Motor noise and print quality

-

@grizewald just the size mismatch I woud have thought.

Raising the temperature for faster extrudes could be bringing the melt to the same temperature, or the system is simply suffering from back pressure caused by trying to shove a larger volume of material through the same size hole. The back pressure will be linked to throughput, but not necessarily in a linear manner.

It's not easy to read into the required correction that much because polymer melt can be weird and exhibit non-newtonian flow and shear thinning charateristics. That said I would suggest that if extrusion rate was having a significant effect on final melt temp you may see a kick in the tail of your required correction graph, but this would be more clearly presented by weaker parts.

As others are saying the ringing is appearing to be a resonance in the system and moving faster simply pushes past the resonant frequency. It's a good reminder that an apparent upper limit may not always be so.

You could run a few no print builds with increasing speed to check where the resonance appears with your sound meter. When preparing your test make sure that all the geometry on one layer has the same feedrate and then speed can be changed ny a simple G1 F,,, command at suitable points. Also ensure you get the angles right to test both single motor and multi motor moves.

-

I guess I'll be ordering some 0.9 degree stepper motors and some new pulleys. At least I only have to order two of them with the core-xy design!

It's worth a try at least and the appearance of the cubes in the article which Veti linked to are very similar to what I'm seeing.

I'll update this thread with the results once I have received and fitted the new motors.

-

OMG. I've been wondering what those VFAs were forEVER. Nothing I did would eliminate them. I've asked on some forum before if anyone had any idea, and nobody did. My photos look exactly like those ones as far as the VFAs go. Now I even know what they're called! LOL. OK, methinks I'm going to have to order some of these .9 degree steppers. I've never thought they'd be worth the upgrade, but if they get rid of these very fine vertical artifacts they'll be worth every cent.

-

Great. More abbreviations, just what we need...

Vertical can crop up for a number of reasons so I'd warn away from piling them all under the same catagory. It is however probably getting close to needing a fault finding guide on the wiki for 'help I can't get shot of these patterns'...

