Duet Gen 3 Teaser

-

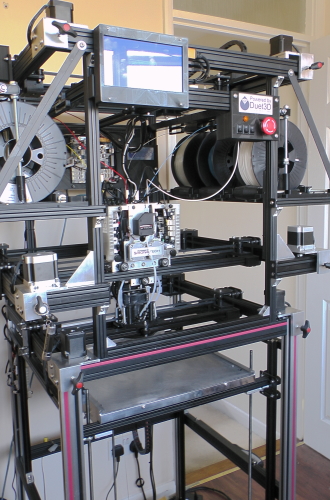

I thought that I would post a couple of pics of my printer as it stands right now - although I can't get back far enough to get the full 1.7 metre height in the pics.

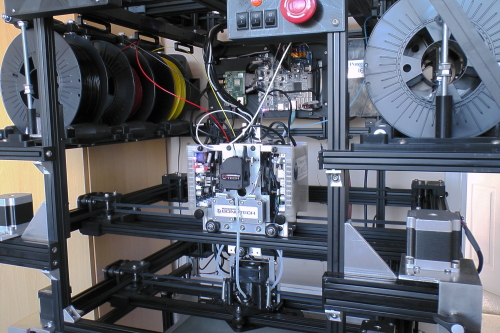

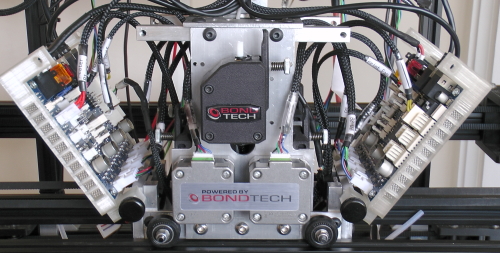

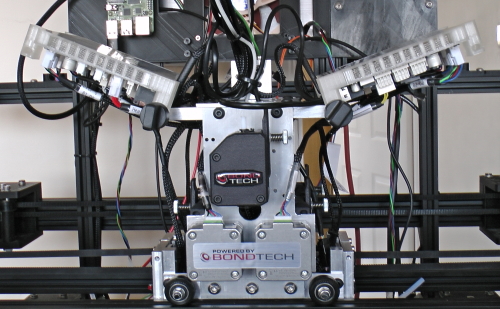

So this is a CoreXYUVAB with 6 extruders. XY is the lowest gantry and currently carries a Diamond 5 colour hot end. UV is the next gantry which moves in sync with the XY apart from when homing. It carries 6 Bondtech BMGs and two Duet gen 3 (prototype) expansion boards. This is the heaviest gantry and is driven by 2.8 Amp Nema 23s. AB is a uppermost gantry and does the opposite moves to the lower two gantries. It carries nothing more that lumps of lead to cancel the forces of the lower two gantries. XY and Z are connected to the 3rd expansion board (not visible in those pics). UVAB are connected to the main board mounted at the back of the printer along with the RPi. Eventually these will have covers.

The total moving mass, excluding the load balancing gantry and now that I have upgraded from 5 extruders to 6 as well as fitted the expansion boards to the extruder carriage, is a tad over 5 Kgs (up from about 3.5 kgs). I used to run non-print moves at 350mm/sec with acceleration set to 1000 mm/sec^2 and see no reason why I won't be able to continue to use those settings with the larger Nema23s driving the now heavier UV gantry (but we'll see)....

-

Looking forward to seeing it in a couple of weeks.

-

That print head makes it feel almost like a sci-fi movie.

-

What are your rocker switches for next to the stop button?

-

@doctrucker said in Duet Gen 3 Teaser:

What are your rocker switches for next to the stop button?

They are just lights. Well two are. One does a circular COB light that goes around the nozzle. The second controls some bright strips that are fixed to the back side of the upright extrusions and which shine back on the extruder and hot end gantries. The third is just spare and not connected to anything. Currently I use a separate 12V PSU for the lights so they are completely independent of the Duet electronics (but that may change).

The emergency stop is a real double pole switch that kills all mains power and there is a neon lamp so that I can tell when mains power is on (not that I need it with all the LEDs on the Duet boards - it'll look very festive at a certain time of year)

-

@edgars-batna said in Duet Gen 3 Teaser:

That print head makes it feel almost like a sci-fi movie.

The print head or the extruder gantry above? But yeah, watching it move at up 350mm/sec is either alarming or impressive depending on your point of view.

-

@deckingman ah ok. I've never got to the point where there is few enough little (or major) jobs on my machines to consider strapping lights to my machines!

That said, I do get it, but resort to an LED tourch at the moment!

-

@doctrucker If you do get around to it, look at "12V LED" in eBay under "Car parts" (or even 24V LED). There is a huge choice mostly aimed at kids who are into "customising". My annular or "halo" hot and light is actually called an "Angle eyes" and the strips are "Daytime running lights". Both were super cheap but seriously bright.

