Is this a good candidate for pressure advance?

-

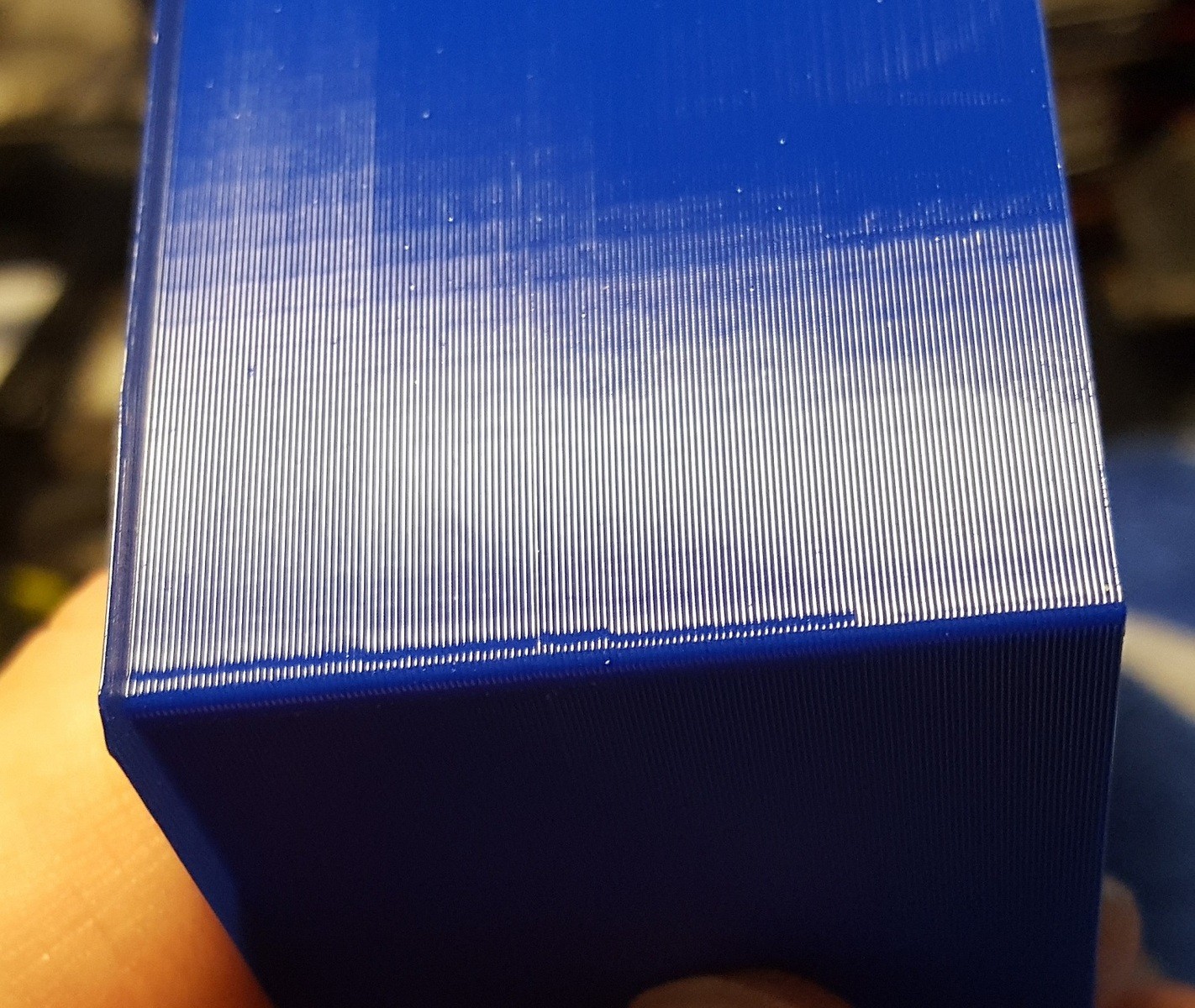

I've been wondering how to get rid of my bulging corners with my D-bot prints, and today, while testing out something else, I ran this test print with four processes running at 30, 40, 50, and 60mm/s (60 is on the left), and noticed the dramatic reduction in corner bulging due to slower print speed.

