Posts made by supertb1

-

RE: CoreXY 1HCL issues 3.5b3posted in Beta Firmware

@dc42, @Phaedrux, @T3P3Tony Any idea why I get this error on start up?

4/27/2023, 9:21:26 PM m122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.5.0-beta.3 (2023-04-14 11:28:15) running on Duet 3 MB6HC v1.02 or later (standalone mode) Board ID: 08DJM-956BA-NA3TJ-6J1F8-3S06R-1U82S Used output buffers: 1 of 40 (40 max) Error in macro line 1 while starting up: Bad command: = === RTOS === Static ram: 154728 Dynamic ram: 118912 of which 200 recycled Never used RAM 69224, free system stack 135 words Tasks: NETWORK(ready,72.2%,207) ETHERNET(nWait,0.0%,401) HEAT(nWait,0.0%,324) Move(nWait,0.0%,243) CanReceiv(nWait,0.0%,772) CanSender(nWait,0.0%,334) CanClock(delaying,0.0%,341) TMC(nWait,16.0%,59) MAIN(running,11.7%,137) IDLE(ready,0.0%,30), total 100.0% Owned mutexes: === Platform === Last reset 02:58:10 ago, cause: software Last software reset at 2023-04-27 18:21, reason: User, Gcodes spinning, available RAM 69224, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0044a000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x04 Aux0 errors 0,0,0 MCU temperature: min 32.1, current 34.7, max 35.4 Supply voltage: min 23.6, current 23.7, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 11.7, current 12.1, max 12.5, under voltage events: 0 Heap OK, handles allocated/used 99/2, heap memory allocated/used/recyclable 2048/28/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0, mspos 680, reads 35246, writes 19 timeouts 0 Driver 1: standstill, SG min 0, mspos 680, reads 35246, writes 19 timeouts 0 Driver 2: standstill, SG min 0, mspos 680, reads 35246, writes 19 timeouts 0 Driver 3: standstill, SG min 0, mspos 680, reads 35247, writes 19 timeouts 0 Driver 4: standstill, SG min n/a, mspos 8, reads 35252, writes 14 timeouts 0 Driver 5: standstill, SG min n/a, mspos 8, reads 35255, writes 11 timeouts 0 Date/time: 2023-04-27 21:19:28 Slowest loop: 27.39ms; fastest: 0.06ms === Storage === Free file entries: 20 SD card 0 detected, interface speed: 25.0MBytes/sec SD card longest read time 2.5ms, write time 0.0ms, max retries 0 === Move === DMs created 125, segments created 3, maxWait 60276ms, bed compensation in use: none, comp offset 0.000 no step interrupt scheduled === DDARing 0 === Scheduled moves 20, completed 20, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.0 === GCodes === Movement locks held by null, null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x0000005 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === Filament sensors === Extruder 0 sensor: ok === CAN === Messages queued 96343, received 171224, lost 0, boc 0 Longest wait 13ms for reply type 6018, peak Tx sync delay 63438, free buffers 50 (min 46), ts 53452/53450/0 Tx timeouts 0,0,1,0,0,0 last cancelled message type 30 dest 127 === Network === Slowest loop: 46.76ms; fastest: 0.03ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0) HTTP sessions: 1 of 8 = Ethernet = State: active Error counts: 0 0 0 1 0 0 Socket states: 5 2 2 2 2 0 0 0 = WiFi = Network state is disabled Module is disabled Failed messages: pending 0, notready 0, noresp 0 Socket states: 0 0 0 0 0 0 0 0 === Multicast handler === Responder is inactive, messages received 0, responses 0 4/27/2023, 9:17:08 PM Error in start-up file macro line 1: Bad command: = -

RE: CoreXY 1HCL issues 3.5b3posted in Beta Firmware

@dc42 I'm not sure what changes need to be made to my homing sequence as listed above, the first line of the sequece shows "M569 P51.0 D0" that should take it out of closed loop and then the axis homes 2 times, then moves to a safe spot and then turns the closed loop feature back on the axis "M569 P51.0 D4" and then performs the polarity detection and zeroing move "M569.6 P51.0 V1" ... as I am typing this I realized that I have the wrong 1HCL listed at the beginning of the sequence...lol... I can't wait for the online configurator to make this stupid proof...lol.

-

RE: CoreXY 1HCL issues 3.5b3posted in Beta Firmware

@dc42 I put the count back to 1000 the one drive.. it was the firmware that gave that feedback in an error as to the read counts.

on the Home sequence instead of M569 P50.0/P51.0 "D0" it should read M569 P50.0/51.0 "D2"? What should the closed loop homing sequence look like with the 3.5.0-B3? -

RE: CoreXY 1HCL issues 3.5b3posted in Beta Firmware

@supertb1 @T3P3Tony @dc42 @Phaedrux Another development that I have now noticed. Why would homing in closed loop on a core XY kick the second axis out of closed loop?

