any suggestion for a connector for the printhead?

-

@matt3o Molex Microfit 3

-

i found this quite interesting, although I doubt i'll try it https://www.youtube.com/watch?v=I-izkShIDXU

(XT60 is a nice connector for high current, but its rated for 60A and just ever so slightly overkill for a hotend)

-

Use a D-Sub whatever, with pins in parallel for the heater.

-

Another vote for the D-sub, but the regular 2-row type. Much easier to solder on, more robust pins.

D-subs are very robust connectors for very little money.There is also a smaller XT connector BTW: the XT30.

-

Was about to ask a very similar questions but minus the probe, Dsub 15 looks like it'll do the trick very nicely!

-

I would still recommend the Molex Microfit 3.0 series which can be had unto 24 way so more than enough also much lighter than D-Sub connectors.

-

I use the microfits in other places and like them but I also use RJ45 for the hot-end signal and low power stuff and simple spade connectors for the hot-end.

-

@Dougal1957 said in any suggestion for a connector for the printhead?:

Molex Microfit 3.0 series

I've used these on other things, and they do work very well. Were it me, I'd be comfortable with my own "psuedo-standard" connector for a standard tool, meaning:

- Stepper (4)

- Sensor/thermistor (2)

- Heater (2)

- Hot end fan (2)

- Part fan (2)

- Sensor for tool alignment(2)

Total 14, with no allowance for future expansion.

From USA supplier Mouser, 16 position are actually slightly cheaper than 14, and I like the expansion possibility:

With no expansion, and no extra sensor, 10 position will work.

-

thanks guys, haven't though about using molex, but it actually makes sense. way easier to handle than dsubs and more flexible!

