@deckingman That was the issue. Huge thanks!

Posts made by Velvia

-

RE: Printer freezes after pruge-line, then restartsposted in General Discussion

-

RE: Printer freezes after pruge-line, then restartsposted in General Discussion

@deckingman Didn't catch that! Will change. Thanks!

-

Printer freezes after pruge-line, then restartsposted in General Discussion

M122

M122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.4.5 (2022-11-30 19:35:23) running on Duet 3 MB6HC v1.01 (SBC mode) Board ID: 08DJM-9P63L-DJ3S0-7JKF0-3S86T-TAJR8 Used output buffers: 3 of 40 (22 max) === RTOS === Static ram: 152760 Dynamic ram: 65564 of which 156 recycled Never used RAM 131712, free system stack 142 words Tasks: SBC(ready,0.6%,468) HEAT(notifyWait,0.0%,322) Move(notifyWait,0.0%,256) CanReceiv(notifyWait,0.0%,944) CanSender(notifyWait,0.0%,336) CanClock(delaying,0.0%,333) TMC(notifyWait,8.1%,57) MAIN(running,91.0%,1197) IDLE(ready,0.3%,30), total 100.0% Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:03:45 ago, cause: software Last software reset at 2023-07-14 20:23, reason: User, Platform spinning, available RAM 132192, slot 2 Software reset code 0x0000 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task SBC Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 Step timer max interval 133 MCU temperature: min 33.3, current 33.4, max 44.8 Supply voltage: min 23.9, current 24.0, max 24.0, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.2, current 12.2, max 12.3, under voltage events: 0 Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0, mspos 78, reads 10531, writes 21 timeouts 0 Driver 1: standstill, SG min 0, mspos 102, reads 10531, writes 21 timeouts 0 Driver 2: standstill, SG min 0, mspos 290, reads 10531, writes 21 timeouts 0 Driver 3: standstill, SG min 0, mspos 24, reads 10538, writes 15 timeouts 0 Driver 4: standstill, SG min 0, mspos 8, reads 10542, writes 11 timeouts 0 Driver 5: standstill, SG min 0, mspos 8, reads 10542, writes 11 timeouts 0 Date/time: 2023-07-14 20:27:42 Slowest loop: 56.78ms; fastest: 0.04ms === Storage === Free file entries: 10 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === DMs created 125, segments created 20, maxWait 92585ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 8, completed 8, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 === GCodes === Segments left: 0 Movement lock held by null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === CAN === Messages queued 2022, received 0, lost 0, boc 0 Longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 50 (min 50), ts 1130/0/0 Tx timeouts 0,0,1129,0,0,891 last cancelled message type 30 dest 127 === SBC interface === Transfer state: 5, failed transfers: 0, checksum errors: 0 RX/TX seq numbers: 9291/9291 SPI underruns 0, overruns 0 State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x2ad48 Buffer RX/TX: 0/0-0, open files: 0 === Duet Control Server === Duet Control Server v3.4.1 Code buffer space: 4096 Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0 Full transfers per second: 41.44, max time between full transfers: 56.4ms, max pin wait times: 31.4ms/12.1ms Codes per second: 0.37 Maximum length of RX/TX data transfers: 3080/992Identical gcode from one day ago works fine. Only difference now is that I updated Prusa to 2.6.0. Otherwise everything is the same.