4/25/2023, 9:42:56 AM M122 b50 Diagnostics for board 50: Duet EXP1HCL firmware version 3.5.0-beta.3 (2023-04-14 13:08:48) Bootloader ID: SAME5x bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 53412, free system stack 180 words Tasks: Move(nWait,0.0%,110) HEAT(nWait,0.0%,82) CanAsync(nWait,0.0%,63) CanRecv(nWait,0.0%,43) CanClock(nWait,0.0%,70) TMC(nWait,42.9%,344) CLSend(nWait,0.0%,152) MAIN(running,55.2%,407) IDLE(ready,0.0%,29) AIN(nWait,1.9%,267), total 100.0% Last reset 00:01:39 ago, cause: software Last software reset data not available Closed loop enabled: no, pre-error threshold: 2.00, error threshold: 4.00, encoder type rotaryQuadrature, position 10 Encoder reverse polarity: yes, raw count 65526 Driver 0: pos -116735, 82.5 steps/mm,standstill, SG min 0, mspos 632, reads 57493, writes 42675 timeouts 0, steps req 3 done 1643 Moves scheduled 13, completed 13, in progress 0, hiccups 0, step errors 0, maxPrep 15, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter -5/5, peak Rx sync delay 205, resyncs 0/0, next timer interrupt due in 6 ticks, enabled, next step interrupt due in 4282244676 ticks, disabled VIN voltage: min 24.4, current 24.4, max 24.4 V12 voltage: min 12.2, current 12.2, max 12.2 MCU temperature: min 24.2C, current 24.6C, max 24.9C Last sensors broadcast 0x00000000 found 0 162 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 368, send timeouts 0, received 394, lost 0, free buffers 37, min 37, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 288, adv 37175/37190 Accelerometer: none I2C bus errors 0, naks 0, other errors 0 4/25/2023, 9:42:41 AM G28 X Driver 51.0 basic tuning succeeded, measured backlash 0.091 step 4/25/2023, 9:42:23 AM M122 b51 Diagnostics for board 51: Duet EXP1HCL firmware version 3.5.0-beta.3 (2023-04-14 13:08:48) Bootloader ID: SAME5x bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 53412, free system stack 190 words Tasks: Move(nWait,0.0%,104) HEAT(nWait,0.0%,82) CanAsync(nWait,0.0%,63) CanRecv(nWait,0.0%,43) CanClock(nWait,0.0%,68) TMC(nWait,42.0%,344) CLSend(nWait,0.0%,152) MAIN(running,56.0%,407) IDLE(ready,0.0%,29) AIN(nWait,1.9%,267), total 100.0% Last reset 00:01:06 ago, cause: software Last software reset data not available Closed loop enabled: no, pre-error threshold: 2.00, error threshold: 4.00, encoder type rotaryQuadrature, position 2 Encoder reverse polarity: yes, raw count 65534 Driver 0: pos -81260, 82.5 steps/mm,standstill, SG min 0, mspos 24, reads 12053, writes 29607 timeouts 0, steps req 1 done 4129 Moves scheduled 8, completed 8, in progress 0, hiccups 0, step errors 0, maxPrep 16, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter -6/3, peak Rx sync delay 206, resyncs 0/0, next timer interrupt due in 16 ticks, enabled, next step interrupt due in 4285859782 ticks, disabled VIN voltage: min 24.1, current 24.1, max 24.1 V12 voltage: min 12.0, current 12.0, max 12.1 MCU temperature: min 25.4C, current 25.8C, max 25.8C Last sensors broadcast 0x00000000 found 0 79 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 332, send timeouts 0, received 351, lost 0, free buffers 37, min 37, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 290, adv 36887/36909 Accelerometer: none I2C bus errors 0, naks 0, other errors 0 4/25/2023, 9:42:13 AM M122 b50 Diagnostics for board 50: Duet EXP1HCL firmware version 3.5.0-beta.3 (2023-04-14 13:08:48) Bootloader ID: SAME5x bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 53412, free system stack 180 words Tasks: Move(nWait,0.0%,110) HEAT(nWait,0.0%,82) CanAsync(nWait,0.0%,63) CanRecv(nWait,0.0%,43) CanClock(nWait,0.0%,70) TMC(nWait,40.4%,344) CLSend(nWait,0.0%,152) MAIN(running,56.5%,415) IDLE(ready,1.2%,29) AIN(nWait,1.8%,267), total 100.0% Last reset 00:00:57 ago, cause: software Last software reset data not available Closed loop enabled: yes, pre-error threshold: 2.00, error threshold: 4.00, encoder type rotaryQuadrature, position -1 Encoder reverse polarity: yes, raw count 1 Tuning mode: 0, tuning error: 0, collecting data: no Control loop runtime (us): min=6, max=21, frequency (Hz): min=10563, max=16667 Driver 0: pos -16912, 82.5 steps/mm,ok, SG min 0, mspos 840, reads 48087, writes 36536 timeouts 0, steps req 4 done 5352 Moves scheduled 8, completed 8, in progress 0, hiccups 0, step errors 0, maxPrep 62, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter -6/5, peak Rx sync delay 204, resyncs 0/0, next timer interrupt due in 13 ticks, enabled, next step interrupt due in 4284715151 ticks, disabled VIN voltage: min 24.4, current 24.4, max 24.4 V12 voltage: min 12.2, current 12.2, max 12.2 MCU temperature: min 24.2C, current 24.6C, max 24.6C Last sensors broadcast 0x00000000 found 0 141 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 502, send timeouts 0, received 538, lost 0, free buffers 37, min 37, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 309, adv 36965/37193 Accelerometer: none I2C bus errors 12, naks 0, other errors 0 4/25/2023, 9:42:02 AM G28 Y Driver 50.0 basic tuning succeeded, measured backlash 0.128 step 4/25/2023, 9:41:45 AM M122 b51 Diagnostics for board 51: Duet EXP1HCL firmware version 3.5.0-beta.3 (2023-04-14 13:08:48) Bootloader ID: SAME5x bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 53412, free system stack 194 words Tasks: Move(nWait,0.0%,104) HEAT(nWait,0.0%,86) CanAsync(nWait,0.0%,63) CanRecv(nWait,0.0%,43) CanClock(nWait,0.0%,68) TMC(nWait,39.1%,356) CLSend(nWait,0.0%,152) MAIN(running,55.2%,417) IDLE(ready,3.8%,29) AIN(nWait,1.9%,267), total 100.0% Last reset 00:00:29 ago, cause: software Last software reset data not available Closed loop enabled: yes, pre-error threshold: 2.00, error threshold: 4.00, encoder type rotaryQuadrature, position 4 Encoder reverse polarity: yes, raw count 65532 Tuning mode: 0, tuning error: 0, collecting data: no Control loop runtime (us): min=6, max=21, frequency (Hz): min=11538, max=16667 Driver 0: pos -49086, 82.5 steps/mm,ok, SG min n/a, mspos 8, reads 38729, writes 64036 timeouts 0, steps req 2 done 0 Moves scheduled 4, completed 4, in progress 0, hiccups 0, step errors 0, maxPrep 56, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter -7/3, peak Rx sync delay 202, resyncs 0/0, next timer interrupt due in 8 ticks, enabled, next step interrupt due in 4273061101 ticks, disabled VIN voltage: min 24.1, current 24.1, max 24.1 V12 voltage: min 12.0, current 12.0, max 12.1 MCU temperature: min 25.4C, current 25.6C, max 25.8C Last sensors broadcast 0x00000000 found 0 91 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 273, send timeouts 0, received 278, lost 0, free buffers 37, min 37, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 306, adv 36670/37183 Accelerometer: none I2C bus errors 12, naks 0, other errors 0 4/25/2023, 9:41:37 AM G28 X Driver 51.0 basic tuning succeeded, measured backlash 0.100 step -

