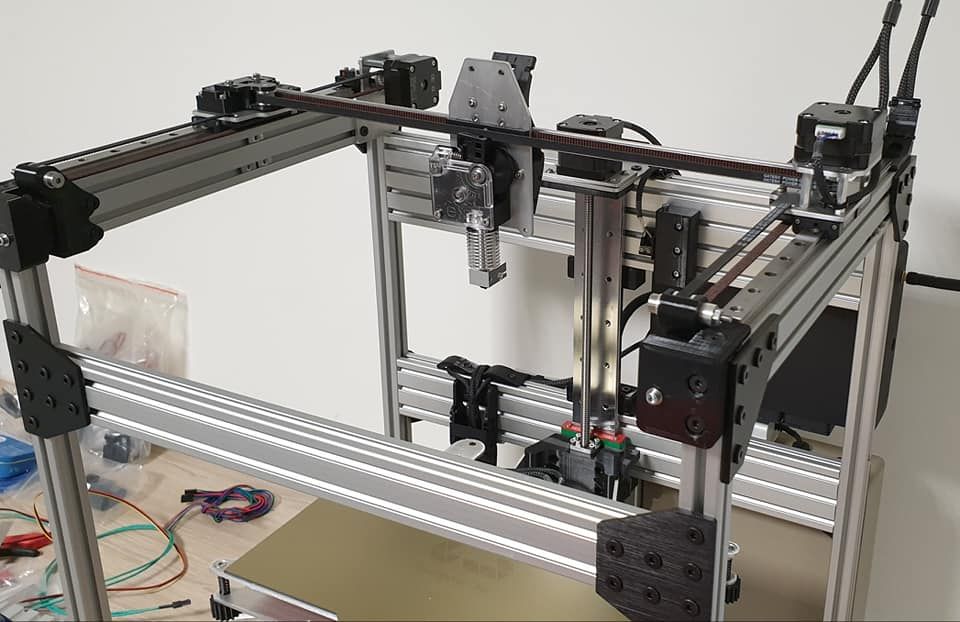

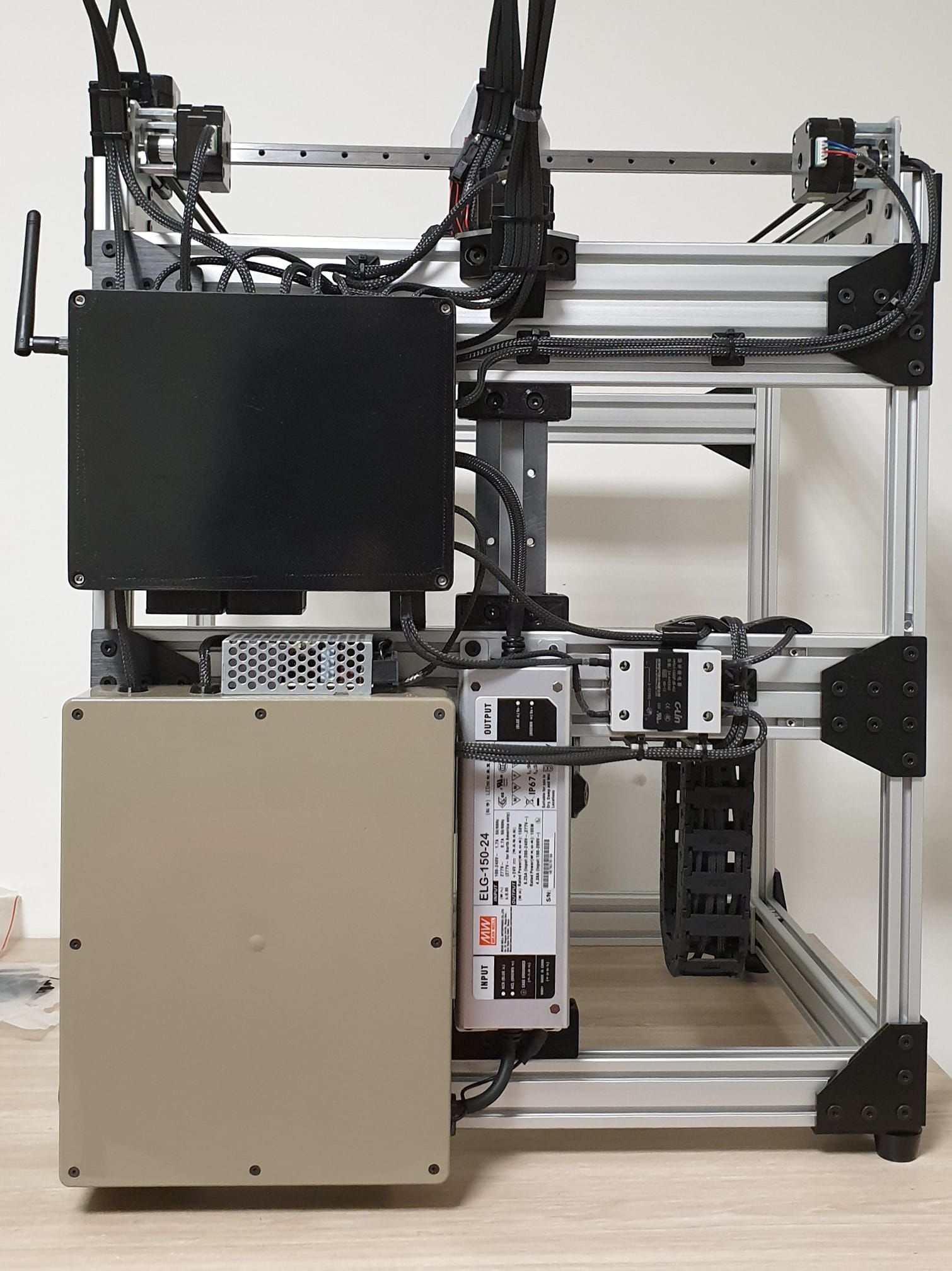

