how to setup duet 3 extension 1LC driver ?

-

@Veti I don't now if it help but I use this motor :

https://www.bondtech.se/wp-content/uploads/2019/02/13003-Nema17-25mm.pdfAnd I have an other question, did the E-step is the step per mm ?

-

@Pseud3mys said in how to setup duet 3 extension 1LC driver ?:

I don't now if it help but I use this motor :

no it does not help. you need to follow the guide and try it for yourself which parameter reduces the standstill noise.

did the E-step is the step per mm ?

i am not sure what you are asking.

-

@Veti Thanks, now fixed in configtool version 3.1.10.

-

@Veti yes I change the mode It is okay now thank you.

-

@Veti I have always some issues..

Some time the button here don't stop spinning, even after than the motor stop spining. -

try a newer dwc

-

Have you defined the heater on the toolboard using the M950 command in your config.g?

For example:

M950 H1 C"121.out0" T1And you need to map the thermistor using the M308 command.

M308 S1 P"121.temp0" Y"thermistor" T100000 B4725 C7. 06e-8 A"Hot End" -

@Veti said in how to setup duet 3 extension 1LC driver ?:

try a newer dwc

It is already the lastest version, beta4.1 for the reprap firmawre and beta4 for the web interface.

-

@CaLviNx yes, this is my config for it:

; configure sensor 1 as thermistor on pin 121.temp0 M308 S1 P"121.temp0" Y"thermistor" T500000 B3600 C1.196220e-7 H-12 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 -

Try this instead

M569 P121.0 S1 ; Driver 121.0 is connected to the extruder motor output (Driver 0) on the toolboard LC1 & goes forwards -

@CaLviNx said in how to setup duet 3 extension 1LC driver ?:

M569 P121.0 S1 ; Driver 121.0 is connected to the extruder motor output (Driver 0) on the toolboard LC1 & goes forwards

ah yes for the driver I aldready put some thing similary:

; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P121.0 S1 D3 V2000 ; physical drive 1.0 goes forwards M569 P122.0 S1 D3 V2000 ; physical drive 2.0 goes forwards M584 X0.0 Y0.1 Z0.2 E121.0:122.0 ; set drive mapping M350 X256 Y256 Z256 E64:64 I0 ; configure microstepping without interpolation M92 X80.00 Y80.00 Z400.00 E415.00:415.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X31800.00 Y31800.00 Z31800.00 E1200.00:1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800:800 ; set motor currents (mA) M84 S0 ; Disable motor idle current reduction -

Please post your complete config.g file.

-

@dc42

Here my full config.g file:; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.9 on Wed Dec 02 2020 17:31:45 GMT+0100 (heure normale d’Europe centrale) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"MultiTool Cartesian" ; set printer name ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P121.0 S1 D3 V2000 ; physical drive 1.0 goes forwards M569 P122.0 S1 D3 V2000 ; physical drive 2.0 goes forwards M584 X0.0 Y0.1 Z0.2 E121.0:122.0 ; set drive mapping M350 X256 Y256 Z256 E64:64 I0 ; configure microstepping without interpolation M92 X80.00 Y80.00 Z400.00 E415.00:415.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X31800.00 Y31800.00 Z31800.00 E1200.00:1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800:800 ; set motor currents (mA) M84 S0 ; Disable motor idle current reduction ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X1000 Y1000 Z800 S0 ; set axis maxima ; Endstops ; WARNING: No endstops configured ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X20:980 Y20:980 S80 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C ; configure sensor 1 as thermistor on pin 121.temp0 M308 S1 P"121.temp0" Y"thermistor" T500000 B3600 C1.196220e-7 H-12 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; configure sensor 2 as thermistor on pin 122.temp0 M308 S2 P"122.temp0" Y"thermistor" T500000 B3600 C1.196220e-7 H-10 L-12 M950 H2 C"122.out0" T2 ; create nozzle heater output on 122.out0 and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S280 ; set temperature limit for heater 2 to 280C ; Fans M950 F0 C"121.out2" Q500 ; create fan 0 on pin 121.out2 and set its frequency M106 P0 S0 H1 T160 ; set fan 0 value. Thermostatic control is turned on M950 F1 C"122.out2" Q500 ; create fan 1 on pin 122.out2 and set its frequency M106 P1 S0 H2 T160 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 S"Extrudeur 0" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 S"Extrudeur 1" D1 H2 F1 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M563 P2 S"Spindle" F-1 ; define tool 2 G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory -

@Pseud3mys said in how to setup duet 3 extension 1LC driver ?:

M350 X256 Y256 Z256 E64:64 I0 ; configure microstepping without interpolation

this will overload your cpu. go with x16 and interpolation for now.