RE: 1HCL 1.0 closed loop controllerposted in Duet Hardware and wiring

@T3P3Tony Hi. I am almost scared to update... I am currently working through issues with my new coreXY (https://forum.duet3d.com/topic/32222/corexy-1hcl-issues/2?_=1682288729468). Apparently the close loop tuning maneuver has changed from the previous coding and it may be part of what is going on with this new machine. I will update and see if any errors develope

-

RE: CoreXY 1HCL issues 3.5b3posted in Beta Firmware

@Herve_Smith thanks... apparently I did that wrong on the first line

-

RE: CoreXY 1HCL issues 3.5b3posted in Beta Firmware

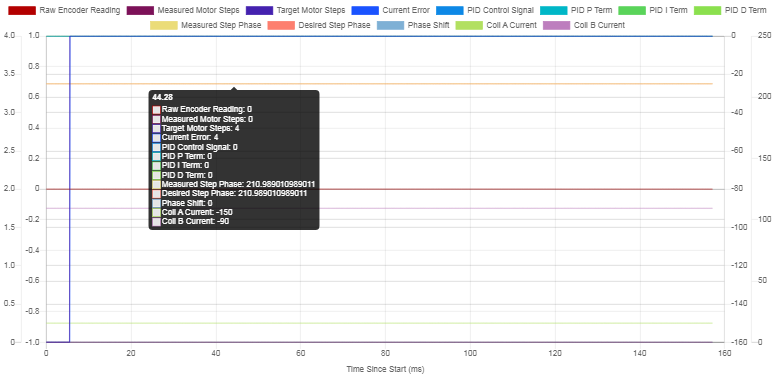

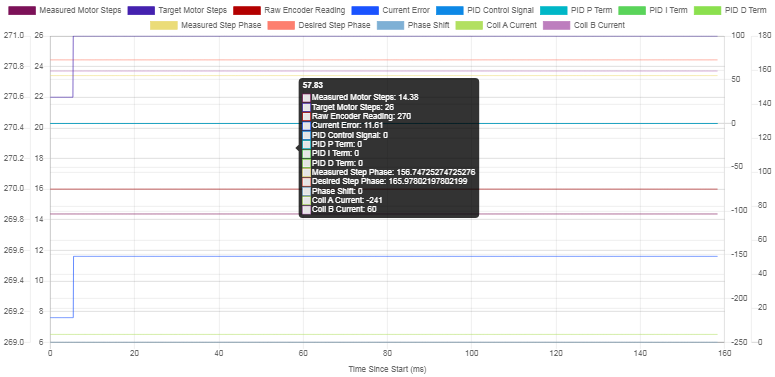

@supertb1 I seen the reverse polarity on P51 so I changed the A+/B+ wires around and now it complains of not being able to calibrate but it shows information on the step maneuver:

51_2023-04-23_04.37.55.csv

-

CoreXY 1HCL issues 3.5b3posted in Beta Firmware

Greetings all (T3P3Toney, DC42, Phaedrux) and any other dev that might be able to help. I am having problems getting my new system to go into closed loop. I have new 1HCL boards (for X/Y), (4) Z axis motors, and an extruder. I am running 3.5.0-B3 on MB6HC and 3.5.0-B3 closed loop plug in. I am running Stepperonline 17E1K-05 100cpr motors (XY) link text My config as follows:

=; Configuration file for Duet 3 MB 6HC (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Tue Mar 07 2023 13:06:17 GMT-0600 (Central Standard Time) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"TRON XY4Z" ; set printer name M669 K1 ; select CoreXY mode ; Wait a moment for the CAN expansion boards to start G4 S2 ; Network M552 P192.168.1.59 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives G4 S1 ; Wait for expansion boards to start M569.1 P50.0 R40 I3000 D0.05 T2 C1000 H80 S200 ; Drive 0 | Y stepper 1000PPR M569.1 P51.0 R40 I3000 D0.05 T2 C939.2 H80 S200 ; Drive 1 | X Stepper 1000PPR. M569 P50.0 D4 S1 ; physical drive 121.0 goes forwards Configure the motor on the 1HCL at can address 50 as being in closed-loop drive mode (D4), Open loop (D2) Not reversed (S1) M569 P51.0 D4 S1 ; physical drive 122.0 goes forwards Configure the motor on the 1HCL at can address 50 as being in closed-loop drive mode (D4), Open loop (D2) Not reversed (S1) M569 P0.0 S1 ; physical drive Z axis 0.0 goes forwards M569 P0.4 S1 ; physical drive Extruder 0.4 goes forwards M584 X51.0 Y50.0 Z0.0:0.1:0.2:0.3 E0.4 ; set drive mapping M671 X-108:476:-108:476 Y15:15:333:333 S10 ;screw 1 (stepper 0) closest to XY home (X-114.3,Y15.875) Screw 2 (stepper 1) near Y switch (X476.25,Y15.875) Screw 3 (stepper2) same side of frame as screw 1 (X-114.3,Y333.375) Screw 4 (stepper3) farthest from XY home (X476.25,Y333.375) M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X82.5 Y82.5 Z402.50 E415.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X1800 Y1800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M917 X15 Y15 ; Set the closed loop axes to have holding current of zero ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X359 Y354 Z360 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!io1.in" ; configure active-high endstop for low end on X via pin !^io1.in M574 Y1 S1 P"!io2.in" ; configure active-high endstop for low end on Y via pin !^io2.in M591 D0 P1 C"!io3.in" S1 ; simple sensor (high signal when filament present) connected to IO_3 for drive 0, enabled M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"io7.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y25 Z3.2 ; set Z probe trigger value, offset and trigger height M557 X50:320 Y50:320 S50 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0 M307 H0 B1 S15.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out2" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 R3.125 K0419:0.162 D4.00 E1.35 S1.00 B0 V24.0 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"out8" Q500 ; create fan 0 on pin out8 and set its frequency M106 P0 C"Tool Fan" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"out7" Q500 ; create fan 1 on pin out7 and set its frequency M106 P1 C"Extruder" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on ; Tools M563 P0 S"Micro-Swiss" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ;Miscellaneous M575 P1 S1 B57600My X/Y homing sequence:

; homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:31 GMT-0600 (Central Standard Time) M569 P50.0 D0 ; Turn off closed loop G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-610 F3000 ; move quickly to X axis endstop and stop there (first pass) G1 H2 X5 F6000 ; go back a few mm G1 H1 X-610 F240 ; move slowly to X axis endstop once more (second pass) G90 ; absolute positioning G1 X10 F3000 ; Move to a known-safe position M400 ; Wait for the move to complete G4 P500 ; Wait for the motor to settle M569 P51.0 D4 ; Turn closed loop back on M569.6 P51.0 V1 ; Perform the tuning manoeuvres for a quadrature encoder G1 X10 F100M122 B50 shows:

4/23/2023, 7:32:24 AM m122 b50 Diagnostics for board 50: Duet EXP1HCL firmware version 3.5.0-beta.3 (2023-04-14 13:08:48) Bootloader ID: SAME5x bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 53412, free system stack 182 words Tasks: Move(nWait,0.0%,104) HEAT(nWait,0.0%,82) CanAsync(nWait,0.0%,63) CanRecv(nWait,0.0%,43) CanClock(nWait,0.0%,68) TMC(nWait,45.0%,344) CLSend(nWait,0.0%,152) MAIN(running,52.9%,417) IDLE(ready,0.0%,29) AIN(nWait,2.0%,267), total 100.0% Last reset 00:40:24 ago, cause: software Last software reset data not available Closed loop enabled: yes, pre-error threshold: 2.00, error threshold: 4.00, encoder type rotaryQuadrature, position -274 Encoder reverse polarity: no, raw count 65262 Tuning mode: 0, tuning error: 0, collecting data: no Control loop runtime (us): min=6, max=38, frequency (Hz): min=10135, max=16667 Driver 0: pos 15673, 82.5 steps/mm,ok, SG min 0, mspos 808, reads 712, writes 52753 timeouts 0, steps req 7 done 6079 Moves scheduled 13, completed 13, in progress 0, hiccups 0, step errors 0, maxPrep 62, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter -6/7, peak Rx sync delay 209, resyncs 0/0, next timer interrupt due in 23 ticks, enabled, next step interrupt due in 2500122050 ticks, disabled VIN voltage: min 24.4, current 24.4, max 24.4 V12 voltage: min 12.2, current 12.2, max 12.2 MCU temperature: min 24.2C, current 24.4C, max 24.6C Last sensors broadcast 0x00000000 found 0 77 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 19454, send timeouts 0, received 21864, lost 0, free buffers 37, min 37, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 316, adv 36955/37189 Accelerometer: none I2C bus errors 12, naks 0, other errors 0M122 B51 shows:

4/23/2023, 7:33:51 AM m122 b51 Diagnostics for board 51: Duet EXP1HCL firmware version 3.5.0-beta.3 (2023-04-14 13:08:48) Bootloader ID: SAME5x bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 53476, free system stack 180 words Tasks: Move(nWait,0.0%,110) HEAT(nWait,0.0%,82) CanAsync(nWait,0.0%,63) CanRecv(nWait,0.0%,43) CanClock(nWait,0.0%,70) TMC(nWait,40.3%,344) CLSend(nWait,0.0%,152) MAIN(running,57.8%,407) IDLE(ready,0.0%,29) AIN(nWait,1.8%,267), total 100.0% Last reset 00:41:52 ago, cause: software Last software reset data not available Closed loop enabled: no, pre-error threshold: 2.00, error threshold: 4.00, encoder type rotaryQuadrature, position 190 Encoder reverse polarity: yes, raw count 65346 Driver 0: pos -113434, 82.5 steps/mm,standstill, SG min 0, mspos 904, reads 16668, writes 2491 timeouts 0, steps req 4 done 8410 Moves scheduled 12, completed 12, in progress 0, hiccups 0, step errors 0, maxPrep 54, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter -7/6, peak Rx sync delay 198, resyncs 0/0, next timer interrupt due in 13 ticks, enabled, next step interrupt due in 2456048963 ticks, disabled VIN voltage: min 24.1, current 24.1, max 24.2 V12 voltage: min 12.0, current 12.0, max 12.1 MCU temperature: min 25.2C, current 25.6C, max 25.6C Last sensors broadcast 0x00000000 found 0 47 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 20139, send timeouts 0, received 22639, lost 0, free buffers 37, min 37, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 307, adv 36688/37174 Accelerometer: none I2C bus errors 8, naks 0, other errors 0any help would be great

-

RE: 1HCL position failure home position G-codeposted in General Discussion

@dc42 Please consider this issue closed, I can't wait for Mr. Rosario's Closed loop tuner pluggin to be available. The guy is so good at this platform and well worth the investment..

