Ditto/Mirror Printing only doing 50% extruder flow? <solved>

-

Edit: Disregard - this was a Slicer issue with a corrupt profile I was using for duplication printing.

Hi there,

I have an IDEX setup and I've done ditto printing a ton in the past but havent in a few months. Since then I've upgraded the firmware to 2.04 -> 2.05.1 and I am seeing a weird behavior doing Ditto/Mirror printing now.

it seems the flow rate to the extruder is 50% what it should be or less. I tested by moving the Extruder multiplier to 200% and it seemed to work close to what it should be if still a bit off.

I can print with the exact same settings on T0 and T1 and have perfect prints, but T2 and T3 just fail epicly and the extruder barely moves.

My tool config is:

;###TOOL DEFINITIONS#### ; Tool 0 X - Left hand Extruder M563 P0 D0 H1 F0 X0 S"Left Titan Aero" ; tool 0 uses extruder 0 and heater 1 and maps X to X, use fan 2 as the print cooling fan G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets ;G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ;Tool 1 U - Right hand Extruder M563 P1 D1 H2 X3 F1 S"Right Titan Aero" ; tool 1 uses extruder 1 and heater 2 and maps X to U, use fan 1 as the print cooling fan G10 P1 X0 Y-3.52 Z0 ; Set initial tool 1 active and standby temperatures to 0C (was -.71 before adjusted the Left X axis down) Tweaked Y it was -2.95 ;G10 P1 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Duplication Tool 2 M563 P2 D0:1 H1:2 X0:3 F0:1 S"Dual Duplication Print" ; tool 2 uses both extruders and hot end heaters, maps X to both X and U, and uses both print cooling fans G10 P2 X76 Y0 U-76 ; set tool offsets and temperatures for tool 2 ;G10 P2 R0 S0 M567 P2 E1:1 ; set mix ratio 100% on both extruders ; Mirror Tool 3 M563 P3 D0:1 H1:2 X0:3 F0:1 S"Dual Mirror Print" ; tool 2 uses both extruders and hot end heaters, maps X to both X and U, and uses both print cooling fans G10 P3 X86 Y0 U-86 ; set tool offsets and temperatures for tool 2 (+10mm offset for clearance due to the mirroring movements) ;G10 P3 R0 S0 M567 P3 E1:1 ; set mix ratio 100% on both extrudersTool 2 and 3 are the ones I am having issues with. I the Mix ratio is set to 100%.

Also seemed like the Z offset was .05 higher than it should be, but that could be down to the 2 heads trying to use the mesh compensation meant for one. The flow rate being broken is the real issue here.

-

@clegg78 I don't really have an answer for this. Most other threads where people have posted their IDEX configs are pretty much the same as yours, eg https://forum.duet3d.com/post/140426. I don't see anything that has changed between 2.04 and 2.05.1 that would affect this either.

According to this guide https://duet3d.dozuki.com/Wiki/ConfiguringMultipleIndependentXcarriagesCartesian#Section_Creating_a_tool_that_uses_more_than_one_carriage_to_print_multiple_copies_of_an_object you need to turn on mixing with

M568 P2 S1. But I think even this is old info, as there's a note in the V1.19 release notes https://github.com/dc42/RepRapFirmware/blob/dev/WHATS_NEW.md#version-119 that says:M568 command to enable/disable mixing no longer does anything because mixing is always enabled. Mixing is not used if the E parameter in the G1 command has multiple values.

So really not sure! Does that help?!

Ian

-

I can't see any reason for this behaviour, and nobody else has reported it. The only change that has been made to mixing behaviour is that for extruder-only moves, if the total mix ratio is not 1.0 then the feed rate is now scaled by the total mix. The means (for example) that retraction and reprime moves with a mix ratio of 1.0:1.0 will happen on both extruders at the same speed as they would on one extruder when the mix ratio is 1.0:0. Previously, if you wanted to keep the same retraction speed when ditto printing as when printing with a single extruder, you would have needed to double the requested retraction speed in the slicer.

I suggest that when you next print n duplicate mode and observe this behaviour, you run the following commands and check that all the values they return are as expected:

M567 P1 (should return 1.0:1.0)

M92 (check the E steps/mm)

M221 (should return 100% for each extruder) -

@dc42 said in Ditto/Mirror Printing only doing 50% extruder flow?:

u next print n duplicate mode and observe this behaviour, you run the following commands and check that all the values they return are as expected:

Thanks @dc42 I am going to run some tests (extruder calibration measurements) to see if the commanded feed distance is what gets extruded when it is in duplication mode. I will also run those commands.

