ToolBoard: 2 wires fan, heater fault and how to extrude ?

-

@dc42

This is my new config for the thermistor:M308 S1 P"temp2" Y"thermistor" T500000 B4723 C1.196220e-7 -

the doc say:

Lnnn ADC low offset correction, default 0 (ignored if the hardware supports automatic ADC gain and offset calibration)

Hnnn ADC high offset correction, default 0 (ignored if the hardware supports automatic ADC gain and offset calibration)but I don't understand, do you have an example of use ?

-

@dc42

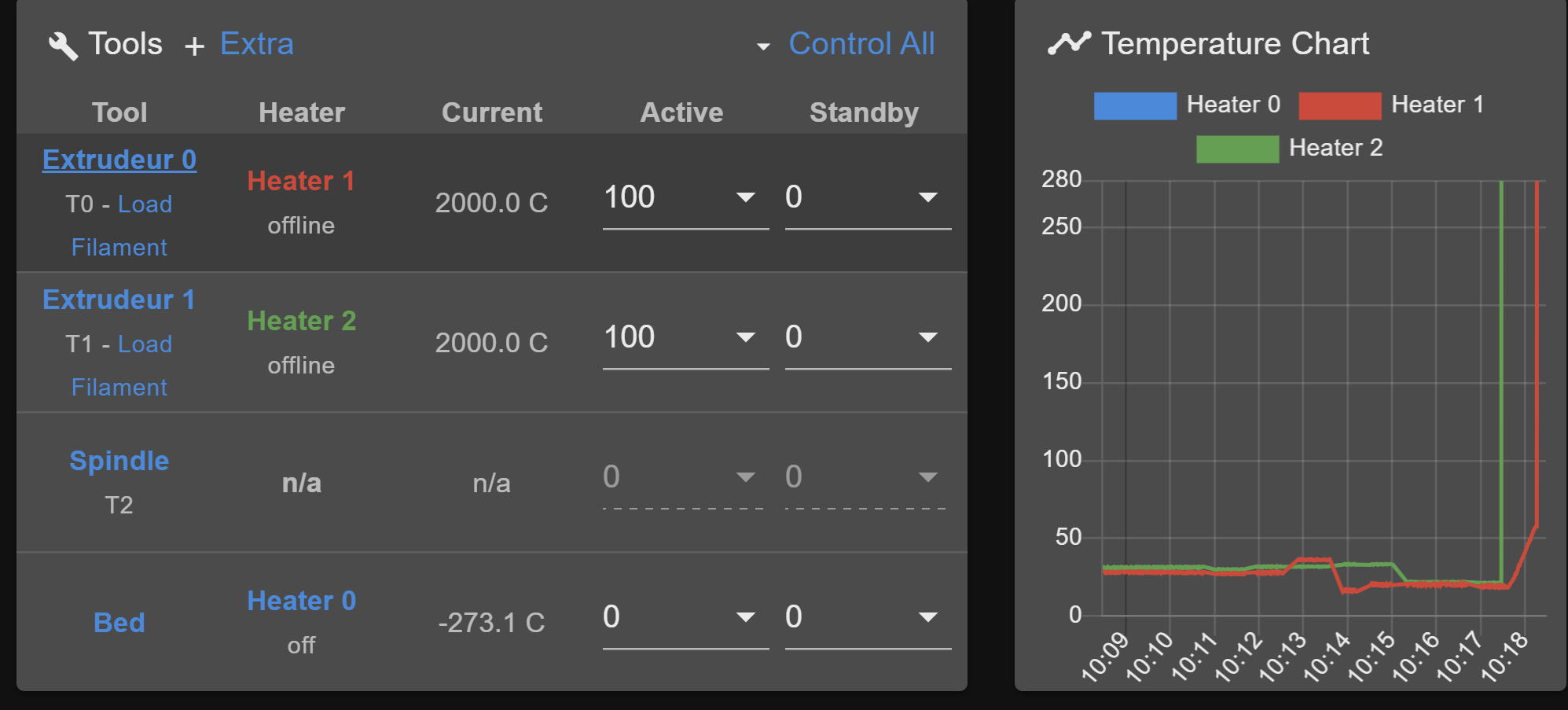

(the Heater 2 is not connected, it is just the heater 1)M308 S1 P"121.temp0" Y"thermistor" T500000 B3600 C1.196220e-7 H-7 ; configure sensor 1 as thermistor on pin 121.temp0 M308 S2 P"122.temp0" Y"thermistor" T500000 B3600 C1.196220e-7 H-10 ; configure sensor 2 as thermistor on pin 122.temp0I modify the config, now at 20°C it return 20°C but je same fault accure after ~30°C..