-

RE: 1HCL position failure home position G-codeposted in General Discussion

@OwenD

Hey I wanted to thank one of my friends who knows this system pretty well, he suggested that i kept it simple and only used one command to solve my problem that I have been working to solve and this is what he came up with.;driver-error.g echo "Driver error has occurred" echo param.S ; send error message to console ;M83 ; relative extruder moves ;G1 E-10 F3600 ; retract 10mm of filament ;G90 ; relative positioning ;G1 Z5 F360 ; lift Z by 5mm ;G1 X0 Y0 F6000 ; go to X=0 Y=0 M25Thanks for your help again @OwenD

-

RE: 1HCL position failure home position G-codeposted in General Discussion

@OwenD

I'm not trying to be anything but 1)most importantly seeking answers to this issue 2)humbled by this experience ...as it is for me to be a little ignorant and learning from someone who obviously knows more about this than I do.

Maybe I do not know the correct responses to your questions which is why I have been asking for a step by step solution to this problem as if maybe everyone who is using MB3 6HC in conjuction with 1HCL boards might be experiencing. I don't know, I can only assume the people over at Duet3d have run into this issue @dc42.

I apologize if maybe I have offended anyone in this conversation. I hope that through your networks/groups a simple solution can be found so that in the future anyone with this issue can find a solution by simply looking and finding it here. -

RE: 1HCL position failure home position G-codeposted in General Discussion

@OwenD

No what I am saying is that while the system is running a program a manual move from intended path returns the ""Error: attempting to extrude with no tool selected." fault on the PanelDue 7." and then the aforementioned behavior ensues. And no I usually do not preheat the tool, that is in the gcode of the slicer app and yes the overall behaviour of any kind of motor stall of the X-Y axis needs to be "Go to the pause location" IE home Z+5. That is the ultamate goal -

RE: 1HCL position failure home position G-codeposted in General Discussion

@OwenD

"</>drive-error.g

Is this a typo?

The file should be driver-error.g"

no this was me learning to use this sites text box."This would try to go to X0 Y0 for any driver error, but if a driver is in error state, that may not be possible.

driver-stall.g"

in closed loop the machine knows where it is at all times. however if the motor failed or the drive board "1HC" failed I am sure the system wouldn't function as intended, I have not had this issue yet.

"Again, you are trying to go to X0 Y0

What happens when you force a driver to stall?

Does the machine move to X0 Y0?

Note, that you have not re-homed the axis, so it may move to where it "thinks" X0 Y0 is, but if it had already skipped many steps then it may end up somewhere entirely different.

EDIT: I don't know exactly how running closed loop will fit into this. It's possible the motor can stall and not lose track of position. That's the whole idea I guess."

Correct."</>homeall.g (wich I do not use because it doesn't work)

What doesn't work?

What happens when you issue G28?

I note you have no M569.1 commands in this file, but yo do in homex.g and homey.g; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:31 GMT-0600 (Central Standard Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-605 Y-605 F1800 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X5 Y5 F6000 ; go back a few mm G1 H1 X-605 Y-605 F360 ; move slowly to X and Y axis endstops once more (second pass) G90 ; absolute positioning G1 X10 Y10 F6000 ; go to first bed probe point and home Z G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioningIt causes the machine to wait for a count of 2 minutes and then it homes the X axis, then the Z axis, then the X axis again, and then the Z axis again. this feature has never worked correctly while the 1HC boards have been in use. It worked fine when I had the axis drivers on the main board.

"Again, what does it do now when there is a stall.

"Like it used to"?

When did it do that?

What has changed since then? e.g. Firmware? From what version to what version?"

Before 3.0 the system would send the axis back to home on a "failure to maintain position" I believe. it is only been in the last year that I have began to have this problem.11/7/2022, 8:51:38 AM M115 B50 Duet EXP1HCL firmware version 3.4.4 (2022-10-14 11:45:14) 11/7/2022, 8:52:07 AM M115 B51 Duet EXP1HCL firmware version 3.4.4 (2022-10-14 11:45:14)with the stall and error.g files as they are, a manual move from position generates a "Error: attempting to extrude with no tool selected." fault on the PanelDue 7.

