Stratsys FDM 8000 convert to Duet 3

-

So far I am the only one posting, except bearer who seems to have changed their mind.

I may as well continue as a sort of blog and see if anyone decides to comment.

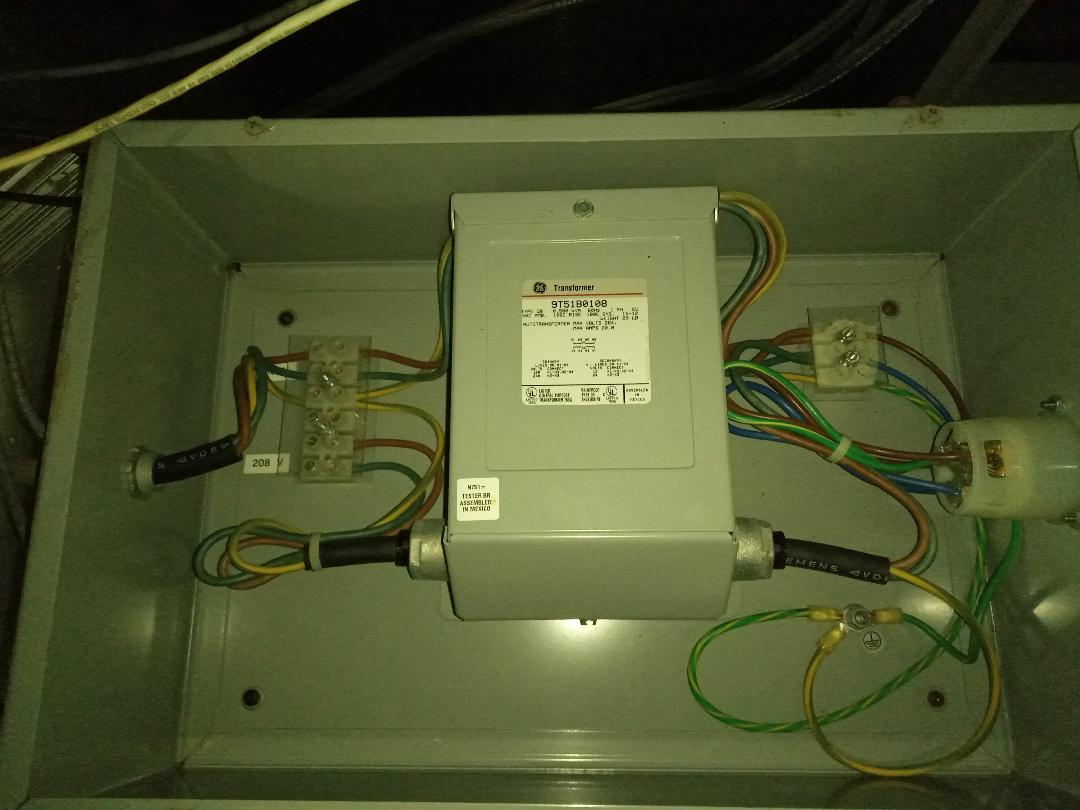

Today I am dismantling the power supplies. Seems confusing in that there is a 500w transformer in a huge box on the input but then the power supply box also has 2 transformers and a 240-115 switch. I can only assume that the power box is used in another product without the input transformer.

The label on the input transformer is misleading in that it claims to be 12-24v output even though it is clearly 230v output.Regarding temperature sensors I am not sure whether to use the existing thermocouples or replace with new thermistors?

-

@Rory166 said in Stratsys FDM 8000 convert to Duet 3:

except bearer who seems to have changed their mind.

my response was based on an early version with different limits, so irrelevant. meanwhile the full schematics have been made available (or more correctly, we've been made aware of their availability).

its not possible to supply the motors with a different voltage than the rest of the board and the 5v and 12v buck converters are the limiting factor. there is a thread here somewhere detailing how to work out the expected back emf to consider increasing the voltage as the absolute max rating is 36v for those chips; but duet3d set the limit at 32v to avoid problems with back emf

but the motors are current driven and will more likely than not never see 32v

Could the 12-24v input be some sort of ups functionality?

