I vote for a simple hour meter.

Best posts made by timcurtis67

-

RE: Total hours of operation/printing feature.posted in Firmware wishlist

-

RE: Dual hotend, one motor possible?posted in Duet Hardware and wiring

It should be possible to do this with a Duet. Just configure each tool (hotend) with the same extruder drive number in the config file. The only tricky part is reversing the drive direction. Once it is set in the config file you will need to change the direction in your tool change files.

If your extruder drive is 4 then you will need a M569 P4 S1 in the tool change file for tool 0 and then a M569 P4 S0 in the change file for tool 1.

Or they could be opposite depending on your dive setup but the idea is it changes the drive direction at the time of the tool change.

-

RE: Core XY firmware.posted in General Discussion

I have a DBot.

Here is my config file and my homing files.I use a BL Touch on this machine so the Z axis is homed with it.

Hope this helps you.

-

RE: Can Anyone Share Their HEVO Configs?posted in Tuning and tweaking

@DIY-O-Sphere said in Can Anyone Share Their HEVO Configs?:

@justinds89 said in Can Anyone Share Their HEVO Configs?:

1 - BLTouch when turning on the printer will sometimes just blink red and not deploy/retract probe.

I had exactly the same issue, that was driving me crazy....

Check the Pin

"Try loosening or tightening the set screw slightly to adjust the trigger sensitivity."The description how to set up the srew is in the manual

In the end a quarter turn had reliably solved the problem.+1 that fixed my issue I had with one of my BL's doing the same thing.

-

RE: RepRapFirmware 2.0beta1 availableposted in Firmware installation

@dc42 said in RepRapFirmware 2.0beta1 available:

Tim, I can confirm that in 2.0beta1 when a G0 command follows a G1 command with extrusion, the G0 command repeats the extrusion. I have fixed it and I will release a new beta tonight or tomorrow.

Great! I will watch for the update and try it out asap. Not sure where you get the time to keep up with these updates but I thank you sincerely.

-

RE: More channelsposted in Hardware wishlist

@klcjr89 said in More channels:

Does the Duet Maestro qualifiy as 'next generation' of Duets? The Revolve has me interested but I am not brand loyal and have been in all the camps. Marlin (yuck), Smoothieware, Repetier, Klipper.

The thing I like about the Revolve is it allows you to get rid of an external Raspberry Pi which people (and me) use for 1080p live streaming of the printer with, for example, a Logitech C920 USB webcam, as the IP camera solution isn't really great at all.

My only comment here is based on the Replicape board I have on my smaller printer. The board itself works okay, Not great just okay. The documentation and the firmware are just not very good at all. They are making a new Revolve board and still haven't gotten the firmware right yet for even the Repilcapes. Buyer beware, make sure you are very good in hacking firmware if you want to take on one of those boards. Not all the features will work yet. Updates are slow and far between.

I've been waiting for 3 years for some good updates that only take days or weeks for the Duet boards.....

-

RE: Can I store and read values from cardposted in General Discussion

@dc42 said in Can I store and read values from card:

It's possible in a macro file to create and write data to a different macro file using the M559 command. Then you could execute the file from config.g. So you could use this method if you used only a few different settings of the RGB LEDs. When conditional GCode, variables and the object model are implemented, you will be able to do a lot more.

Can't wait for this option.

Can't wait for this option.

-

RE: Microstepping in relation to deviation?posted in Tuning and tweaking

@phaedrux said in Microstepping in relation to deviation?:

You get to use interpolation

To avoid confusion, I believe @jackatom74 is refering to a 16 tooth pulley. Not 1/16 microstepping.

-

RE: Make use of variablesposted in Firmware wishlist

@dc42 said in Make use of variables:

This week I have been designing a mechanism for conditional and looping GCode with variables. I will publish the proposal soon.

Sweet! I've been waiting for this feature.

-

RE: nozzle wipeposted in 3D Printing General Chat

@deckingman said in nozzle wipe:

@arhi For info, I'm currently working on a better "bucket". What I mean by that is with a mixing hot end, I sometimes have to purge as well as wipe. That purged plastic has to be collected, otherwise it would end up getting onto the belt that drives the lead screws. My current "bucket" is too shallow and I have to empty it more often than I would like.

Conditional g code on the horizon.... If bucket.purge == full then empty.

-

RE: Survey: Usage of a 3D-Printerposted in General Discussion

Yeah I thought it was pretty straight forward.

-

RE: Microstepping in relation to deviation?posted in Tuning and tweaking

@Phaedrux Yeah I do that all the time...