-

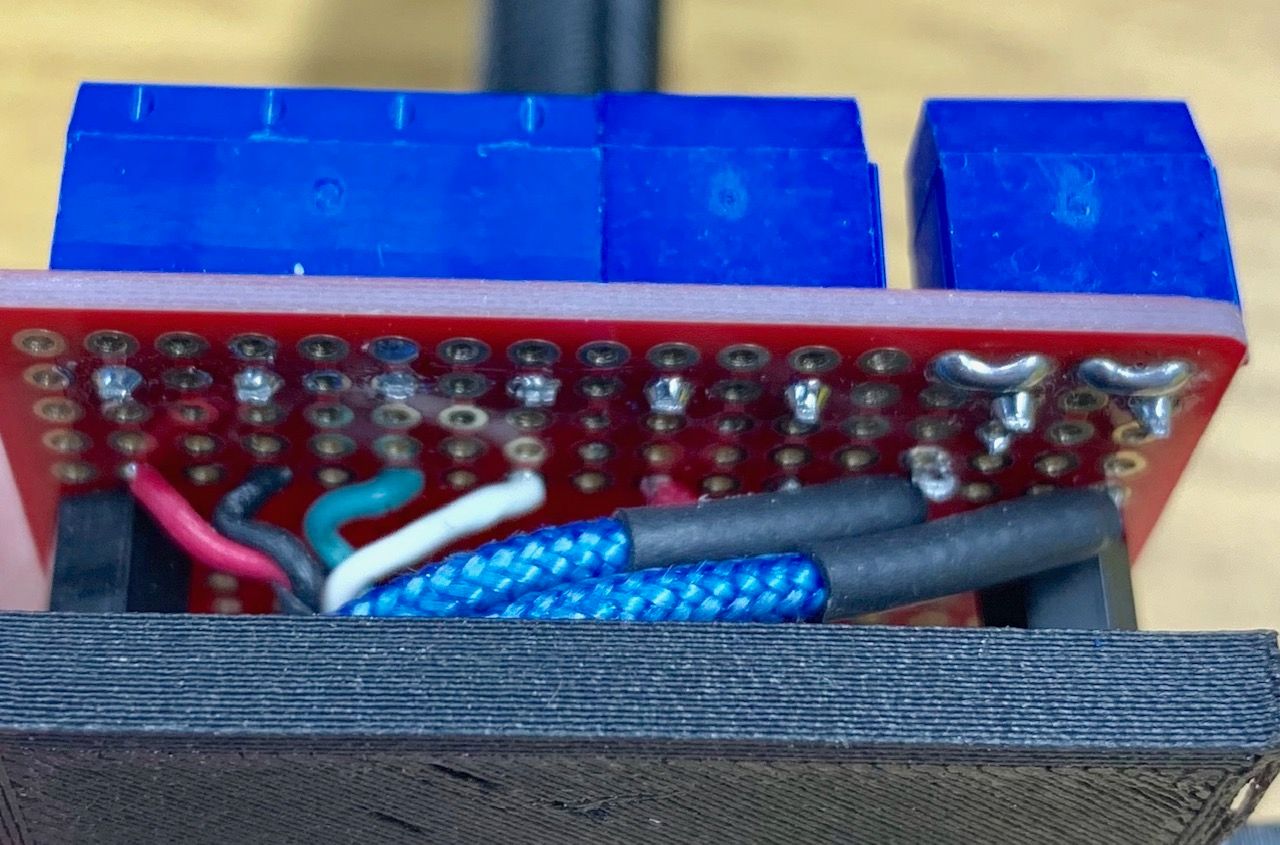

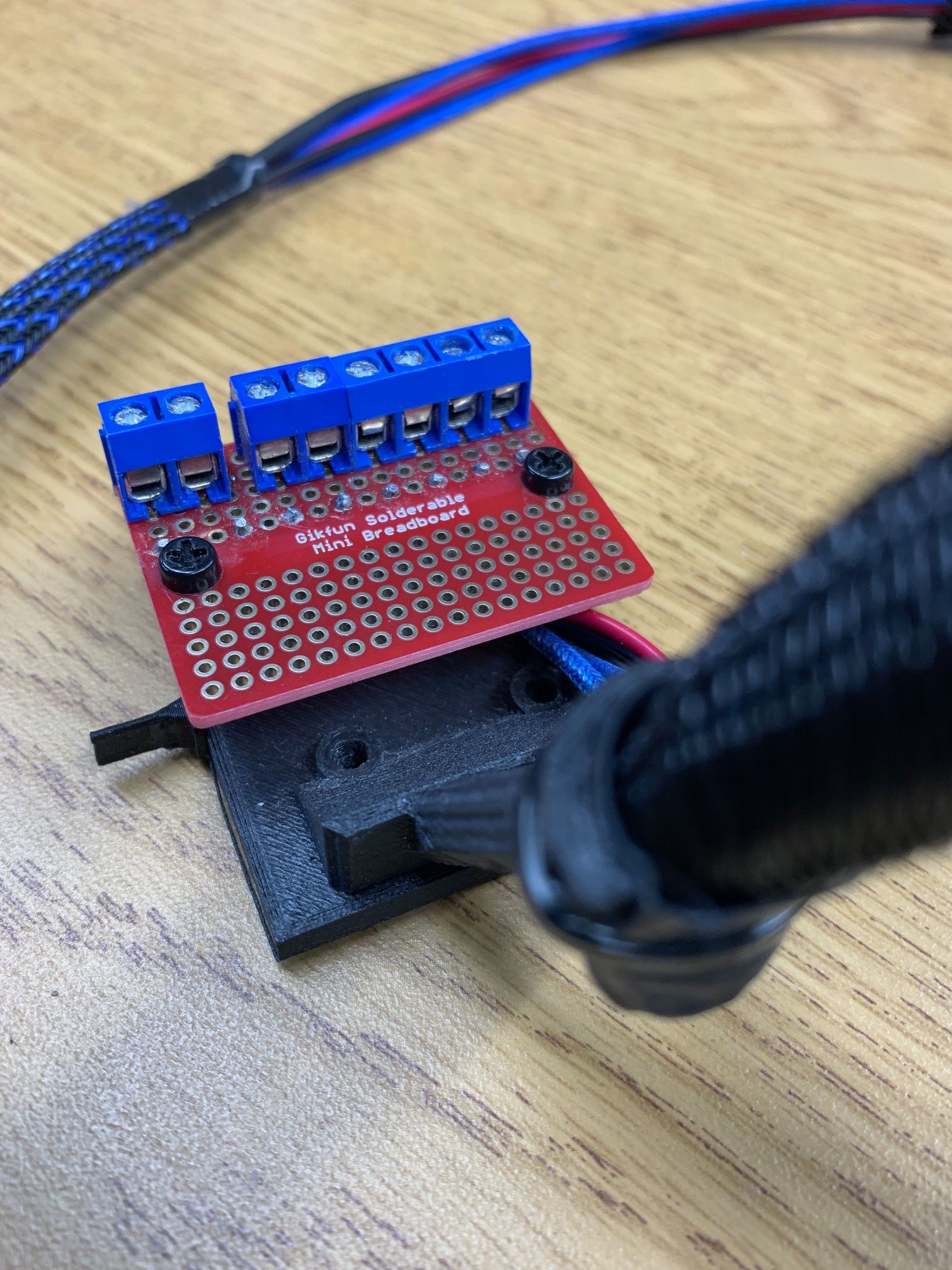

@matt3o Not sure if this would work for you (see pics).

Using extension/adapter cables or adding connectors to a harness adds bulk and creates potential failure points.

I found this method to be the best. If anything needs to be changed, its simple. Supports up to 16 terminal points.

