My P3Steel V4

-

Hi!

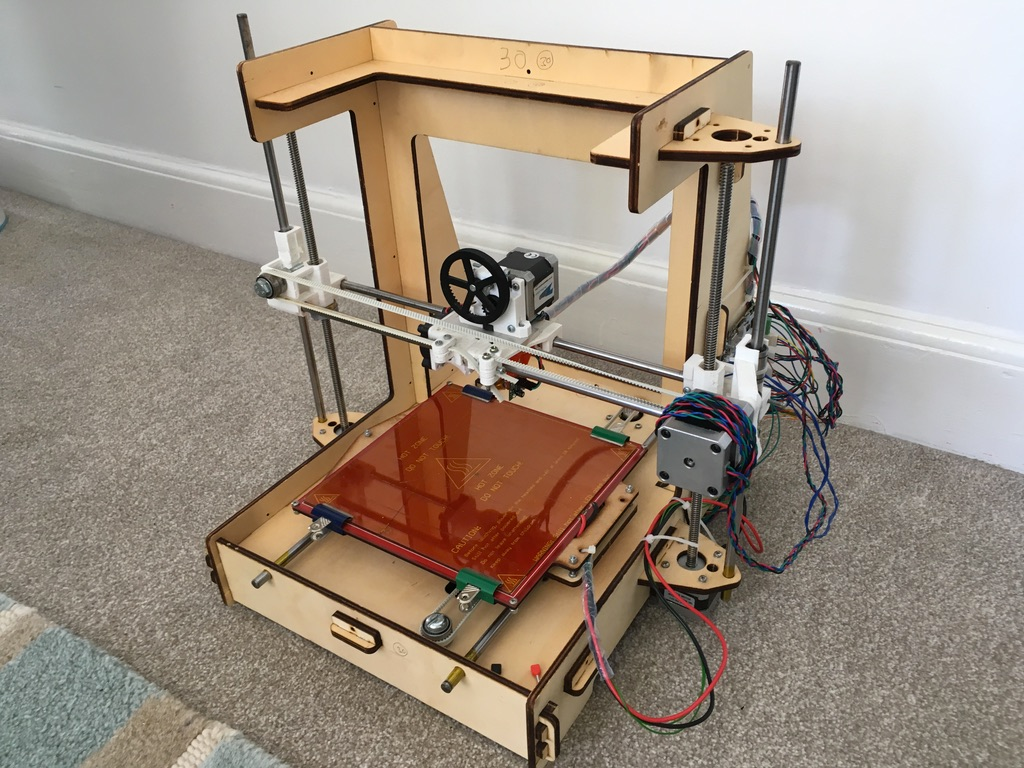

I wanted to show you my little P3Steel V4 that I've built.

The frame is a P3Steel V4 I bought on eBay and the same seller had a metal ZX-kit.

It first started out to just be a upgrade for my second printer, a CTC I3 Pro B, but I wanted to keep it as it was printing great. So I started looking around for electronics that might be good, I saw the Duets but they where a bit pricey and the Maestro hadn't been released yet. So I ordered a GT2560, it's the same on the CTC. When it arrived it was broken so that didn't go as planned... Then I saw the MKS boards, they looked great so I ordered a MKS Gen 1.4 and a TFT and some other accessories. I then realized that they didn't have that great documentation and some other issues I didn't want to deal with. During the time I was waiting for the board to be deliverd I orderd some essential parts, such as the Titan Aero and so.The printer got put in storage for some time, then this spring I didn't to just have standing on a shelf taking up space. So I ordered a Maestro and a BLTouch, while I was waiting for those to arrive I was reading up on the Maestro and decided that I wanted to go the 24V route instead of the 12V route I had planned at first. So the heated bed I had ordered didn't work, it was 12V only... But I had seen E3D's heated beds and I really wanted to use them, so that made it easy to order. I also ordered new steppers and good quality belts while I was at it.

There are some pieces of sheetmetal that I've modified or "designed" and have had cutout by a local shop. Those are the electronics sidepanel and the power sidepanel. The modified bits are the X-carriage rod holders. Originaly they where spaced 46mm apart, but the extruder mount had 45mm spacing.As you can see in the pictures there are som pieces missing, most importantly partcooling but also a sheetmetal piece for the RJ45 to be mounted to and a cover for the live terminals on the SSR. It also need a coat of paint, but I want it to be completed first so I can manage the wiring a bit better.

I know there's a wall of text in here, but I wanted to tell you the story of this printer. It's not all of it but a large part. I've left out some not so great decisions in building this printer.

