Tired of Mod, tweak, tune, repair, rinse, repeat...

-

So it's up and printing. 7,000mm/min no problem, so it's beating my Tevo BW's score of 1,800 by a bit. For a torture test of the bed I bumped the speed up to 17,000mm/min in simplify3d. The filament ground out on the raft so I killed the heaters and air printed a benchy to get my readings. The side to side wiggle of the bed was 0.002in/0.05mm. The frame flex at 11.75in/300mm on the front span is the same at 0.002in/0.05mm. I think that will go away almost entirely with a rigid enclosure and then we'll see how much of the bed's movement is it's own.

PIR foam might go on the outside of that depending on what I choose for material and whether or not the 800watt heater and .360 thick bed are enough to heat the enclosure to the desire temps. I'm thinking 60-70*C. For now i'm probably going to go plexi so I can see it and troubleshoot. Although I do have a potential source for more of the aluminum plastic sandwich composite stuff the electronics are mounted to. Also curious about something like this https://www.merrittsupply.com/product/spaceage-versatile-series-30-lb-thermo-lite-board/

Bed wiggle

https://www.youtube.com/watch?v=oDJJwl-0OqA&feature=youtu.beFrame flex

https://www.youtube.com/watch?v=Y71p6a-50U8&feature=youtu.be -

@macguyver I like the measurements- is there any way you can measure bounce at the free end of the cantilevered bed? I would expect that to be worse than lateral movement.

The bed heater alone won't get your large enclosure up to 60-70C. Once the bed reaches set temperature, the power used to maintain that temperature is only 200W or so. You'll need extra heat to raise the enclosure temperature. I print ABS at 50C chamber temp and my printer's enclosure is about 420 liters. I use a 500 watt heater with a low speed fan (a 208VAC fan running on 117VAC in) to quietly and gently blow air across the heater. The combo of the bed's 750W heater and the 500W enclosure heater gets the enclosure up to 50C in about 20 minutes. The fan is wired in parallel with the heater so that if the SSR fails on (that's how they fail) the fan will keep blowing air across the heater and limit its temperature rise. I still need to add a TCO.

The enclosure panels are dual layer polycarbonate that's frequently used to make greenhouses. It is lightweight, provides thermal insulation (if you tape the ends of the panels) and lets light pass through. It also provides some nice visual effects when the LEDs reflect on the surface of the material. It doesn't contribute to structural rigidity at all, and probably produces toxic fumes if it burns. The front access doors are just plain polycarbonate so I can see through them. They don't provide much insulation at all.

-

It's got a print going at 8,000mm/min and i'm seeing about the same amount of bounce as frame flex and wiggle. Kept bumping the printer trying to reach inside to get video though and it used the same bracket i made to test the frame flex so it is bound to have some travel it's self. Once it is enclosed I will try to remember to test it again.

That said if I ever make another it will probably be dual rail. Still cantilever, just 2 rails spread apart 8-10 inches and the ballscrew in the middle.