-

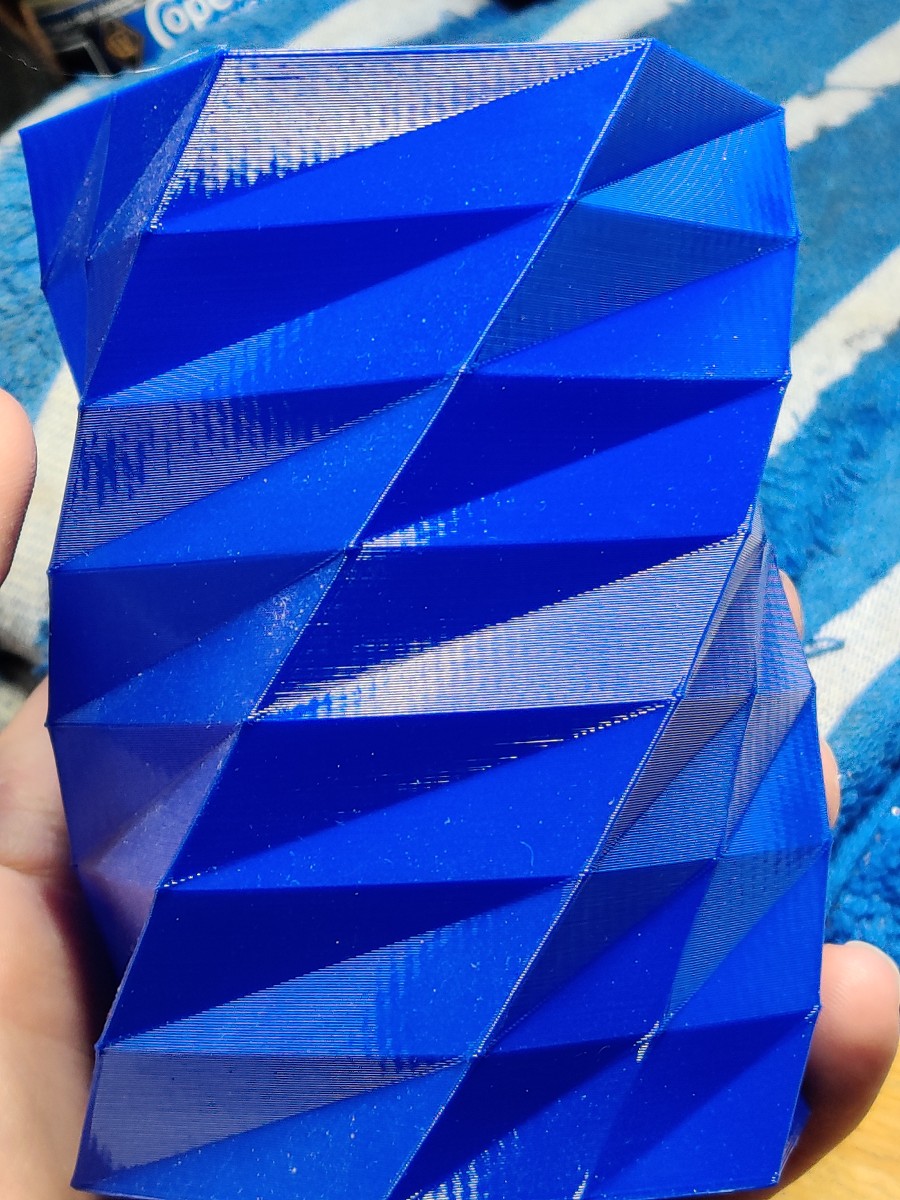

Here's a classic example of FVAs in one of my old prints, a simple vase in PETG. You see this corrugated pattern all over the enter surface. I've looked at this with a high-power loupe, and it does appear to be an issue with a very slight pulsing in the lay-down of the filament. If I'm reading the article linked by Veti above correctly, this is caused by slight accelerations and decelerations of the X/Y steppers in the course of doing their steps, not by pulsation in the extruder. If this diagnosis is correct, a switch to 0.9 degree steppers could make that mostly disappear. One might think that the frequency of the pulsation would double and I'd simply get the corrugation at twice the frequency, but if the magnitude of the changes is also cut in half it's possible that the physical difference in how much filament is laid down in each layer per "pulse" is also cut in half, with the result that its effect drops below some threshold of visibility.

Am I understanding this correctly?

-

@sethipus said in Motor noise and print quality:

Am I understanding this correctly?

thats how i understand it as well.

thats why going to a 16 tooth pulley helps as well, as it further decreases the distance between each step. -

@veti said in Motor noise and print quality:

switching to 0.9 degree steppers and 16 tooth pulley giving me 200 steps/mm the artefacts where gone.

Similar experience here.

Also switching to gates belts and adding a flip to my belts so that smooth side was riding on the smooth bearings as idlers also helped a lot. Toothed idlers didn't help. Perhaps because 16T idlers are quite small and the belt teeth didn't seem to mesh smoothly.

-

I just ordered a pair of these .9 degree steppers which should be here Sunday, so I should be able to report back sometime Sunday evening.

I'll pull out some dark-colored PETG (gotta see if I have enough of this same blue left) and print a vase like this before I do the swap, and then after with the new .9 degree steppers using the exact same g-code file, in order to compare. I will return and report. Fingers crossed.

-

It sounds like we're all going for more and smaller steps!

To an extent, this makes sense, but I've been playing today with a simple object which a member in the other active "print quality" thread is having trouble with. I thought I'd simply be able to print it with one of my standard profiles and everything would come out looking beautiful.

No such luck!

I'm seeing poor surface quality and ugly loops escaping the print at layer changes. If I can get the camera on my microscope working, I'll post some proper pictures.

For a comparison, I fired up my Anycubic i3 Mega. The print's not quite finished yet, but I think I can see similar artefacts at later changes on that printer as well, along with the infill showing through, which I don't see on my prints from the V-Core.

I guess it's time to do some slicing with Slic3r and see how those go.

3D printers are fun, but I have to say, getting them to print properly gets to be less and less fun. There are just so many variables that it makes the process painful in the end.

-

@sethipus said in Motor noise and print quality:

I just ordered a pair of these .9 degree steppers which should be here Sunday, so I should be able to report back sometime Sunday evening.

I'll pull out some dark-colored PETG (gotta see if I have enough of this same blue left) and print a vase like this before I do the swap, and then after with the new .9 degree steppers using the exact same g-code file, in order to compare. I will return and report. Fingers crossed.

Exactly the same motors as I ordered earlier today, except mine are being shipped from Germany. I ordered direct from the manufacturer's web site and they only cost me $15.89 each, plus $11.57 shipping.

I hope the price you paid wasn't anything like the $21.99 Amazon is showing me! -

@grizewald said in Motor noise and print quality:

@sethipus said in Motor noise and print quality:

I just ordered a pair of these .9 degree steppers which should be here Sunday, so I should be able to report back sometime Sunday evening.