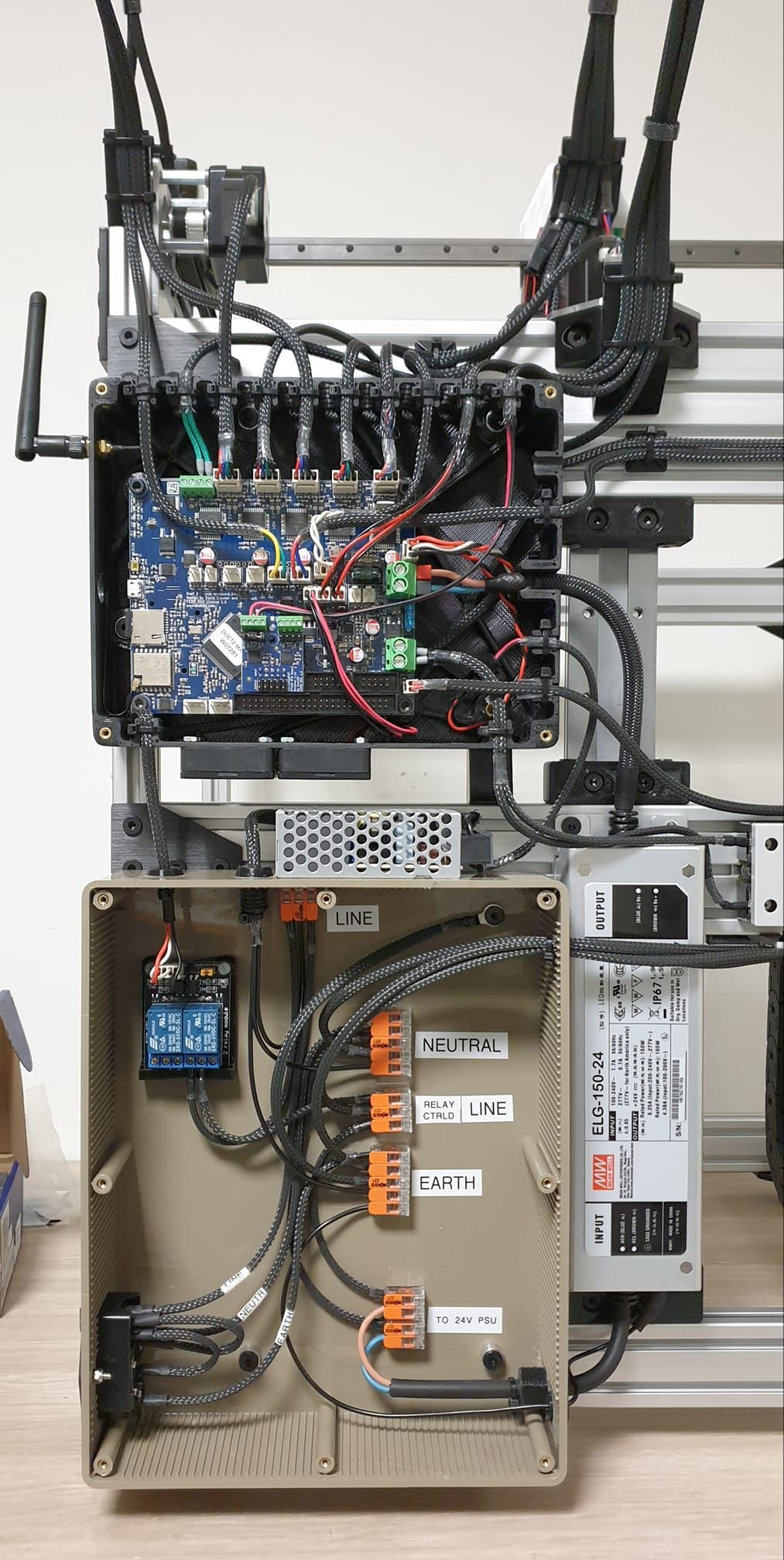

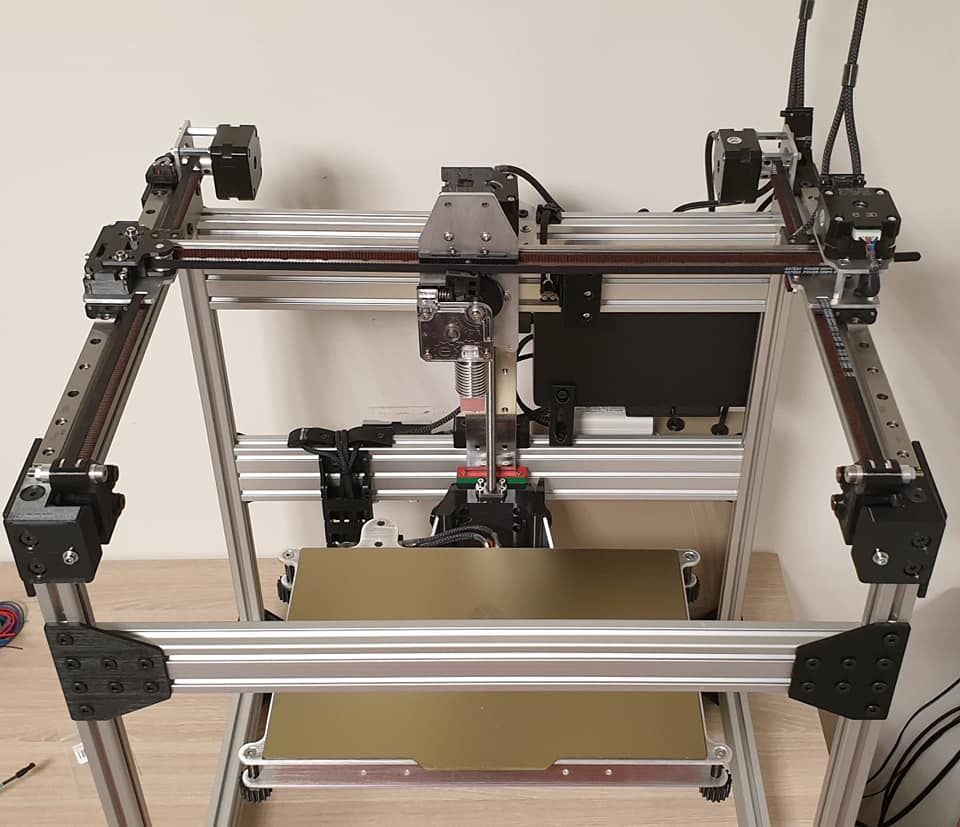

