@T3P3Tony Hi I am a new user and have registered account. I tried to post a new topic and it went to spam. How do I proceed to letting me post to the forum.

Best posts made by Willo47

-

RE: Managing Spam accountsposted in General Discussion

-

RE: My CoreXY 500X500X500 duet wifi controlled printerposted in My Duet controlled machine

Hi there, I have reduced the size of my pictures and will uploadload them onto the site to solve any further problems.

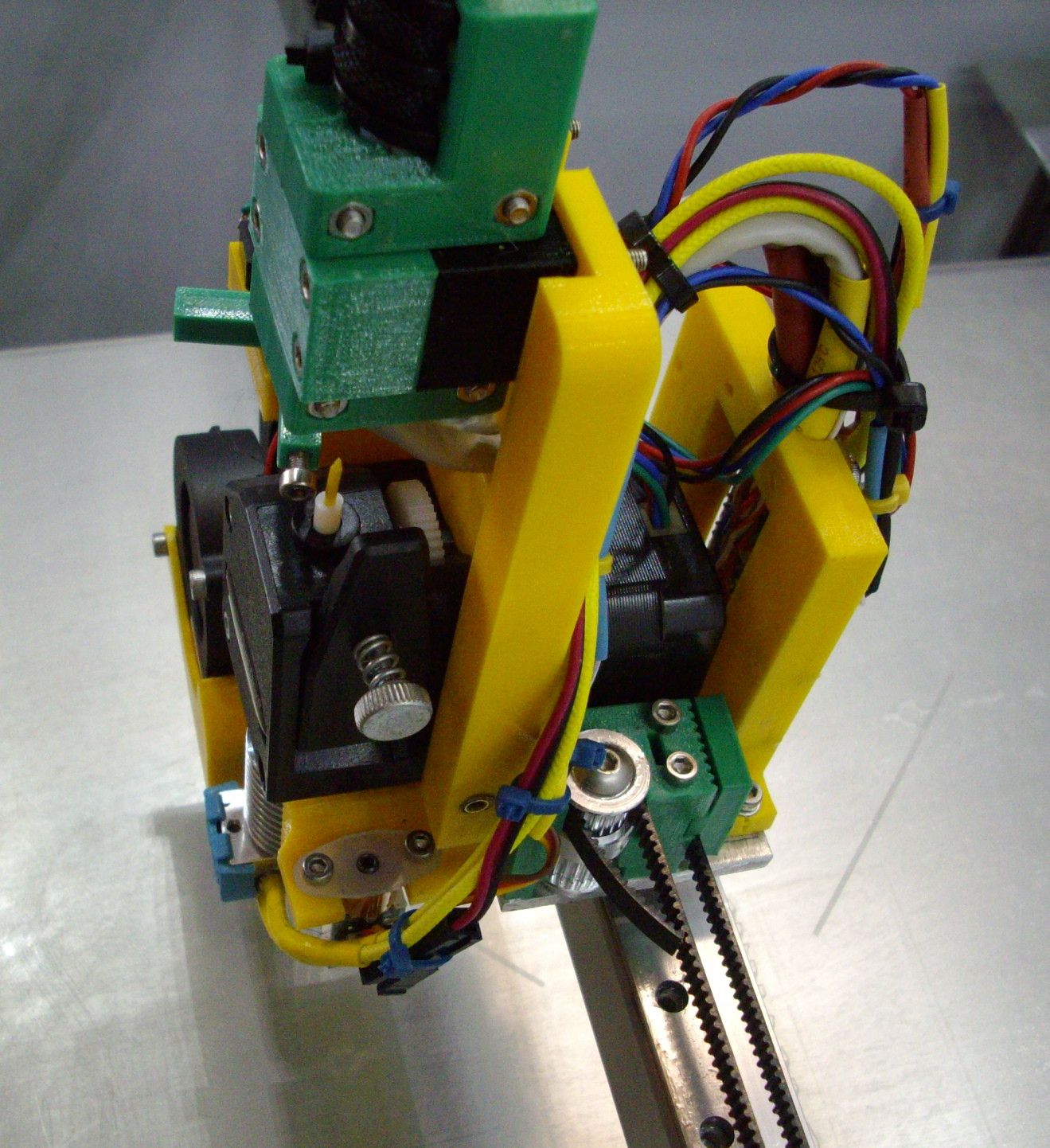

Picture of extruder with continously variable belt tensioner.

Picture of extruder with continously variable belt tensioner.

Hotend fan shroud with integrated BL touch mount.

Duet wifi and 7inch panel due case on swivel mount.

