@fcwilt I have not. Honestly, I hadn't heard of it. Can I infer that you think I need to try to get the bed more level? Bed mesh compensation can't compensate this much? I'm going to try to disconnect the frame itself and try to ensure that is straight.

Latest posts made by Terradive

-

RE: Bed levelling assistance.posted in Tuning and tweaking

-

RE: Bed levelling assistance.posted in Tuning and tweaking

I have thumb screws. However, if I adjust them it throws the other corners off more.

-

Bed levelling assistance.posted in Tuning and tweaking

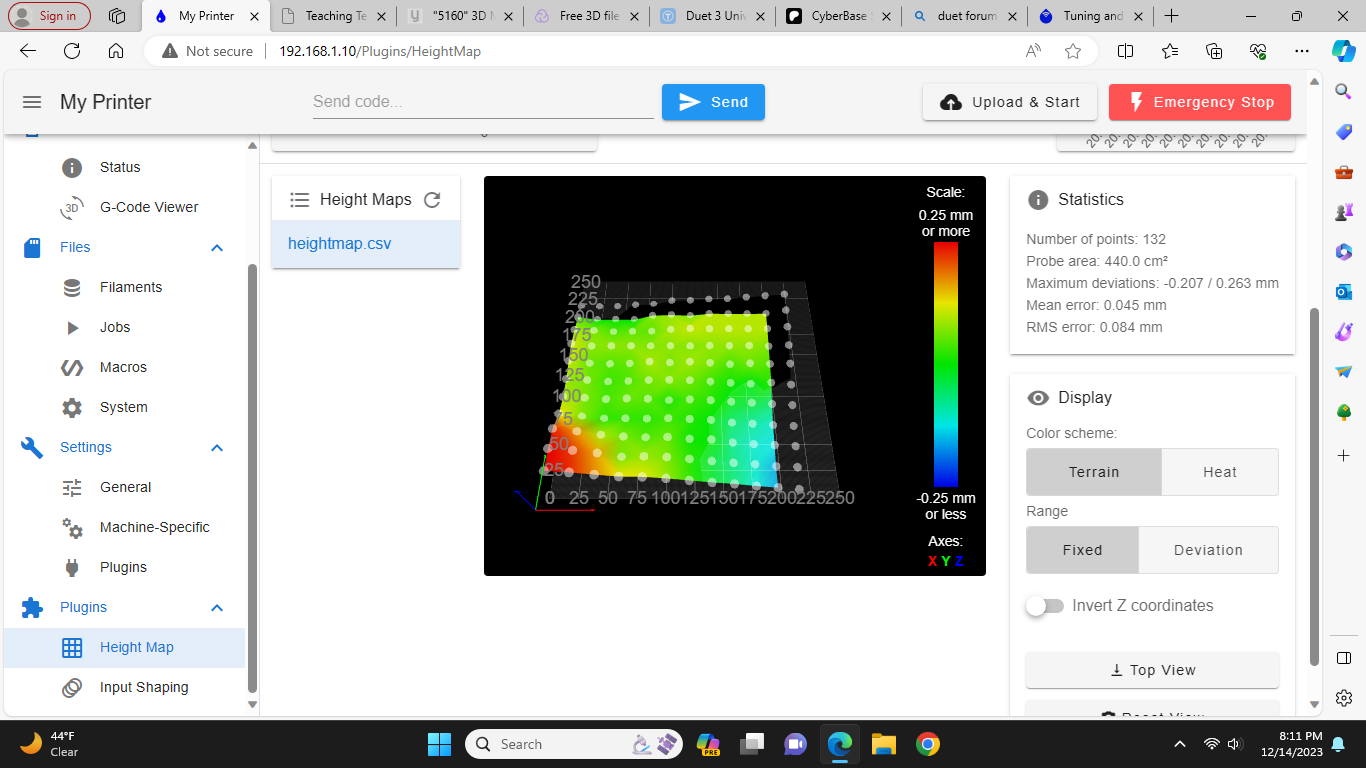

I'm having problems with the first layer. I have a bltouch. I've mapped the bed and think it's pretty level. However there seems to be something wrong with the height adjusting. On the left side the filament is almost loose. On the right side it's so close to the bed it's not putting out filament. I've got it homing to the front left corner. Maybe the bed readings need to be inverted?