Running a simple bed leveling program and causing a stall causes the print head to move toward home but then it raises the print head 5mm and then it goes back out to print... so wierd.11/7/2022, 9:04:07 AM Resume state saved 11/7/2022, 9:03:46 AM Driver error has occurred Driver 50.0 error: failed to maintain position 11/7/2022, 9:03:29 AM Driver error has occurred Driver 50.0 error: failed to maintain position 11/7/2022, 9:02:54 AM Driver error has occurred Driver 50.0 error: failed to maintain position 11/7/2022, 9:00:02 AM Error: Attempting to extrude with no tool selected. 11/7/2022, 8:57:24 AM Driver error has occurred Driver 50.0 error: failed to maintain position 11/7/2022, 8:54:27 AM Driver error has occurred Driver 50.0 error: failed to maintain position Error: Attempting to extrude with no tool selected. 11/7/2022, 8:54:06 AM Error: Attempting to extrude with no tool selected. 11/7/2022, 8:53:58 AM Driver error has occurred Driver 51.0 error: failed to maintain positionso the drive-error.g and the driver-stall.g will not work as they are currently. But we are getting somewhere, at least it isn't just stopping in the middle of the print anymore.

-

RE: 1HCL position failure home position G-codeposted in General Discussion

code_text ```; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:31 GMT-0600 (Central Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Colossus Openbuild" ; set printer name ; Network M552 P192.168.1.65 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives G4 S1 ;wait for expansion boards to start M569.1 P50.0 T2 C5 E5:10 ; Configure the 1HCL board at CAN address 50 with a quadrature encoder on the motor shaft that has 20 steps per motor full step. M569.1 P51.0 T2 C5 E5:10 ; Configure the 1HCL board at CAN address 51 with a quadrature encoder on the motor shaft that has 20 steps per motor full step. M569 P50.0 D4 S1 ; Configure the motor on the 1HCL at can address 50 as being in closed-loop drive mode (D4), Open loop (D2) and not reversed (S1) X axis M569 P51.0 D4 S1 ; Configure the motor on the 1HCL at can address 51 as being in closed-loop drive mode (D4), Open loop (D2) and not reversed (S1) Y axis M569 P0.0 S1 ; physical drive 0.0 goes forwards Z 1-2 axis M569 P0.4 S1 ; physical drive 0.4 goes forwards Extruder M584 X50.0 Y51.0 Z0.0:0.1 E0.4 ; set drive mapping M671 X-122.25:689.20 Y0:0 S3.0 ; leadscrews at left (connected to Z0) and right (connected to Z1) of X axis M350 X32 Y32 Z32 E16 I1 ; configure microstepping with interpolation M92 X106.5 Y257 Z795.00 E339.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X1000 Y3000 Z3000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M917 X10 Y0 ; Set the closed loop axes to have a holding current of zero ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X609 Y609 Z762 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!^io1.in" ; configure active-high endstop for low end on X via pin !^io1.in M574 Y1 S1 P"!^io2.in" ; configure active-high endstop for low end on Y via pin !^io2.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z M591 D0 P7 C"io5.in" L7 R55:150 E22 S1 ;Bigtree smart filament moniter v2 set to moniter between 55%-150% of 7 counts over a distance of 22mm M591 D0 ; display filament sensor parameters for extruder drive 4 M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"^io7.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P100 X60 Y0 Z2.68 ; set Z probe trigger value, offset and trigger height M557 X100:500 Y100:500 S100 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0 M307 H0 B1 S10.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S110 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out2" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"out8" Q500 ; create fan 0 on pin out8 and set its frequency M106 P0 C"Tool Fan" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"out6" Q500 ; create fan 1 on pin out6 and set its frequency M950 F2 C"out7" Q500 ; create fan 2 on pin out7 and set its frequency M106 P1 C"Extruder" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on ; Tools M563 P0 S"Hemera" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue </>drive-error.g ; pause.g ; called when a print from SD card is paused ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:32 GMT-0600 (Central Standard Time) M83 ; relative extruder moves G1 E-10 F3600 ; retract 10mm of filament G91 ; relative positioning G1 Z5 F360 ; lift Z by 5mm G90 ; absolute positioning G1 X0 Y0 F6000 ; go to X=0 Y=0 </>driver-stall.g ; pause.g ; called when a print from SD card is paused ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:32 GMT-0600 (Central Standard Time) M83 ; relative extruder moves G1 E-10 F3600 ; retract 10mm of filament G91 ; relative positioning G1 Z5 F360 ; lift Z by 5mm G90 ; absolute positioning G1 X0 Y0 F6000 ; go to X=0 Y=0 </>homeall.g (wich I do not use because it doesn't work) ; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:31 GMT-0600 (Central Standard Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-605 Y-605 F1800 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X5 Y5 F6000 ; go back a few mm G1 H1 X-605 Y-605 F360 ; move slowly to X and Y axis endstops once more (second pass) G90 ; absolute positioning G1 X10 Y10 F6000 ; go to first bed probe point and home Z G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioning </>; homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:31 GMT-0600 (Central Standard Time) M569 P50.0 D0 ; Turn off closed loop G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-240 F3000 ; move quickly to X axis endstop and stop there (first pass) G1 H2 X5 F6000 ; go back a few mm G1 H1 X-240 F240 ; move slowly to X axis endstop once more (second pass) G90 ; absolute positioning G1 X50 F3000 ; Move to a known-safe position M400 ; Wait for the move to complete G4 P500 ; Wait for the motor to settle M569 P50.0 D4 ; Turn closed loop back on M569.6 P50.0 V31 ; Perform the tuning manoeuvres for a quadrature encoder G1 X0 ; Move back to X0 G1 H2 Z0 F6000 ; lower Z again </>Home Y ; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:32 GMT-0600 (Central Standard Time) M569 P51.0 D0 ; Turn off closed loop G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 Y-240 F3000 ; move quickly to X axis endstop and stop there (first pass) G1 H2 Y5 F6000 ; go back a few mm G1 H1 Y-240 F240 ; move slowly to X axis endstop once more (second pass) G90 ; absolute positioning G1 Y25 F3000 ; Move to a known-safe position M400 ; Wait for the move to complete G4 P500 ; Wait for the motor to settle M569 P51.0 D4 ; Turn closed loop back on M569.6 P51.0 V31 ; Perform the tuning manoeuvres for a quadrature encoder G1 Y0 ; Move back to X0 G1 H2 Z0 F6000 ; lower Z again </> pause.g ; pause.g ; called when a print from SD card is paused ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:32 GMT-0600 (Central Standard Time) M83 ; relative extruder moves G1 E-10 F3600 ; retract 10mm of filament G91 ; relative positioning G1 Z5 F360 ; lift Z by 5mm G90 ; absolute positioning G1 X0 Y0 F6000 ; go to X=0 Y=0 / </>11/6/2022, 7:38:44 PM M115 B0 FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.4.4 ELECTRONICS: Duet 3 MB6HC v1.01 FIRMWARE_DATE: 2022-10-20 16:19:01 / </>11/6/2022, 7:39:24 PM M115 B1 Error: M115: Response timeout: CAN addr 1, req type 6024, RID=14 / </>11/6/2022, 7:40:03 PM M115 B2 Error: M115: Response timeout: CAN addr 2, req type 6024, RID=15 / Issue at hand: when my printer fails to maintain position or the X-Y steppers stalls I want it to move my print head to home position Z+5 like it used to do. -

