I did that and I can see that could have been a good thing to do if it went wrong

Posts made by TPJensen

-

RE: How to I make probe stop soonerposted in General Discussion

-

How to I make probe stop soonerposted in General Discussion

Hello I just got a wham bam kit for my Anycubic Predator, but I would like to know how do I get my probe to stop the fast dive sooner so it dont crash into the bed before leveling it.

Here is my config files

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2 on Tue Feb 26 2019 21:31:01 GMT+0000 (Greenwich Mean Time); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves; Delta Settings

M665 L440.000 R227 H456.0 B185.0 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 A0.00 B0.00 ; Put your endstop adjustments here, or let auto calibration find them; Network

M552 S1

M550 P"Anycubic Predator" ; Set machine name

M551 P"" ; Set password

M552 P0.0.0.0 S1 ; Enable network and acquire dynamic address via DHCP

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80.00 Y80.00 Z80.00 E425.77 ; Set steps per mm

M566 X1000 Y1000 Z1000 E1000 ; Set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z12000.00 E10000 ; Set maximum speeds (mm/min)

M201 X3000.00 Y3000.00 Z3000.00 E3000.00 ; Set accelerations (mm/s^2)

M906 X1000.00 Y1000.00 Z1000.00 E1100.00 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Retraction

;M207 S4.0 F5000 R-0.025 T2500 Z0.5 ; Firmware retraction; Axis Limits

M208 Z0 S1 ; Set minimum Z; Endstops

M574 X2 Y2 Z2 S1 ; Set active high endstops; Z-Probe

M558 P4 H3 F120 T6000 ; Set Z probe type to switch and the dive height + speeds

G31 P500 X0 Y0 Z16.0 ; Set Z probe trigger value, offset and trigger height

M557 R115 S20 ; Define mesh grid

G29 S1 ; Load the heightmap; Heaters

M307 H0 A137.8 C533.3 D1.5 V24.3 B0 ; Disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4300 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4300 C0 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S255 ; Set temperature limit for heater 1 to 240C; Fans

M106 P0 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S0 I0 F500 H-1 ; Set fan 2

; Tools

M563 P0 D0 H1 F0:2 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic saving after power loss is not enabled

; Custom settings are not configured

M572 D0 S0.1 ; Pressure Advance

;M591 D0 P2 C4 S1 ; Activate filament sensor

M404 N1.75 ; Set for print monitor

M592 D0 A0.07772 B-0.00029 ; Nonlinear extrusion. Set parameters for extruder drive 0; Miscellaneous

M501 ; Load saved parameters from non-volatile memory

T0 ; select first tool -

RE: Help to setup BMG clone extruderposted in Duet Hardware and wiring

@sinned6915 said in Help to setup BMG clone extruder:

@TPJensen How are you fairing so far?

It is up and working now and makes good prints... my Esteps was 368.21 that looks spot on in the prints. Some filament as you say is a bit differnt in my simplify3d. 0,99 - 0,95

I love the Duet2 wifi board and paneldue in my mind the best upgrade I have. On PanelDue there is only one thing and that is baby steps can only be done when the printer starts. I know I can do it on webcontrol just it could be nice to have the option.

-

RE: Help to setup BMG clone extruderposted in Duet Hardware and wiring

@DocTrucker said in Help to setup BMG clone extruder:

@TPJensen Didn't mean to imply you had, sorry if it came across like that.

That is okay... dont worry I like your post and follow you 100%...

I have a mate that did buy his first printer 1½ years ago and he did buy alot of clone things and I helped as good as I could.... Now the same mate have only orig. parts and 6 printers.... Untill I started to help him he had given up and put his printer up for sale put with a little help he went from boring failed prints to good prints and he did thing is was fun and he has just ordered Ultimaker 2+ Extended.. So if your help one also with clone parts then it can be good for the original company also.. (in this case very good)Just has you also say @DocTrucker

-

RE: Help to setup BMG clone extruderposted in Duet Hardware and wiring

@DocTrucker said in Help to setup BMG clone extruder:

clone Duets

I would like to make this clear I do NOT have clone duet.

-

RE: Help to setup BMG clone extruderposted in Duet Hardware and wiring

You are right that buying the orignal is surely the best and you get better quality. But I also buy that but as you say my money is my money and as a hobby I got more than one and not cheap once. I cant buy everything original like I want to. But again you are right that I should do that.

It is always nice to get others input and answers.

BTW everything else is original on ALL 5 of my printers so hope that gives a little credit in your mind.

Thanks for your "answer"

-

RE: Help to setup BMG clone extruderposted in Duet Hardware and wiring

My extruder has a very good grib so no problems there....