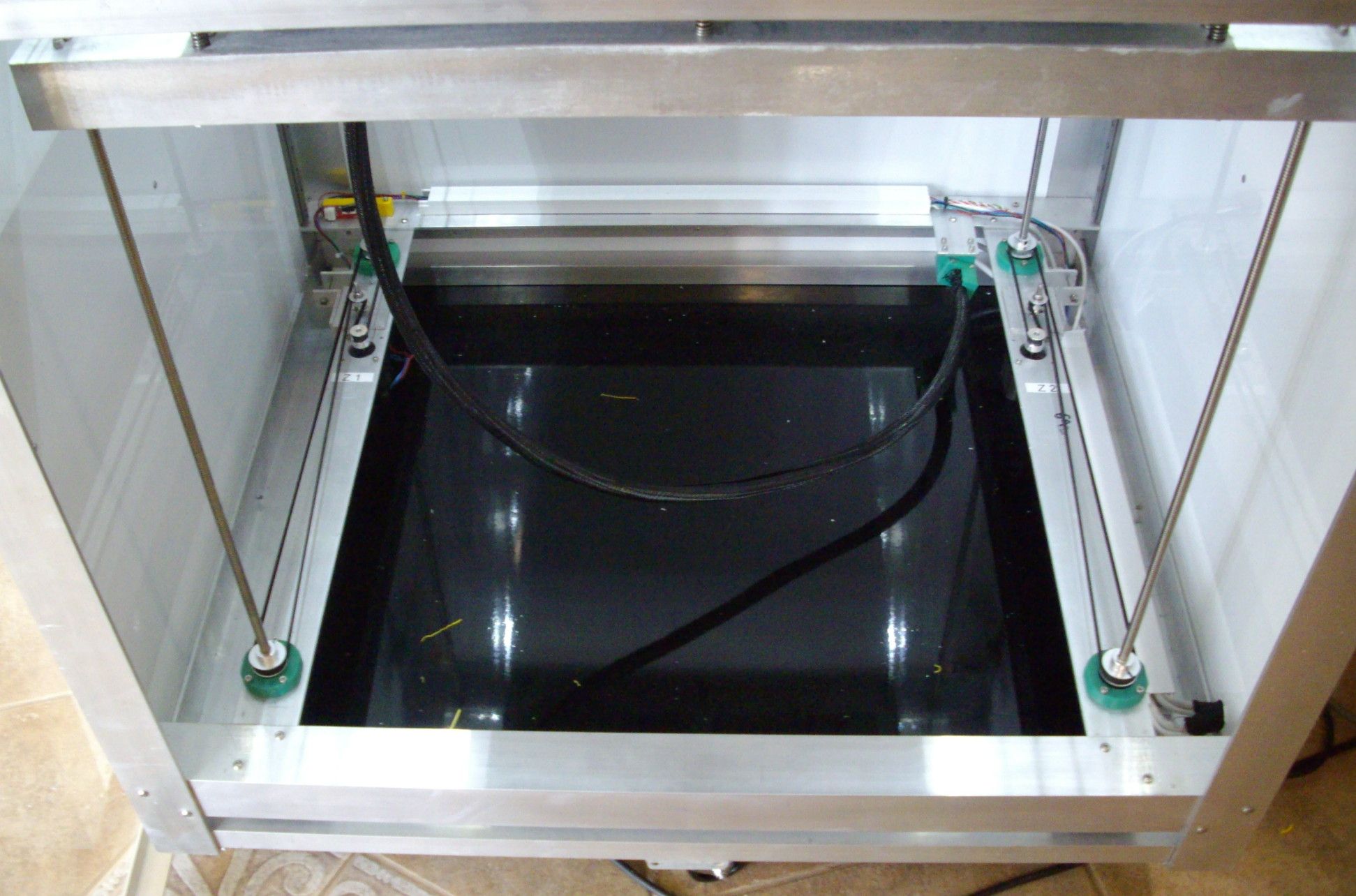

The printer fully enclosed suitable for printing nylon and ABS

Four lead screws Z mount driven by two independent Z steppers to allow two point bed leveling.Hope this works.

-

Solutions to Core XY printer successposted in Tuning and tweaking

Hi, I have just spent some months building a CoreXY printer from scratch using rails with a print volume of 500X500X500 mm and have just succeeded (after a huge effort) in tuning the printer and getting a good quality print.

I would like to thank all of the contributors to this forum for the information and also the RepRap community for all the work put in. Without them I would not have succeeded. I have just observed the forum and this is my first post.

I would like to put a few items of information on this post which may help others on their journey:- I had problems right at the end in getting a good first layer. I was getting a lot of stippling on the first layer. Changing temperature, layer height and extrusion widths did nothing to solve it. The problem turned out to be simple. During the tuning process I used the same print over and over and did not clean the bed after each print. I was using PETG for tests and adhesion is not generally a problem. A clean with Isopropyl alcohol solved the problem. I am using a flexible buid plate from Wham Bam using PEX.