-

whopsie, forgot the link https://raw.githubusercontent.com/Duet3D/Hardware/master/Duet3/Duet3_MB6HC_schematic_v1.0.pdf

(but i suspect the lack of postings is the lack of a clear question; not many need >24v)

-

@bearer Thank you very much. I will look up the link you posted. Yes I agree the voltage should be nowhere near 32v as the resistance of the windings on the motor I can see is less than 1 ohm and i will set the current at 3A, should be less than 3V steady state but dynamic may be another matter. The X Y motors I cannot see the full label but what I can see says 65 volts weirdly. I am thinking to start with 24v and increase to 30 later if needed.

No I dont think the 12- 24 is correct. Just a bog standard isolating transformer.

-

i don't think you should be to worried about the voltage rating on the motors, there is usually ample headroom.

https://www.reprapfirmware.org/

you'll find a emf calculator on that site, it'll also give you an indication of how fast you can drive with a given voltage/current.

-

@bearer I apologise the transformer is not in circuit as such. I took a photo and can now see the mains runs right through. I may as well remove it. Would make a nice battery charger perhaps. They cost $450 so sbout the price of a 3d printer these days.

-

@Rory166 Wow! That is a big machine! It took a while to even find a picture of one.

Introduced in 1997... I expect it has some nice mechanical bits. But pretty big for a print area of 18"x18"x24" (457.2 x 457.2 x 609.6 mm) nowadays. Must have been very impressive at the time, though.Just to encourage you to continue to post your conversion... keep up the good work! I had a quick google and couldn't find anything useful for helping (seems no one else has tried converting these), except your thread on the RepRap forums. Interesting the conversion was originally considered back in 2012! https://reprap.org/forum/read.php?1,135821

There was this thread about converting an FDM 2000: https://reprap.org/forum/read.php?1,807230

Says that the extruders are DC motors rather than steppers. What are yours?

User manual (which I'm sure you've found) https://support.stratasys.com/products/fdm-legacy-platforms/fdm-2000-3000-8000Ian