; Configuration file for Duet WiFi (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.16 on Sun Jul 16 2023 09:26:47 GMT-0500 (Central Daylight Time) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S0 ; physical drive 1 goes forwards M569 P2 S0 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping ;M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 Z400.00 E562.00 ; set steps per mm M350 X16 Y16 Z32 E128 I1 ; configure microstepping with interpolation M566 X15000.00 Y15000.00 Z600.00 E600.00 ; set maximum instantaneous speed changes (mm/min) M203 X30000.00 Y30000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X1500.00 Y1500.00 Z400.00 E600.00 ; set accelerations (mm/s^2) M906 X1600 Y1600 Z1000 E600 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M204 P2000 T4000. ;set travelspeeds ;M593 P"zvdd" F24 s.05 ;ringing ghosting M593 P"zvddd" F60 s0 ;ringing ghosting ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X250 Y250 Z400 S0 ; set axis maxima ;Retraction M207 S1.0 F2400 Z1.0 ; Endstops M574 X2 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop M574 Y2 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M558 P9 C"zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds G31 P500 X-13 Y-25 Z.675 ;set Z probe trigger value, offset and trigger height M557 X0:250 Y15:250 S20 ; define mesh grid M950 S0 C"exp.heater3" ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 R0.219 K0.199:0.000 D8.53 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit ;M307 H0 R2.763 K0.583:0.009 D3.81 E1.35 S1.00 B0; V24.0 M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 ;M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M307 H1 R2.763 K0.583:0.009 D3.81 E1.35 S1.00 B0 M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" ; create fan 0 on pin fan0 and set its frequency M106 P0 S0.4 H-1 ; set fan 0 value. Thermostatic control is turned off ;M950 F1 C"fan1" ; create fan 1 on pin fan1 and set its frequency ;M106 P1 S0.4 H-1 ;M950 F2 C"fan2" Q500 ;M106 P2 s1 h-1 ; set fan 2 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ;M563 P0 D1 H2 F2 T0 ; Custom settings are not defined M82 M591 D0 P7 C"e0stop" L7 R75:125 E22 S1 ;filamentsensor M572 D0 S0.12 ;pressure advance in duet linear advancebed.g

; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Tue Feb 07 2023 20:54:03 GMT-0600 (Central Standard Time) M561 ; clear any bed transform G29 s1 ; probe the bed and enable compensationHome all

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Tue Feb 07 2023 20:54:03 GMT-0600 (Central Standard Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X+555 Y+555 F1800 ; move quickly to X or Y endstop and stop there (first pass) G1 H1 X+555 ; home X axis G1 H1 Y+555 ; home Y axis G1 X-5 Y-5 F6000 ; go back a few mm G1 H1 X+555 F360 ; move slowly to X axis endstop once more (second pass) G1 H1 Y+555 ; then move slowly to Y axis endstop G91 ; absolute positioning G1 X-125 Y-125 F6000 ; go to first bed probe point and home Z G30 ; home Z by probing the bed G29 S1 ; turn on height map ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioning ;G92 Z0 ;tell the firmware where we arehome z

; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Tue Feb 07 2023 20:54:03 GMT-0600 (Central Standard Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G90 ; absolute positioning G1 X120 Y120 F6000 ; go to first probe point G30 ; home Z by probing the ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioning

-

RE: Help appreciatedposted in General Discussion

@droftarts thanks for your help. Here’s pics. I have .9 motors on the x and y axis. Lgx lite withe the steel gears upgrade. Hi win Linear rails on x y z.

-

RE: Help appreciatedposted in General Discussion

@droftarts yeah I did that. I’m not seeing the wood grain pattern. I’m seeing vertical lines packed closely together. The videos don’t talk about that much

-

Help appreciatedposted in General Discussion

I have an ender 6 with duet wifi mother board. I've been having issues with VFA horizontal lines at.1 layer height since installing the duet 2. I'd like to try a run with TMC2209 stepper motor drivers. What is going to be the easiest/cheapest way of doing this? When you buy a duet 3 you have to install stepper drivers? Are there potentially better stepper drivers out there? My goal is to print as quickly as possible at low layer heights. Any thoughts ideas are helpful.

-

RE: BTT Smart filament sensor setupposted in Third-party add-ons

@Phaedrux I moved the xstop cable over to the e0 slot and tapped the button a couple of times. The light flickered. I'm not real great with multimeters, I unplugged the cable at the sensor. With the printer off, I then put the positive connection to the v wire and the negative connection on the ground. The numbers changed slightly. I then turned on the machine and repeated the test and the numbers changed more.

-

RE: BTT Smart filament sensor setupposted in Third-party add-ons

This is my wiring. Do you see any problems? I've tried printing from both drives neither works. They're wired identically. -

RE: BTT Smart filament sensor setupposted in Third-party add-ons

@jay_s_uk It's printing using tool 1.

-

RE: BTT Smart filament sensor setupposted in Third-party add-ons

@jay_s_uk No data received. I set the r value down to R1:200. It still stopped in another test. I'm trying to rule out any gcode problems assigning drives. I think I have the wiring correct.