gcode

; generated by PrusaSlicer 2.6.0+win64 on 2023-07-14 at 17:00:12 UTC ; ; external perimeters extrusion width = 0.80mm ; perimeters extrusion width = 0.80mm ; infill extrusion width = 1.00mm ; solid infill extrusion width = 0.80mm ; top infill extrusion width = 0.80mm ; support material extrusion width = 0.80mm ; first layer extrusion width = 0.80mm M201 X10000 Y10000 Z1500 E9000 ; sets maximum accelerations, mm/sec^2 M203 X12000 Y12000 Z4800 E7200 ; sets maximum feedrates, mm / min M204 P8000 T12000 ; sets acceleration (P, T), mm/sec^2 M566 X600.00 Y600.00 Z60.00 E420.00 ; sets the jerk limits, mm/min ;TYPE:Custom T0 ; Select tool 0 G28 ; home all axes G92 E0.0 M104 S200 ; preheat extruder to no ooze temp ; wait for extruder temp M140 S75 ; set bed temp M109 S200 ; wait for extruder temp M400 M564 H1 S0 ; allow movement outside print area (S0) of all homed axes (H1) M400 G1 X189.5 Y-83.0 Z20.00 F4000 ; wipe nozzle over brass brush G1 X189.5 Y-83.0 Z14.00 G1 X177.0 Y-90.0 Z14.00 F3000 G1 X179.5 Y-80.0 Z13.00 G1 X189.5 Y-83.0 Z13.00 G1 X191.5 Y-69.0 Z14.00 G1 X177.0 Y-90.0 Z14.00 G1 X191.5 Y-69.0 Z14.00 G1 X177.0 Y-90.0 Z14.00 G1 X191.5 Y-69.0 Z14.00 G1 X177.0 Y-90.0 Z14.00 G1 X191.5 Y-69.0 Z13.00 G1 X189.5 Y-83.0 Z13.00 G1 X179.5 Y-80.0 Z13.00 G1 X189.5 Y-83.0 Z13.00 M190 S75 ; wait for bed temp M400 G1 X179.5 Y-80.0 Z13.00 G1 X189.5 Y-83.0 Z13.00 G1 X179.5 Y-80.0 Z13.00 G1 X189.5 Y-83.0 Z13.00 G1 X179.5 Y-80.0 Z13.00 G1 X189.5 Y-83.0 Z13.00 G1 X191.5 Y-69.0 Z13.00 G1 X177.0 Y-90.0 Z13.00 G1 X191.5 Y-69.0 Z13.00 G1 X177.0 Y-90.0 Z13.00 G1 X191.5 Y-69.0 Z13.00 G1 X177.0 Y-90.0 Z13.00 G1 X191.5 Y-69.0 Z13.00 G1 X179.5 Y-80.0 Z13.00 G1 X189.5 Y-83.0 Z13.00 M400 ; wait for previous action to finish G1 X0 Y0 Z13 F4000 ; move to middle of bed to probe M400 M564 S1 ; restrict movement outside print area M400 G1 Z9 F8000 ; move to 9mm above bed to probe M400 ; wait G30 F2000 ; probe middle of bed to establish Z0 to avoid babystepping every time M400 ; wait G1 X164 Y38 Z5 F8000 ; set nozzle above bed M400 ; wait G1 G30 S-1 F1200 ; set nozzle into bed to prevent oozing M104 S250 ; set extruder temp M109 S250 ; wait for extruder temp M400 G1 z0.4 ; set nozzle 0.3mm aboe bed to purge G1 X122.6 Y118.6 E30 F800 ; purge intro line G21 ; set units to millimeters G90 ; use absolute coordinates M82 ; use absolute distances for extrusion G92 E0 M572 D0 S0.20 ; pressure advance M579 X0.9978 Y0.0.9902 Z1 ; X, Y and Z scaling G29 S1 P"heightmap70.csv" ; S1 = load specific heightmap M107 ;LAYER_CHANGE ;Z:0.3 ;HEIGHT:0.3 G1 E-3 F3600 G92 E0 G1 Z.5 F12000 G1 X.003 Y-73.992 G1 Z.3 G1 E3 F3600 M204 P3000 ;TYPE:Skirt/Brim ;WIDTH:0.8 G1 F2400 G1 X75.528 Y-73.988 E9.92946 -

Input Shaping for different toolsposted in Tuning and tweaking

Can I run separate input shapers for different tool heads? For example M593 P"zvddd" F47 for T0 and M593 P"mzv" F42 for T1, if I put them under each specific tool in the config file?

-

RE: Heated bed noiseposted in Duet Hardware and wiring

@T3P3Tony It's a 24v bed. It says it's a 120w bed, so 5 amps? Have not tried higher frequencies than 300

-

RE: Heated bed noiseposted in Duet Hardware and wiring

@infiniteloop It's definitively the bed. It's from where the cables are soldered to the bed.