-

@clegg78 said in Ditto/Mirror Printing only doing 50% extruder flow?:

@dc42 said in Ditto/Mirror Printing only doing 50% extruder flow?:

u next print n duplicate mode and observe this behaviour, you run the following commands and check that all the values they return are as expected:

Thanks @dc42 I am going to run some tests (extruder calibration measurements) to see if the commanded feed distance is what gets extruded when it is in duplication mode. I will also run those commands.

While I have an IDEX machine, I have not yet tested ditto/mirror mode. I'll give it a whirl (hopefully tonight) and see what happens.

-

@dc42 so I did some calibration tests.

Using stationary Extrusion calibration tests I found they were extruding pretty close to the same wether T0, T1, or T2 (duplication) was being used. I did find a small steps per mm calibration issue I needed to fix (you can see below they are both at 821steps per mm, after calibration it was 808/825 which does answer some extruder to extruder mismatches I was seeing, but not the total print failure.)

4/8/2020, 11:35:08 AM M221 Extrusion factor(s) for current tool: 100.0% 100.0% 4/8/2020, 11:34:57 AM M92 Steps/mm: X: 200.000, Y: 200.000, Z: 1600.000, U: 200.000, E: 821.000:821.000 4/8/2020, 11:34:46 AM M567 P2 Tool 2 mix ratios: 1.000:1.000 4/8/2020, 11:34:40 AM M567 P1 Tool 1 mix ratios: 1.000So stationary tests like this everything seemed to work OK. I made sure to run the same scripts/macros I have my slicer call before the job starts as well. I am going to try another print and see what happens. I'll try the same commands mid print as well.

-

@dc42 so I may be tracking this down... this actually seems like a weird Z offset issue. If I use T1 or T0 they seem to go to the right calibrated bed height, no flow issue differences, no print quality differences. If I do T2 (or T3), I need to babystep down the Z -.15 to get the print height to look correct. .15 is a huge height difference for a .3mm layer height print. This makes sense that I was seeing the need to go to 200% flow to get the print to lay right. (I have bed height compensation turned off for all 3 just to keep things the same)

Once this test print is done I am going to see if I can quantify the height difference.

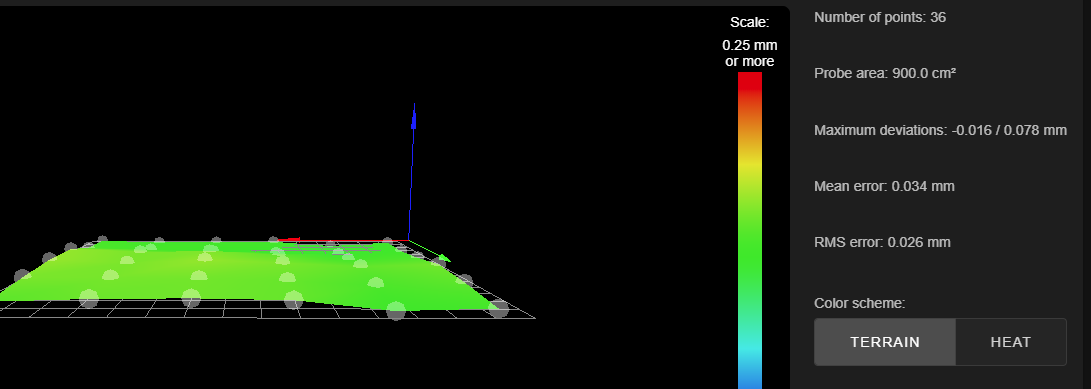

My bed isn't 100% perfect, but its not too far off:

So when the bed mesh compensation is turned off it shouldn't make much difference in the middle of the board. How does the mesh compensation work when both toolheads are being used at the same time? I am guessing it bases it off of one of the tools positions and it cant do both. Especially not a .15mm height difference. I have Z0 defined in the tool config (added it as I noticed it was missing from the config)

-

@dc42 So I ID'd the issue!!! It is NOT a Duet problem, it was 100% Simplify3D. The profile I was using for duplication went bad somehow... or corrupt. Even though it was based on a profile that worked fine, it does not. I took an older profile and tweaked it for this filament and it printed like a champ.

Its hard to compare exact code, but it does seem like it was doing some real odd extrusion numbers.

The fact my individual tool profiles printed fine, but the tool profiles for duplication and such all failed really was messing with me and looked like a printer issue!

Sorry, My bad, I'll go and beat myself up now

-

@sebkritikel it was my slicer acting weird and specifically for the profile I use for the duplication printing, it was failing.