While discussing it with a friend I offered up that it might have something to do with pressure buildup in my bowden tube that can't be relieved in time due to the rapid deceleration/acceleration into and out of the corners, where the lower print speed requires less plastic flow rate.

While researching it I stumbled upon this:

https://duet3d.com/wiki/Pressure_advance#How_to_enable_and_configure_pressure_advance

Is this what the symptoms look like that inspired the pressure advance feature? This test was done with aggressively low acceleration and jerk settings to eliminate possibilities for something else I was testing, so it makes sense to me. I haven't had a chance to fool around with this feature yet due to the printer being busy, but I'm thinking of just using the starting value listed in that wiki and seeing what happens.

-

And I guess the followup question is this: as shown in the photo above, if I print at 30mm/s the corner bulging is barely visible, so with pressure advance, would corners actually underextrude at that speed?

-

This doesn't directly answer your question, but I found this http://ddd.k8400.hoehnemann.net/Theorie.html and this http://ddd.k8400.hoehnemann.net/pa/pressure%20advance.html about pressure advance this afternoon and found it very helpful. While it appears dated and not the same algorithm, it must be based on the same theory or my test results are flawed. I made a 10mm tall octogon with changing perimeter walls similar to the one he did and sliced it with single walls. I printed it at S0 and S0.01. The S0.01 walls were less varied (change in width from corner to corner) so I took a jump to S0.05 and the variation was less but apparently reversed. I must admit that I don't fully comprehend that result and it bears repeating at S0.06 to see if it was a fluke or not. Next I tried S0.04 which was just about spot on. I didn't have time, but I plan to see if the S0.04 setting works the best at higher and lower print speeds. I did print a taller version of the same octogon at S0.04 and varied M566. There were pronounced differences in the corners with M566 changes which I didn't see when varying M572.

-

My printer was tied up all afternoon, but I'm running that same test box right now with S0.1 as recommended as a starting point in the wiki article. I'll have to try some other things. I need to check my M566 values because I think I'm being affected by that extruder acceleration. It did seem to be running noticeably slower on the 60mm/s layers

-

Yes, I think that's a good candidate for pressure advance. The faster you print, the more the pressure is advanced. So the same pressure advance setting should in theory work for all speeds.

When testing pressure advance, make sure you didn't have S3D's "coast to end" feature enabled when slicing the files.

-

David, would having wipe nozzle on interfere with this in any way?

-

-

Hmm, well I've done quite a few experiments last night and today, and so far it hasn't been working for me as expected.

At my 60mm/s print speed the pressure advance settings just don't seem to be reducing the corner bulging to any noticeable degree in at least the .1-.8 range or so. By the time I got to S2.0 I saw noticeable improvement in the corner bulging, but something else was going on that caused catastrophic underextrusion on the corner where all my layer changes and direction reversals was taking place. I'm not talking about 90 degree corners, I'm talking where the nozzle got to the corner and reversed direction 180 degrees to go down the adjacent wall at the same layer, or the nozzle moved up in Z to the next layer height and began the wall at the new layer.

With S2.0 I was seeing the extruder just stop extruding as it headed into the corner and coast in like 30 or 40mm, leaving those perimeters catastrophically underextruded.

What I'd see with S2.0 was that at every 90 degree corner the extruder would jerk backwards and then jerk forward again really rapidly as the nozzle approached and then left that corner, except the one corner where all the layer changes happened it would stop extruding completely 30-40mm away from the corner, not jerking back at all, literally just stopping, then simply resume once it hit the corner and made the turn for the next line. No jerking back and forth at all, simply stopping and then resuming.

In the .1-.3 range I saw the extruder jerking back and forth into and out of corners by small amounts, and if my 566 jerk settings were high enough on the extruder setting it would even be a violent and loud event, but it didn't seem to affect the actual corner budging very much.