-

RE: Heated bed noiseposted in Duet Hardware and wiring

@achrn Thanks for the input. I guess I'll just have to live with the low clicking noise from a low PWM.

-

RE: Heated bed noiseposted in Duet Hardware and wiring

@infiniteloop I did. I've tried everything between Q2 and Q300. Nothing helped, just changed the tone of the noise. However the low "clicking" sound from Q10-20 is better than the singing/whining from 100+

-

RE: Heated bed noiseposted in Duet Hardware and wiring

Using M307 H0 B1 still causes it to make the sound. Can I use Q parameter (PWM) at some really high value? Like over 20k so I don't hear it?

-

RE: Heated bed noiseposted in Duet Hardware and wiring

@achrn Is there a solution I can use in RRF?

-

RE: G32 on dual-Z axis cartesian problemposted in General Discussion

@droftarts This fixed it, thank you!

edited config.g to M671 X223:-30 Y0:0 S1 -

G32 on dual-Z axis cartesian problemposted in General Discussion

When I run G32, it correctly measures the set points, but the leadscrews will adjust in the opposite direction, making the gantry skewed and uneven to the bed.

M122

M122 === Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.4.5 (2022-11-30 19:41:16) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: P5DZW-GQ6KL-K65J0-409NU-KKW1Z-H1QDZ Used output buffers: 1 of 40 (13 max) === RTOS === Static ram: 103652 Dynamic ram: 110352 of which 0 recycled Never used RAM 27708, free system stack 206 words Tasks: NETWORK(ready,11.5%,253) HEAT(notifyWait,0.0%,358) Move(notifyWait,0.0%,363) CanReceiv(notifyWait,0.0%,942) CanSender(notifyWait,0.0%,336) CanClock(delaying,0.0%,341) TMC(notifyWait,0.7%,115) MAIN(running,85.3%,425) IDLE(ready,1.6%,30) AIN(delaying,0.9%,272), total 100.0% Owned mutexes: === Platform === Last reset 00:00:13 ago, cause: software Last software reset at 2023-03-01 13:03, reason: User, GCodes spinning, available RAM 27556, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 MCU revision 3, ADC conversions started 13666, completed 13666, timed out 0, errs 0 Step timer max interval 1396 MCU temperature: min 32.5, current 33.3, max 33.6 Supply voltage: min 24.0, current 24.0, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 140, read errors 0, write errors 1, ifcnt 109, reads 683, writes 9, timeouts 0, DMA errors 0, CC errors 0 Driver 1: standstill, SG min 138, read errors 0, write errors 1, ifcnt 147, reads 683, writes 9, timeouts 0, DMA errors 0, CC errors 0 Driver 2: standstill, SG min 74, read errors 0, write errors 1, ifcnt 110, reads 682, writes 9, timeouts 0, DMA errors 0, CC errors 0 Driver 3: standstill, SG min 56, read errors 0, write errors 1, ifcnt 110, reads 682, writes 9, timeouts 0, DMA errors 0, CC errors 0 Driver 4: standstill, SG min 0, read errors 0, write errors 1, ifcnt 74, reads 683, writes 9, timeouts 0, DMA errors 0, CC errors 0 Driver 5: not present Driver 6: not present Date/time: 2023-03-01 13:03:17 Cache data hit count 25423027 Slowest loop: 3.73ms; fastest: 0.13ms === Storage === Free file entries: 10 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 2.0ms, write time 0.0ms, max retries 0 === Move === DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === CAN === Messages queued 119, received 0, lost 0, boc 0 Longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 18 (min 18), ts 67/0/0 Tx timeouts 0,0,66,0,0,51 last cancelled message type 30 dest 127 === Network === Slowest loop: 15.35ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 = WiFi = Network state is active WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.26 WiFi MAC address e8:68:e7:e5:50:1f WiFi Vcc 3.35, reset reason Power up WiFi flash size 2097152, free heap 24096 WiFi IP address 10.0.0.34 WiFi signal strength -74dBm, mode 802.11n, reconnections 0, sleep mode modem Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0config.g