I'll pull out some dark-colored PETG (gotta see if I have enough of this same blue left) and print a vase like this before I do the swap, and then after with the new .9 degree steppers using the exact same g-code file, in order to compare. I will return and report. Fingers crossed.

Exactly the same motors as I ordered earlier today, except mine are being shipped from Germany. I ordered direct from the manufacturer's web site and they only cost me $15.89 each, plus $11.57 shipping.

I hope the price you paid wasn't anything like the $21.99 Amazon is showing me!I can't tell if there is sarcasm lurking in here (

), but under the assumption that there isn't, I saw these steppers for like $13.something on the steppersonline website, but they'd be shipping from China, and there'd be some shipping charges. I did indeed pay the $21.99 each from Amazon, but I have Prime so the shipping was free, and I'll have them on Sunday instead of waiting a couple/few weeks. If you divide the $12 shipping charge for two steppers, add that to the $15 purchase price you paid, you're waiting for them to arrive from Germany for within pennies of what I paid to have them on Sunday.

), but under the assumption that there isn't, I saw these steppers for like $13.something on the steppersonline website, but they'd be shipping from China, and there'd be some shipping charges. I did indeed pay the $21.99 each from Amazon, but I have Prime so the shipping was free, and I'll have them on Sunday instead of waiting a couple/few weeks. If you divide the $12 shipping charge for two steppers, add that to the $15 purchase price you paid, you're waiting for them to arrive from Germany for within pennies of what I paid to have them on Sunday.Of course, if you were just acknowledging that through some subtlety that doesn't come across well through text, the above is already understood. Either way, if I could have saved a couple bucks one way or another and had to wait a while versus having them nearly immediately, I found the tradeoff acceptable.

One thing is I don't understand steppers well enough to know what specifications for them are important beyond 1.8 degree or 0.9 degree steps, the best matched to a printer, etc. I just know that if Phaedrux is using them already and they're fine, then they're fine, so those are the ones I went with.

-

@grizewald said in Motor noise and print quality:

3D printers are fun, but I have to say, getting them to print properly gets to be less and less fun. There are just so many variables that it makes the process painful in the end.

If you look at my profile on Thingiverse, pretty much every part I've uploaded has been some upgrade or accessory for a 3D printer.

I long ago came to the conclusion that for diehard printer hobbyists the primary purpose for having a 3D printer was for printing upgrades for their 3D printer.

I print figurines and other toy or decorative stuff too, but I'm not artistic enough to design any of that. I can brute force out a workable solution for my upgrade part needs, though, so that's what I contribute.

-

@sethipus No sarcasm at all, I was just wondering why the prices were so much higher than I paid, including German sales tax and hoping you hadn't been ripped off.

Amazon don't trade in Sweden yet, so things like Prime are unavailable to me. -

Yeah, Prime is kind of a game changer for those who can access it. The free shipping, combined with it being free 2-day shipping, is pretty awesome. It's not always hard to find a lower price somewhere else, but if that other place adds shipping charges, it's usually hard to find something that's overall cheaper to my door than Amazon. In my case I probably could have saved a couple dollars in exchange for waiting for 2-4 weeks for the steppers to arrive from China, versus satisfying the natural desire for immediate gratification by getting them in two days. Not a hard choice.

If it turns out the .9 degree versus 1.8 degree change in steppers, and the consequent reduction in the magnitude of any effects on print quality from the acceleration and deceleration of individual motor steps really does solve my "corrugated effect" surface artifacts, I will be overjoyed. This is a problem that's plagued many of my prints since I first built the D-bot. The texture is only very slightly tactile if you run your fingers over it. It's about 80% visual in that with shiny filaments like PETG, under the right lighting conditions, it just sticks out like a sore thumb and makes the surface look a lot less smooth than they really are.

-

@sethipus said in Motor noise and print quality:

This is a problem that's plagued many of my prints since I first built the D-bot.

it was driving me crazy. i did so many changes to my printer until i changed the motors.

on the plus side, the rest of the printer was also improved because of the tinkering i did along the way. -

OK, my 0.9 degree steppers arrived today, so I ran a test. I have some good news and some bad news.

