High Temperature printing

-

Separation of the build volume and the motor/belt section can easily be done with bellows. I would suspect there would be issues with leakage or heat just traveling through the bellows but these things can be mitigated.

No mater what, your costs for the printer increase exponentially as you allow for hotter and hotter build environments -

I've acutally written my master's thesis about designing and building a HT printer. In my case, HT refers to a build chamber temperature of about 160-200 °C and nozzle temperatures of 350-450 °C.

The main challenge was in fact to design a motion system that would either withstand the heat or be excluded from the heated and isolated build chamber. I chose igus drylin in a stainless version with HT capable gliding foils, as well as high pitch spindles with nuts from the same polymer (I work at igus and did my master's there, if someone wants to look at the design, do so here). In this case, the linear rails are kept in the build chamber while the spindles protrude through the isolation to the outside, where they are driven by the steppers.

Doing so allowed me to bypass the Stratasys patent which seemed to be the sensible thing at the time.

If I were to design one such printer again, I would change a few things over the last design (aside from general considerations like accessibility and manufacturability). Most notably I would consider changing to a belt-driven, maybe coreXY system that is isolated by bellows as suggested before. A design that incorporates this is shown here.In contrast to some who commented before, I'm very much of the opinion that the higher the chamber temperature, the better. While you can certainly produce some nice parts at 70 °C (at which temperature most available belts start to go out) sneaking up to Tg of the polymer is ideal and will allow to freely print parts of any shape without problems. And while for most use cases, materials like PA and PC (natural or filled) will do the trick, if you want to process materials like Ultem or PEEK (that have not been highly altered to be suited for lesser temperatures), you need that 160-200 °C chamber temperature at least.

If it doesn't become clear from this, IMO it's not the main challenge to reach the required nozzle temps. A 60 W heater, maybe water cooling for the hotend and a berd-air system for part cooling (or pressurized air for both, which is available in most workshops) does the trick. In my setup I'm running an E3D setup with the standard heater cartridge. The standard temperature sensor cartridges are garbage in this application and have been replaced by a high quality, braided-line version.

-

i print 500C easily with a dyze hotend and extruder....works all day long

-

@imrj said in High Temperature printing:

i print 500C easily with a dyze hotend and extruder....works all day long

Could you share a little more detail on your printer, your overall setup, the material you use und the size of the objects you are printing?

-

Really interesting thread here.

How about using lead screws for high temp chambers? It seems like you could adapt the Ultimaker style x/y mechanism to use lead screws instead of rods and belts, and thus keep everything sensitive outside the chamber. It could be made cheap and simple, except that you would probably need to make some custom metal parts.

-

@sonderzug I have a giant (1m cubed) custom high temp printer I've been building for years as I'm hoping to one day sell machines. I can confirm e3D's 60W premium heater in combination with the Chimera+ (Aqua), copper plated heater block and nozzle X will heat and hold heat beyond your wildest dreams. I only went up to 400C but the auto PID results said this configuration could reach >800

-

@owlfab yeah, imo lead screws is the way to go (if you want to put all of the linear motion system into the heat chamber). Using high pitch (say 10 mm) screws gives you reasonable speeds while maintaining resolution.

@Print3d thanks for the confirmation. Yeah I'm pretty sure it's just about the wattage of the heater. My problem is also that the Duet is thrown off when the enclosure is not as hot as it was during PID tuning.

How do you solve heating the build volume? What temperatures can you reach? -

wow, nice thread here guys!

-

Depending on the travel length and desired print speed lead screws or ball screws may suffer whip. Unless of course you compensate by increasing the diameter, which in turn increases weight & load on the drive motor to change direction. A balancing act for sure.