By S.4 or so I started to see the first signs of underextrusion in the corner where the layer changes happened. By S.8 I saw the first voids appear in the corners immediately around that wall. By S1 to S2 those voids turned into catstrophic 10-30mm sections of massive underextrusion.

I've got the coasting setting in S3D turned off completely in these tests. I can't figure out why the advance pressure setting is causing the nozzle to simply coast into and then resume extruding out of that one corner by such large values.

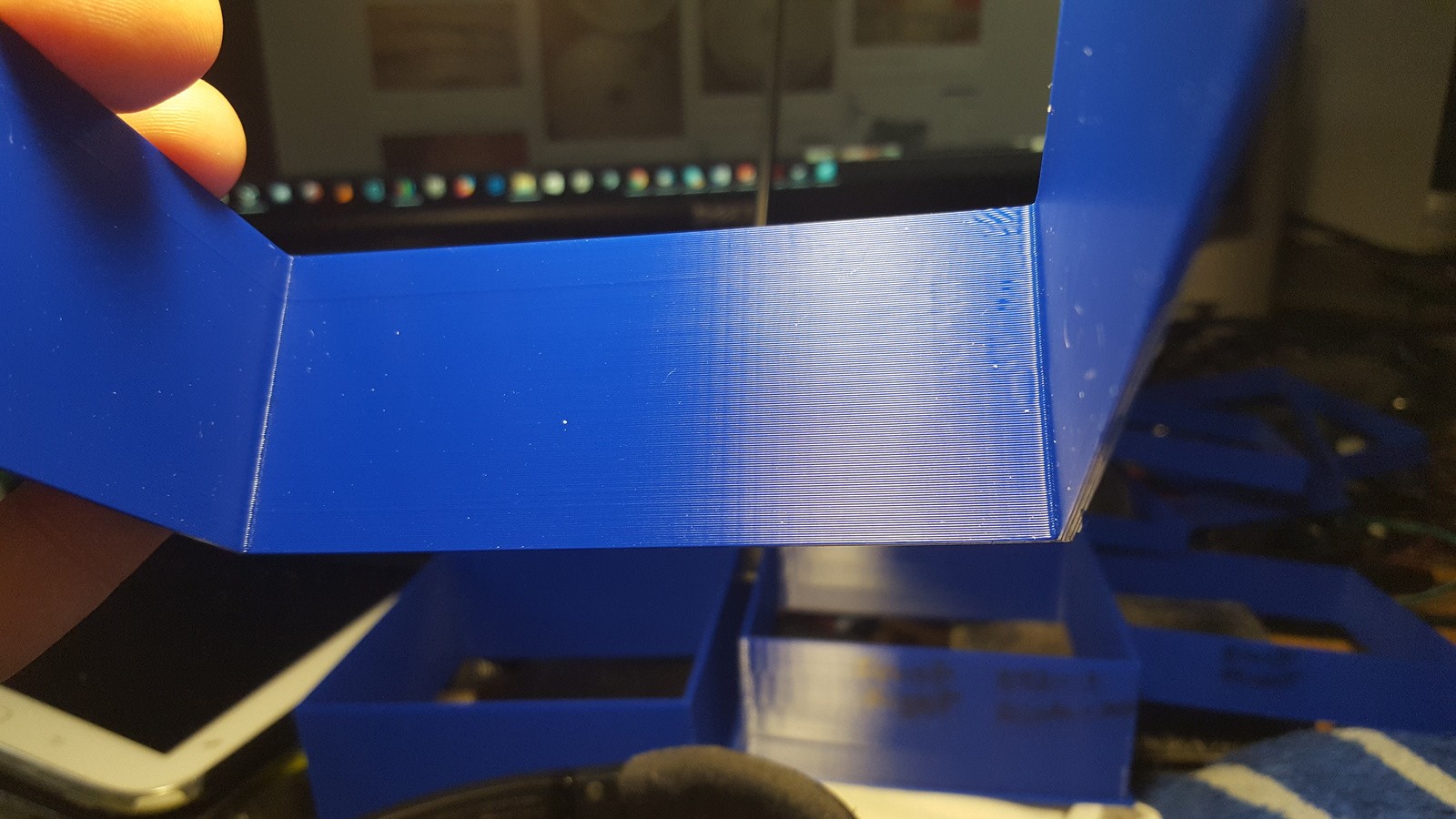

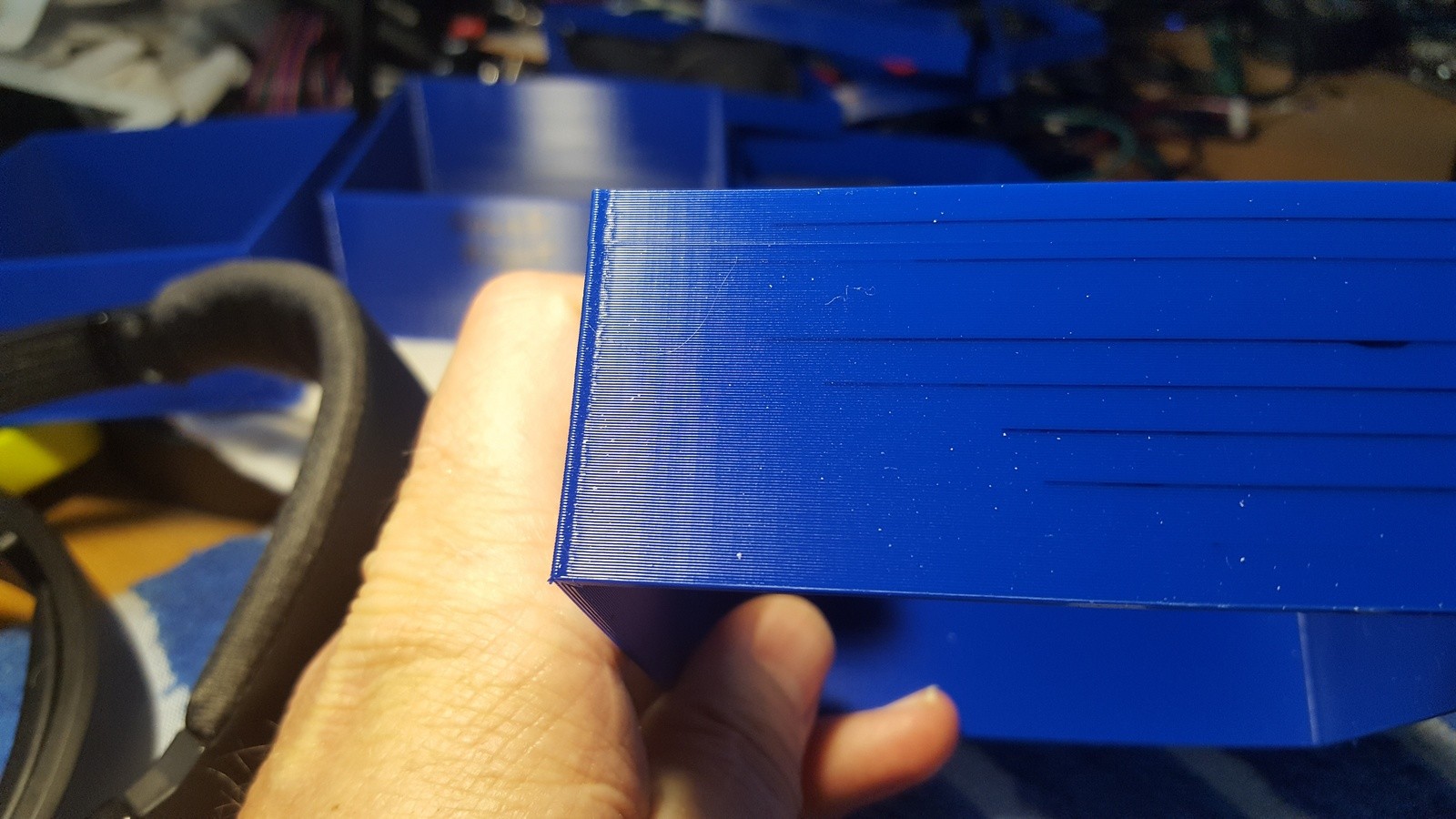

Here's a pic that shows a wall printed out at 60mm/s all the way up, where every few minutes I changed the S value from .1 all the way up to .8. The .8 value shows the first consistent voids in the lines heading into that corner where all the layer changes happen, due to it coasting for an unreasonable amount of time heading into that corner. The first little bulge you see, around the middle of the Z height going into that wall, happened at S=.4. From S=.1 to S=.3 there wasn't much of a noticeable problem with this corner.

Here's the opposite wall during that same print. The black lines are where I marked the edge of the top layer with a Sharpie after making a new change to the S value of M572. Notice that the corner bulging doesn't appear to have been affected in really any noticeable way.

Here's a view of just around the corner from the corner in the previous photo. This side shows where the nozzle is coming out of that corner and accelerating back into the current line. The .1 value is at the bottom, by the top it's at .8. The corner has actually been subtley altered here, but the bulging is still there, and the real change is that the initial portion of that line appears to be lagging a little in extrusion, so there's a slight dip for the first few milimeters coming out of the corner.

