Duet 2 Wifi Always Disconnects from Wifi and PanelDue

-

@jay_s_uk said in Duet 2 Wifi Always Disconnects from Wifi and PanelDue:

And an output of M115 so we can confirm the firmware version

Included in M122 output, except for firmware date.

Ian

-

I connected via USB. YAT say's I am connected on com3. I send M115 YAT sends, but does not receive anything.

-

@Quadcells Try a different cable? It would be very odd that the firmware isn't accessibly by USB either.

Ian

-

try a different cable even if the computer sees the Duet 2 board like it does and say's it is on com port 3?

I will do it, just seems strange. -

I have tried 6 cables, it's easy to see what cables work as the one that do Duet 2 shows up in Device Manager and the cables that don't work Duet 2 does not show up in Device Manager. I also tried every baud rate in the pull down list.

Still M115 does not report anything back after sending.

/bill -

@Quadcells installed the Driver?

-

What driver?

-

@PCR The laptop I am using had those drivers installed. I went and re-installed the drivers and YAT.

YAT connects to the Duet2 wifi, but sending M115 or M122, still no response from the Duet2 Wifi board.

I guess I will have to wait to see what happens when the filament runs out.

Would it help to see my config.g file? I happen to download it before I started the print. -

@Quadcells said in Duet 2 Wifi Always Disconnects from Wifi and PanelDue:

Would it help to see my config.g file?

Can't hurt. Does seem that all communication has ceased. I'd guess some buffer overflow, that hasn't effected the motion planner. I'd still expect pause to work, but then you're going to have problems restarting it. I'd feed in filament behind the old filament so it doesn't pause, to finish the print, rather than risk it pausing but failing to restart. If you have M911 (power loss) defined, you could just pull the plug!

Ian

-

It will be tough to push filament thru the way my setup is, but I can try. This really sucks if I lose this print.

I never set up M911 since I have my printer on a large UPS. But I will now if it helps in this type of problem. I also have debug off (M111 S0).

BTW: this communication lose happens on both of my Duet2 Wifi boards. After this I really need to find out why this happens. Maybe I should think about moving to RRF3.x but was skeptical since one printer is a delta, the other a core xy with a Bltouch which I heard could be problems with RRF3.x but that might of been in earlier release of the firmware.;*** Networking

M552 S1 ; Turn network on;welcome sound

M300 P2000 S5000; General preferences

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M111 S0 ; Debug off

M555 P1 ; Set output to look like RepRap

M575 P1 B57600 S1 ; Comms parameters for PanelDue

M667 S1 ; Select CoreXY mode

; Disable Fan 1 thermostatic mode

M106 P1 H-1; Drives

M584 X0 Y1 Z5:6:7 E3:4:8:9 ; Map Z to drivers 5, 6, 7. Define unused drivers 3,4,8 and 9 as extruders

M569 P0 S0 ; Drive 0 goes forwards (change to S0 to reverse it)| X stepper

M569 P1 S1 ; Drive 1 goes backwards | Y Stepper

M569 P2 S1 ; Drive 2 goes forwards | Extruder

M569 P3 S0 ; Drive 3 goes forwards | Extruder (unused)

M569 P4 S1 ; Drive 4 goes forwards | Extruder (unused)

M569 P5 S0 ; Drive 5 goes backwards | Front Left Z

M569 P6 S0 ; Drive 6 goes backwards | Rear Left Z

M569 P7 S0 ; Drive 7 goes backwards | Right Z;Leadscrew locations

M671 X-9.72:-11.26:343.31 Y16.6:278.3:150.0 S7.5 ;Front left, Rear Left, RightS7.5 is the max correction - measure your own offsets, to the bolt for the yoke of each leadscrew; Axis and motor configuration

M350 X16 Y16 Z16 E16 I1 ; set 16x microstepping for axes & extruder, with interpolation

M92 X201.5 Y201.5 Z3200 E837 ; Set steps per mm, X/Y may be more around 201.5 for accuracy

M566 X1000 Y1000 Z30 E20 ; Set maximum instantaneous speed/jerk changes (mm/min)

