Kossel xl custom built. Ir sensor coding fixed

-

If you still have problems when you try again, let me know which step you get stuck at. You mentioned "night and day" - are you sure that the IR sensor is giving a consistent trigger height regardless of the lighting conditions?

-

If you still have problems when you try again, let me know which step you get stuck at. You mentioned "night and day" - are you sure that the IR sensor is giving a consistent trigger height regardless of the lighting conditions?

Yeah I followed your guide on checking for consistent triggers and it aligns to the guide. I finaly have a few hours to work on it so ill start fresh with endstop adjustments set to zero and see if it will play ball today.

Thank you David

I just want to print something haha

-

Ok I tested the trigger height 10 times now and 5 times it came up with Z1.363 and 5 times it came up with Z1.403

I was going to just test it 5 times to make sure it was consistent but on the 5th time it came up with Z1.403.

So I did one more test as piece of mind and it went back to Z1.363. then from the 7th time to the tenth time it produced Z1.403So ill use 1.403 as the trigger height since it was the last set that showed up but is this something that I should be worried about?

-

You have a trigger height variation of 0.04mm, which is higher than ideal. If you see only those 2 values, this suggests that your Z resolution is only 0.04mm, which is unusually high. The steps/mm in your config.g file is 80, which would give 0.0125mm. Perhaps you have binding in one of your carriages, or play in the joints.

However, this should not stop you printing.

As I said before, do make sure that settings in config-override.g are not overriding changes you make. If in doubt, clear out or delete the config.override.g file.

-

I have changed my Step/mm to 100 as DjDemonD suggested.

I have a Feeling its the linear rail on Z now that you mention it when I was installing it it didn"t seem quite as smooth as the others so i washed the bearings down with brake cleaner and re-lubed them with some lithium grease rebuilt the carriage which seemed to help but i guess it wasn't enough. luckily I have some Hiwin Linear rails coming to bad they aren't black but function over form

-

If your steps/mm is 100 (which implies you are using 1.8deg motors and 16-tooth pulleys) then your Z resolution is 0.01mm. So I would expect the trigger height measured by repeated probing at the same point to vary by +/- 0.01mm if your mechanics is working really well.

-

I think it's the z linear rail as after I do a calibration I home the printer then go to check the z height and it's set too high.

-

Just a side note, according to Thomas Slanderer (a YouTuber passionate about 3D printing and an engineer) tested the IR probe and measured that it varies when the bed is heated vs when the bed is cold. See here: https://youtu.be/il9bNWn66BY

It is something that I never would have thought of, but good to keep in mind when setting up the macros for preparing your printer.

-

Yeah I have seen his channel I like his videos. Iv managed to print simple stuff now but I tend to get blobs and so own that harden to the point that it actually ends up knocking the effector off the rods well printing.

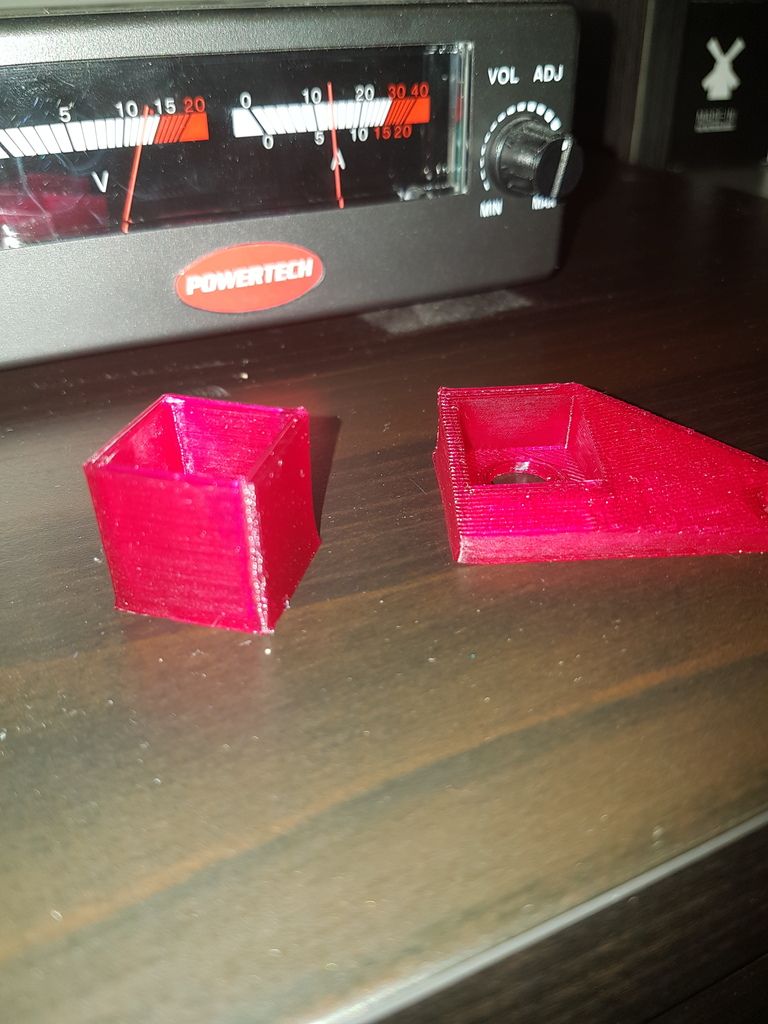

Here's what I can print with ease.

But this is the problem that's happening. Don't know if you can see it.

-

I think you have some over extrusion. Have you calibrated your extruder steps/mm?

-

Yeah I have I think the issue is that the z height keeps ending up being to low even after recalibration and re adjustment of trigger height it still ends up squishing after to much so it creates pressure in the Bowden and also buldges on the outline layers problem is I do t know how to fix it.

-

Reduce the trigger height in the G31 Z parameter. You can use baby stepping to experiment with how much to adjust the nozzle height.