Help with settings...

-

Hi to all,

I have a Anycubic linear plus with:

- duet 2 wifi board;

- hayden rods;

- smart effector;

- PT100;

- ultrabase;

- on order a Zesty Nimble V2.

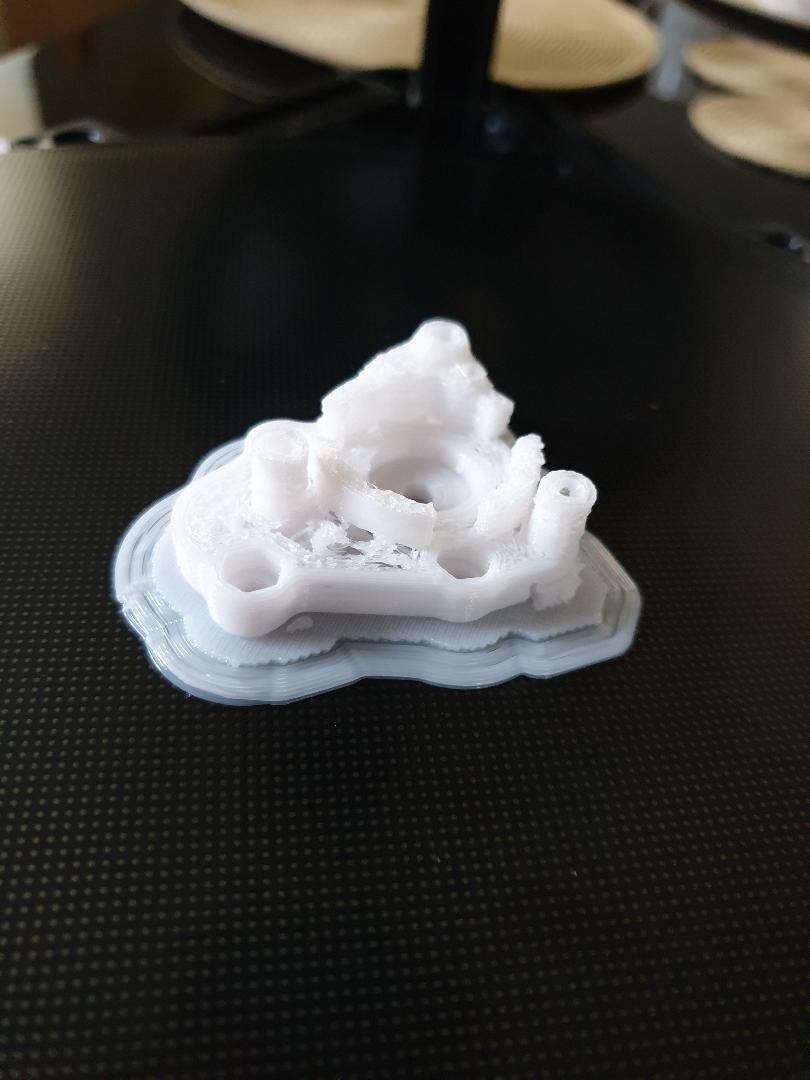

I fight with this crappy prints for over a month. I really need help with some settings.

I use Simplfy3D and a have: - bed temp. 70C;

- hotend temp. 210C;

- nozzle 0.4mm (brass);

- extrusion multiplier - 0.95;

- retraction 5mm;

- speed retraction 3000 mm/min;

-layer height 0.15mm; - first layer - height 110 - width 100 - speed 55;

- raft;

- no fan.

Printer is calibrated (I think, maybe not). No warnings. Z probe working properly.

Why I have this terrible results? See photos

-

nimble and 5mm! retract ? this is to mutch reduce this to 1 or 2 mm.

Here you can find a guide to calibrate your extruder (step 5)

can you post your config.g please -

Nimble is on the way. I still use the original extruder with Capricorn tube.

config AKL.g -

@gabi68 said in Help with settings...:

on order a Zesty Nimble V2.

oh sorry i have this overseen try first to controll your calibration from the extruder

-

- Any advice for doing a better calibration besides the measurement method?

- "Nimble (biggest crap ever)". Why is that?

-

Assuming you are printing with PLA, I think you are printing much too hot. Try dropping the hot end temperature by 5C and 10C. A print cooling fan will help too.

-

Hi David,

I was thinking about that and actually tried, but the extruder start skipping like the PLA was not melted properly.

I will try tomorrow with a lower temp. -

Shouldn't need a raft.

Layer 0 adhering says your Z calibration is OK.

Are you sure your PT100 is calibrated properly ? This looks like it could be a wildly wrong temperature.

-OR-

Extrusion is way off. What extruder? Have you calibrated by the measurement method with at least 100mm of movement?

-

@Danal

The machine is calibrated, I think. I will do it again today after work. PT 100 don't give any warnings. Thermal tuning saved with a M500.

On both attempts I saw the same behaviour, the first 15 layers are laid down beautifully. Starting with layer 16 where the infill is almost finished the gaps appear. It looks like the filament don't stick anymore on the previous layer.

Why is that? -

Are you sure that you haven't inadvertently configured your slicer to change the temperature or some other parameter at layer 16?

Or perhaps the nature of your model changes a lot at layer 16, e.g. changes from having large infill areas to small infill areas?