@chrishamm that does appear ( on the first and only try ) to have fixed it - thankyou

Posts made by ukwebb

-

RE: Paused message doesnt self clearposted in Duet Web Control

-

RE: Paused message doesnt self clearposted in Duet Web Control

@phaedrux any thoughts on the issue

- does anyone else have the issue?

-

RE: Paused message doesnt self clearposted in Duet Web Control

I'm happy to be proved wrong, but why would it be due to paneldue ? the print does resume and the browser shows that - and the paused message goes from paneldue . Its only on the Duet Web interface that still shows it.

-

RE: Paused message doesnt self clearposted in Duet Web Control

@phaedrux updated to 3.4.0

same thing

-

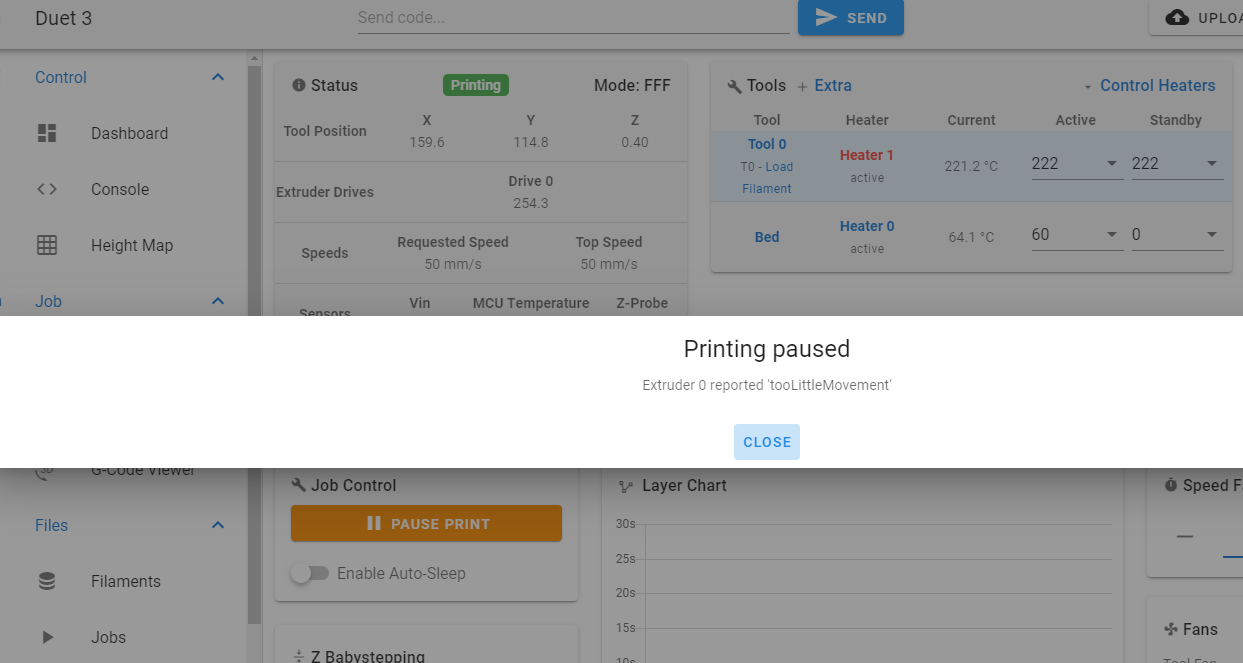

Paused message doesnt self clearposted in Duet Web Control

Not sure if this is a bug, or a bug that has been fixed but I've noticed that ... if my printer pauses due to the filament sensor, and I then resume the printer via the PanelDue, next time I lview the web interface, the message saying "your print is paused - Extruder 0 reports too little movement" appears, even though in the background you can clearly see the x,y positions moving happily away.

clicking dismiss on the message has zero effect, other than clearing the message - its just concerning when you first view it as you think the printer has paused again.

I'm on stable release 3.3.0 with a Duet3Mini5+ in standalone mode

Any thoughts? -

RE: Dual z Stop and Piezo Bed Levelposted in Firmware installation

@palgon no one can give you the exact measurements, other than you, as you have the printer to measure it!.

Home your printer, then move the print head Y position until it's in line with your Y rods. That will give you the Y value.eg something around 165

Then make sure x is at the 0 position and measure the distance from the tip of the nozzle to the approx centre of the z rod.