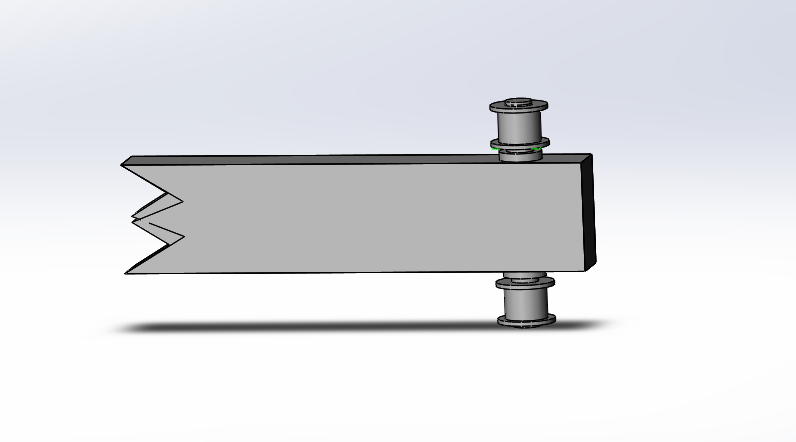

One possible suggestion for passing belt drive through the sealed enclosure might be a thru axle. Please excuse my rough pic

You get the idea tho

-

@Hytek said in High Temperature printing:

[...]lead screws or ball screws may suffer whip.

I'm not sure to understand: do you mean there can be a mechanical issue? The screws can bend under load?

-

Yes, depending on the length, diameter & inertia force applied in the change of direction the lead screw can flex. In a slight case these 'flexes' will show up in the print surface. In heavier cases can cause unwanted noise, vibrations and shorten component life.

I'm not saying lead screws can't be used, just suggesting there are things to consider when making that choice. -

Ok, thanks!

-

@sonderzug said in High Temperature printing:

I've acutally written my master's thesis about designing and building a HT printer. In my case, HT refers to a build chamber temperature of about 160-200 °C and nozzle temperatures of 350-450 °C.

The main challenge was in fact to design a motion system that would either withstand the heat or be excluded from the heated and isolated build chamber. I chose igus drylin in a stainless version with HT capable gliding foils, as well as high pitch spindles with nuts from the same polymer (I work at igus and did my master's there, if someone wants to look at the design, do so here). In this case, the linear rails are kept in the build chamber while the spindles protrude through the isolation to the outside, where they are driven by the steppers.

Doing so allowed me to bypass the Stratasys patent which seemed to be the sensible thing at the time.

If I were to design one such printer again, I would change a few things over the last design (aside from general considerations like accessibility and manufacturability). Most notably I would consider changing to a belt-driven, maybe coreXY system that is isolated by bellows as suggested before. A design that incorporates this is shown here.In contrast to some who commented before, I'm very much of the opinion that the higher the chamber temperature, the better. While you can certainly produce some nice parts at 70 °C (at which temperature most available belts start to go out) sneaking up to Tg of the polymer is ideal and will allow to freely print parts of any shape without problems. And while for most use cases, materials like PA and PC (natural or filled) will do the trick, if you want to process materials like Ultem or PEEK (that have not been highly altered to be suited for lesser temperatures), you need that 160-200 °C chamber temperature at least.

If it doesn't become clear from this, IMO it's not the main challenge to reach the required nozzle temps. A 60 W heater, maybe water cooling for the hotend and a berd-air system for part cooling (or pressurized air for both, which is available in most workshops) does the trick. In my setup I'm running an E3D setup with the standard heater cartridge. The standard temperature sensor cartridges are garbage in this application and have been replaced by a high quality, braided-line version.

@sonderzug Is your thesis readable somewhere ? Thank you.

-

@bricoletout Hi, unfortunately it isn't at this point, but the downloadable CAD model goes a long way in explaining the principles.

-

@sonderzug said in High Temperature printing:

@bricoletout Hi, unfortunately it isn't at this point, but the downloadable CAD model goes a long way in explaining the principles.

Thank you for your answer. I downloaded the CAD files.