; Configuration file for Duet 3 Mini 5+ (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Tue Feb 28 2023 22:26:05 GMT+0100 (Central European Standard Time) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet Bear" ; set printer name M669 K0 ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 D3 V10 ; X physical drive 0.0 goes forwards M569 P0.1 S1 D3 V10 ; Y physical drive 0.1 goes forwards M569 P0.2 S0 D3 V10 ; Z physical drive 0.2 goes forwards M569 P0.3 S0 D3 V10 ; Z physical drive 0.3 goes forwards M569 P0.4 S1 D2 ; E physical drive 0.4 goes backswards M584 X0.0 Y0.1 Z0.2:0.3 E0.4 ; set drive mapping M350 X32 Y32 Z16 E16 I1 ; configure microstepping with interpolation M92 X320.00 Y320.00 Z400.00 E932.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z600.00 E3600.00 ; set maximum speeds (mm/min) M201 X2000.00 Y2000.00 Z100.00 E250.00 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S60 ; Set idle timeout M671 X-30:223 Y0:0 S1 ; define dual driven z-axis ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X228 Y208 Z198 S0 ; set axis maxima ; Endstops M574 X2 S3 ; configure sensorless endstop for high end on X M574 Y2 S3 ; configure sensorless endstop for high end on Y M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Sensorless homing sensitivity ;M915 X S30 H140 R0 ; sensitivity of X and Y sensorless homing, R2 = pause print M915 Y S10 H200 R0 ; sensitivity (S) of X and Y sensorless homing, R2 = pause print ; Z-Probe M558 P5 C"io3.in" H2 F2000 T12000 A3 S0.03 ; set Z probe type to unmodulated and the dive height + speeds G31 P500 X25 Y-24 Z0.83 ; set Z probe trigger value, offset and trigger height M557 X30:225 Y15:225 S60 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" Q13 T0 ; create bed heater output on out0 and map it to sensor 0, PWM 25 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"thermistor" T100000 B3950 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"out5" Q500 ; create fan 0 on pin out5 and set its frequency M106 P0 S1 H1 T50 ; set fan 0 value. Thermostatic control is turned on ; Tools M563 P0 S"Biqu H2" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory T0 ; select first toolbed.g

; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Tue Feb 28 2023 22:26:05 GMT+0100 (Central European Standard Time) M561 ; clear any bed transform M558 H3 F2000 T12000 ; dive height G28 G30 P0 X223 Y79 Z-99999 G30 P1 X30 Y79 Z-99999 S2 -

RE: Heated bed noiseposted in Duet Hardware and wiring

@dc42 Didn't change anything unfortunately. Still whining.

-

Heated bed noiseposted in Duet Hardware and wiring

@oliof I have a similar problem now, but setting to a low value just creates a clicking noise instead. Tried many values, from 2 to 300. Prusa style bed, Duet Mini 5+ wifi, latest firmware.

-

RE: [3.4.0rc1] I think the bed heater is overheating?posted in Beta Firmware

@zapta Is it possible to attach a bed with only RTV? Why is this not the norm? The 3M adhesive kinda sucks for anything over 110 C. Does Keenovo deliver pads with no adhesive?

-

RE: LIS3DSH orientation on a Delta printerposted in Duet Hardware and wiring

@Phaedrux Thank you for the help. Now I run as many times as I want, even with the Input Shaping plugin. No more crashes!

-

RE: LIS3DSH orientation on a Delta printerposted in Duet Hardware and wiring

@Phaedrux Thanks. I do that by running "M997 S0:1", right? Been a while

-

RE: LIS3DSH orientation on a Delta printerposted in Duet Hardware and wiring

@dc42 I was able to get three readings, but now every time I try to get readings, it freezes the mainboard and it restarts.