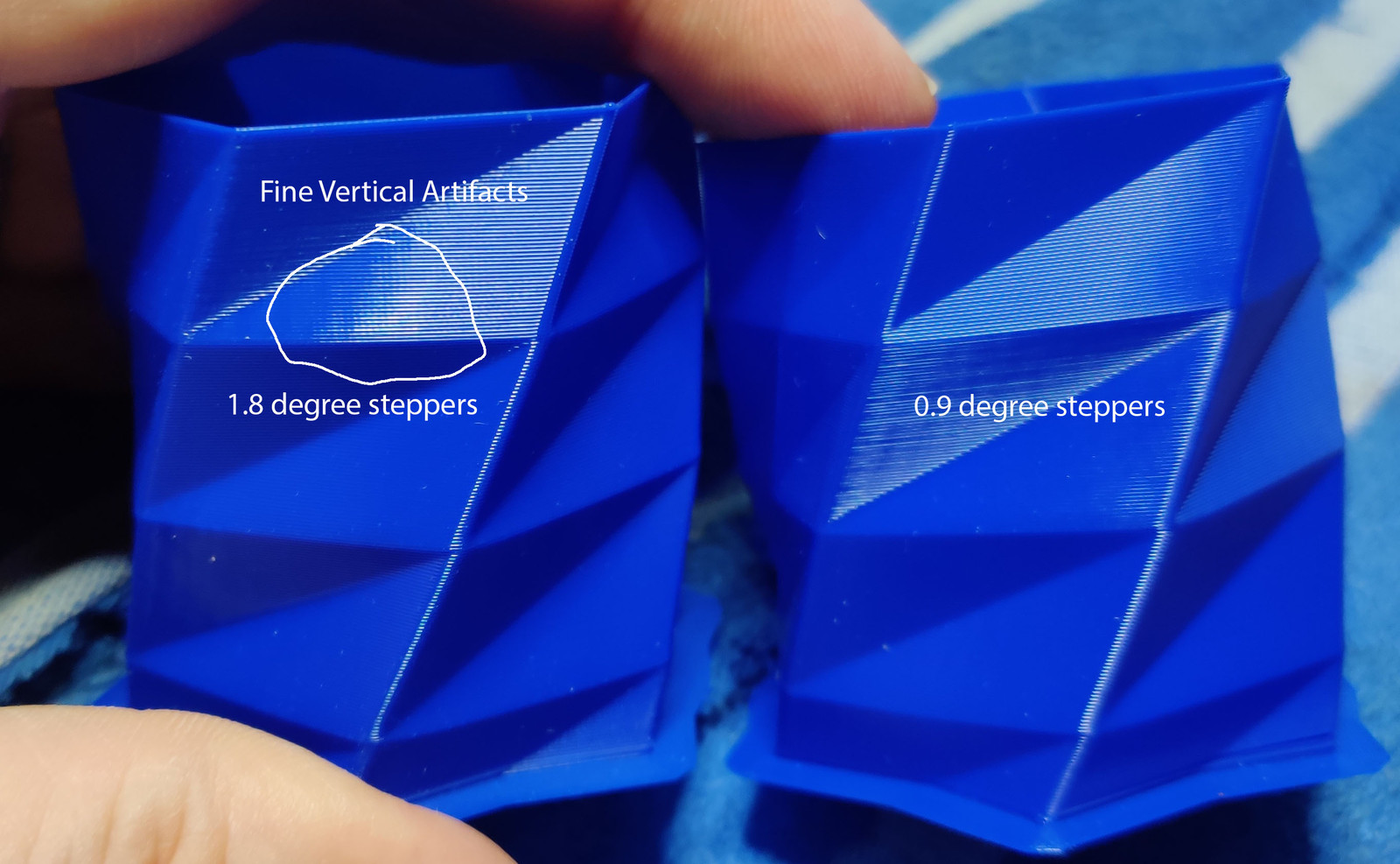

I printed a small faceted vase with my original 1.8 degree steppers still installed. Swapped out the steppers for the new 0.9 degree ones, doubled my steps setting in the config.g, rebooted, then printed the exact same vase gcode file with the new 0.9 degree steppers running the show.

-

Good news: There does seem to be subtle improvement in the surface quality of the vase printed with the 0.9 degree stepper, with a much smaller and more subtle fine vertical artifact that I could see if I looked really closely at the surface of the print from the 1.8 degree steppers being essentially eliminated.

-

Bad news: the "corduroy effect" that I see on flat surfaces with reflected light on shiny filament printed structures did not go away, and that was more noticeable than the VFAs that did go away.

Here's a photo showing the fine VFAs on the left-side vase, which was printed with the 1.8 degree steppers in my X/Y motion system. There are moire and other effects with my phone camera that make it difficult to photograph these things, but those VFAs are not visible in person in the vase on the right.