-

Nice! I've nearly built a P3Steel a number of times, just never quite hit the 'buy' button. There's a couple of other people on the forum with P3Steels, eg @DocTrucker

Ian

-

now convert it to a prusa i3 bear

-

@Veti said in My P3Steel V4:

now convert it to a prusa i3 bear

Ha! I've reused my hardware so many times:

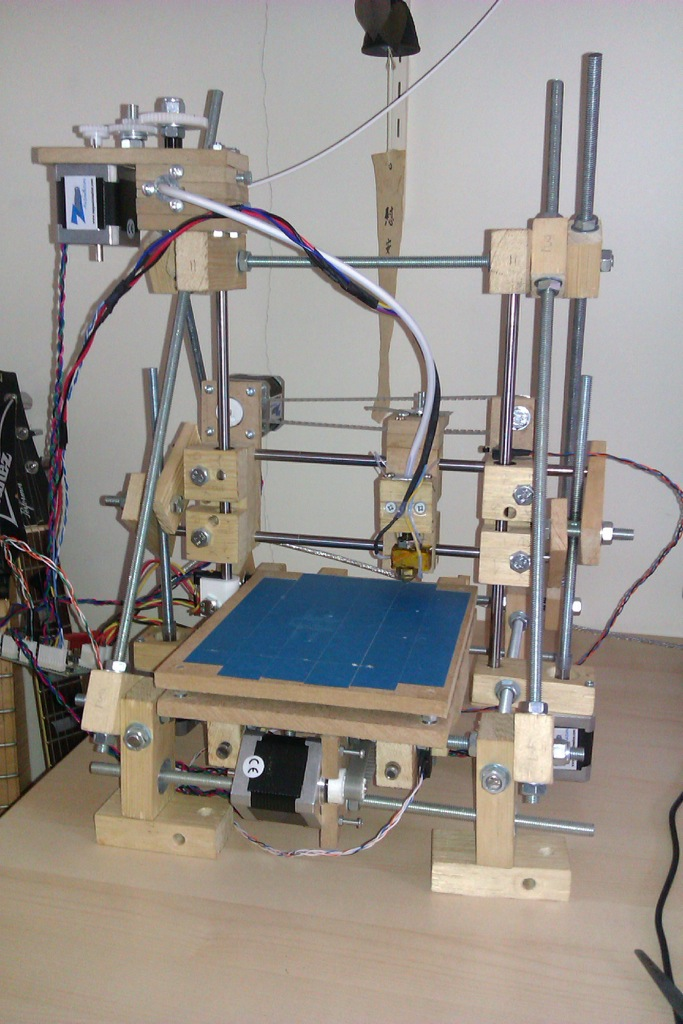

2010 - 1X2 Repstrap

2011 - Prusa i2 printed on 1X2 (current machine still using same X axis!)

2012 - my take on a Prusa i2 (stronger corners with cross-bracing)

2012-13 - Various bits made it into a Printrbot (printed version), Prusa i2 (built for my nephew) and Printrbot LC (won in competition for being first to post a video of a printed Printrbot printing!) before going back to previous machine

2013-2016 worked at RepRapPro, so lots of Mendels, Huxleys, Ormerods and Fishers. Then got more involved with CNC for a couple of years, keeping just a Fisher delta working. Finally resurrected into it's current form, using (at the very least) the motors from the 1X2:

Currently running 3mm filament through a customised RepRapPro extruder and J-Head, but plan to update to a Bear X axis and 1.75mm extruder when I've run out of 3mm filament!Ian

-

@droftarts said in My P3Steel V4:

Ha! I've reused my hardware so many times:

yes you never finish. there is always something else to try or tweak.

-

Welcome to the mix. Yup guilty as charged. I've two working P3s. Been a bit quiet this week as direct extrusion and a large inductive sensor have been challenging to package!

Just running calibration at the moment. Ideal pressure advance appears to have dropped from 0.35 right down to 0.044!

I'm very hopeful for the next real build...

I'm very hopeful for the next real build...Best of mine is running duet v0.6 with the expansion shield, but have the parts to build a system that will run reprap firmware on the dev board for the Duet3's main processor. Looking forqard to that, but to be honest most of the limitations I've struck have been printer hardware based rather than evem the Duet v0.6. To that note I like the adjustable positioning for the znuts on that all metal design! That said I'm trying a few new (at least to me) things on my next p3 build which wouldn't have left me needing to cut new metal parts.

-

@DocTrucker The Z-nuts are not adjustable on this design, maybe it looks that way with the metal by the endstop but that's only a spacer for it.

Could someone help me to find some neat solution for partcooling?

I've seen a design on Thingiverse that was made for the extrudermount that I have, but that was before I even considered getting one of those so I didn't save that and now I can't find it...