You'll get something like -30mm. Then move the X across as close as you can to the right side, and again measure the nozzle to rod distance. Remembering to add in the X position. So if the head is at position 330, and the rod is a further 30mm away, then your number is 360mm.So in the examples above the positions would be -30,165 and 360,165

-

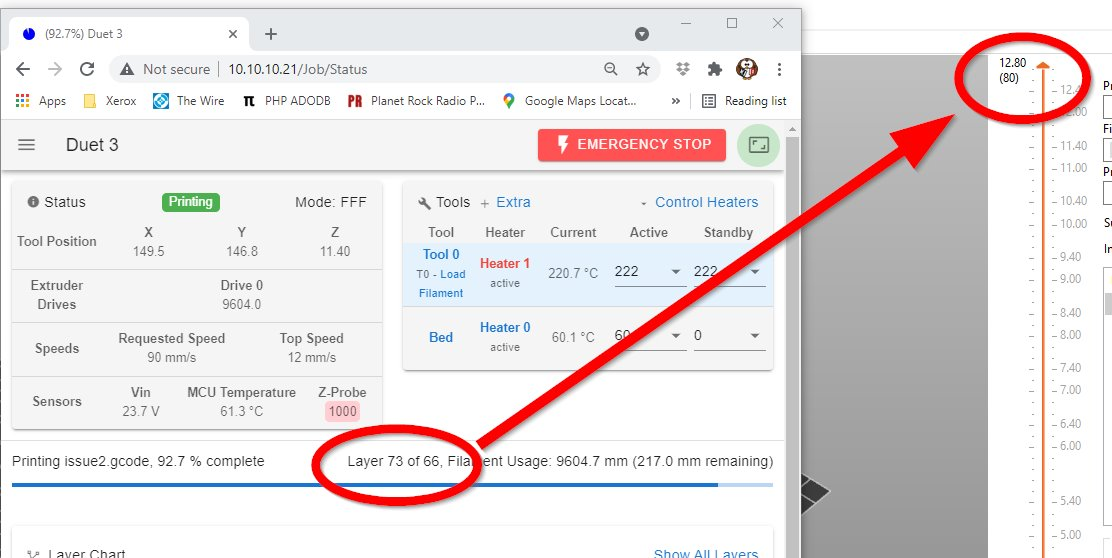

RE: total number of layers issueposted in Duet Web Control

reprap/sprinter firmware

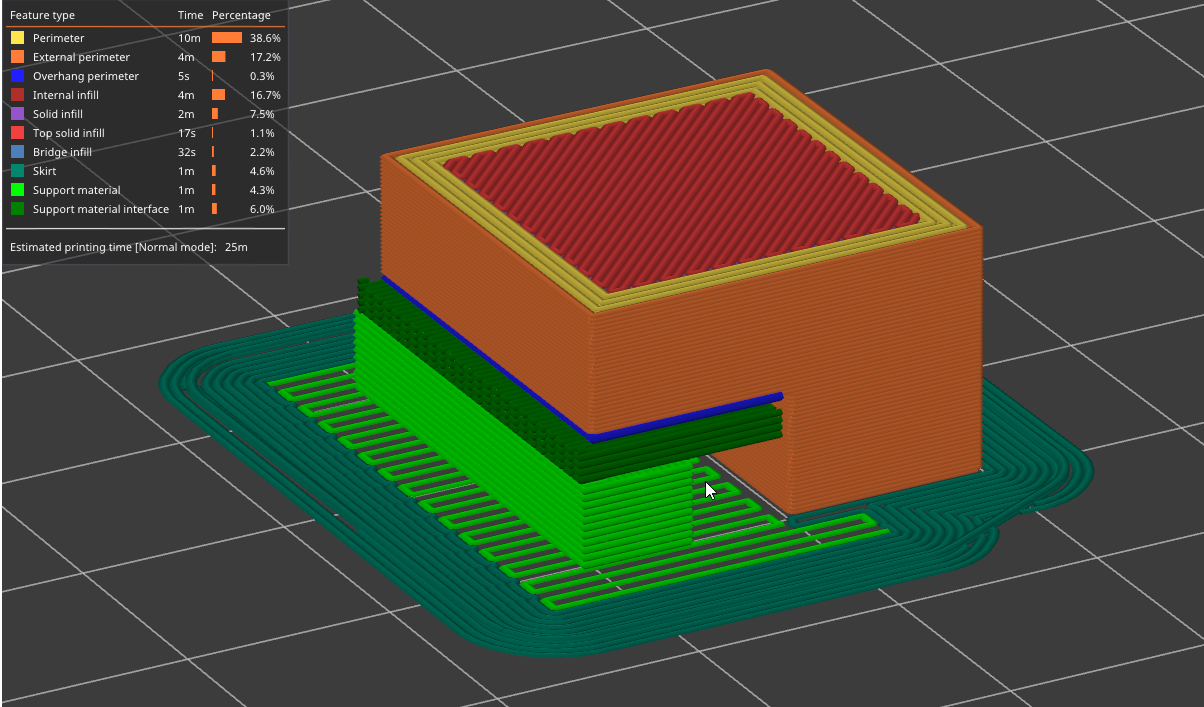

I am using "Synchronize with object layers " turned off - ie not sync'd

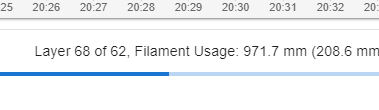

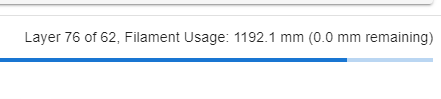

i did wonder if this was the reason, but it looks very odd when it starts showing now on layer 70 of 66 !i've made a simpler layergcode.gcode example gcode file, which has the same effect with 76 layers according to Prusa.

-

RE: Dual z Stop and Piezo Bed Levelposted in Firmware installation

@palgon

I have a corexy machine with the same as you describe

ie Duet3 mini5+ ( very similar to duet2 )

two z motors left and right

precision piezo sensoronce you're on RR3 these are the relevant lines in my config

; Z Lead screws

M671 X-100:400 Y160:160 S20 ; leadscrews at left (-100,160) and right (400,160); Endstops

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M558 P8 R0.3 F150 T4200 C"!io3.in" H3 ; PP sensor in digital mode connected it io3.in

G31 Z0.05 ; set Z probe trigger value, offset and trigger heightM557 X20:280 Y20:280 S60 ; define mesh grid

-

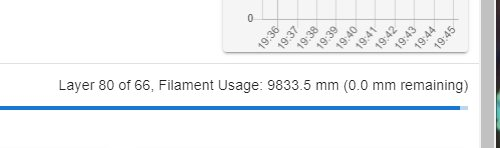

total number of layers issueposted in Duet Web Control

just found a slight bug in dwc 3.3.0 on duet 3 mini5+

when my model is sliced with prusa slicer 2.3.2 it shows 80 layers

but dwc shows 66. however it then gets to a point of doing more than the 66 layers ! ie layer 70 of 66 !

waiting for it to finish - it did actually get to layer 80

-

Failed driver on Duet3 Mini5+ ??posted in Duet Hardware and wiring

I bought two duet 3 mini5+ 's through E3D earlier this year, but one of them has suddenly developed a fault today, after being turned off for a few days.

