Release 3.01-RC10

-

@Leblond I tried to bring it back to version 3.0 but with the same results, it also gives me z offset problems, even following the procedure available with the macros, the height of the z offset is incorrect, in practice it is too low and the I find the G30 command only in the configuration and not elsewhere

-

@Leblond, I've used extrusion from DWC many timis with RRF 3.01-RC10 and DWC 2.1.5. So I think there must be something in the sequence of what you are doing that is different. Please can you do the following:

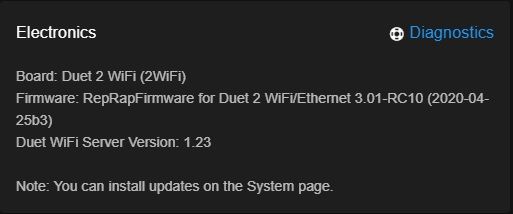

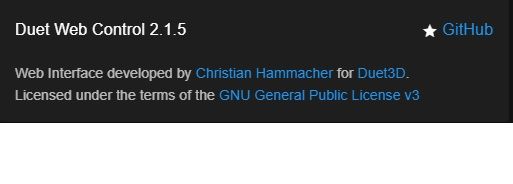

- Install 3.01-RC10 and DWC 2.1.5

- In DWC Settings, check that you really are running those versions.

- Try to reproduce the problem, taking note of the sequence of commands you used to get to the problem

When the problem occurs:

- Check that you have a tool selected

- Check that the temperature of that tool is at least 160C or that you have cold extrusion enabled

Report the sequence you used to get to the problem here.

-

hello dc42 Thank you for your intervention

the update sequence was:

- Update of FW 3.01-RC10

- DWC update directly from the .zip file

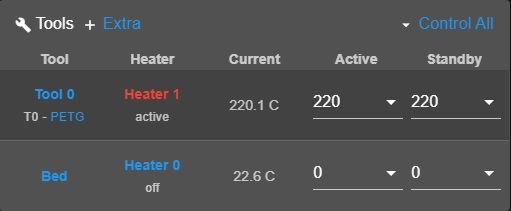

The nozzle is selected and active: ok

FW 3.01-RC10 loaded: ok

DWC 2.1.5 loaded: ok

The temperature is 220: okI created a macro for ease of use to clean the nozzle:

G1 X0 Y0

M104 S220 T0

M109 S220 T0

G1 E30 F200

I bring the temperature to 220, the macro is active, the head moves to the chosen coordinates, but it does not extrude and it is still, I manually try to extrude, but nothing happens and it does not give me any errors whatsoeverI am attaching photos for viewing:

-

-

Thanks. So the manual extrusion buttons in DWC are not greyed out, but pressing them does nothing. Is that correct?

Which firmware version were you using before, when extrusion was working?

Please send the following commands from the console, and check that the E values reported in the responses are expected:

M92

M906

M913

M563 P0Also please confirm that the hot end heatsink fan is running, and that you can push filament through the hot end by hand to make sure that you don't have a filament jam.

-

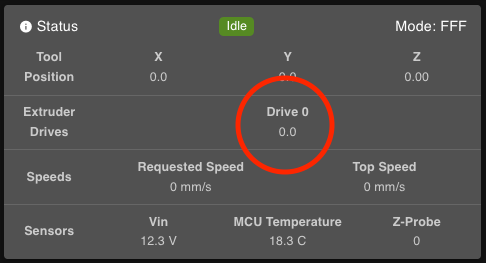

@Leblond Does the extruder position change? Here:

Ian

-

@droftarts guys I will make the checks tonight after work and keep you informed, I realized that the E0 motor is struggling to turn Responding to @droftarts it is at 0.0 but once I try to extrude 10mm the motor vibrates but does not move, but on extruder driver it marks me from 0 to 10mm, tonight i try to clean the nozzle and i will tell you everything

-

@droftarts good morning everyone, after several tests I found out that the nozzle was blocked, what stole me was the engine that did not jump but remained motionless, however I had to replace the nozzle and clean the heat breack, therefore solved, thanks to everyone for the commitment, there is always something to learn here.

-

the cases are two at the origin to the problem of the blocking of the extrusures "correct me if I'm wrong !!", 1: when the trigger is wrong, that is too attached to the plate and does not extrude, by force of give and give yes the filament is compact and freezes, 2: filament dirty or low temperature, but the problem encountered by me is strange perhaps it has something to do with it

the motor voltage? it is set to 800 but, and in any case it should jump, make the usual "tac tac ..." noise which has not happened to me and which has caused a waste of time for me and for you, I was wondering if there was a way via SW to check if an engine actually runs or not, type ammeter? -

@Leblond Yes, there is a way to detect motor stalls. See https://duet3d.dozuki.com/Wiki/Stall_detection_and_sensorless_homing#main

-

@chrishamm ok thanks, I print it and I care about it

-

Good morning and good May 1st

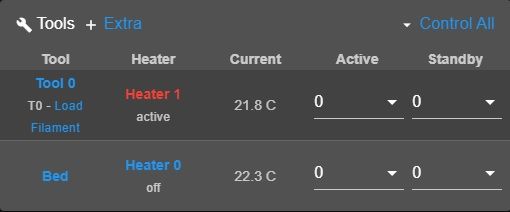

Well I have a problem that repeats itself every time I homing, then I thought the last problem had been the fault of the nozzle blocked by the filament, in part yes, it blocked because the extruder motor stops, now I understood the reason, the tests I did are all without filament in order not to damage the nozzle, I describe what I did:

1: I set the temperature to 180 in order to have the extrusion and retraction buttons active the drive buttons work very well and the motor responds

2: if I homing all the axes and retry the procedure n.1 the extruder no longer works

3: I did the single homing of the axes

4: homing x axis and retrying the extruder and it works

5: homing y axis and retrying the extruder and it works

6: z axis homing and try again the extruder does not work

I tried to load the fw one by one starting from 3.0 until the last beta and the problem persists,

7: I removed the sd and reformatted and loaded the fw but nothing happens

Any suggestions on this?

for @ dc42

m92

Steps / mm: X: 80.000, Y: 80.000, Z: 400.000, E: 424.000

M906

Motor current (mA) - X: 800, Y: 800, Z: 800, E: 800, idle factor 30%

M913

Motor current% of normal - X: 100, Y: 100, Z: 100, E: 0

m563 p0

Tool 0 - drives: 0; heaters (active / standby temps): 1 (180.0 / 0.0); xmap: X; ymap: Y; fans: 0; status: selected -

to restart the engine I have to reset with the command M999

-

@Leblond said in Release 3.01-RC10:

6: z axis homing and try again the extruder does not work

Please post your homez.g file.

-

@dc42

; homez.g

; called to home the Z axis

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Thu Apr 23 2020 22:39:29 GMT+0200 (Ora legale dell’Europa centrale)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G90 ; absolute positioning

G1 X60 Y50 F6000 ; go to first probe point

G30 ; home Z by probing the bed; Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z10 F100 ; lift Z relative to current position

;G90 ; absolute positioning -

now I have mounted the fw 2.05 to see if even with this it does the same problem

-

Is the tool still selected when you have this problem? Send T by itself to report the current tool number.

-

@dc42 ok I reassemble the FW and then I tell you

-

@dc42 made reloaded FW 3.01-RC10

yes the tool is always active

1/5/2020, 14:51:33 T

Tool 0 is selected -

@dc42 I compress all the sd and send it to you?