaching the limit of a household power outlet.

I'd be very curious to see a power draw graph from power on to end of print.

-

@oryhara I tried a heat gun for a heated enclosure once. Lucky I didn't burn the house down when it melted down.

I now use a pair of 200W ceramic heaters with 80mm fans blowing on them. Done this with good results in a few printers. In a bigger enclosure they don't put out enough heat by themselves, but add a heated bed to the equation and you're good.

https://www.amazon.com/Forfuture-go-Reptile-Infrared-Ceramic-Appliances/dp/B07KT8VBNC

-

@CaLviNx said in Chamber heater plan:

Where did you find that heating element ?

McMaster-Carr might not be friendly for you, depending on where you are located

https://www.mcmaster.com/3575K411/Other vendors to get you pointed in the right direction

https://content.thermon.com/pdf/Caloritech/Catalog/FS_Catalog.pdf

https://www.tempco.com/Tempco/Resources/08-Strip-Resources/FinnedStripCatalogPages.pdfThat heater should be from a Stratasys machine. Might be120V, 400W (stamped on the end) or so (looking at one as I type - P/N starts with FS2001, ends with G102).

-

@zemlin

When you say it melted down, what do you mean? -

@Phaedrux I don't have any means to measure the power drain. The chamber heater runs in bang-bang mode IRIC, and the bed in PID. When I start an ABS print, the bed heater and chamber heater both come on at full blast. It takes the bed heater 3 or 4 minutes to get to 105C at which point it starts kicking off and on. The chamber heater takes about 20 minutes to get the chamber up to 50C, and then it turns on and off every minute or so.

The average power while a print is running is probably 300W or so, but of course, peaks are much higher whenever both heaters are on at the same time.

-

@oryhara I don't have photos, but it was an inexpensive heat gun, steel and plastic. It was a real mess when I found it with lots of smoke tracks and scars up the side of the insulation sheet I used to build my enclosure. Took many hours of disassembly and cleaning on my printer to clean all the residue off from the burning plastic in the enclosure.

-

@zemlin

did you have it running constantly in the chamber?Maybe i should rethink my plan and use a different heat source...

-

@oryhara - no, I had it on a stand-alone controller. It heated the space nice and quick, but it didn't last long before it smoked. I would STRONGLY discourage you from taking that route - even with a higher quality heat gun.

This is the temperature controller I've used on my heated enclosure projects.

https://www.amazon.com/Inkbird-Temperature-Controller-Fahrenheit-Thermostat/dp/B019I3YCFS

I hook the cooling circuit up to exhaust fans and have it vented to draw outside are when the fans are running. -

So it seems the heat gun is out. A number of other heat source options have been put forward in this thread. They are as follows.

$65 500W Bolt-Mount Heater from mcmaster who also sells a

$30 500W ceramic lamp heater which are also at amazon as

$16 200W ceramic lamp heaters(suggested to use 2) and I also found

$20 500W PTC heating element, available in many wattages, i just list the 500W for comparison sakeall of these will require a fan to circulate the heat generated, so I'm not factoring that into the comparison.

I'd rather use the maestro to control the heater so it turns on and off with the print than a standalone controller i'd have to manually turn on and off for printing.

And of course all this work is to print ABS(without warping) which I've largely migrated away from in favor of PETG. But I've got a pretty big stockpile of ABS and it would be nice to not have it go to waste. also i like acetone smoothed ABS. its so shiny.

oh and a side note, I just did some quickmafs on my enclosure. It is about 350 liters in volume.

-

@oryhara My printer's 420 liter volume takes about 20 minutes to heat up to 50C with a 500W chamber heater and 750W bed heater setting the bed to 105C.

You can get a coffee maker for $5 at a second hand store and it pull a 500-1500W heater out of it, with a TCO to guard against excessive temperature rise.

-

@mrehorstdmd what temperature would you recommend getting a TCO at?

I've seen them all the way down to 60C but they were all non-resettable temperature fuses.

I'm not overly concerned with the cost. I was just summing up the various things mentioned. I'm actually leaning towards the most expensive of the listed options because its the one that is intended for this use. "The right tool for the right job" and all that. Or maybe the heat lamp but I'm not sure I can fit that into my enclosure without compromising build volume or gantry travel.

-

@oryhara Heat lamps use a high temperature filament to radiate heat to whatever they are shining on (like keeping a plate of food warm in a restaurant). I think a convective heater similar to the one I used would be better for the 3D printer application.

I think the TCO temperature you use will depend on how the heater works and how it's installed in your printer. IRIC, the heater I used can get up to about 400C if there's no fan blowing on it, so I think putting a 100C TCO maybe 10 cm directly above the heater will protect against fan failure. It would also protect against SSR failure by allowing the enclosure temp to get up to about 80C and then shut the heater down. I don't think anything in the printer will be damaged by short term exposure to 80C.

The last thing you want is a self resetting TCO that keeps cycling power on and off to an unsafe, uncontrolled heater.