-

Using RRF 3.2beta4 you can set the H and L parameters automatically even on tool boards. See https://duet3d.dozuki.com/Wiki/Calibrating_thermistor_and_PT1000_readings#Section_Semi_automatic_calibration.

-

The fault with heater 2 is expected. There is no heater connected, so when the heater output is turned on, the firmware doesn't see a rising temperature, so it flags a heating fault. This is to avoid a dangerous situation, for example if the heater is working but the thermistor has fallen out of the heater block.

The reason that heater 1 is reporting a fault is probably that your M307 parameters are inappropriate for your hot end. In particular, the A597 parameter is probably too high. What type of hot end is it, and what is the power of the heater cartridge?

-

@Pseud3mys, I have investigated your M122 report and discovered that the heat task stack can overflow when a tool board reports a heater fault. I have fixed this in release 3.2beta4.1 of the tool board firmware, and put an updated Duet3Firmware-TOOL1LC.bin file in the release at https://github.com/Duet3D/RepRapFirmware/releases/tag/3.2beta4.1. Please update your tool boards to this version. M115 B# (where # is the CAN address of the tool board) will report version 3.2beta4 if the old firmware is running, and 3.2beta4.1 if the new firmware is running.

-

@dc42 hi, With beta 4.1 boards don't reset, and with the semi auto config for H and L thermistor, 1 of the 2 return the correct temperature, and the heating work with this one. But, the second is still wrong (by 15°C, at ~17°C), what is the problem ? The two have exactly the same config except for H and L setting.

-

I check the 2 resistances values, both are at 4.34 Kohm (~11°C). but one thermistor return ~10°C degrees more than the real temperature (~21°C)..

And it is enough to raise a fault with the heater, so it is disturbing.M308 S1 P"121.temp0" Y"thermistor" T500000 B3600 C1.196220e-7 H-12 L0 M308 S2 P"122.temp0" Y"thermistor" T500000 B3600 C1.196220e-7 H-10 L-12All the value are equal exept for H and L but they don't change anything significantly (I tried to put the same value).

So why one of the thermistor return a wrong value ? -

measure the resistance of the thermistors at room temperature and see of they measure the same value.

-

@Pseud3mys said in ToolBoard: 2 wires fan, heater fault and how to extrude ?:

I check the 2 resistances values, both are at 4.34 Kohm (~11°C).

Yes I already did it. It is the same value (4.34 kohm) at 11°C

-

can you measure the resistance of R21 on the boards

another thing to try is switch to the second thermistor port

121.temp1

-

Okay thank you I will try that this evening.

-

okay so the R21 resistance is about 2K18 for both two board.

I saw on an other post that is the correct value. -

then i dont know where the difference comes from.

you could get some pt1000 ones. maybe they provide better results. -

@Veti said in ToolBoard: 2 wires fan, heater fault and how to extrude ?:

then i dont know where the difference comes from.

you could get some pt1000 ones. maybe they provide better results.but the thermistor isn't the problem, the two have the same resistance.

-

@Veti I there a way to have the value that read the borad directly ?

-

i dont know where it could come from.

i would play a bit with the H and L values.

what do you get when you set the same on both?

-

@Veti I have a difference too, but I played a bit with the H and L value and now it is okay, the hotend doesn't return fault.

-

@Pseud3mys said in ToolBoard: 2 wires fan, heater fault and how to extrude ?:

I check the 2 resistances values, both are at 4.34 Kohm (~11°C). but one thermistor return ~10°C degrees more than the real temperature (~21°C)..

And it is enough to raise a fault with the heater, so it is disturbing.M308 S1 P"121.temp0" Y"thermistor" T500000 B3600 C1.196220e-7 H-12 L0 M308 S2 P"122.temp0" Y"thermistor" T500000 B3600 C1.196220e-7 H-10 L-12All the value are equal exept for H and L but they don't change anything significantly (I tried to put the same value).

So why one of the thermistor return a wrong value ?You don't need to set the H and L values in config.g because after you run the semi-automatic calibration procedure, the required H and L values are store in non-volatile memory.

You could try removing the H and L values and run the semi-automatic calibration again on the board that is showing the error. But if that doesn't work, use your manually-adjusted H value.

-

@dc42 I change the H value manually and now it work. Thank you for your help !