CNC: Tool Offsets, Coordinate Systems, Confusion

-

I suggested to chrishamm long ago that DWC needs an option to display both machine and work coordinates. But I am guessing that your fork goes beyond that.

-

Thanks everyone - I've managed to run a few simple test cuts after using my "cheapishaw" probe, and I'll try a more complex part tomorrow. So far it's looking very promising.

-

@vwegert Good luck!

@Ryan-Lock ditto!

Workspace switching and handling sounds great, having been batch-making PCB's via a web interface without it i can comfortably call it a killer feature I got heartily sick of having to switch to the console to swap co-ordinate systems. Adding macro buttons helped, but made the UI look diseased.

I got heartily sick of having to switch to the console to swap co-ordinate systems. Adding macro buttons helped, but made the UI look diseased. -

@EasyTarget Yeah we have found for users doing production manufacturing they require easy use of all work coordinates. After the release of this version, the next thing i am going to add is the ability to apply custom names to the systems, instead of just numbers.

-

This sounds very intriguing. Are there some screenshots anywhere of it up and running on a CNC?

-

@Danal I haven't got any to hand right now, but will make some

-

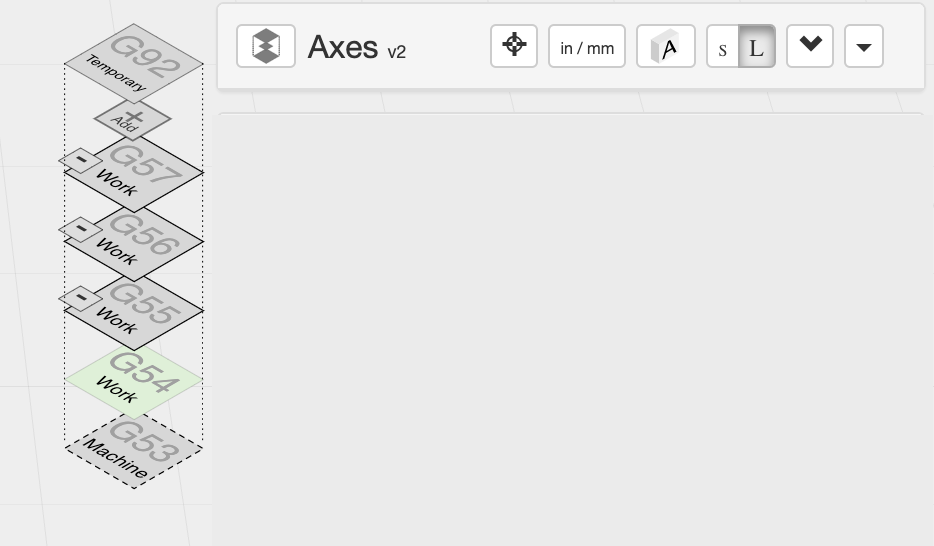

Take a quick look at the work coordinate selector built into ChiliPeppr.:

When not connected to a controller board, it WILL show the coordinate selector, it will not show the axis DROs for work and machine.

I like the coordinate selector. Play with the + and - buttons, click on a level and see it highlight, etc. Source for it is here: http://github.com/chilipeppr/widget-wcs Javascript/HTML5, so easy to grab chunks and reuse them in browser based apps.

Actually, I like the DRO style display as well, but I will need to be connected to a board to show you a screen shot.

-

Thanks for the info, their system is pretty nice! I like their graphics to see which layer you are on.

Mine is simply just a drop down list which allows you to select which one. On one of the settings page i am hoping to add a panel where you can see the work zero for each system in machine coordinates, edit them, and give each system a custom name, which will then show in the drop down instead of the number.

-

Nice screenshot.

One suggestion: Make Work v Machine visually different. Larger/smaller, different colors, etc. It is fairly standard to make Work larger/bolder/brighter.

-

Thanks for the suggestion i will see what i can do.

-

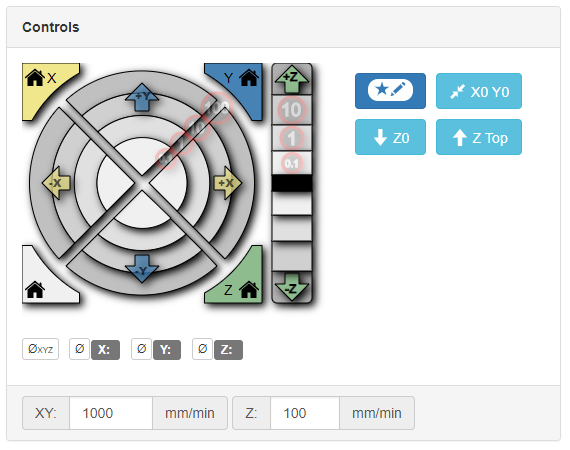

IF we are making suggestions here; this is mine. I do a lot of manual jogging when making PCB's etc. The ESP3D derived jog control panel on my esp32 based controllers webUI is excellent; heartily recommended, very intuitive to use.

The blue buttons at the right are Macros, the little buttons beside the machine position are for zeroing individual or all axes. Per-axis homing is also supported and has proved handy on occasions.

Not shown is how each concentric ring is a different amount; and a clear animation hilights exactly what you are about to click on, and what it does.

This is slightly out of date; the latest version shows machine as well as workspace position, I like having the macro editor right there in the panel too.

I just switched to using this after using the jog controls in LaserWeb a lot; those are similar layout to the Duet WebUI, easier to mis-click, I do have some foundation for preferring the bullseye approach. -

@EasyTarget Thanks for the suggestions, i will take them all on board. I have had a few other people prefer the bullseye approach to jogging as well. I have stuck with the current Duet Web Control jogging in our control to speed up production. But definitely something for the future. I have also got a lot of request for keyboard jogging.

-

@Ryan-Lock said in CNC: Tool Offsets, Coordinate Systems, Confusion:

I have also got a lot of request for keyboard jogging.

Listen to those requests! It's something on my wish-list too.

-

@EasyTarget Haha i will figure it out

-

When Adrian Bowyer was developing the first firmware for the Duet, I tried to get him to put a bullseye similar to Pronterface's into RepRapFirmware, to make it easier for people transitioning from Pronterface! Never happened...

Ian