M906 X800 Y800 Z800 E800:800 ; set motor currents (mA)

you need to set the correct current for the motors. go with 75% of the rated current.

-

The X, Y, Z motors are, for now not connected. I am just tring to setup the extruder/hotend. So I don't use the XYZ driver.

-

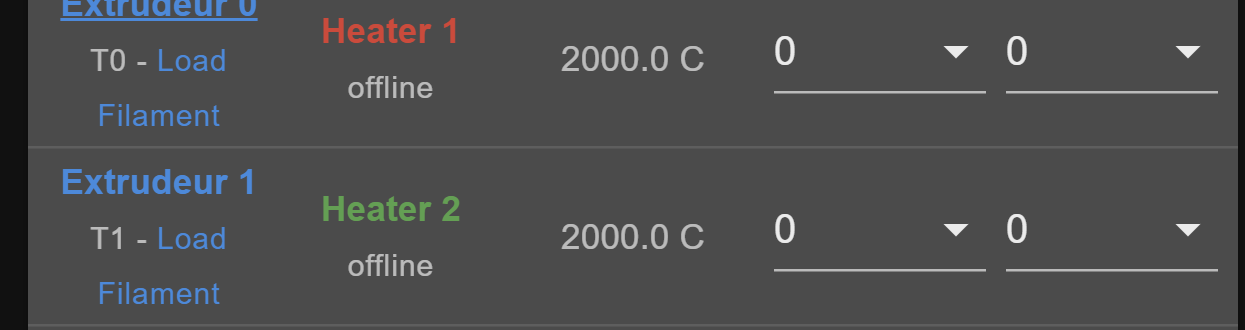

just to prevent, after a restart when we change the config.g file (when we click yes on the pupop "reset board ?") this happen:

I am in beta4.1 and I think this didn't happen in beta4 (whoever I am not sure).

I just need an emergency stop to fixe it. -

I tested now and it seem to not sping without stoping anymore. So I assume that the issues is okay.

-

@Pseud3mys said in how to setup duet 3 extension 1LC driver ?:

just to prevent, after a restart when we change the config.g file (when we click yes on the pupop "reset board ?") this happen:

I am in beta4.1 and I think this didn't happen in beta4 (whoever I am not sure).

I just need an emergency stop to fixe it.Known reasons for the "offline" heater status being reported are:

-

You have updated the tool board firmware but not restarted the Duet since then. The next version of DWC will prompt you to restart the Duet after updating tool or expansion board firmware.

-

The tool or expansion board has reset. This often happened in tool/expansion board firmware 3.2beta4 if a heater fault or temperature reading error occurred. I have fixed it in tool/expansion board firmware 3.2beta4.1, which I added to the 3.2beta4.1 release files yesterday.

-

-

It is a reset:M122 B122

Diagnostics for board 122:

Duet TOOL1LC firmware version 3.2-beta4.1 (2020-12-03)

Bootloader ID: not available

Never used RAM 4580, free system stack 96 words

HEAT 50 CanAsync 89 CanRecv 83 TMC 60 MAIN 326 AIN 64

Last reset 00:00:19 ago, cause: software

Last software reset at 2020-12-03 10:17, reason: HardFault, available RAM 4360, slot 1

Software reset code 0x0060 ICSR 0x00417003 SP 0x200011c0 Task

Stack: 20001014 00000012 0001d3e3 00000000 20000928 0001757d 000184fe 01000000 0000aed0 0000afca 20001210 200032d8 00000020 00017d11 20004668 00000000 20001300 000086e5 0000aed0 20004678 0000afca 41a73180 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5

Driver 0: position 0, 80.0 steps/mm, standstill, SG min/max 0/0, read errors 0, write errors 1, ifcnt 36, reads 9946, writes 9, timeouts 0, DMA errors 0

Moves scheduled 0, completed 0, in progress 0, hiccups 0

No step interrupt scheduled

VIN: 12.3V

MCU temperature: min 28.7C, current 28.9C, max 28.9C

Ticks since heat task active 197, ADC conversions started 19940, completed 19940, timed out 0

Last sensors broadcast 0x00000000 found 0 201 ticks ago, loop time 0

CAN messages queued 99, send timeouts 0, received 189, lost 0, free buffers 36But I am in beta 4.1 and it happen with both heater off. Only when I reset the board via the dialogue box that appear then we save the config.g file