Magnetic Filament Monitor question

-

@oozeBot You can, it just won't be as accurate due to filament hysteresis. To get sensible numbers out of it, you may need to increase the 'E' parameter (minimum extrusion length before a commanded/measured comparison is done) to something much larger than 3mm, perhaps 10 to 20 mm. Then setting the range very wide with the 'R' parameter (allow the filament movement reported by the sensor to be between aa% and bb% of the commanded values), such that only no movement triggers it, eg R5:200.

Make sure your filament sensor firmware is on the latest version, which reports 'agc' and 'mag'. I've just updated the troubleshooting section of the Magnetic filament sensor to explain these! See https://duet3d.dozuki.com/Wiki/Duet3dFilamentMonitor_RotatingMagnetVersion?revisionid=HEAD#Section_Errors_during_operation

Ian

-

I use it with about 50cm reversed bowden (PTFE tube with 4ext 3int mm diameter), that has ~50cm. It works without any issues with settings:

M591 D0 P3 C"<some_io>.in" S1 L25.4 R60:140 E12.7

-

Thank you both for the insight.. I picked one up awhile back but am just now getting to testing it out. Maybe we won't get the full benefits from it the way I detailed, but as long as problems are detected within ~50mm, I think it will suffice.

-

@oozeBot if you just want present/not present then a simple switch does the job.

For it to work ok far from the extruder the path needs to be constrained, that means on a retract the extruder needs to push the filament all the way back up the feed tube past the sensor. That means retracts may not be able to be as fast.

-

@T3P3Tony what I like about the idea of using your magnetic filament monitor instead is that, for any reason, it stops spinning, I can conclude something is wrong and the print must be stopped.

A switch can’t do that.. all it can do is detect a runout.

-

Best is to have both - filament monitor with switch. This solves one problem (at least for me) - when runout is detected by filament monitor filament end tip is too far, and extruder can not push back enough filament to take it out of tube. Switch has the advantage that it reacts basically immediately.

-

@oozeBot yes absolutely but for that to be most use it needs to be close enough to the extruder to react in an appropriate time so.

-

-

@oozeBot Fix issues - yes. But simple filament runout detection? Imo in case filament runout detected, it would be nice that extruder is able to push back what is in the tube up to the point, that this leftover can be pulled out by fingers without disconnecting bowden (reversed bowden in my case).

-

@T3P3Tony quick question. Can i supply the sensor with 5V?

-

@T3P3Tony i saw that the AtTiny44 will handle 5V. Does the Magnetic Sensor aswell? I will try to use the Sensor on a BTT SKR Board

-

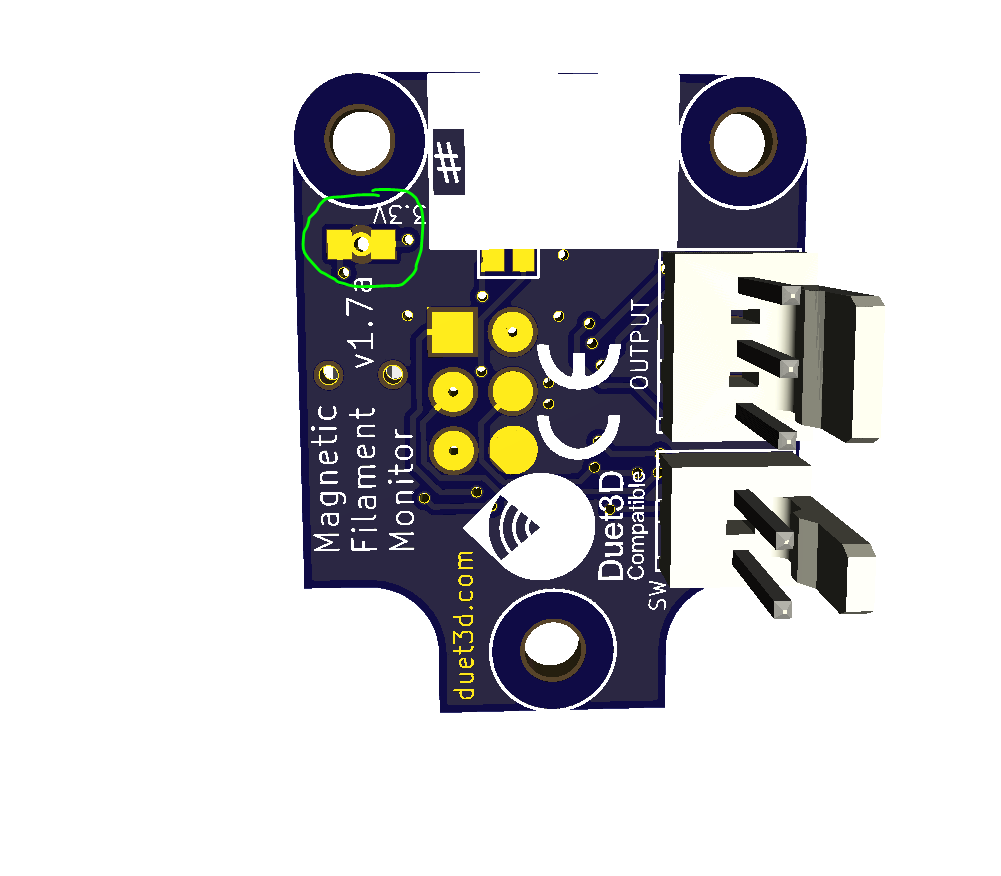

There is a cuttable jumper on the back of the filament monitor marked 3.3v:

If you use a small drill bit to carefully remove the connection between the two pads then the sensor will operate in 5V mode. I would test that the pads are actually disconnected by checking that there is no continuity between them with a voltmeter.

-

@t3p3tony just FYI. It's not noted in the wiki

would be nice to do!

would be nice to do!