My is a clone and they say Esteps 415 also but I'am at 388.21 but when I startet to print E368.21 before the print surface got nice and smooth... But in another tread i have one wrote to me that it could be the filament that not was the same all the way I he was right. The filament I used was one there came with the printer.

-

RE: Rough area on top layersposted in Tuning and tweaking

Yes okay I see your point.... It can be that the filament is not the best "NO NAME" I got it with the printer and only used it for test but I see it is maybe not the best idea to use it for...

UPDATE: used premium to calibrate. Filament and before it 100 mm = E388.21 and now with multi tests and did take the advange then 100mm = E367.18

-

RE: Rough area on top layersposted in Tuning and tweaking

I think you are right... I can also do that on simplify3D and I have made 2 profiles for filament so far...

But I did Esteps with PLA and the same PLA I did print with had Rough area on it.... So just for fun I did try and print and see where the print had the best surface and smooth but I think it was much off then... the calibratet esteps was E388.21 and I found the best surface with E368.21 ? -

RE: Rough area on top layersposted in Tuning and tweaking

Okay I will try and see if I can get a code pieced together there will work or try

-

RE: Rough area on top layersposted in Tuning and tweaking

Can I use the Filament tap on the DWC to create filament with the correct Esteps/extruction ?

-

RE: Rough area on top layersposted in Tuning and tweaking

Okay that info helps me alot thank tou very much.. I did not know I have to do that when it was same brand but I did know if I go from PLA to PETG

-

RE: Rough area on top layersposted in Tuning and tweaking

Hi I have tried 95% and it is alot better than before, but need a bit more.

But why is this when I extrude 100mm and get 100mm and it is off anyway ?

-

RE: Rough area on top layersposted in Tuning and tweaking

@whosrdaddy said in Rough area on top layers:

Rough top surface is mostly an indication of overextrusion. Try printing the same object but change the extrusion rate in DWC at say 95% and see if it makes a difference...