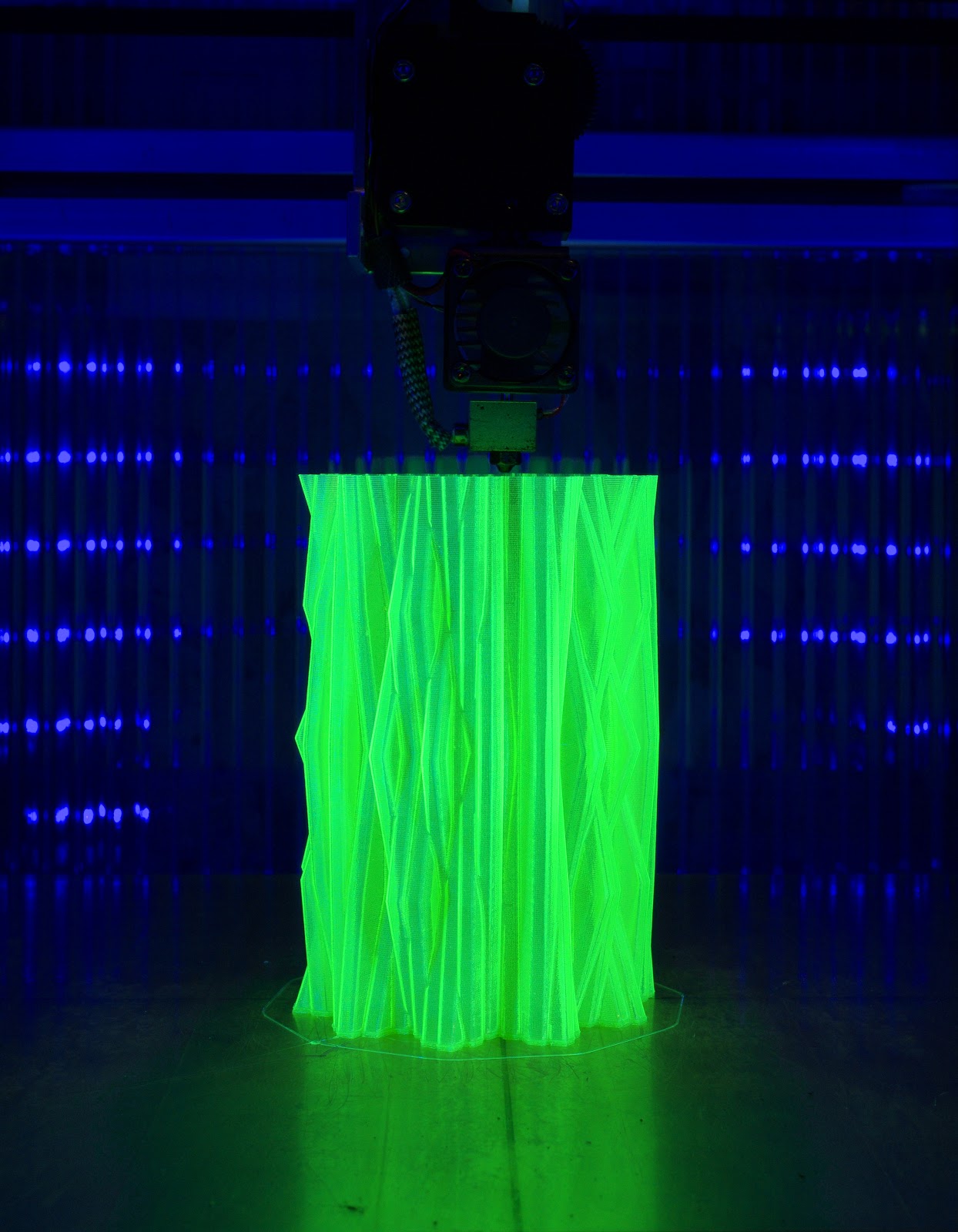

And here are a couple of pics from that 8,000 print, fresh off the printer, because someone told me its what the cool kids do.

![20191013_212829[1].jpg](/assets/uploads/files/1571027483018-20191013_212829-1-resized.jpg)

![20191013_212844[1].jpg](/assets/uploads/files/1571027497816-20191013_212844-1-resized.jpg)

![20191013_212909[1].jpg](/assets/uploads/files/1571027512747-20191013_212909-1-resized.jpg)

-

I had to put this on the back burner for a while, but now she's pretty much fully assembled and up and running. I'm pushing a direct drive aero 0.4 volcano, 0.2 layer heights at 150mm/s with more than satisfactory results. I can push it to 300, but the ringing is terrible, never shifted a layer though. I'll eventually upgrade the rail carriers to the next highest preload and see if I can push it faster.

My biggest hurdle was getting everything connected to the raspberry pi. It's still a bit wonky, and crashes the duet2 sometimes, but at least I get print finished alerts now. I'm guessing I have to upgrade to the duet3 to get the print paused because of filament alerts though.

And because it's finished, for now. I grabbed a handtruck and wheeled it over to my neighbor that had a scale big enough to weigh it. 230 LBS/104.3KG and solid as a rock! That will easily jump another 75-100 once I get all the drawers in it and fill them up.

-

My God! What hinges!