-

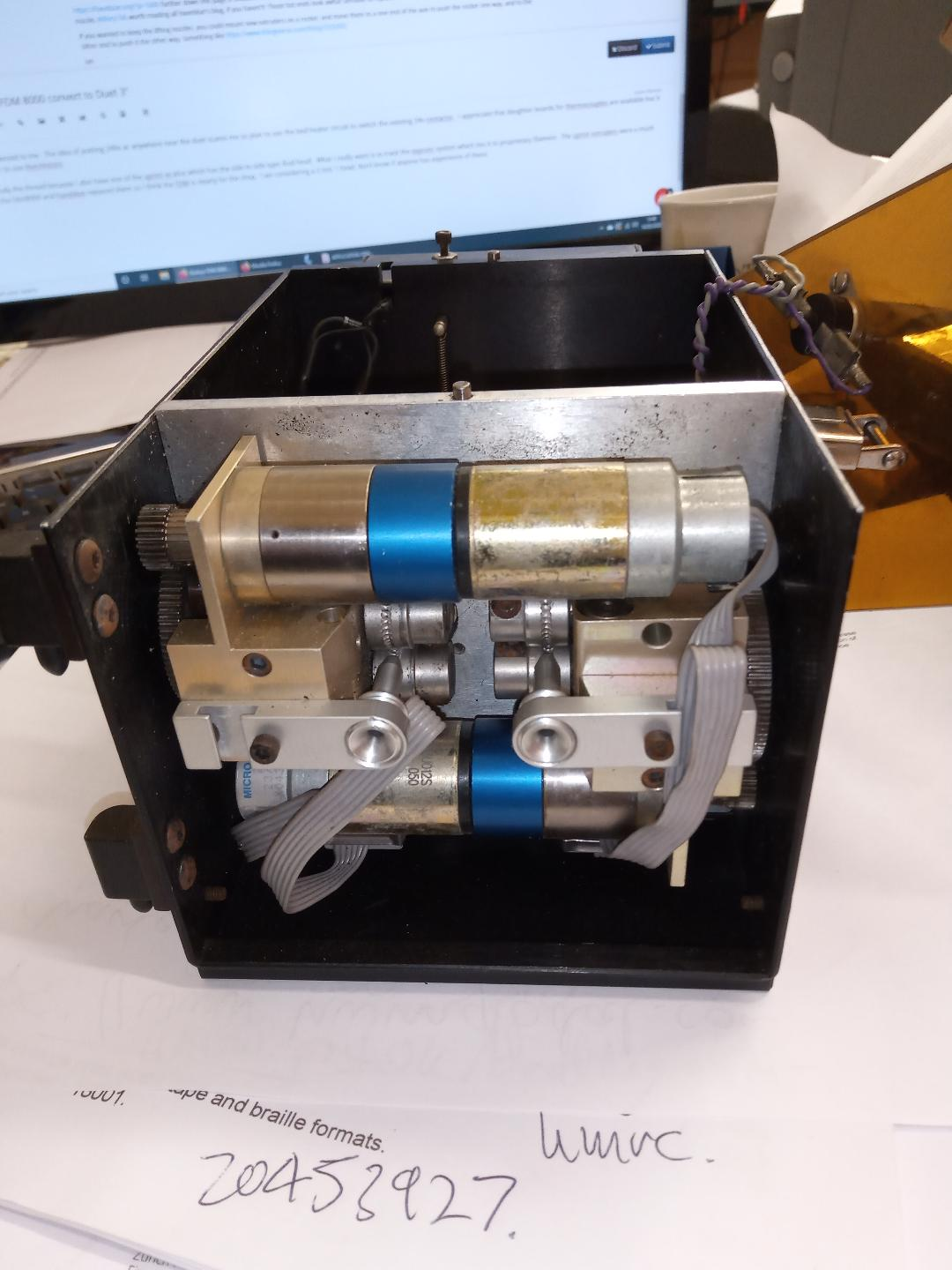

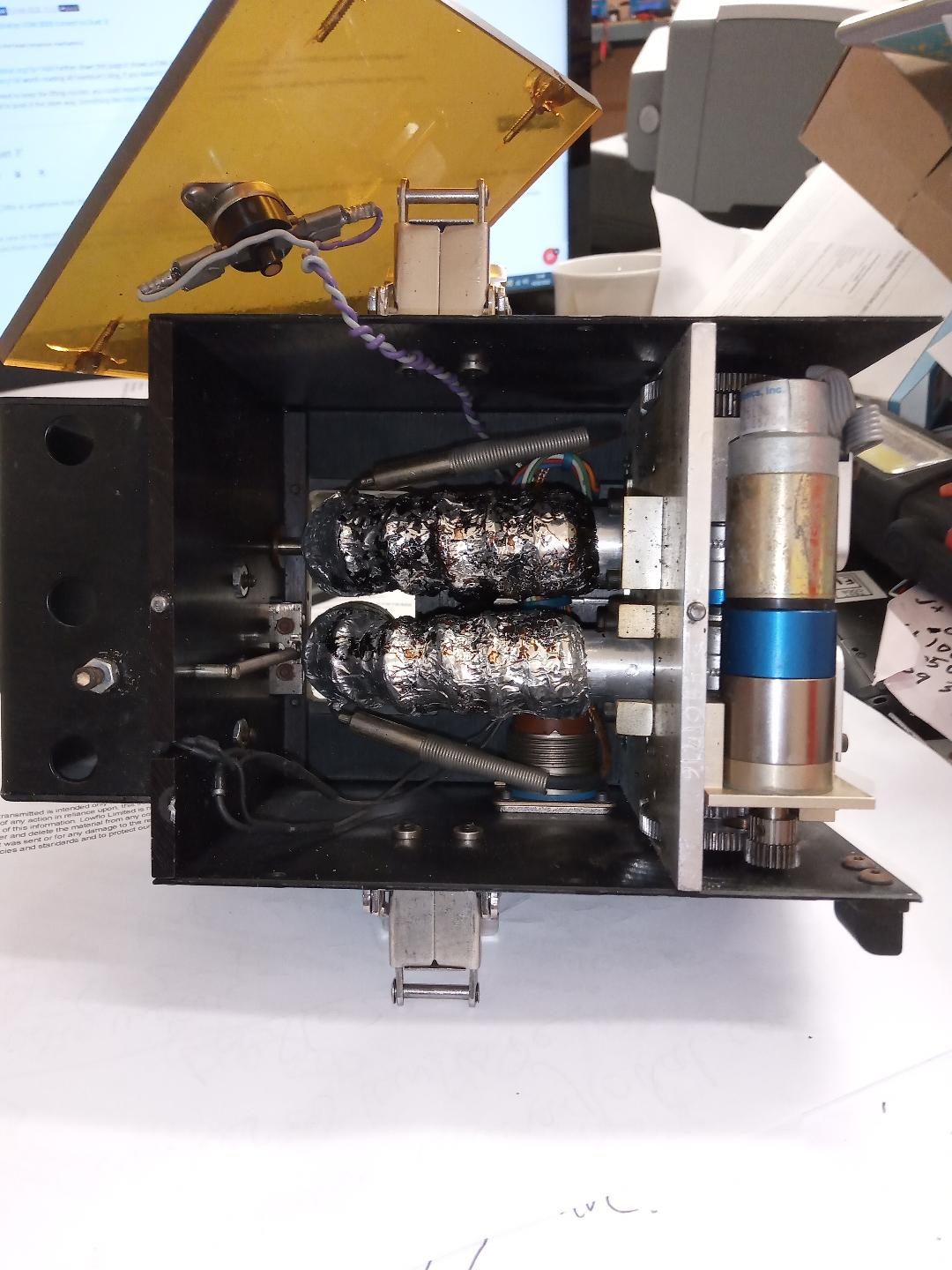

Yes these are the same machines that the OP on reprap had. The ramps board and steppers were inside still in box. The steppers were not man enough for the z motor and dont know about the xy yet. The things are massively heavy, each cover plate is heavy steel. The thermal insulation has degraded and will need replacing. I am thinking if i do a good job with 2" solid insulation I may leave the covers off. The extruder motors are rumored to be 3ph brushless. I am thinking to build a new extruder assembly with modern components.

-

@droftarts Haveblue on the reprap forum implores people to try the original machine before converting. The one I am coverting has no controller the other was working but failed. I will have a lot of spare parts to try and repair the failed one.

-

Just to update on progress so far. The wiring has been pulled back to the new control position behind where the original control panel. The existing contactor seems suitable to control the environment heating. Most other functions seem to be 24v. The main 24v psu seems adequate for the whole chebang. Even the lights which will now be led. I am planning to replace the existing extruder assembly completely, it has mains heaters, thermocouples and dc brushless motors. None of which is compatible with the standard Duet 3. Also I have no idea how to control the head retraction function although this may be possible. The support head is lower than the other and retracts when not in use.

-

Tha mains heaters can be driven from the Duet via DC/AC SSRs. The printer might already have SSRs separate from the other electronics.