-

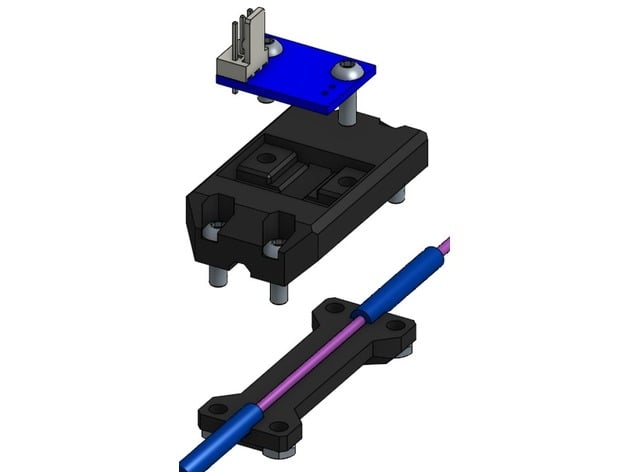

RE: My approach to the Housing for Duet3D Laser Filament Monitorposted in Filament Monitor

I like this version. I'm going to print one up for my own testing.

Thank you

-

RE: Truthiness. Verified Truthiness.posted in Firmware wishlist

@rcarlyle The most accurate machines in the machine shop that I work in are Wire EDM machines. The don't use encoders but instead use glass scales to detect movement. That way back lash in the couplers, ball screw nut and uneven wear in the lead screws don't have to be compensated for. The glass scale detects and reads the movement of the head in each direction very accurately. With a machine resolution of .00005".

Encoders are nice but they still only rely on the motor shaft movement and don't account for wear in the lead screw.

Even if you could have the printer head move with extreme precision, can you have the hot plastic squirt out with just as much precision?

In my opinion the reality is these printer are just glorified play-doe fun factories in that they just squirt stuff through a hole.

I have used indicators set up to confirm I am getting great repeatably with my X and Y axis. Much closer than my extruder can print.

-

RE: Core XY firmware.posted in General Discussion

@Helensdad You're welcome. Defiantly shout out if you need and help. I'll try to help out.

Merry Christmas to you as well.

-

RE: Berd-Air pump configuration notes for Duet usersposted in Tuning and tweaking

@hergonoway said in Berd-Air pump configuration notes for Duet users:

@ayudtee

And did you use a jig to bend the "circle" part?One way to bend soft tubing is to fill it with salt (table salt) and tape the ends shut. Pack it pretty tight and then you can bend it to as tight a circle as you need.

Then remove the tape and tap it until all the salt comes out. I blow air thru it as well afterwards.

-

RE: Problems with new Laser Filament Monitorposted in Filament Monitor

@brunofporto said in Problems with new Laser Filament Monitor:

Have you tried my casing design? I have a large exposed length of filament based on a hypothetical aperture I calculated from some datasheet parameters.

I had no issues with shiny metallic petg or translucent materials with it. Just make sure you cut the filament tip diagonally so it enters the exit hole nicely

I modified your housing to run the filament through at a 10 angle to see if it makes any difference in the accuracy. I don't post on Thingiverse but here is a link to the STL files. Note I have not printed these yet so there could be fit issues.

https://drive.google.com/drive/folders/1b8wBl5uZ1qwoimONZLIcWlFULOlNsJaq?usp=sharing

Once I confirm if the angle approach works I will go back and "pretty up" the housing.

-

RE: Truthiness. Verified Truthiness.posted in Firmware wishlist

@danal said in Truthiness. Verified Truthiness.:

@timcurtis67 said in Truthiness. Verified Truthiness.:

@rcarlyle The most accurate machines in the machine shop that I work in are Wire EDM machines. They don't use encoders but instead use glass scales to detect movement.

OK, I am going to be "That Guy".

A glass scale IS "an encoder". Attached to the final carriage instead of the motor shaft, which has tremendous advantages. Still, it is encoding position.

I think what you are saying is that they don't use rotary encoders on the motors. Which, as you point out, attaching the (glass scale) sensor to the final "control point" self-compensates for all backlash, etc. I have a mill that works this way, and it is great.

Yep that's what I'm saying. A glass scale is a type of encoder. A much more accurate one over time for the simple fact that with age the driving forces behind any mechanical movement wear. Rotary encoders on the end of servos (like in most CNC mills) only read the shaft movement, and that is before the coupler even.

But truly my point was the fact that are encoders really necessary on a glorified hot melt glue gun machine? (Thanks Ian

)

)If you like them and feel you will get better prints with them then by all means go for it.

-

RE: Changes in inner structure visible on surfaceposted in General Discussion

Looks like shrinkage to me. It appears to be a large part the bottom 5mm may be cooling and sucking the outside inwards. The when you print the upper wall it prints much faster and can get around the perimeter before too much cooling takes place.

Just my thoughts anyway.

-

RE: IDEX calibration problemsposted in Tuning and tweaking

I'm not sure if this will help you or not but here is my config and tool free files for my IDEX printer. If you check out the Tools area and look at tool 2 definition you will see how I have it set up for ditto printing.

0_1528195452792_config.g

0_1528195474894_tfree0.g

0_1528195482160_tfree1.g

0_1528195490754_tfree2.g