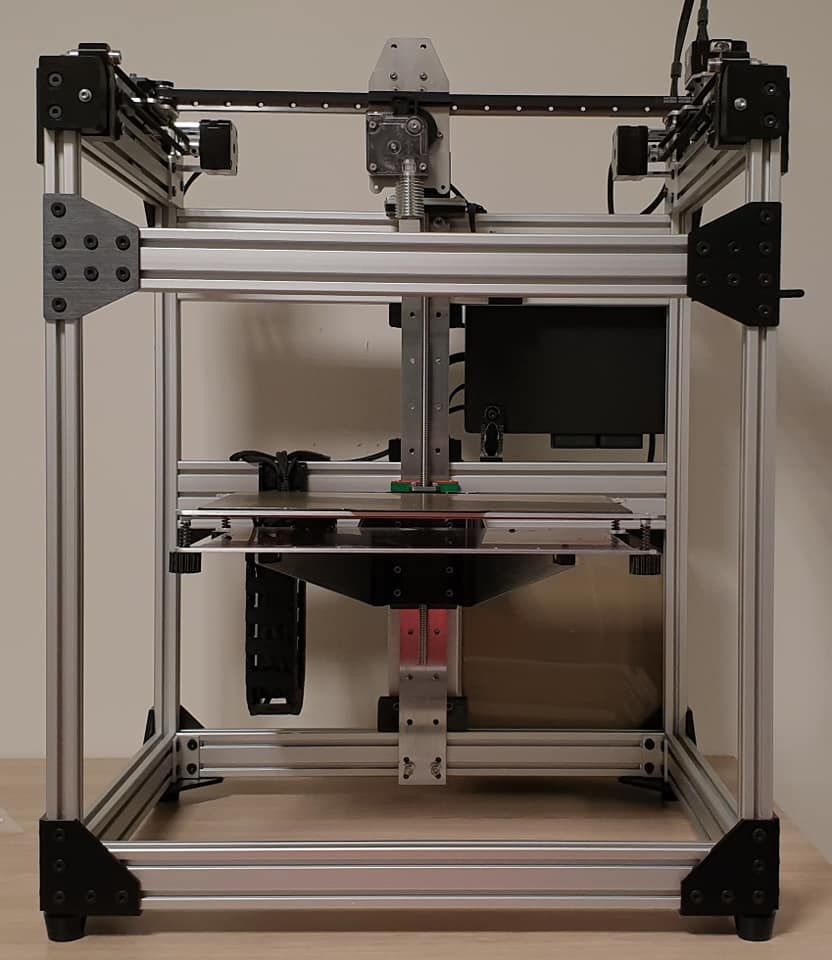

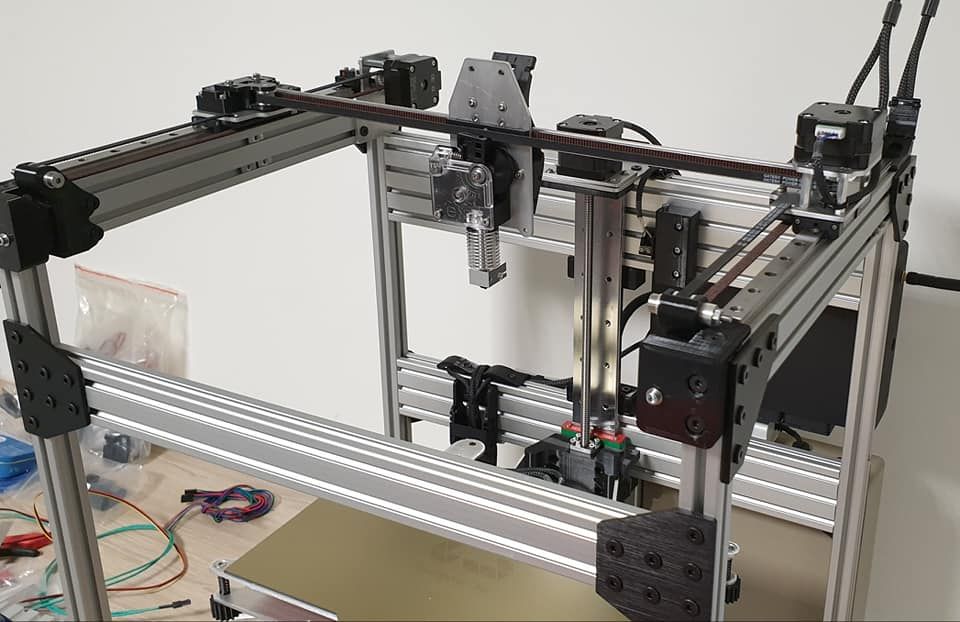