the 5th ( #4 ) stepper driver appears to have failed. I use this for the extruder as 0&1 do X & Y, 2 & 3 do the two Z motors,I've been having intermediate feed problems for a week or two but just put it down to the filament, but then today it simply says "Error: Short-to-ground on driver 4" when ever the filament is instructed to be extruded or retracted. (the extruder setup is e3d's titan extruder with v6 )

This happens even when i replace the motor and wire with a known good one

and also putting the existing extruder motor wire onto a different driver it too works wellso i can therefore only conclude that the stepper driver itself has failed.

Any ideas or do i have a faulty board?

-

RE: Duet 3 Mini 5+ VIN under-voltage issues in SBC modeposted in Duet Hardware and wiring

I too ( as previously mentioned ) was having this issue , and to test the undervolt side I've swapped back to standalone mode, but kept everything else the same, so the pi4 is still running,its still running Duet interface ( although it cant connect! ), its still running the 7" touch hdmi screen and C270 webcam etc etc etc. The only difference is the onboard SD card, and disconnected the GPIO cable.

2 weeks have now passed and not a single undervolt issue. -

RE: Duet 3 Mini 5+ VIN under-voltage issues in SBC modeposted in Duet Hardware and wiring

Just to add another voice, I and also getting this same issue.

Last night, 70% and 5 hours into a print it just stopped, and displayed VIN undervoltage event (0.0v) and then Insufficient axis homed

My setup is based around a coreXY machine, with a dedicated meanwell 5v 5a psu for the pi, and a meanwell 24v 6amp supply for the printer, the hot bed is 240v

Also, this hasn't happed until recently - i think after i did an apt update. so it was probably fine on 3.1 but not 3.2

-

RE: [DSF Extension] Exec On MCode (was: Shutdown SBC)posted in DSF Development

followed your video and got it installed and working in 5 minutes - superb work - thanks

-

RE: Duet 3 Mini 5+ : Initial announcementposted in General Discussion

would the Duet 2 Maestro Dual Stepper Driver Expansion Module board work on the duet3mini5+? or will it be a specific board for the duet3mini?