-

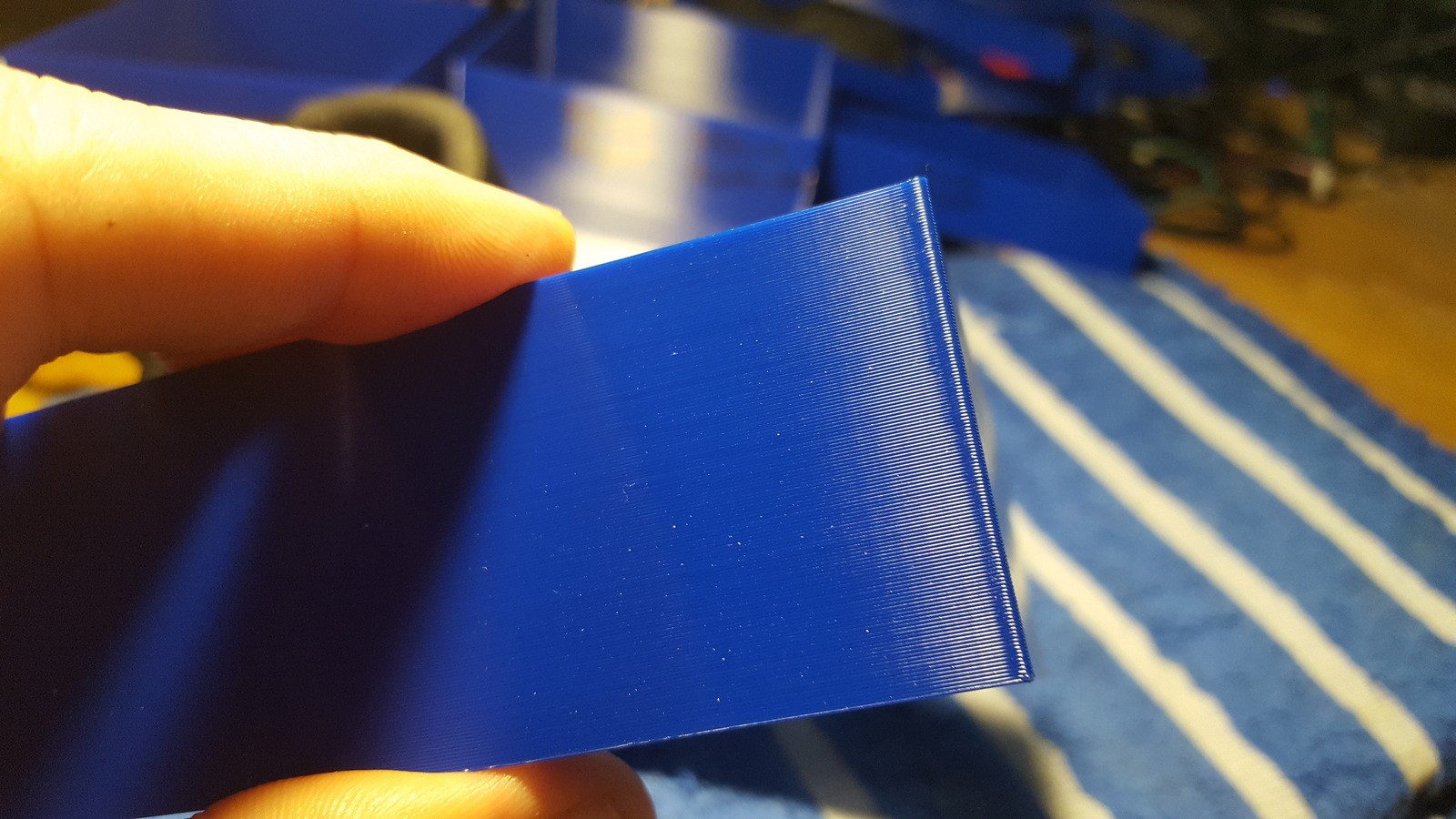

Oh, here's a view of the corner, on another test print, where the S value of M572 was at 2.0, and the extruder simply stopped a good 40mm or so from the corner and coasted all the way in, and then simply resumed, with no repriming or anything, as it left that corner to print the line.

-

I read a comment somewhere where DC42 said that one may have to reduce retraction a little bit if pressure advance is used, but having the extruder completely stop and just coasting for 40+mm before entering a corner seems a little redonkulous to me, assuming that a retraction is to blame for it behaving this way in that corner only. My retraction is currently at 5mm due to the bowden tube.

-

I have found that having pressure advance enabled results in layer offsets (likely caused by skipped steps) about once in 50-100 hours of printing. It seems more prevalent on parts with lots of small segments and complex geometry.

Since it's so infrequent it's pretty hard to debug, so I've turned it back off. Which is a shame because it does help sharpen corners up some with long bowden drives.

-

I have found that having pressure advance enabled results in layer offsets (likely caused by skipped steps) about once in 50-100 hours of printing. It seems more prevalent on parts with lots of small segments and complex geometry.

Since it's so infrequent it's pretty hard to debug, so I've turned it back off. Which is a shame because it does help sharpen corners up some with long bowden drives.

Which firmware version were you using when that happened?

-