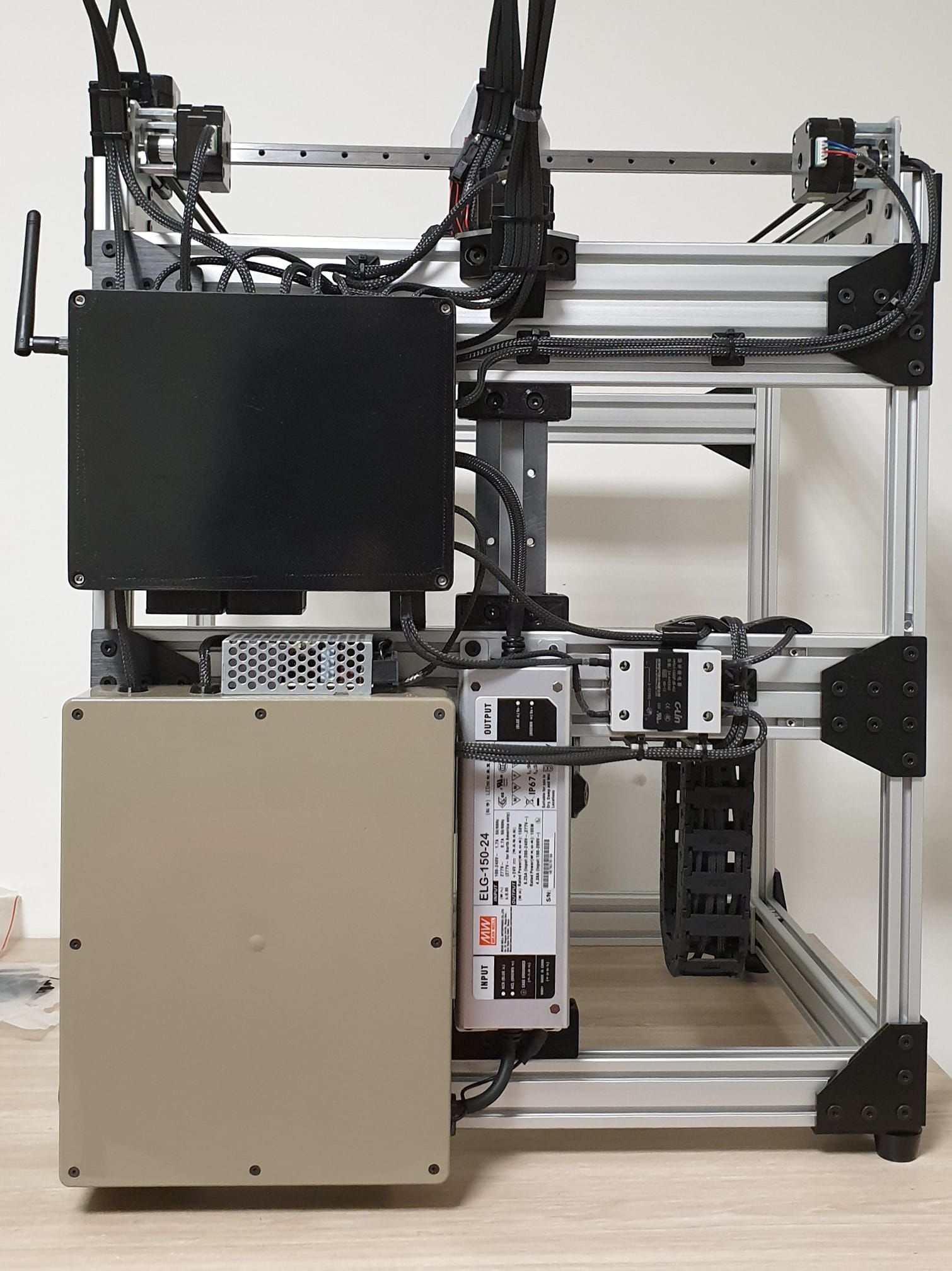

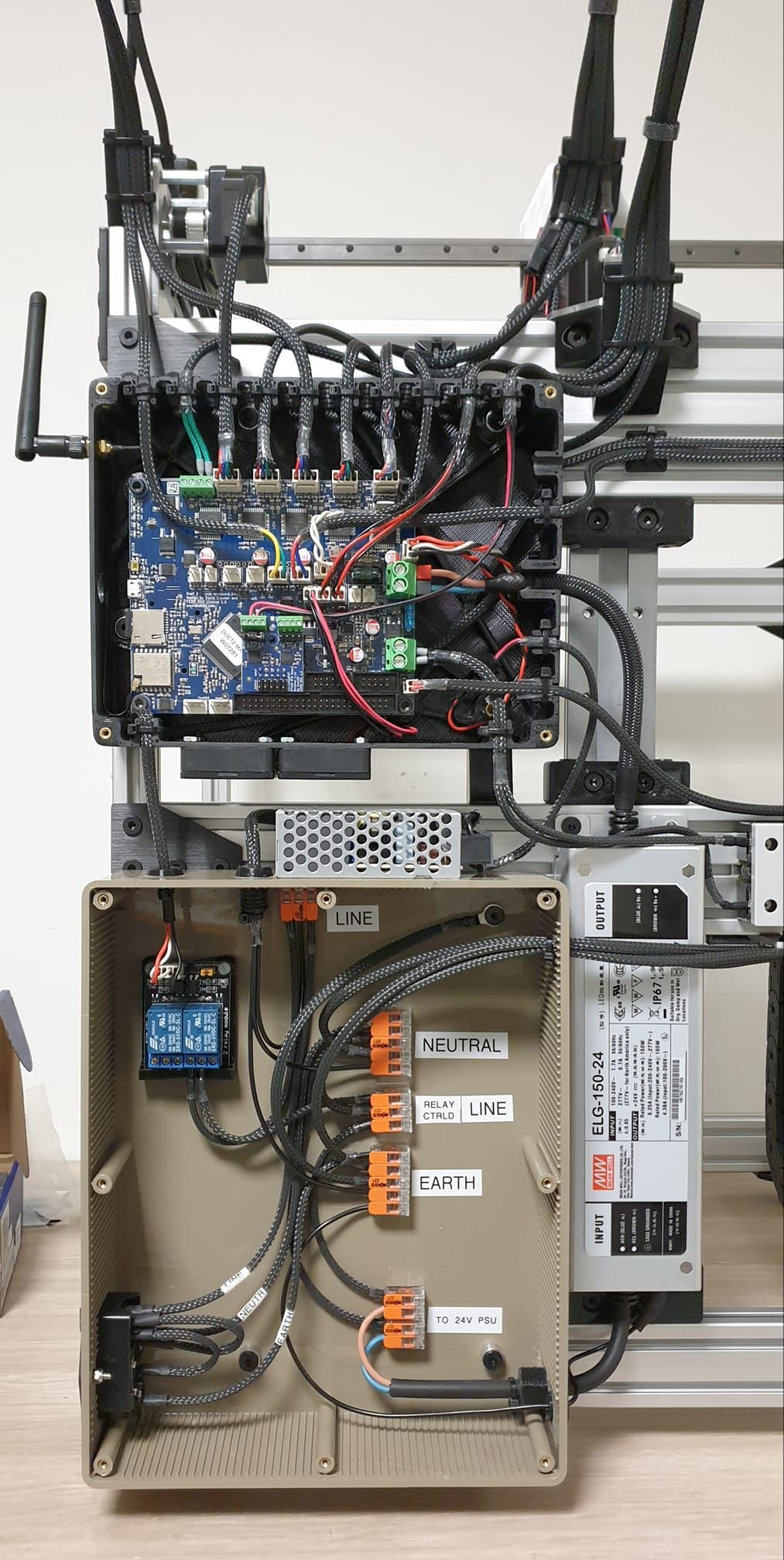