-

RE: Pressure advance Slow downposted in Tuning and tweaking

@MadMonkey How did it go

I had the same problem, and found that I had set very low jerk values in prusaslicer

I had the same problem, and found that I had set very low jerk values in prusaslicer

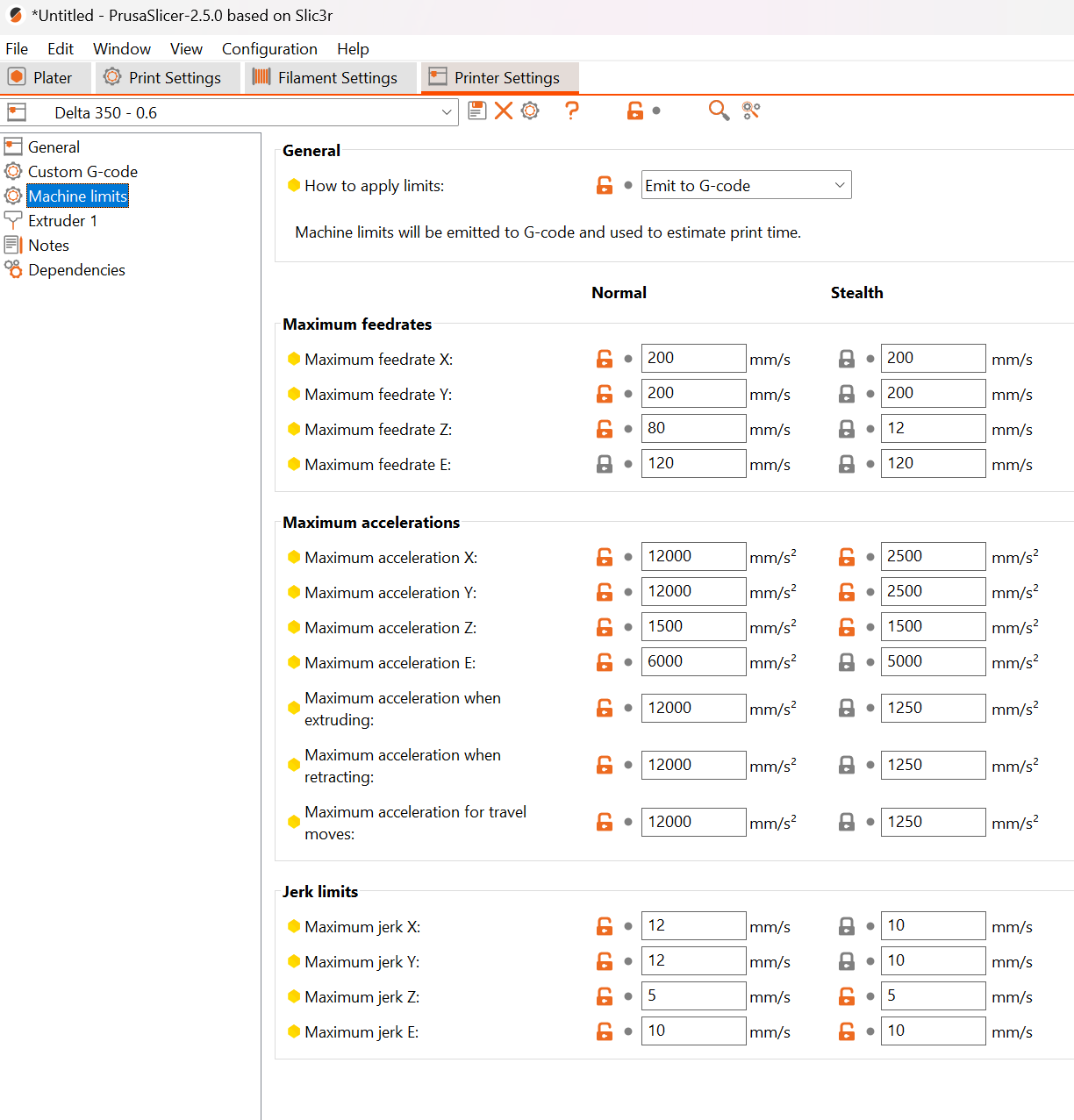

I had set minimum E jerk to 1 mm/s, then changed it to 10 mm/s as in the picture, and now it prints fast as if I don't have pressure advance enabled. My settings are for a self built delta printer.