All that's missing is a printed label plaque

-

@bricor thanks, that is also pretty clever and super easy if you need to change parts

-

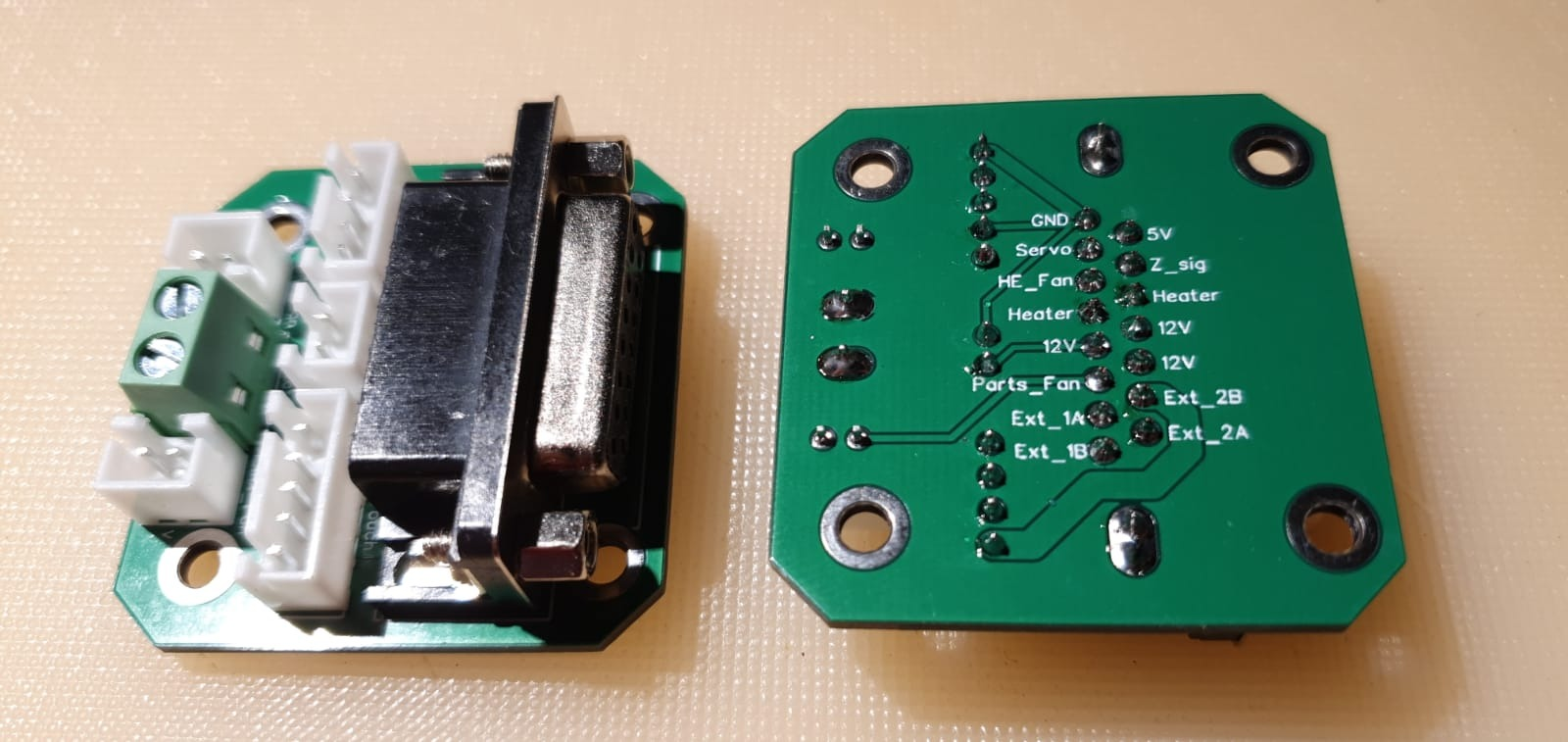

Check out this project:

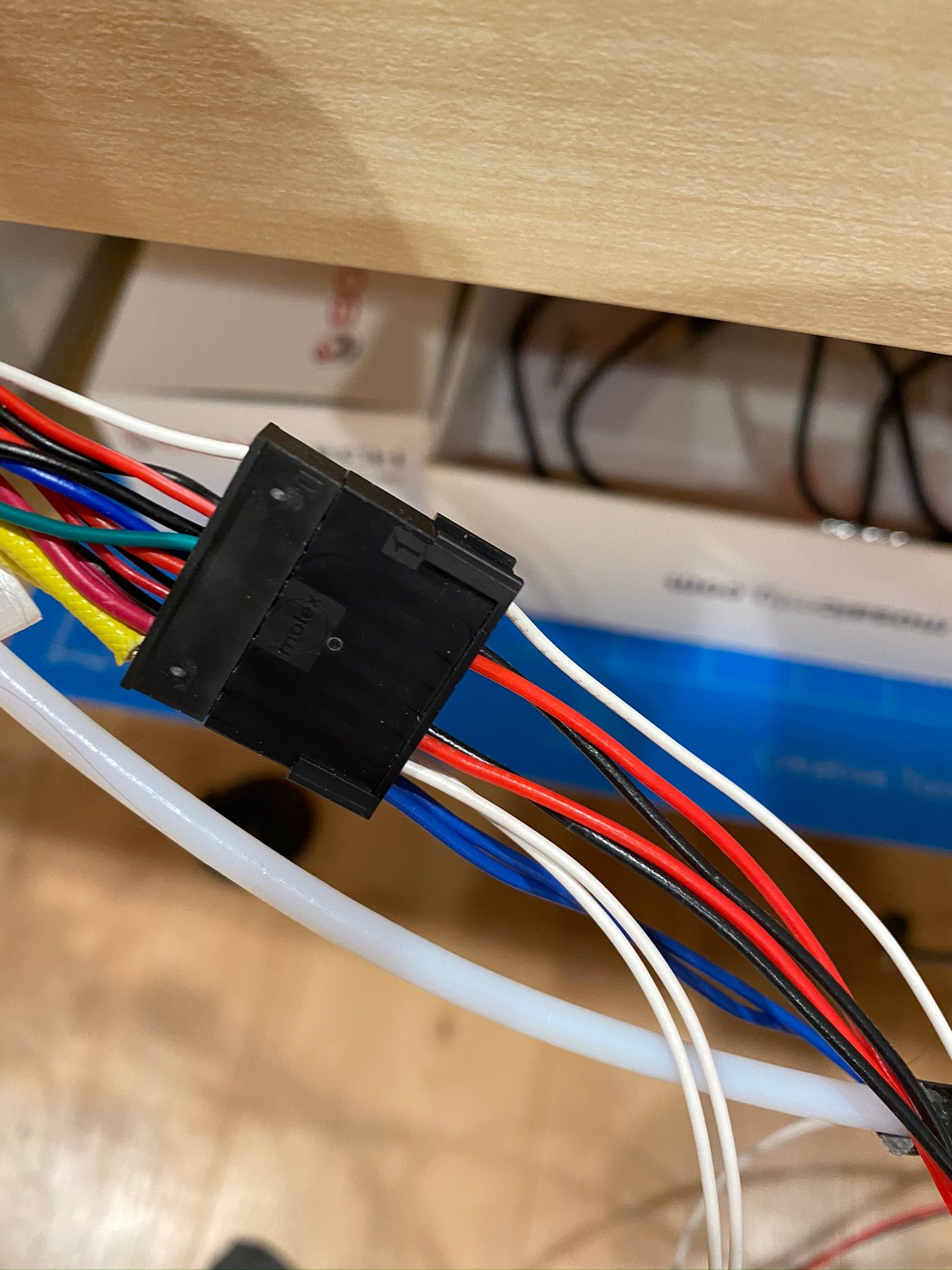

https://www.hackster.io/viktorsilivanov/quick-swap-board-for-3d-printer-hotend-fb26e4@matt3o I'd be interested to know where you found that cable.

I had some boards made and have populated but not installed yet, they'll be part of a new build.

-

Just a thought, you can distribute high currents over two wires and/or contacts. This may give you more flexibility. Also, Some wires can be merged, e.g. the +24V for heater and fans.

(Duet people mentioned in the past a possibility for smart head board that just need power and CANBUS data, this would make requirements like yours easier to solve).

-

@littlehobbyshop that is very close that what I was planning to do, with less fancy PCB and more DIY

The cable is from a local supplier but I believe they can be easily found. They are sold as "security/alarm cables" they come in many variants.

The cable is from a local supplier but I believe they can be easily found. They are sold as "security/alarm cables" they come in many variants.

@zapta at the moment I'm only sharing the positive leads of the fans, that's all I need but I'll check what else I could share. thanks!

-

So I decide to go the Molex Microfit way on a toolchanger. Purchased Molex 16 pin, m/f, pins, etc. Pleasantly enough, they were smaller than I'd thought.

This is working out well, the connectors are great... but... do be aware it is labor intensive. Every wire going to a tool now requires three crimps. One for the Duet board, one for the male molex, and one for the female molex. I haven't even gotten one tool completely setup!

Not saying anyone should/shouldn't... just be aware.

-

@Danal they are indeed smaller than I thought!

I got used to crimping, that wouldn't be a big issue. Still not sure if I want to go with a more polished solution (like the one posted by @littlehobbyshop ).

I've also found connectors with dedicated pins for power, but let's not go overboard

thanks for your report btw!

-

I'm using Wago 221 for everything.

This relieves me from soldering and I can throw out the old fans without working.