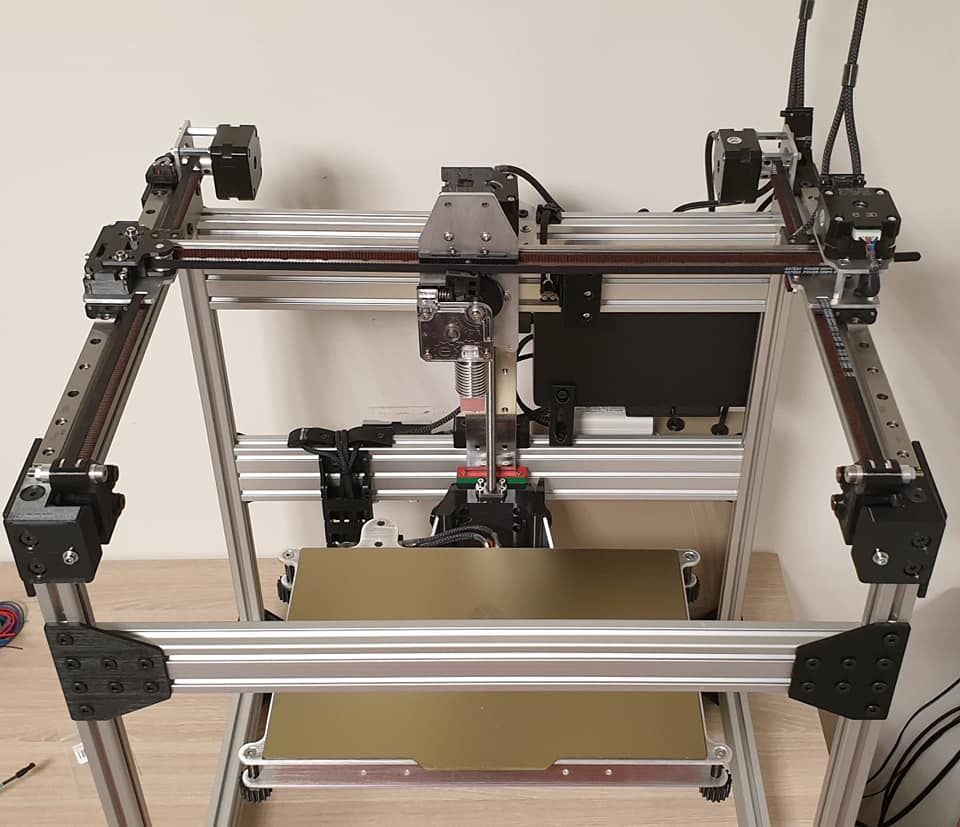