- The live Z for tuning first layer height which is available on the Prusa Original MK3 is not available on RepRap firmware. Baby stepping implemented on the DWC does not seem to work. Here is my solution :

Using M206 does change the end stop ie M206 Z0.05 effectively moves the bed coordinates to lower the extruder head. If you want to lower further you need M206 Z0.10 and so on . I have made a series of macros to move the head up and down. I have made a simple square print to fine tune my Z height. Once OK I send a M500 to store it in EEPROM. In my print start up code I use M501 to read the value back. If you use mesh bed compensation the M206 commands seem to have no effect during the print so I do my tuning prior to printing. Once tuned the setting seems to remain OK. - Initially I used a non temperature compensated inductive Z probe which drifted too much with temperature so I replaced it with a genuine BL touch probe. Thanks again for the post by Betrue3D for the invaluable informatin. I had a few consitency problems which turned out to be not a probe problem but how I mounted the probe. The probe mount has to be closely associated with the hotend tip and to that end I printed a custom cooling shroud for the hotend with ribs which engate with the hotend heat sink and I directly printed the BLtouch mount onto the shroud. The relationship between the hotend and the probe now remain constant. I do however do all of my calibration with the hotend at temperature. I also set my trigger threshold to 500 to make sure that I don't get inconsistent triggering due to electrical noise.

- Make sure that the Z homing point is exactly the same place as one of the mesh bed leveling probe points. I had a bed crash in the middle of the bed which caused a dimple in the print bed (the homeall.G made by the configurator swapped Z with the Y axis which caused the problem). I happened to home on this dimple but did not probe on this point. The bed mesh compensation map varied considerably in height until I moved the home and probe to the same point (in the middle and away from the dimple) As a check , irrespective of how level your bed is, the home and probe point on the mesh bed should always be close to zero.

Hope the above may helps someone on their journey to 3D printing success.

-

RE: My CoreXY 500X500X500 duet wifi controlled printerposted in My Duet controlled machine

Reply to "Strips" re bed leveling.

My build plate is fitted to a frame which is supported at each of the four corners by the lead screws.

The build plate is supported at 9 points (three at each side and one in the middle) by 4mm threaded rod screwed into the base plate (pre threaded prior to fixing magnetic build plate) and locked with a nut. The bed held off the frame by very stiff compression springs. I made my own using 1.6mm spring steel wire wound on a 5mm mandrel and about 15mm long. The springs need to be stiff enough to be able to bend the 5mm thick build plate a small amount so that any bow can be removed from the plate.

For initial leveling I printed a mount for a dial gauge on the extruder carriage and used that to get it withing +/-50 microns. This saved a lot of time as you can get almost instant indication of how level the bed is.

Once that was done I fitted the extruder and used the BLtouch probe to probe the bed using the via the DWC. Initially I only had 9 points on the mesh which coincided with the bed adjustement points. After each adjustment I did the two point be leveling prior to doing another mesh be leveling probe. It took few itterations to get it level. Once I was happy I then did a 64 point mesh bed grid which I use when doing a print. The final bed leveling is done with the bed heated to 80deg C which I use for the first layer bed temperature for PETG which I am currently printing.

I am currently printing a 400mm 5 spoke test wheel to check out the bed. Looks good so far. -

RE: massive overextrusion, E-Steps are calibratedposted in Tuning and tweaking

Hi,

This may be a bit late to help but I will post it anyway.

I have had massive overextrusion myself and have decided the easiest way of overcoming this after much searching for the problem is to just reduce the extrusion factor until it prints well and leave it at that.I have built a large (500X500X500) core XY printer which I use for engineering components using mainly Nylon CF. This is the printer I have massive over extrusion.

I also have a Prusa MK3S and use the Prusa Slcr to do my slicing.The coreXY printer uses a Duet Wifi board with two independant Z axis drives. All of the X,Y,Z axis are calibrated and also the extruder is also calibrated. When printing I also checked that my extruder nozzle was the correct diameter (o.6mm) and that the first layer print was exactly the correct level (by using a vernier caliper to test the extrusion thickness and also the first layer thickness).

I tested my extrusion using just a single first layer and a spiral vase cylinder and found the perfect print at 0.75 extrusion factor. I now slice all of my prints using this and they come out perfectly.I spent a lot of time trying to solve why the overextrusion because there seems to be almost a religious belief in the 3D printing community that if the extrusion factor is more than 5% from 1 then there is a major problem that needs to be hunted down at all costs.

I might mention that my MK3S also over extrudes but a an extrusion factor of 0.9 seems to print OK.

Hope this was helpful.