M203 X10500 Y10500 Z900 E3600 ; Set Maximum speeds (mm/min)

M201 X3000 Y3000 Z20 E1000 ; Accelerations (mm/s^2)

M906 X2240 Y2240 Z1345 E320 I60 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z-0.2 S1 ; set axis minima and low homing switch positions (adjust to make X=0 and Y=0 the edges of the bed)

M208 X300 Y290 Z300 ; set axis maxima and high homing switch positions (adjust to suit your machine)

;M208 S1 Z-5 ;set minimum Z travel; Endstops

M574 X1 Y1 Z0 S1 ; set homing switch configuration (x,y at min, z at max) IF YOU NEED TO REVERSE YOUR HOMING SWITCHES CHANGE S1 to S0; Z-Probe

;*** If you have a switch instead of an IR probe, change P1 to P4 in the following M558 command ***

M574 Z1 S2 ; Set endstops controlled by probe

M556 S0 X0 Y0 Z0 ; Set orthogonal axis compensation parameters

M557 X15:215 Y15:195 S20 ; Define mesh grid;BLTouch

;M558 P9 X0 Y0 Z1 H5 F50 T6000 A5 S0.02 ; original

M558 P9 H5 R1 F50 T6000 A5 S0.02 B1 ; from railcore Wiki

G31 X-10.0 Y44.8 Z0.935 P25 ; Customize your offsets appropriately.

;G31 X2.10 Y42.8 Z2.140 P25 ; original, Customize your offsets appropriately.

M307 H3 A-1 C-1 D-1; Heaters and thermistors

M307 H0 A215.7 C711.5 D0.8 S1.00 B0 ; Bed Heater You should set the model parameters by auto tuning (using M303) for your setup.

M307 H1 A270.7 C90.4 D6.7 B0 S1.0 ; Kraegars Heater 1. You should set the model parameters by auto tuning (using M303) for your setup.

M307 H2 A270.7 C90.4 D6.7 B0 S1.0 ; Kraegars Heater 2. You should set the model parameters by auto tuning (using M303) for your setup.

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M143 H1 S280 ; Set temperature limit for heater 1 to 280C

M143 H2 S280 ; Set temperature limit for heater 2 to 280C

M305 P0 S"Bed" T100000 B3950 R4700 H0 L0 ; BOM thermistor values. Put your own H and/or L values here to set the bed thermistor ADC correction

M305 P1 S"E0" T100000 B4725 C7.06e-8 R4700 H0 L0 ; E3D Semitec 104GT2 thermistor values. Put your own H and/or L values here to set the first nozzle thermistor ADC correction

M305 P2 S"E1" T100000 B4725 C7.06e-8 R4700 H0 L0 ; E3D Semitec 104GT2 thermistor values. Put your own H and/or L values here to set the first nozzle thermistor ADC correctionM305 P101 X1001 S"Duet Drivers"

M305 P102 X1002 S"Duex5 Drivers"M305 P103 X3 T100000 B4725 C7.06e-8 R4700 H0 L0 S"Chamber Temperature" ; Chamber Temperature sensor connected to Duex5 board

M305 P104 X405 T22 S"Filament DryBox Temperature"

M305 P105 X455 T22 S"Filament DryBox Humidity[%]"M305 P106 X6 T10000 B3950 R4700 H0 L0 S"Coolent Temperature" ; Tool 1&2 heat sink cooling.

; Fans

M106 P0 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off 24v.

M106 P1 S1 I0 F500 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off 24v.

M106 P2 S1 I0 F500 H-1 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off 24v.

M106 P3 S1 I0 T25 H103 ; Chamber fans 0.24amps 12v.;M106 P7 S1 ; Buzzer

M106 P7 S50

M106 P7 S0M106 P8 F100 L0.6 B1 T20:40 H100:101:102 C"DuetWifi/Duex5 Fans" ; fans for cooling Duet wifi and Duet Duex5 stepper chips 12v.