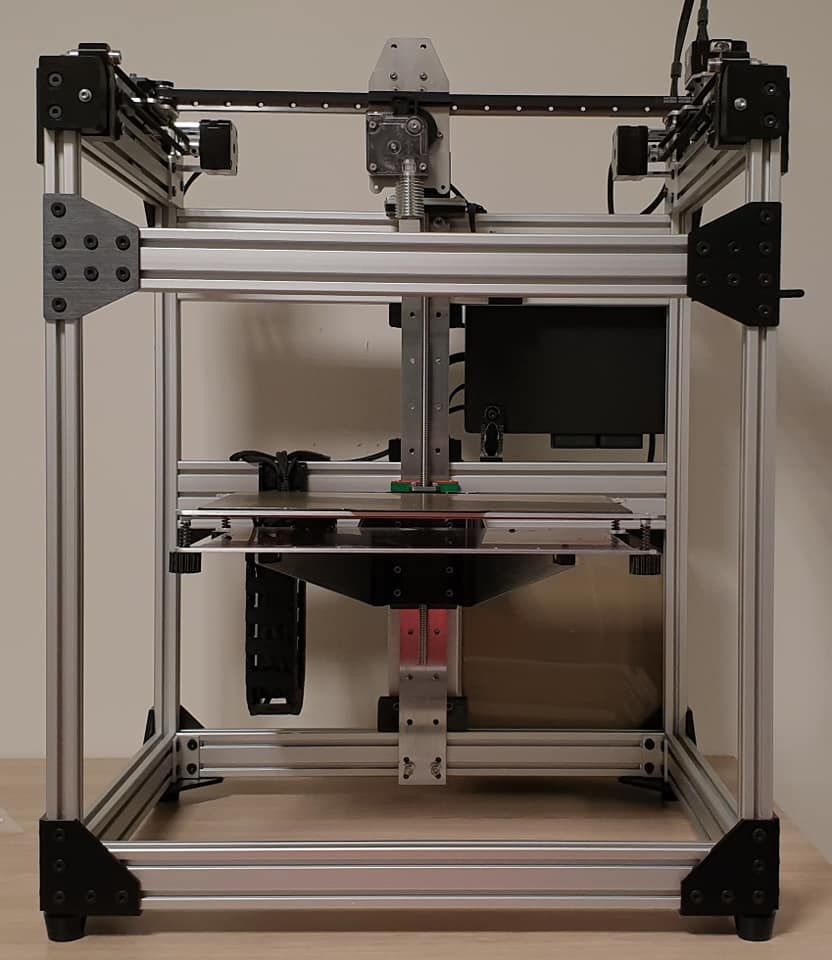

Some pictures of the last printer i designed and built.