-

Great overall, and particularly nice panel wiring.

-

@mrehorstdmd The theme of the build was overkill. I don't want to reprint or readjust things every few months. + those hinges have to hold 3-4 rolls when I get a toolchanger in there. I almost went even bigger, but then I damaged the PEI on the bed and have been too lazy to change it out. Benefit of a larger bed, i'll just print on the parts that are still good for now.

-

Very Nice! What do the wire strippers do?

-

@gtj0 When I remove filament from the hotend I usually have a bulge on the end. I don't like pulling that through the bowden as it can cause it to stretch. Wouldn't matter much on the direct drive, but it's a good practice. Eventually I'll get one of those fancy blue cutters everyone has, but I already had these.

-

@macguyver said in Tired of Mod, tweak, tune, repair, rinse, repeat...:

@gtj0 When I remove filament from the hotend I usually have a bulge on the end. I don't like pulling that through the bowden as it can cause it to stretch. Wouldn't matter much on the direct drive, but it's a good practice. Eventually I'll get one of those fancy blue cutters everyone has, but I already had these.

HA! From the picture I thought they were attached to the tool head and you were doing some 3D wire stripping.

-

It's been a while since I've updated this, but figured I would update it with what I've learned so far.

The speed is absolutely amazing. Most filaments now print at 250-300mm/s with a direct drive titan aero. I think there is more speed to be milked, but I'll need to do to a dual drive extruder and the apocalypse is slowing E3d down.

It has only skipped steps twice in the entire year. Both times the acceleration was at 8,000. 6,000 she would shake a bit, even in her weight class. It can handle 3-4,000 fine, but with ghosting on every edge. Currently it is at 1,800. I'm currently using 6mm belts and the next printer will have 8-12mm. I would/will probably make the next one 1-200lbs/100kg heavier too.

Reliability. This is after all the main reason I built the thing. I went through the other day and started checking fasteners. Not a single one has come loose. Neither has any of the brackets, connectors, etc. I have found myself leaning on the bed while oiling a rails a few times, and when I check the level it's still perfect. I would say this category has been a success.

Temperature. I had always theorized that corexy would heatup the chamber above the build plate before the rest of the chamber. What I didn't suspect was that these 2 zones would never balance out. Above the build plate will always be 10-20 degrees warmer than below. This could also be a side effect of the electronics chamber sharing a common wall. That said, I have seen chamber temperatures of up to 58C with a build plate temp of 110. Most times however it bounces between 45-50. This is with polycarbonate side panels. I will eventually insulate the build chamber and get that up higher, though I have yet to see any prints crack.

Dialing in filaments. I've found most slicers dial in settings like retraction in 0.2mm increments by default. I have found that with many filaments I need to dial that in at 0.01mm increments. I had an ASA that would leave blobs with a negative restart distance of 0.04, and holes at 0.09.