-

@deckingman The gantry above the head makes it really stand out. It's alarmingly impressive.

-

@edgars-batna said in Duet Gen 3 Teaser:

@deckingman The gantry above the head makes it really stand out. It's alarmingly impressive.

Funnily enough with just the 6 extruders the gantry it is actually smaller in X and Y but a bit taller in Z than the 5 extruder gantry I had before. But when I added the expansion boards, it suddenly looked so much bigger, even though they only add about 15mm to the width either side. I thinks it's just because it turns a pyramid shape into a cube but the overall width and height remain almost the same.

What I do like is that before, I had a huge cable drag chain with 40 plus conductors going to the extruder/hot end gantry. Now I just have power in and data in and out to the expansion boards and a carrier bag full of old cable that I've torn out.

-

I probably should have added these pics as well.

The expansion boards are fixed to the extruder gantry using knurled thumb bolts. So to gain access to the connectors, I can undo the upper ones and then the boards can be hinged from the bottom like this....

To gain access to the 6 extruders for loading filament and so forth, I can remove the lower thumb bolts and the boards can be hinged from the top like this.........

-

I didn't realize you can use multiple expansion boards until a few days ago when I saw your printer. Which cables are used to connect to the main Duet 3? It looks surprisingly clean considering how much stuff is going on.

I also now wonder if there will ever be an adapter or cable to connect older type boards to Duet 3?

-

@edgars-batna

As well as the ability to run >12 steppers, being able to mount expansion boards closer to motors was one of the big reasons why I wanted to upgrade.Expansion boards are "daisy chained". So each one has data in and data out. The last board in the "chain" has links across a couple of pairs of pins. There are 4 DIP switches which are used to set the board address. It's a binary address so from 0 to 1111 which is 15 in decimal and which means that there can be up to 16 expansion boards. The data cables are two twisted pair with RJ11 plugs so High Speed ADSL 2 are ideal. On the advice of DC42 I bought some Kenable ones in various lengths. I did buy a crimping kit to make my own which was OK with solid core cable but I needed multi-core flexible for the moving gantry, and I failed miserably when I tried to fit RJ11 plugs to this type of cable.

My understanding is that the Duet guys plan to have a range of expansion boards which will have different functionality. I wouldn't be surprised if one of those boards might be along the lines of the smart effector - a kind of smart tool board, but that is just speculation on my part. And perhaps we might see boards designed for use with external steppers, or perhaps a camera. Again, just speculation on my part but I can see all sorts of possibilities using a CAN bus approach.

Edit. Ref the printer being "clean considering how much stuff is going on", that's one advantage of having all those gantries - plenty of channels to run cables in.

I used about 70, one metre lengths of Open Build slot cover (big thanks to Ryan from Ooznest!!).

I used about 70, one metre lengths of Open Build slot cover (big thanks to Ryan from Ooznest!!). -

@edgars-batna said in Duet Gen 3 Teaser:

I also now wonder if there will ever be an adapter or cable to connect older type boards to Duet 3?

I doubt that will be something we would make as the older Duet processors do not support CAN-FD which we use for the BUS. Someone may hack something together to use the ethernet network and write custom firmware so that a Duet 2 board could be an expansion module on a Duet 3 controlled machine...but thats a lot of work!

-

so @deckingman is famous now:

-

@T3P3Tony he he, won't take 'em long to find him hiding on here either!

-

Bugger. I've spent the last 66 years keeping a low profile. Hardly any pictures of me exist. I don't "do" any social media. No twitter, no Facebook, nothing. But now I have been thrust into the limelight...........

-

@deckingman I'd love to get by without facebook etc but I thing my group +/- a few years were the first to go through where socials are expected.

Anyhow you're a blogger!

-

@deckingman said in Duet Gen 3 Teaser:

But now I have been thrust into the limelight...........

Now that you are a star, life will never be the same....

Seriously, if you would design it now from scratch, would you do anything differently?

-

@zapta said in Duet Gen 3 Teaser:

Seriously, if you would design it now from scratch, would you do anything differently?

Of course - many things. For one thing, I'd pay more attention to fixings when designing parts to reduce the number of different lengths and diameters of bolts and screws. I'd probably make it slightly wider at the base so that it is more stable. I'm not entirely happy with the way the filament reels are mounted because it increases the overall width to the extent that it won't quite fit through a door without taking it apart.

It will continue to "evolve". Now that I have an insulated garage door, I plan to move it out of my spare bedroom, as soon as I can make space for it in the garage. So I'll likely fit retractable wheels or castors to make it easier to move around. Loading filament is a bit of a pain with 5 or 6 reels and I'm not very disciplined at removing it from the printer. So I plan to enclose the reels and fit some sort of dryer/dehumidifier. Or I might enclose the entire thing in a cubicle of some sort. Then I have an old 17" laptop kicking around, which isn't much use. So I plan to hang that on the printer using an arm of some sort. And of course, I have to buy/design/make a better "mixing" hot end......