Duet based of course like all the others

Some pictures of the last printer i designed and built.

Duet based of course like all the others

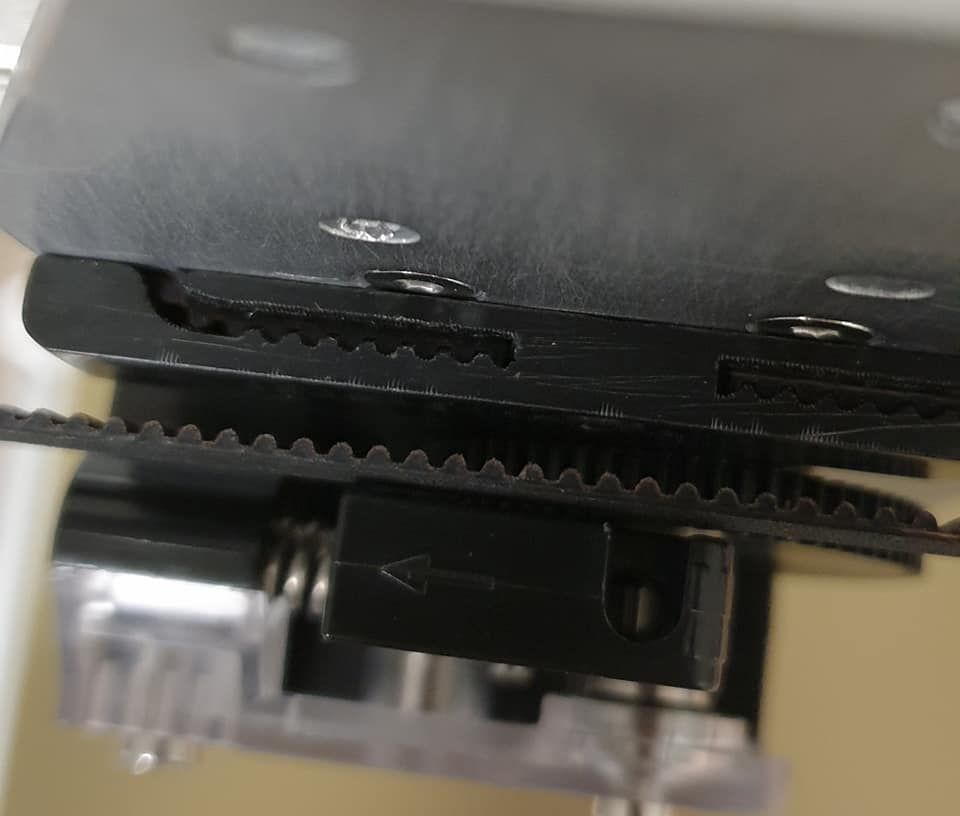

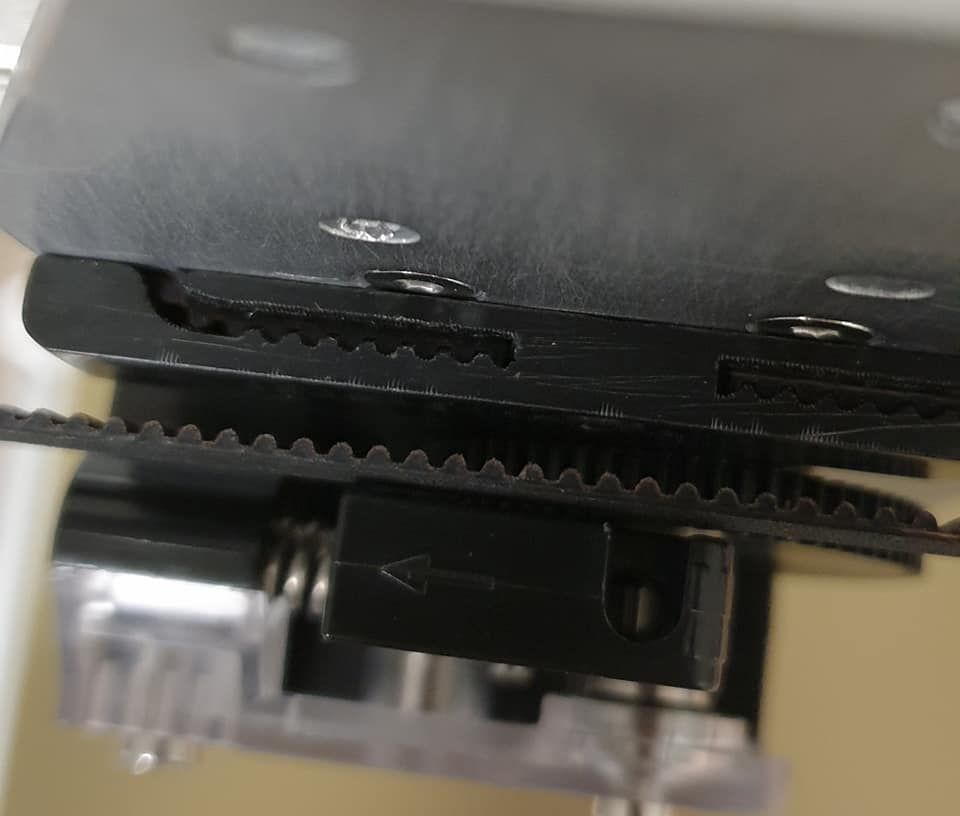

"as long as the critical segments are parallel".