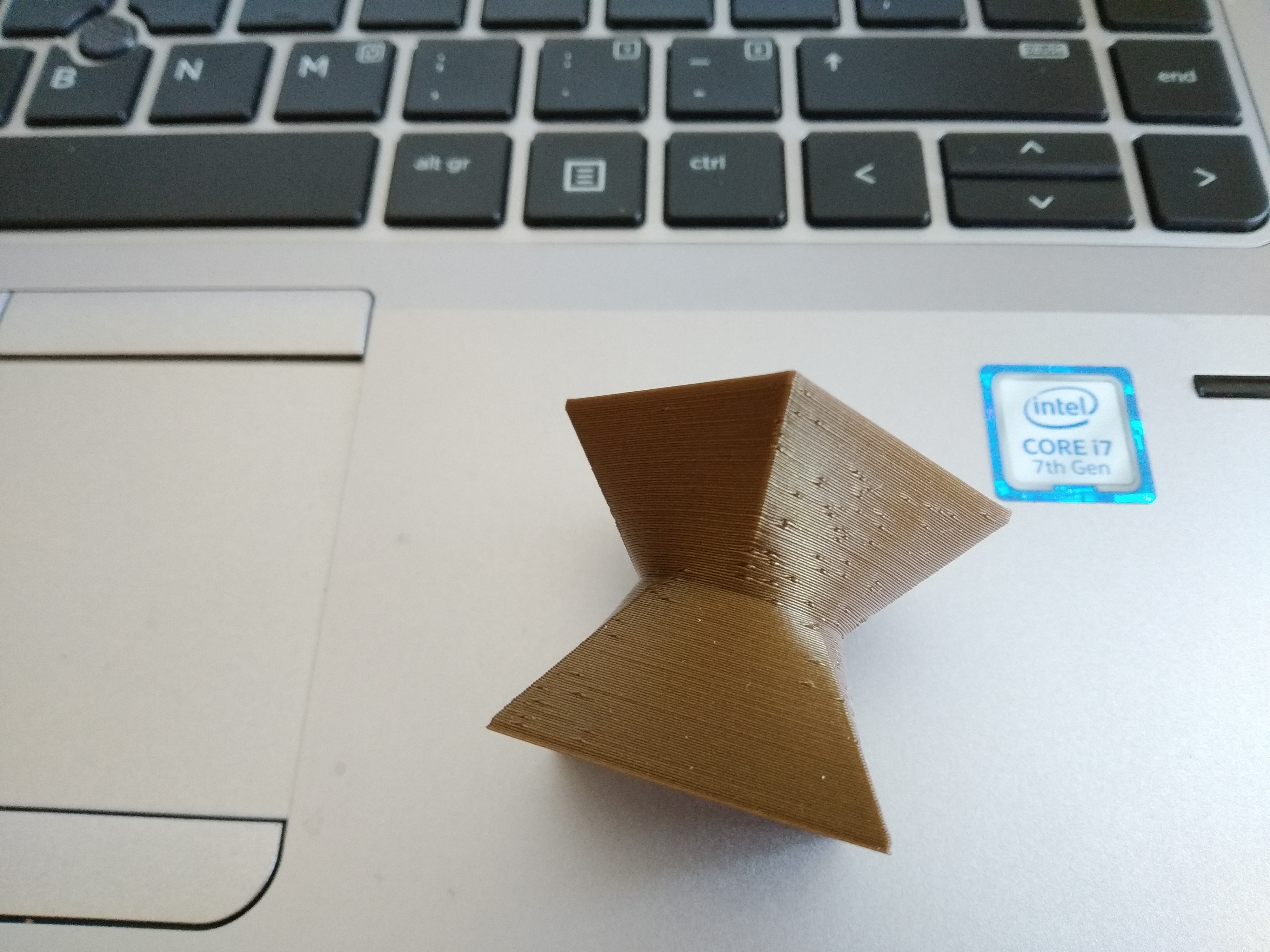

Here is a photo from further back and with a slightly different lighting angle that shows the coarser and more visible "corduroy effect" that I see on lots of flat surfaces that I print.

Bottom line is that my printed surfaces do look better at a more subtle level, and artifacts that I can in fact see in the 1.8 degree stepper prints do not show up with the 0.9 degree stepper print, but the more visible corduroy effect is still something which eludes me. Still not sure what that comes from.