The thermocouples can be connected to the Duet via the daughter board provided that the thermocouple wires are electrically isolated from the thermocouple casing.

What drives the head retraction mechanics? A Solenoid perhaps, or stepper motor, or DC motor?

-

@dc42 said in Stratsys FDM 8000 convert to Duet 3:

What drives the head retraction mechanics?

https://haveblue.org/?p=1600 further down this page it shows a FDM 2000 head which I think is the same, and mentions that it uses a solenoid to lift the support nozzle. @Rory166 worth reading all haveblue's blog, if you haven't! Those hot ends look awful! Sensible to replace it.

If you wanted to keep the lifting nozzles, you could mount new extruders on a rocker, and move them to a one end of the axis to push the rocker one way, and to the other end to push it the other way. Something like https://www.thingiverse.com/thing:3335003

Ian

-

@dc42 looks like a solenoid to me. The idea of putting 240v ac anywhere near the duet scares me so plan to use the bed heater circuit to switch the existing 24v contactor. I appreciate that daughter boards for thermocouples are available but it seems much cheaper to use thermistors .

@droftarts I will study the thread because I also have one of the uprint se plus which has the side to side type dual head. What I really want is to Hack the eeprom system which ties it to proprietary filament. The uprint extruders were a much later version than the fdm8000 and haveblue replaced them so I think the FDM is clearly for the chop. I am considering a 2 into 1 head, don't know if anyone has experience of these.