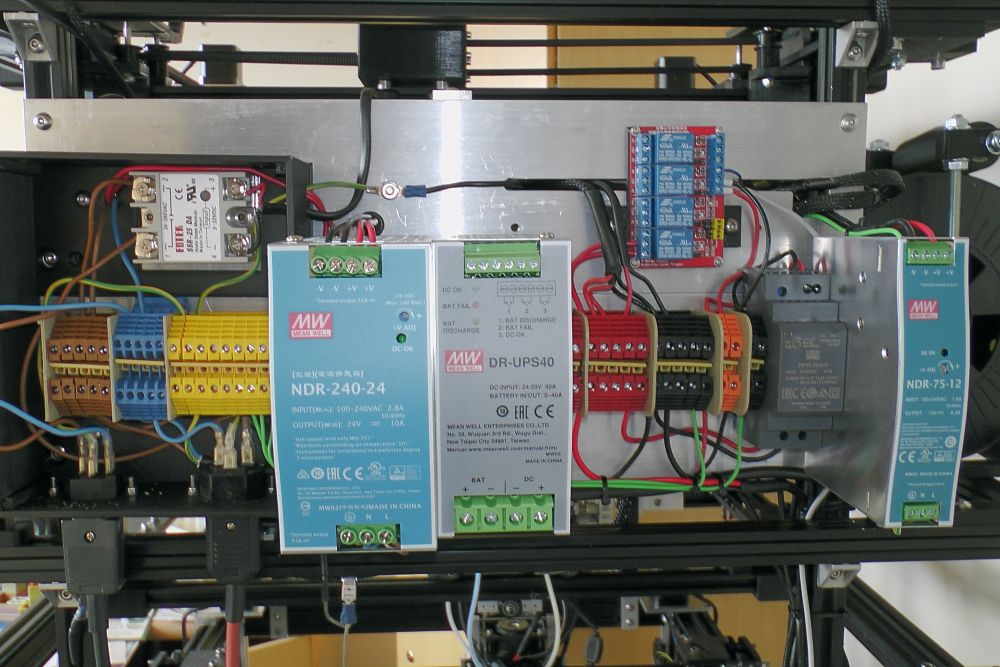

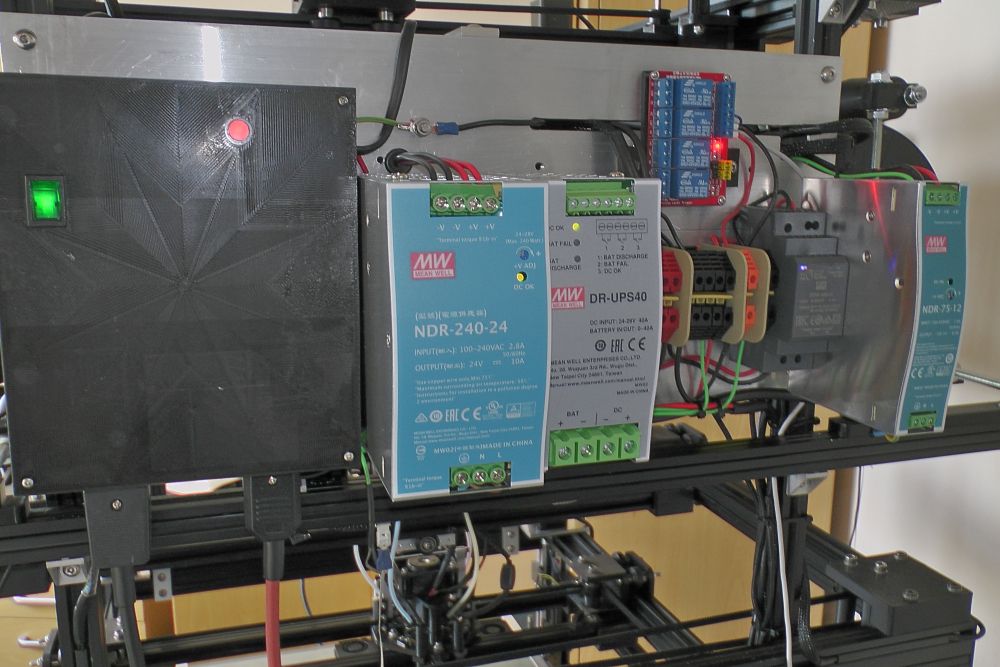

Electronics. This is often the most neglected part of builds. First off, DIN rails. They are amazing. Mounting all my electronics to the side panel makes them wonderful to work on, add things, troubleshoot, etc. Since it is cooled by fans and sharing a wall with the printer however, it is pulling heat away from the build chamber. I will eventually move them to a drawer at the bottom of the printer.

The biggest thing I learned is it is going to take longer than you think. There is a lot of information out there for what I would classify as hobbyist grade printers. While a lot of that wisdom will carry over, a lot of it won't and you need to figure out what does or doesn't. You often pay more for this when you buy a machine, than the machine it's self.

-

Let's see it print!

For the chamber temps a fan would help even out the temp differential.

For retraction, try using firmware retraction. Makes setting and tuning retraction on the fly much easier.

-

Made a few more changes. Added a Chamber heater. Didn't have room for the relay for said heater with my previous setup, so I moved all the electronics to a drawer. with plenty of din rails, and room for more in the future...

