Pressure advance quality issues

-

Hi. I'm migrating from RAMPS1.4 onto DuetWIFI and face some troubles with PA.

My hardware is a DIY Prusa i3-like machine with 1.75 filament diameter mk10 feeder, approx. 450mm Bowden tube and 0.3 mm E3DV6 nozzle.

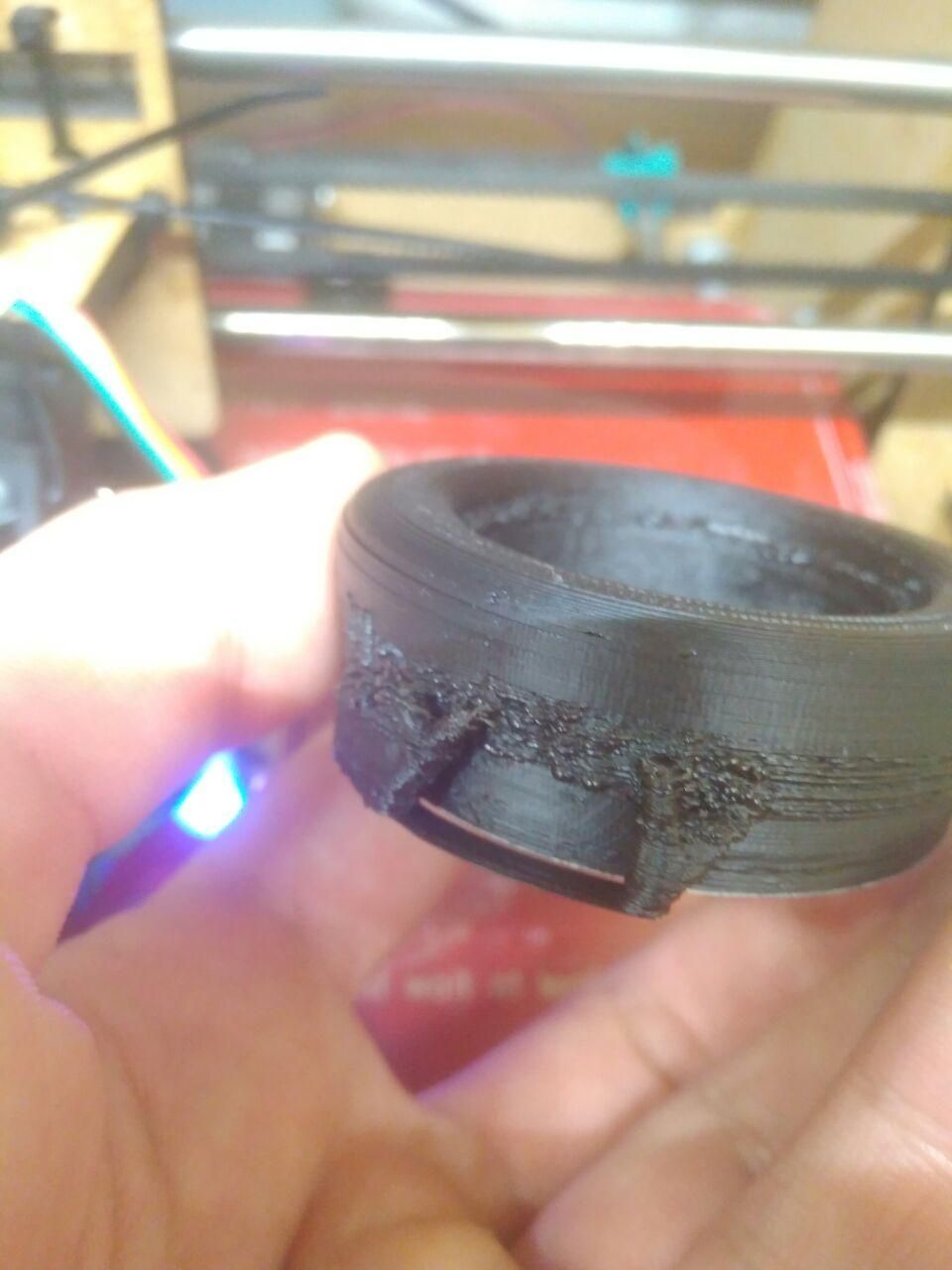

I've calibrated the PA factor to 1.I got some strange defect onto embossed text or frequent small features. (Calibration cube prints without issues)

It looks like hard under-extrusion or nozzle clogging or filament grinding and affects only the outer perimeter.With disabled PA (K = 0) quality is perfect (except this blobs, that should be fixed by PA. Ironic.)