thanks I will try that

-

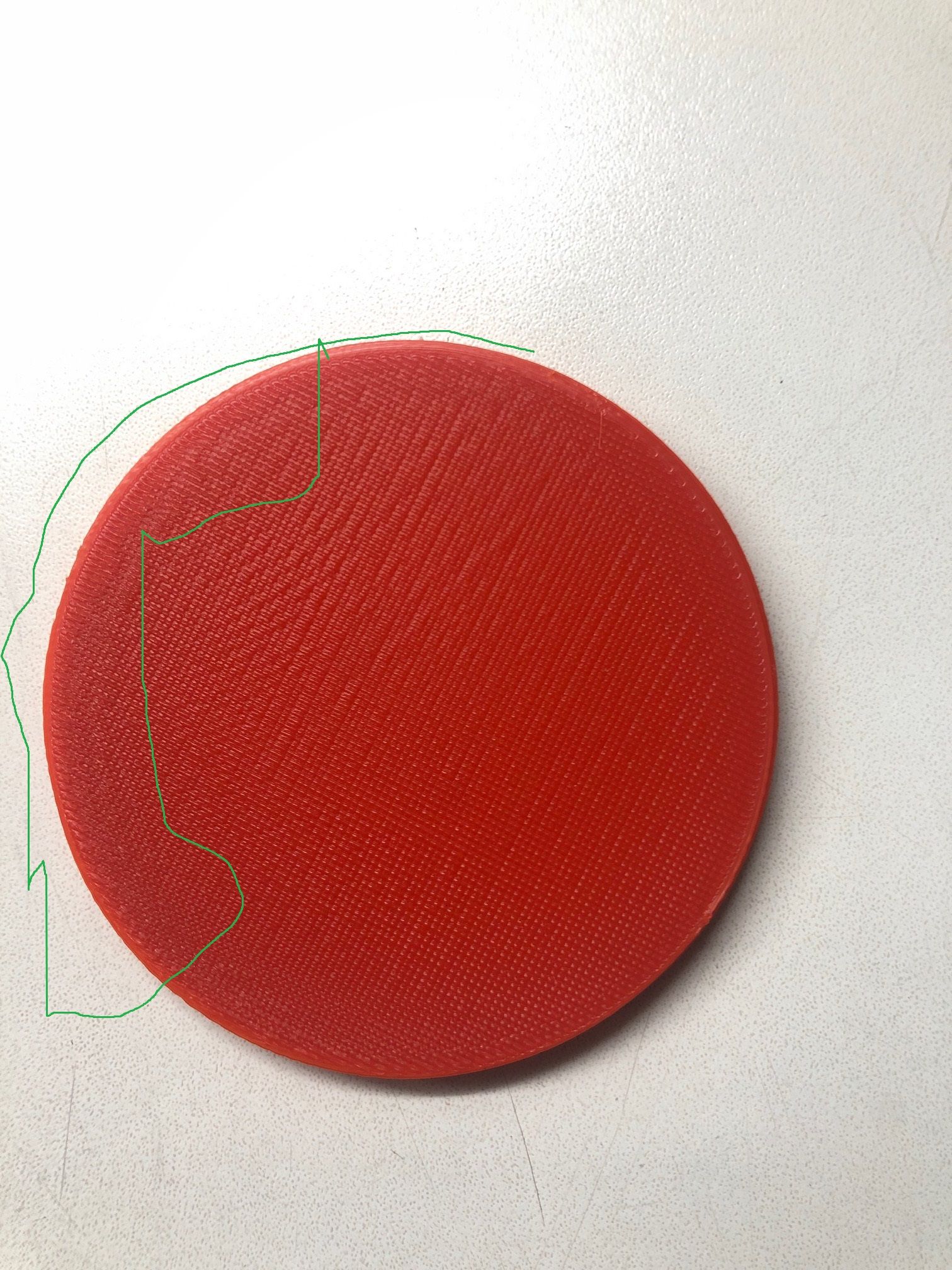

Rough area on top layersposted in Tuning and tweaking

Hi I have a Anycubic Predator have Duet2 Wifi and just upgraded the extruder to a BMG clone.

I have calibratet the extruder so extruder 100 mm I get 100mm

also done rectraction test and that is also perfect.But when I print first layer is very good and fine but on finish top layer gets rough but not all over, can find out what is wrong.

Here is a photo of a print the area with green is rough

Layer 0,18 - Temp 195 - Bed 50

Filament PLA

Print speed 125mm/s

Buttom layer 5

Top layer 6

-

RE: Help to setup BMG clone extruderposted in Duet Hardware and wiring

@Veti said in Help to setup BMG clone extruder:

yes if it extrudes in the correct direction.

Super I will set it up as soon my on going print are finsihed thanks for your help @Veti

-

RE: Help to setup BMG clone extruderposted in Duet Hardware and wiring

@Veti said in Help to setup BMG clone extruder:

have you changed the stepper motor?

No I have not changed the stepper motor.

M92 X80.00 Y80.00 Z80.00 E380.45 ; Set steps per mm Is the E380,45 The only thing I need to change ??``` -

Help to setup BMG clone extruderposted in Duet Hardware and wiring

Hello

Is there someone there can help me what to write in the config.g when I install BMG clone extruder on my Anycubic Predator ?Here is my config.g file

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2 on Tue Feb 26 2019 21:31:01 GMT+0000 (Greenwich Mean Time); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves; Delta Settings

M665 L440.000 R227 H456.0 B185.0 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 A0.00 B0.00 ; Put your endstop adjustments here, or let auto calibration find them; Network

M552 S1

M550 P"Anycubic Predator" ; Set machine name

M551 P"" ; Set password

M552 P0.0.0.0 S1 ; Enable network and acquire dynamic address via DHCP

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S0 ; Drive 3 goes forwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80.00 Y80.00 Z80.00 E380.45 ; Set steps per mm

M566 X1000 Y1000 Z1000 E1000 ; Set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z12000.00 E10000 ; Set maximum speeds (mm/min)

M201 X3000.00 Y3000.00 Z3000.00 E3000.00 ; Set accelerations (mm/s^2)

M906 X1000.00 Y1000.00 Z1000.00 E1000.00 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Retraction

M207 S4.0 F5000 R-0.025 T2500 Z0.5 ; Firmware retraction; Axis Limits

M208 Z0 S1 ; Set minimum Z; Endstops

M574 X2 Y2 Z2 S1 ; Set active high endstops; Z-Probe

M558 P4 H3 F120 T6000 ; Set Z probe type to switch and the dive height + speeds

G31 P500 X0 Y0 Z16.0 ; Set Z probe trigger value, offset and trigger height

M557 R115 S20 ; Define mesh grid

G29 S1 ; Load the heightmap; Heaters

M307 H0 A137.8 C533.3 D1.5 V24.3 B0 ; Disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4300 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4300 C0 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S250 ; Set temperature limit for heater 1 to 240C; Fans

M106 P0 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S0 I0 F500 H-1 ; Set fan 2

; Tools

M563 P0 D0 H1 F0:2 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic saving after power loss is not enabled

; Custom settings are not configured

M572 D0 S0.1 ; Pressure Advance

;M591 D0 P2 C4 S1 ; Activate filament sensor

M404 N1.75 ; Set for print monitor

M592 D0 A0.07772 B-0.00029 ; Nonlinear extrusion. Set parameters for extruder drive 0; Miscellaneous

M501 ; Load saved parameters from non-volatile memory

T0 ; select first toolHere is a photo of the extruder