I upgraded the stepper wires to 20 gauge. This was a challenge. The jst connectors that nema 1.7's use are for 24 gauge max. It was difficult and took some time to get the connectors over the insulation.

I upgraded my part cooling fan to a 5020 and this thing is blowing more than the 4 pack of 5015s I had before it combined!

I've moved over to Prusaslicer from Simplify3d. S3d was giving me issues with at the start of extrusions on some parts. PS seems to have fixed those, though I will find out for sure this week when I print one of the parts that was giving me a lot of problems. Imo PS seems to handle higher speeds better than S3d, and the time estimates are closer to reality.

![20210131_011221[1].jpg](/assets/uploads/files/1612085340838-20210131_011221-1-resized.jpg)

![20210131_011314[1].jpg](/assets/uploads/files/1612085376029-20210131_011314-1-resized.jpg)

-

Very neat! I'd be interested in seeing a list of all the things you 'fortified' or considered and made adjustments to in order to get the rigidity you now like.

A much easier request though - which 5020 fan are you using?

-

-

@macguyver that machine is awesome but i think you underestimated the weight of the moving gantry. Looking at the prints there are a lot of problems caused by too much speed/acceleration value. Considering that a normal core xy is printing at 150mm/s without that it would be a limitation for that build size. However, also at lower speed, i'm sure that this machine is going to be a really reliable workhorse! Keep up the great work.

-

@macguyver

Do you have any problems with heat-expansion on your gantry?

I've just heated up my chamber to 50C and noticed the gantry moved much easier by hand, than I was used to.

I've fixed the crossbeam of my gantry only on one side and let the other side float in one direction because I was afraid of heat-expansion when I built it. But still it runs tighter, when cold.

IMHO, the belts are now your weakest link. My philosophy " Sturdy frame, but lightweight gantry" -

@o_lampe As the frame expands, the pulleys and motors move father apart, increasing tension on the belts (assuming the belts don't expand much when warmed). That may be what causes the increased effort to move the mechanism when it's warm.

I keep one end of the X axis fixed on the Y axis pulley block and the other end is mounted using a second bearing block on the X axis rail. That allows the Y axis rails and pulley blocks to move apart as the mechanism heats up while preventing motion in any direction but X.

I've never paid attention to the force required to move the mechanism over temperature changes. It works fine at all temperatures.

-

@lael said in Tired of Mod, tweak, tune, repair, rinse, repeat...:

Very neat! I'd be interested in seeing a list of all the things you 'fortified' or considered and made adjustments to in order to get the rigidity you now like.

A much easier request though - which 5020 fan are you using?

There are 2 main sources of flex in most frames. The attachment points, and the frame material itself. Gussets and brackets tend to be a bandaid for both of these.

The main goal was to get away from gussets, brackets, and the slop of extrusions for the motion system. The second goal was to make the frame and everything that attaches to it as constrained as possible. Parts like the Z upright, Z steppper/ballscrew mount, and even the belt idlers are aligned and kept rigid and aligned with pins through reamed holes and the entire frame is assembled with M8 bolts.

That makes all the attachment points solid. From there the weak link would be the material of the frame itself, and that's easily solved with bulk. A 4mm plate may flex, if an 18mm plate does, you have bigger problems.

As for the fan. Amazon sent me this one by mistake, and I'm glad they did.

adda ab05012ub200b00 I had ordered a adda ab05012dx200600. The second one they sent me was correct, and does not compare in performance. -

@o_lampe said in Tired of Mod, tweak, tune, repair, rinse, repeat...:

@macguyver

Do you have any problems with heat-expansion on your gantry?

I've just heated up my chamber to 50C and noticed the gantry moved much easier by hand, than I was used to.

I've fixed the crossbeam of my gantry only on one side and let the other side float in one direction because I was afraid of heat-expansion when I built it. But still it runs tighter, when cold.

IMHO, the belts are now your weakest link. My philosophy " Sturdy frame, but lightweight gantry"no problems with expansion. I used Mic6 for the whole motion system though, so any expansion should happen fairly evenly without any warping.

And yes, belts are weakest link. Next one gets 10-12mm, or rapid traverse ballscrews...