There is my "classic" calibration pattern from K=0.00 to K=1.20. I also adopt marlin calibration pattern and got similar results.

I use:

- E max speed 60mm/s (40mm/s retraction speed)

- E jerk 10mm/s

- E accel 1000mm/s^2

- 6 mm retraction length

Here is my config.g

And cura profile

I've already tried:- Reducing E jerk down to 5mm/s

- Reducing E accel down to 500mm/s^2

- Reducing the K factor to 0.6s and 0.1s

- Disabling ringing compensation

I have run of ideas. Has anyone encounter similar issues? Any other ideas I can to try?

Thanks. -

@LidaDida, one thing I did notice is your microstepping settings. With RRF it is normally recommended to use 16 with interpolation as follows:

M350 X16 Y16 E16 Z16 I1 ; Set X, Y, Z, and E microstepping with interpolation -

@LidaDida I have had similar issues with prints with short stepped segments which made the extruder go crazy with pressure advance. I found that increased x & y jerk helped (and accel a bit too). My theory is that it means the head slows down less at each corner so the extruder maintains a more constant speed so you get less kick back from the pressure advance.

I have a corexy so could push my jerk and accel quite high, but you might get some gains. I also pushed up my currents so my motors could keep up better, but they soon got quite toasty...

Also, I found that doing the speed change script wanted a much higher pressure advance than 'normal printing' would have. Personally, I prefer the single walled cube method described on the Pressure Advance wiki for calibration, then tweak it a bit on some actual prints -

In addition to the above two good suggestions you can try these settings as well

M566 X600 Y600 Z120 E3000 ; set maximum instantaneous speed changes (mm/min) M203 X12000 Y12000 Z900 E6000 ; set maximum speeds (mm/min) M201 X800 Y800 Z300 E3000 ; set accelerations (mm/s^2)PA value of 1 is quite high. Try half that and test with actual prints.

Pressure advance and marlin's linear advance are not directly interchangeable.

-

@Kolbi said in Pressure advance quality issues:

it is normally recommended to use 16 with interpolation

It seems like a step in the right direction. Now it, as expected, over extrudes on the text and even primes (untracts). It's interesting because after installation I calculated steps/s and no axis exceeded the limit of 180k steps/s, mentioned on the wiki.

Now I'm printing samples to approve that theory.

@engikeneer said in Pressure advance quality issues:

@LidaDida the extruder go crazy with pressure advance

I noticed another difference with marlin, that thin wall skin prints much slower. But I think, that is because of marlin use interpolation for accel calculations.

I also pushed up my currents so my motors could keep up better, but they soon got quite toasty...

Heh, my feeder now is under active cooling with 80mm fan

Personally, I prefer the single-walled cube method described on the Pressure Advance wiki for calibration

I prefer "print another calibration cube" method))

@Phaedrux said in Pressure advance quality issues:

In addition to the above two good suggestions you can try these settings

Increasing rather than decreasing? I will try that.

@Phaedrux said in Pressure advance quality issues:

Pressure advance and marlin's linear advance are not directly interchangeable.

For the marlin, I've used K=0.6. I've noticed, that PA also tries to compensate retracts. Because of that, every second PA post suggests reducing retraction. On marlin, I used an extra prime amount and wiping for this purpose.

Thanks to everyone for replies. Waiting for samples to be ready.

-

@LidaDida said in Pressure advance quality issues:

every second PA post suggests reducing retraction. On marlin, I used an extra prime amount and wiping for this purpose.

Yes, pressure advance will already be pulling the filament back before the retraction, so reducing the retraction distance is recommended to prevent clogs from pulling the hot filament up into the heat break.

It's also recommended to disable any wipe or coast in the slicer.