I doubt it's a an extruder stepper issue from the extruder still using 1.8 degree steppers, since the BMG clone I'm now using is around a 4:1 reduction, plus microstepping, so it's hard to believe that with the fairly large "wavelength" of this periodic effect this is caused by ideosyncrasies with the stepper during single steps. In fact I think I can prove that it isn't: I'll print the vase using .3mm layers and again using .2mm layers (these were with .25mm layers) and then see if the wavelength of this effect changes or stays the same. I believe from past prints I've done with different layer heights that in fact the wavelength will stay the same.

-

-

The predominant vertical features I can see in those pictures appear coarse, more like ~2mm in pitch? Belts and pulleys are your next target then. I've had a few crap 'GT2' pulleys from ebay and the gates E3D pulleys didn't perform best in the linked Prusa forum post on vertical artefacts.

Back to the vertical fine artefacts I think you can see them on both, but they are much shorter than the big pattern. They are likely to improve with a 0.9 stepper on the extruder, but as a poster on the BIG Prusa forum post says it's a whole pile of problems and you've got to tackle the coarse ones first, which in this case looks suspiciously like belts.

Before going too in depth disconnect your drive belts and make sure the axis move freely and don't get noticeably tight near the extents (and often spring away from if let go) of their travel.

...I'm a few steps behind. Shelved development work Ormerods to get a few test platforms based on P3Steel chassis working.

-

@sethipus So, not a cure-all then? Kind of expected but it looks like an improvement at least.

My major problem at the moment is the bugs that seem to be creeping in to the latest releases of Cura.

I had a model with lots of supports printing yesterday and even though I'd set "avoid supports when travelling", every layer, I could see the head doing a travel move straight over the tops of the supports at the rear of the model, making a nice noise as it did it! Thankfully, it didn't manage to dislodge the supports as they were printed on top of a brim. The next print with supports will have to be done with agonising "lift Z when travelling" settings.

Then there's the settings for trying to hide the Z-seam. Does this look anything like "sharpest corner" to anyone?

-

@doctrucker said in Motor noise and print quality:

Prusa forum post on vertical artefacts

@doctrucker, yeah those bands are as close as I can measure 2mm apart, so it's gotta be belts or pulleys or something. I recall a couple years ago going through some agonizing about that, and at the time I replaced some idlers that in the D-Bot by default are just two stacked flanged bearings with toothed idlers to see if that made a difference, and it didn't. Gonna have to start over here. Just ordered some genuine Gates belt and a couple Gates pulleys for my steppers. My D-Bot was built with probably just some generic Chinese gt2 belt, so maybe that'll make a difference. Once the belts and those two pulleys are replaced, assuming the banding doesn't disappear, I'll figure out my next move and look into replacing other idlers in the mechanism again. Sigh.

@grizewald yeah it wasn't a cure-all, though I believe it did subtly improve the surface in that, aside from that 2mm pitch fine banding pattern, the surface otherwise is a little smoother. I don't regret going to the .9mm steppers. I haven't used Cura in a quite a while. I started with Cura, then used a pirated copy of S3D for a while, then after a while I observed that between Cura and S3D I was more and more using S3D only, so I forked out and bought it legit (I thought of the pirated copy as a sort of ad hoc extended trial...). The last version of Cura I used was many versions ago (for one thing, I was gone for the last year on a military deployment, so everything had been updated while I was out). I'm also experimenting right now with Slic3r. I recall the last time I went through all this there were features in each slicer I used that weren't in the others, and I recall thinking if I could just combine the best aspects of every slicer into one program that would be amazing. I just printed a couple things using the gyroid fill in Slic3r and quite liked it, though my first impression was that it's just a gimmick. Maybe it is. Btw in that photo you posted those zits would be annoying as hell. In S3D I force all layers to start in the same spot, and try to orient the print so that spot is on the backside of whatever I'm printing, if it has a backside.

Anyhow, to the topic of this thread, I do think that the .9 degree steppers can improve surface quality, but there are other things that cause surface problems, and at least in my experience the other things have more of an effect than the resolution of the steppers.

-

@sethipus is it this the d-bot from thingiverse:

https://www.thingiverse.com/thing:1001065

That's the one I built for a previous employer. I had serious vertical lines too. I was originally running a v0.6 duet on it and hoped that swapping to a Duet 2 would help, but it didn't. Last thing I did was add a twist in the belt so the tooths weren't running over the bearings, probably a bit I missed in the build manual. That helped a bit but didn't really nail it.

Not looking forward to that fight on my new machine!

Edit: using three screws did remove a lot of the bounce from the elevator.