; Fans as LEDs

;M106 P4 S1 ; Status LED GREEN 3D Printer Printing

;M106 P5 S1 ; Status LED RED 3D Printer Warning or paued

M106 P6 S1 ; Status LED BLUE 3D Printer Idle; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0.0 Y0.0 Z0.0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

;*** If you have a single-nozzle build, comment the next 2 lines

M563 P1 D1 H2 ; Define tool 1

G10 P1 S0 R0 X0.40 Y20.00 ; Set tool 1 operating and standby temperatures

;G10 P1 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic power saving.

; Uncomment to enable auto-pause if the power voltage drops below the pause threshold.

; The firmware records the current state of the print so that it can be resumed when power is restored

; M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss; Filament Sensor

M591 D0 P1 C3 S1 ;Filament Sensor on E0, High when filament present, E0 end stop, filament monitoring enabled which triggers pause.g

M591 D1 P1 C4 S1 ;Filament Sensor on E1, High when filament present, E1 end stop, filament monitoring enabled which triggers pause.g; Custom settings

M570 S360 ; Hot end may be a little slow to heat up so allow it 180 seconds

M106 P0 S0 ; turn off fans

M106 P1 S0 ; turn off fans

M106 P2 S0 ; turn off fans

T0 ; select first hot end; Miscellaneous

M501 ; Uncomment if you wish to load saved parameters from non-volatile memory -

Update:

I decided to send M552 S1 to the printer via YAT and then the printer showed up on my wireless network.

But still cannot access the Duet using DWC.

I sent M552 S0 and the blue LED next to the wifi module turned off.

I sent M552 S1 and the LED flashed and then stayed on.

Still cannot access the Duet board. -

@Quadcells Try M552 S-1 (disables Wifi module), then M552 S1. But I think it's unlikely to work, as it seems like all comms are not working. It would be really good to get an M122 report as soon as you can!

Ian

-

Hi, Well I could not feed the filament through and it paused and no way to resume.

Funny how "STOP" worked on the paneldue and nothing else. As soon as I hit Stop connection to YAT started to work.

M155 returned - Firmware ver: 2.05.1 Electronics: Duet Wifi 1.02 + DueX5 Firmware_date: 2020-02-09b1

M122 returned:Bill Tortorello billtortorello@gmail.com

12:01 PM (0 minutes ago)

to me=== Diagnostics ===<LF>RepRapFirmware for Duet 2 WiFi/Ethernet version 2.05.1 running on Duet WiFi 1.02 or later + DueX5<LF>Board ID: 08DGM-9T6BU-FG3S0-7J1F0-3S86R-KA5VF<LF>Used output buffers: 1 of 24 (15 max)<LF>=== RTOS ===<LF>Static ram: 25712<LF>Dynamic ram: 95072 of which 0 recycled<LF>Exception stack ram used: 320<LF>Never used ram: 9968<LF>Tasks: NETWORK(ready,1440) DHTSENSOR(blocked,228) HEAT(blocked,1232) DUEX(suspended,160) MAIN(running,3740) IDLE(ready,160)<LF>Owned mutexes:<LF>=== Platform ===<LF>Last reset 00:10:07 ago, cause: software<LF>Last software reset at 2020-09-24 11:48, reason: User, spinning module GCodes, available RAM 9744 bytes (slot 3)<LF>Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0xffffffff Task 0x4e49414d<LF>Error status: 0<LF>Free file entries: 10<LF>SD card 0 detected, interface speed: 20.0MBytes/sec<LF>SD card longest block write time: 0.0ms, max retries 0<LF>MCU temperature: min 35.5, current 35.8, max 36.0<LF>Supply voltage: min 24.1, current 24.2, max 24.3, un[Warning: Maximal number of bytes per line exceeded! Check the EOL (end-of-line) settings or increase the limit in the advanced terminal settings.]

-

Can you change the line ending setting in YAT so that we can see the full report?