RE: 1HCL position failure home position G-codeposted in General Discussion

@dc42 you know what would make this all alot easier is if I could simply change the default process from "Pause print without running pause.g and inform user via message box" to "Pause print using pause.g and inform user via message box" How do I do that? Or better yet, can I get a firmware update that has that change in it?

-

RE: 1HCL position failure home position G-codeposted in General Discussion

@OwenD Hello, I made a file (driver-stall.g) in my .sys directory and dropped the example in there. then I entered M957 E"driver-stall" D1 in my command line and it returned "M957 E"driver-stall" D1

Warning: Driver 0.1". now it does not recognize my tool, it immediately causes my X axis to fail to maintain position. so the settings in the stall file need to be adjusted. Ok I have a Duet 3 6HC, "2" 1HCL boards (P50,P51) X and Y respectively. "2" Z axis motors (0,1) on the main board. The extruder is on (4). do I need to place the physical address of the drives that are on the boards inside the [0] on the command lines for this driver stall.g and how would the Z axis look on the command line? move.axes[0,1]? I tried to enter the actual board addresses in the command lines and it still does not recognize the tool. ok.. so I don't think your model as it is will work for my setup. I tried your ";driver-stall.gG60 S3 ; save position to slot 3G28 X Y ; home X & YG1 R3 X0 Y0 Z0 ; Move back to saved position" line and it causes my machine to forget the X and Z axis home at the start of my print end the program and then home the X and Z axis so that is not going to work either. What changes need to be made to these examples to help make them work for my applications? what information can I give to you to help with this process?