but they will never be if you switch from 20T to 16T without moving the pulleys holes **.

you just can't modify the number of tooth of the pulleys without critical segments to lose parallelism.

because pulleys on both sides of the belt. it would be possible if every pulley or idler was running on the same side of the belt, but it's not the case, whatever belt arrangement you use, there will always be pulleys or idler on both side of the belt on critical segments.

** Which is actually impossible because the center of the new hole for the 16T pulley would be inside the already existing hole of the 20T pulley. that is almost impossible to cleanly do afterwards.

I'd stick to 0.9° steppers under 24V, and follow duet's guide to choosing steppers and especially the recommended inductance value.

@o_lampe said in Wavy surface problem.:

We all cross our fingers, that there's no backdraw using RRF3, but may I ask you a favor and print one of those with a printer running RRF2.x ?

I have absolutly no idea if it's related to RRF3, and i honestly doubt about it.

I'll still try downgrading to rrf2 because i tried so much things...

It's so hard to be 100% sure that there is no mechanical problem. But i changed so much things that there is not much possibilities left. + i changed one thing at a time so i dunno.

At the moment i am 99% sure that it is stepper related.

I have built a moire / VFA stl file that amplifies the problem and will post a test process soon. I am preparing a more rational test approach than what i did before, but it takes a lot time and i'm stuck into SpoolMonitor project atm.

Btw i really decided to solve this thing. It's a pain in my quest to perfect print quality

I ordered several other boards and different drivers so i can really tweak all settings. The post about VFA on prusaprinter forum is a treasure, take time to read it, and like people say, be ready to fall into the rabbit hole  : https://forum.prusaprinters.org/forum/original-prusa-i3-mk3s-mk3-user-mods-octoprint-enclosures-nozzles-.../stepper-motor-upgrades-to-eliminate-vfa-s-vertical-fine-artifacts/

: https://forum.prusaprinters.org/forum/original-prusa-i3-mk3s-mk3-user-mods-octoprint-enclosures-nozzles-.../stepper-motor-upgrades-to-eliminate-vfa-s-vertical-fine-artifacts/

So in my desperate quest about those motor vibrations, i switched to Klipper.

It was not that easy, but it solved all my problems. Maybe it's because trinamic chopper values, maybe it's because input shaper somehow deals with steppers vibrations, i don't know.

My tests are not enough serious / scientifically made to pull a conclusion.

All i can tell is i spent a lot of time and money on this, and i litteraly searched in every possible direction.

TBH the firmware is the really last thing i suspected.

I know VFA's are something you see in very special cases, but imho rrf default trinamic chopper values should be revised and modified to be closer to what Klipper use.

And it's not like i tried with only one stepper type, i tried a lot of different common steppers on the market.

@egon-net said in Wavy surface problem.:

Can you test Klipper without input shaper? I wonder how much of the quality increase is beacuse of it...

Sure. as soon as the current print finishes i'll do that.

@hiroaki said in Wavy surface problem.:

@tpra Hello. That print result is excellent ! Can you show me a photo how your printer is constructed?

Hello, nothing crazy, it's a simple cartesian.

You can find pictures here : https://forum.duet3d.com/topic/21792/my-latest-duet-cartesian-printer

The Z drive has been completly modified since the pictures so it's closer to the one i designed on the funX4. Imho the printer would benefit a lot stronger and heavier frame. That"s why the next one will be a mix of the FunX4 Z and frame + RatRig's vcore3 XY carriage / EVA extruder holder.

@ccs86 said in Wavy surface problem.:

I am very curious to see this as well!

Input shaper benefits are pretty well established at this point, and I am anxiously awaiting the feature to roll out for RRF (hopefully supporting my Maestro board). But, I have had a suspicion that something in RRF is driving the steppers in a way that sets up a resonance.

Sorry it took time, i'm printing a no-input-shaper test with the exact same gcode used on the right picture of my comparison, will post results when i'm back at noon.

Tbh i don't think it has anything to do with input shaper. I also have the exact same suspicion as you about "something in RRF is driving the steppers in a way that sets up a resonance".

You know what makes me crazy with this ? the problem exists, and it's ignored. I don't even understand that seeing the comparison i posted above, no dev wondered or even asked me more informations.

I mean, it's not like if a guy who just got its first printer said "it's it does not work why???".

I thought the print quality spoke for itself. Clearly not. So why bother ?