Who's printing masks, respirators, etc?

-

What are you printing?

Source for models?

What materials are you using?

How many have you printed?

anything else? -

I'm printing mainly face shields with petg in the German Group #makervsvirus we are over 5000 Private Persons and we will Print all we can.

-

I just finished a batch of 50 bias tape folders for people sewing masks. It took 21 hours to print 50 of them because the design is suitable for repairing potholes in roads. Each uses almost 9g of filament. I redesigned it to use about 3g of filament and they will print in about 1/3 the time, too. Running a test print of 10 pieces now, should finish in about 1:30.

Preparing to print NIH approved face shields once I have all the materials to assemble them.

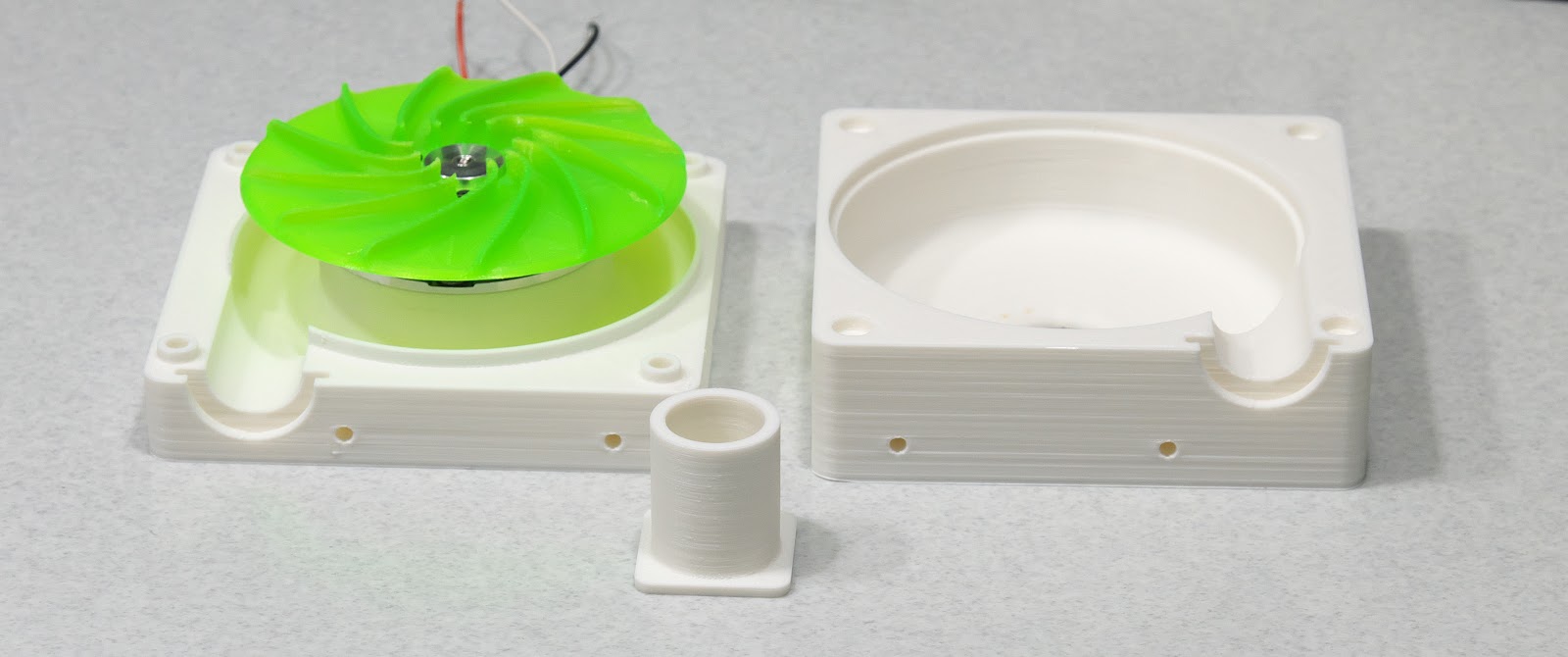

A 3D printable CPAP blower I made about 2 years ago seems to be generating a lot of interest among people trying to design ventilators. I think it's too big a project to quickly design a ventilator from scratch. I think it would be smarter and faster to do what I did with the CPAP blower- copy the mechanical parts of an existing machine because all the engineering has already been done. I think the machines that squeeze a resuscitator bag have the best chance of getting done quickly.