-

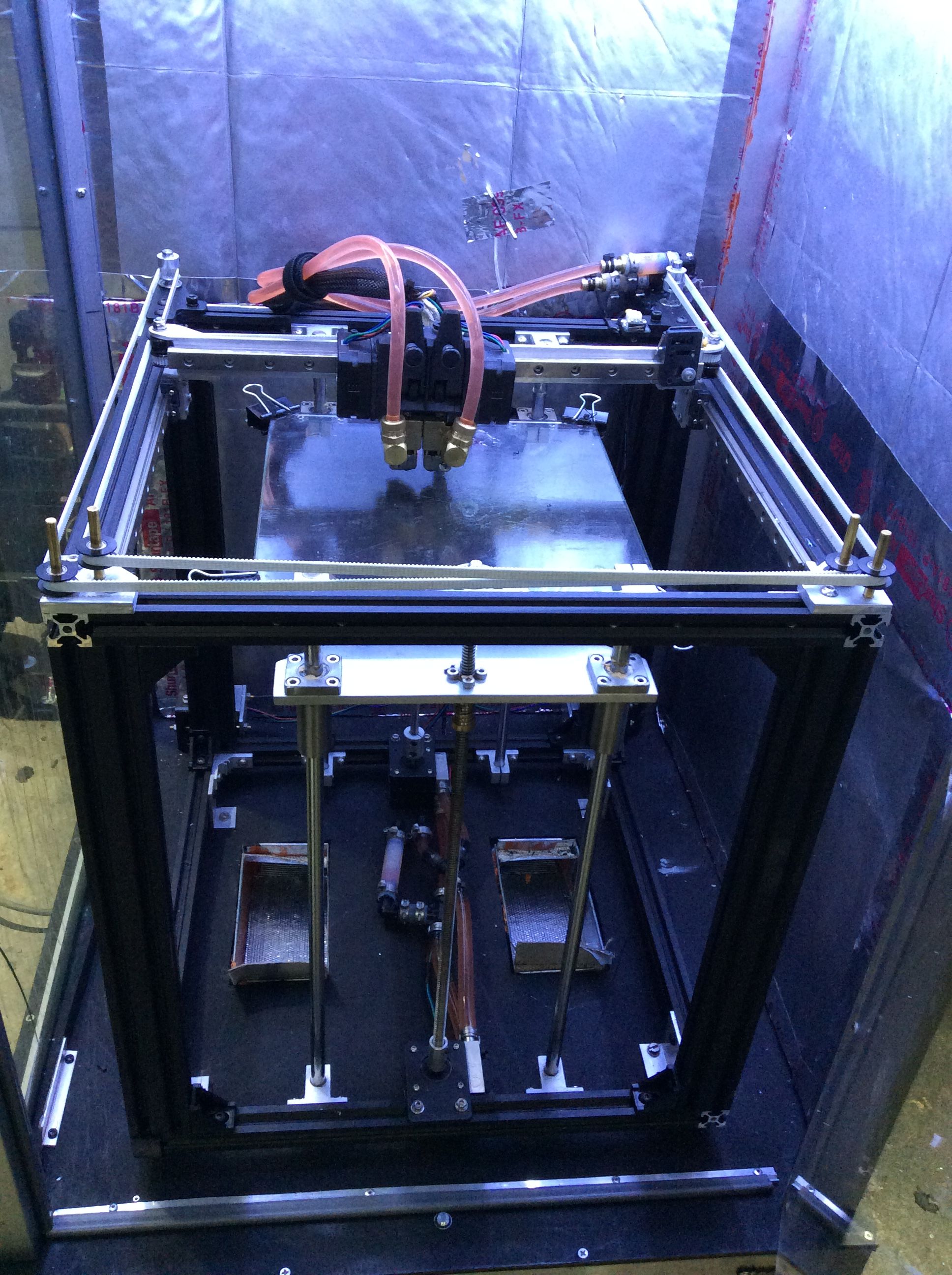

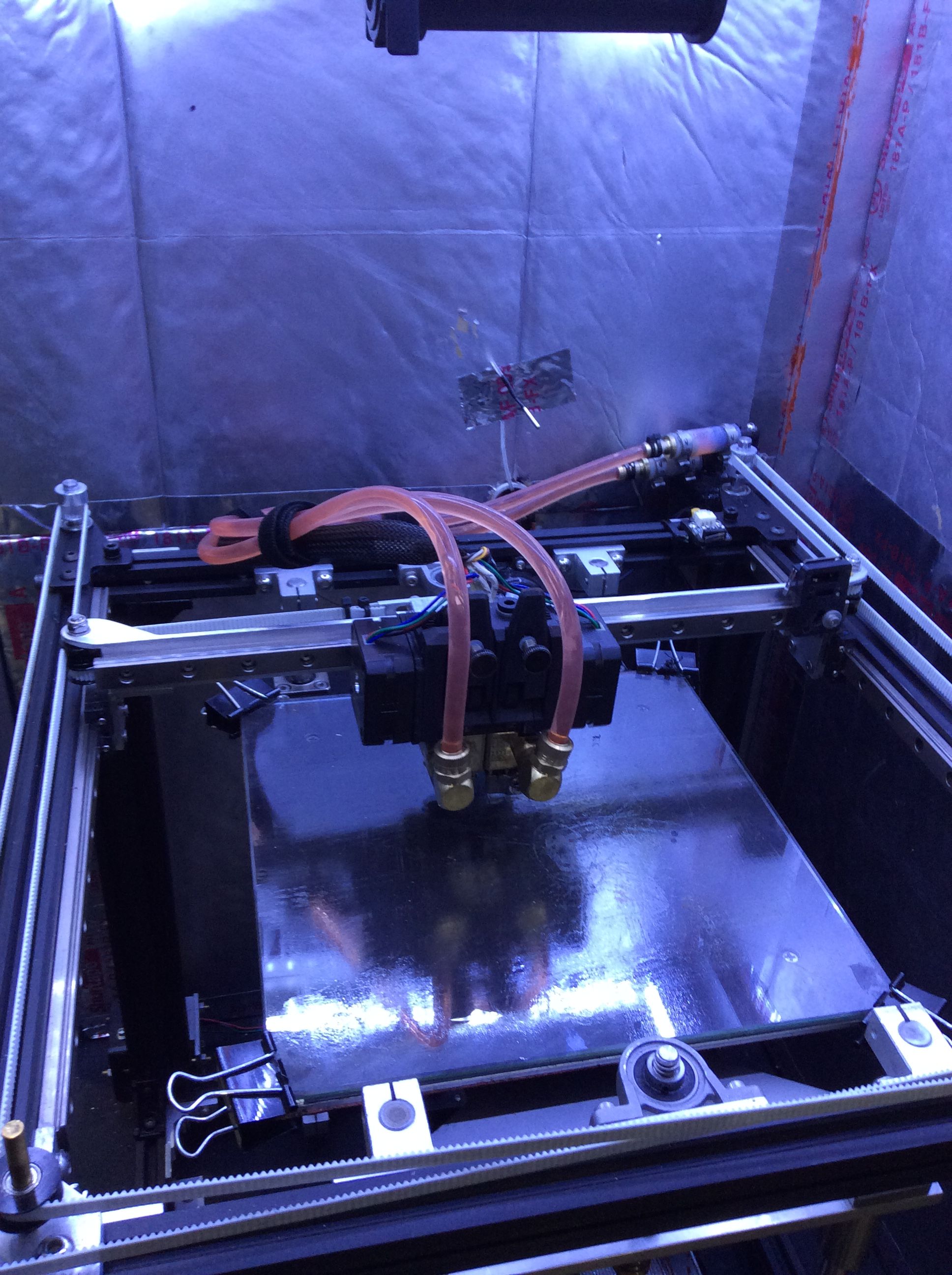

High heat printer builds are like putting out small fires everywhere. As soon as you get a handle on something, something else comes into play. EVERYTHING starts to matter when you start building up that kind of heat. I just tested out my high heat version 3.0 today which went surprisingly well.

This is my work in progress, I built the enclosure out of aluminum on top of a old stainless toolbox my father-in-law gave me, the enclosure's 24 x 24 x 36. It has a 1400W heater/fan combo I found on amazon for $30 originally for a gas fireplace. Everything's insulated and sealed with fire-foam or high heat silicone. The setup utilizes a main return duct at the top of the enclosure used to recirculate the air, it maxes out at roughly 120C. Insides a Ender 5 that I Frankensteined into a core xy running a BMGX2-M w/ mosquito liquids, you can almost cook an egg on the extruder steppers...Its been a fun project but I feel like I got more wrapped up into the challenge of getting it there than anything. Any questions feel free to reach out.

This is my work in progress, I built the enclosure out of aluminum on top of a old stainless toolbox my father-in-law gave me, the enclosure's 24 x 24 x 36. It has a 1400W heater/fan combo I found on amazon for $30 originally for a gas fireplace. Everything's insulated and sealed with fire-foam or high heat silicone. The setup utilizes a main return duct at the top of the enclosure used to recirculate the air, it maxes out at roughly 120C. Insides a Ender 5 that I Frankensteined into a core xy running a BMGX2-M w/ mosquito liquids, you can almost cook an egg on the extruder steppers...Its been a fun project but I feel like I got more wrapped up into the challenge of getting it there than anything. Any questions feel free to reach out.