-

Hi,

M122<CR>

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 2.05.1 running on Duet WiFi 1.02 or later + DueX5

Board ID: 08DGM-9T6BU-FG3S0-7J1F0-3S86R-KA5VF

Used output buffers: 1 of 24 (15 max)

=== RTOS ===

Static ram: 25712

Dynamic ram: 95072 of which 0 recycled

Exception stack ram used: 320

Never used ram: 9968

Tasks: NETWORK(ready,1440) DHTSENSOR(blocked,228) HEAT(blocked,1232) DUEX(suspended,160) MAIN(running,3740) IDLE(ready,160)

Owned mutexes:

=== Platform ===

Last reset 00:10:07 ago, cause: software

Last software reset at 2020-09-24 11:48, reason: User, spinning module GCodes, available RAM 9744 bytes (slot 3)

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0xffffffff Task 0x4e49414d

Error status: 0

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest block write time: 0.0ms, max retries 0

MCU temperature: min 35.5, current 35.8, max 36.0

Supply voltage: min 24.1, current 24.2, max 24.3, under voltage events: 0, over voltage events: 0, power good: yes

Driver 0: standstill, SG min/max not available

Driver 1: standstill, SG min/max not available

Driver 2: standstill, SG min/max not available

Driver 3: standstill, SG min/max not available

Driver 4: standstill, SG min/max not available

Driver 5: standstill, SG min/max not available

Driver 6: standstill, SG min/max not available

Driver 7: standstill, SG min/max not available

Driver 8: standstill, SG min/max not available

Driver 9: standstill, SG min/max not available

Date/time: 1970-01-01 00:00:00

Cache data hit count 1826154892

Slowest loop: 4.13ms; fastest: 0.08ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Move ===

Hiccups: 0, FreeDm: 160, MinFreeDm: 160, MaxWait: 0ms

Bed compensation in use: none, comp offset 0.000

=== DDARing ===

Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0

=== Heat ===

Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Segments left: 0

Stack records: 2 allocated, 0 in use

Movement lock held by null

http is idle in state(s) 0

telnet is idle in state(s) 0

file is idle in state(s) 0

serial is ready with "M122" in state(s) 0

aux is idle in state(s) 0

daemon is idle in state(s) 0

queue is idle in state(s) 0

autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 202.15ms; fastest: 0.08ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0)

HTTP sessions: 0 of 8- WiFi -

Network state is running

WiFi module is connected to access point

Failed messages: pending 0, notready 0, noresp 1

WiFi firmware version 1.23

WiFi MAC address 84:f3:eb:42:ad:1b

WiFi Vcc 3.42, reset reason Turned on by main processor

WiFi flash size 4194304, free heap 25696

WiFi IP address 192.168.39.129

WiFi signal strength -42dBm, reconnections 0, sleep mode modem

Socket states: 0 0 0 0 0 0 0 0

=== Filament sensors ===

Extruder 0 sensor: ok

Extruder 1 sensor: ok

- WiFi -

-

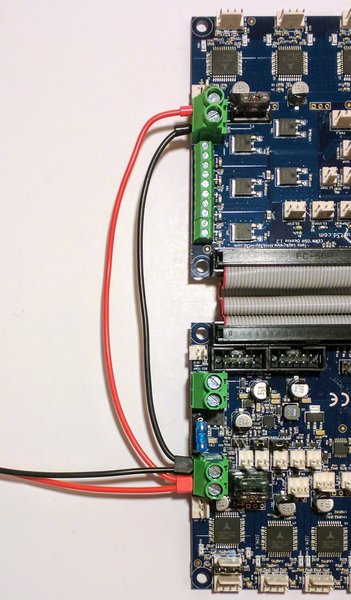

Thanks. Since you're running a Duex I have to ask if it's wired to spec as lockups like this can happen when the ground cable isn't wired as shown here: https://duet3d.dozuki.com/Wiki/Duex2_and_Duex5_Features#Section_Wiring

-

@Phaedrux is this wrong?

-

I can't really see with your wire sheaths on, but does it look like this?

-

@Phaedrux no, mine has the wires from the power supply going to the Duex5 then to the Duet wifi.

-

@Quadcells Wasn't there another thread about your power/GND wiring? I think we ended up thinking it was okay.

Ian