Oh, here's a view of the corner, on another test print, where the S value of M572 was at 2.0, and the extruder simply stopped a good 40mm or so from the corner and coasted all the way in, and then simply resumed, with no repriming or anything, as it left that corner to print the line.

http://imagizer.imageshack.us/v2/1600x1200q90/922/Q1tKjp.jpg

I've same issue with pressure advance, i removed this functionality from my setting. I found my issue was related to jerk setting :

https://www.duet3d.com/forum/thread.php?id=1216Thanks for this well documented thread, i was not able to do what you do ! I hope it will help David to find the problem.

Best regards,

Hugues -

Which firmware version were you using when that happened?

First noticed on 1.10, but also seen on 1.17-based firmware. But it was a lot less frequent on 1.17.

-

I read a comment somewhere where DC42 said that one may have to reduce retraction a little bit if pressure advance is used, but having the extruder completely stop and just coasting for 40+mm before entering a corner seems a little redonkulous to me, assuming that a retraction is to blame for it behaving this way in that corner only. My retraction is currently at 5mm due to the bowden tube.

I'm not surprised at that behaviour, because I've seen in your other post that you were using S2.0 as the pressure advance setting. That is far too high. The optimum value is generally in the range 0.05 to 0.25.

-

Which firmware version were you using when that happened?

First noticed on 1.10, but also seen on 1.17-based firmware. But it was a lot less frequent on 1.17.

If you can find a print that reproduces the problem reliably in firmware 1.18.1 then I'll try to work out what is happening. You can help by running M122 after layer shifting occurs and reporting the Step Errors count.