-

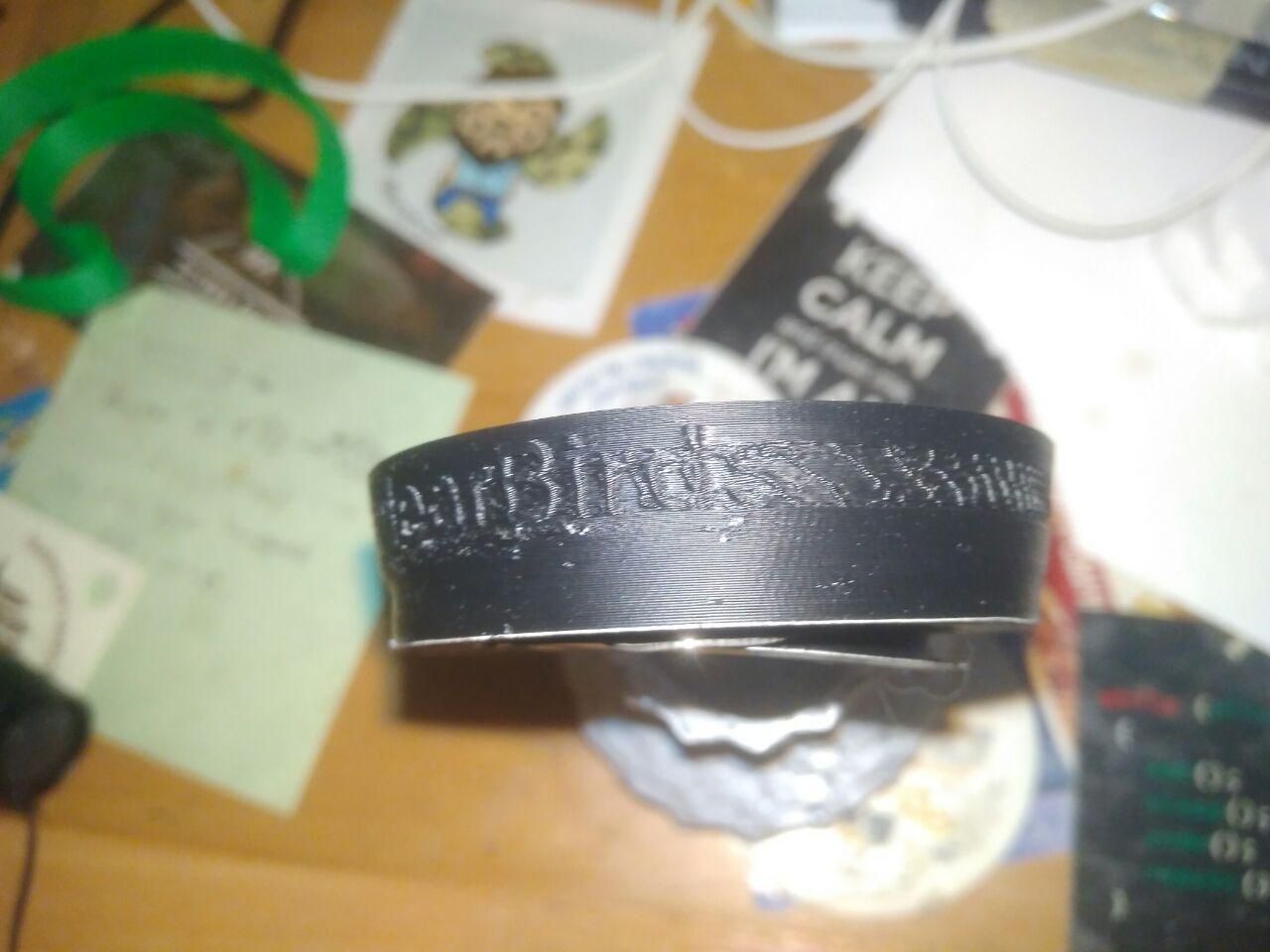

The first samples are ready.