-

I haven't started yet. The local places aren't currently asking or accepting public made items. Though the local 3D printing cafe is producing a stockpile and waiting for approval from the authorities.

@mrehorstdmd said in Who's printing masks, respirators, etc?:

I think the machines that squeeze a resuscitator bag have the best chance of getting done quickly.

Bag valve mask. And yes those definitely look more promising in the short term since they can easily be repurposed.

-

@gtj0 I'm printing the Prusa rc3 face shield frame, and sending them off to https://www.wethebuilders.com/projects/11 who are assembling them and distributing them at cost to the Maryland area. I will pass 50 printed by Monday, and I think many thousand have been produced by the whole team.

-

I was going to start printing masks for my neighbors, many of whom are "at risk" category, but I'll be damned if I can get a first layer to stick today.

-

I'm printing clips for baseball cap face shields that assembly workers will wear as they continue their "essential activities"

Can't seem to get any layers to stick either on any of my machines!

-

@gtj0 said in Who's printing masks, respirators, etc?:

I was going to start printing masks for my neighbors, many of whom are "at risk" category, but I'll be damned if I can get a first layer to stick today.

Too much peanut butter...

-

@Phaedrux said in Who's printing masks, respirators, etc?:

@gtj0 said in Who's printing masks, respirators, etc?:

I was going to start printing masks for my neighbors, many of whom are "at risk" category, but I'll be damned if I can get a first layer to stick today.

Too much peanut butter...

HA! I did manage to get the plate perfectly clean and get the new Printbite+ sheet attached.

Anyway, I figured out my issue (Simplify3D) and am printing one of the models that don't require supports. -

I am printing for a local organization here that takes the printed parts and takes care of the medical protocol, assembly and distribution.

It's a variation of the prusa design.

This video has good ideas for optimizing the prints to sub 1H

https://www.youtube.com/watch?v=_bt1UZAnxnA (it's not the design I am printing but should apply to all designs) -

Printing the NIH approved face shields. Assembling with report covers 3 hole punched. Placing them in transparent 50 gallon bags, about 20 per bag, with NIH documentation stapled across opening of bag and big letter sheet that says: "YES, can be sterilized with Alcohol or Peroxide, DO NOT AUTOCLAVE. Replace transparency with any suitable 8.5x11 and standard spacing 3 hole punch. " Or similar. Very short.

Then setting bags aside to see if North TX area flares or otherwise runs short on PPE. I'm not even going to attempt to deal with any kind of administration... if we flare, I'm walking straight into various ER entrances and handing them over to Triage staff. While wearing one, (and plenty of other PPE), of course.

-

And... whoever above said they can't get them to stick today... it is the weirdest thing: My two most reliable printers (big fast delta and Prusa Mk3) have failed to print these (six at a time on the big delta and one at a time on the Prusa) for the weirdest reasons.

For example, the big delta spit its bowden out of the top of the extruder. Twice. It has never done that in the last 3 years since I built it... The Prusa crashed detected for no apparent reason on one print, and spaghetti-fied another. It never does that. And so on... weird.

-

Currently printing these face shields for Liverpool and Whiston hospitals in the UK, https://www.matterhackers.com/covid-19 , https://3dverkstan.se/protective-visor/

-

@boldnuts you must be local. I hail from St Helens! Working on local contacts for PPE myself but need to sort machine.

-

Appropos Covid-19, Dr Vax, a 3D Printing vlogger reported a week ago that he contracted the virus and was under induce comma and ventilator for a week.

https://www.youtube.com/channel/UCWEX2NVlLeIQr3v-cIF9LxA/community

-

Dr Vax is back from his Corona ordeal.

-

Missed that. Haven't come across them before, I will check there stuff out. Good news their through it after a rough ride.

-

I'm printing face shields, either the lite version, from 3DVERKSTAN, or a better version, designed by some guys of our hackerspace for the local hospital.

@mrehorstdmd, I printed this bias tape folder, which makes the final fold too, and works decently well. I use it to make masks from PP fabric. I also designed a clip for such links.

-

Almost feels a bit silly, but with 120mm build platform and its limited what I can make - but I ended up making a bunch of these that had the sole purpose of offsetting a monitor by 20mm or so. Its definitively in the "etc" category..

Why? Local company sent out a bunch of monitor stands and monitors to boost productivity in the home office, but hadn't tested the new curved 27" screens fit the monitor stand they had been using in the offices. At 3kg pr screen i figured a printed part would do.