Firstly, I print a control sample with K=0 and without extra prime amount

It was good as expected

Next, I decreased K factor by half and got almost expected result with overcompensation

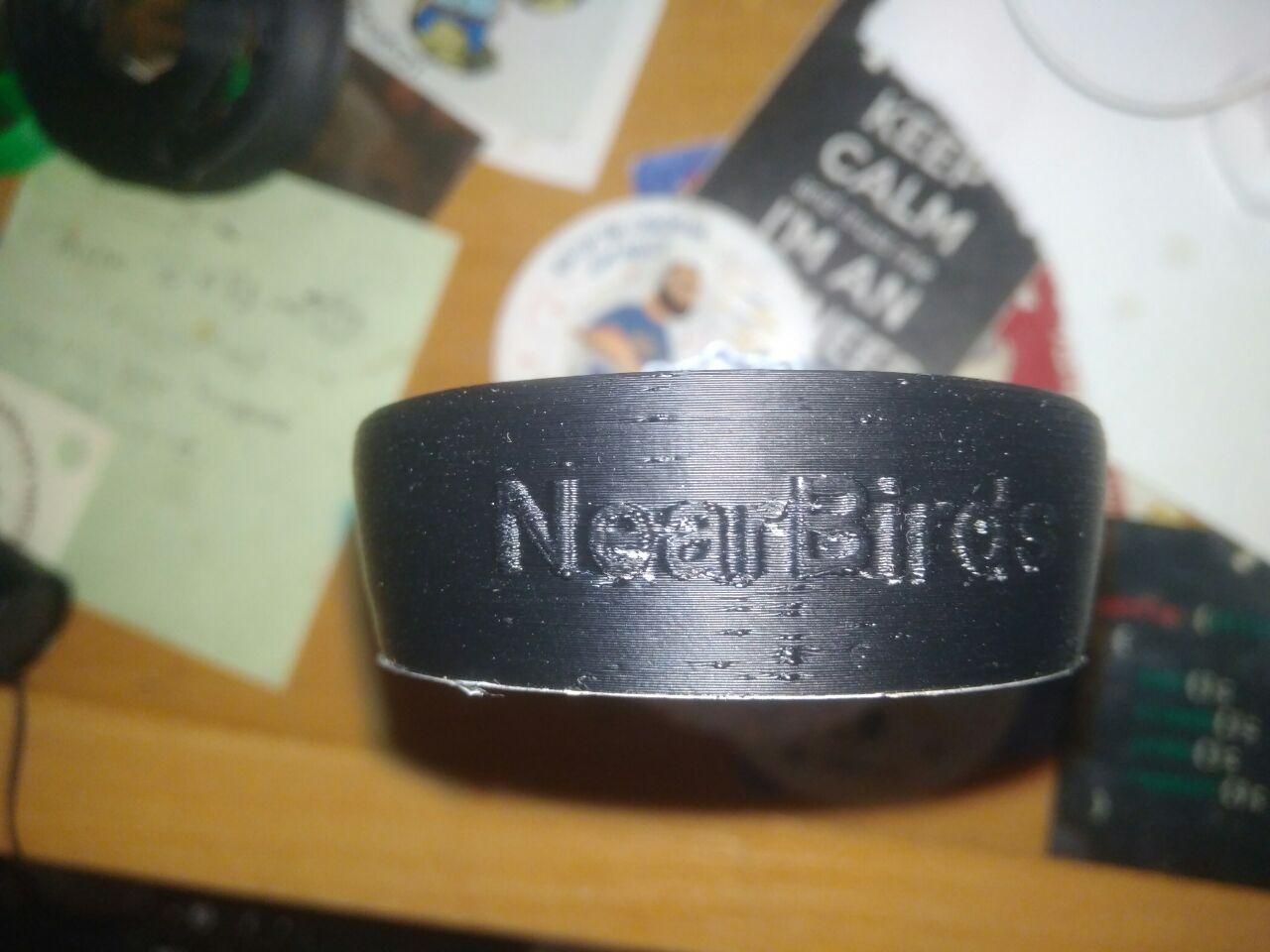

Then I printed the K=0.3 sample. 0.3 is the recommended starting point for my Bowden length. It still looks overcompensated on the text. The bottom one was printed with my default settings. For the upper one, I use @Phaedrux advice and raised extruder speed/accel/jerk settings. It's maybe slightly better, but I can't notice a difference.

Then I thought, maybe my old K calibrations are not applicable after microstepping change and I print another calibration pattern.

And it points back to K=1. Why?Now I'm trying to print a single-walled cube test. Now my cubes look like PA isn't exist at all and the width of the layers is the same on all of the length. Even while acceleration to 80mm/s. And the cura sometimes wants to fill tiny gaps on the corners, but these are other topics for googling.

On the next step, I will try to recalibrate flow, maybe PA also affects that.PS. All my PA samples printed with 5mm retraction, maybe I should lower it more?