Hi Guys!

Been lurking around here for a while and want to get some input on my build.

I've worked with printers, lasers and other NC-machines for a while, but this is my first 3d-printer build.

My main goal is to build a rigid quality machine. Hopefully it will be able to maintain quality at high speeds (hopefully 200-300mm/s).

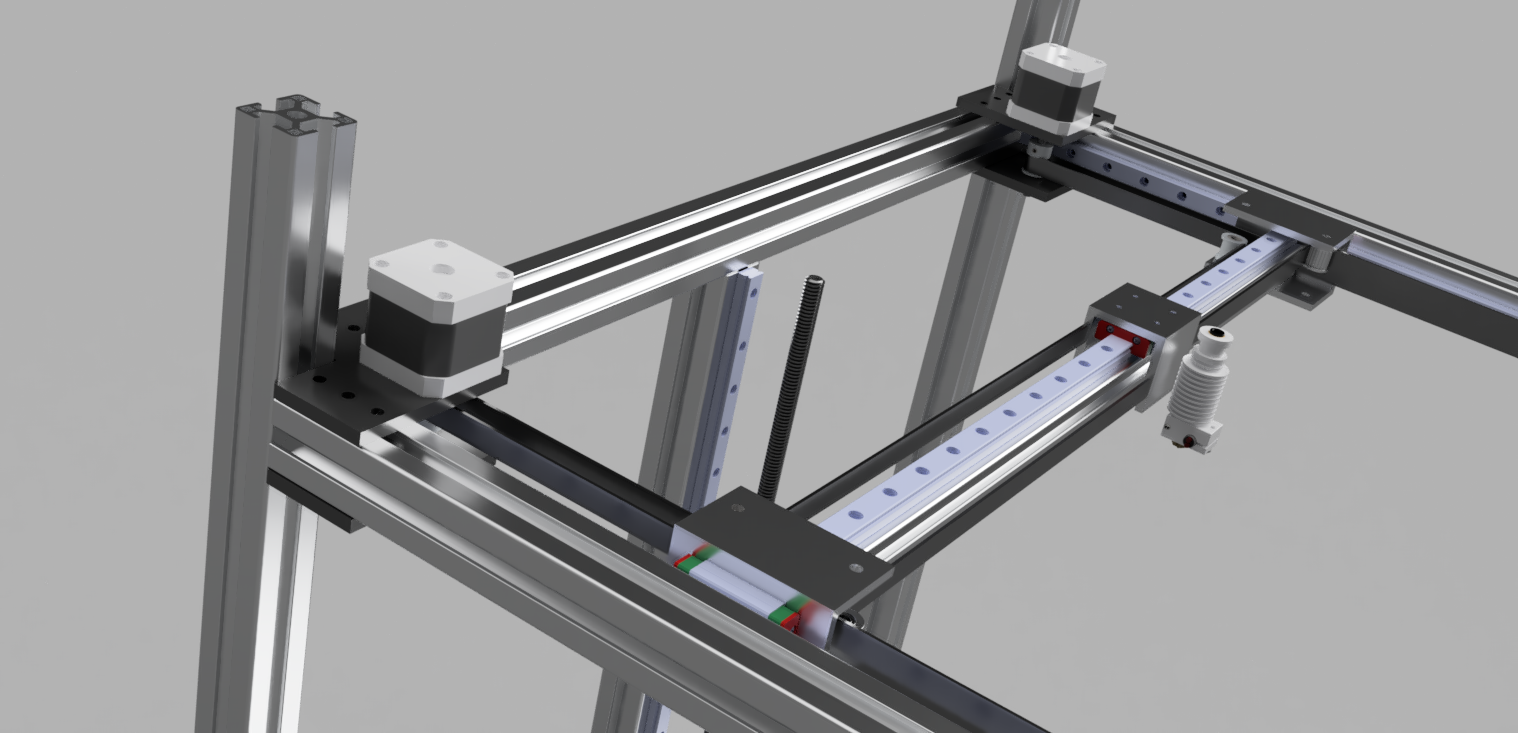

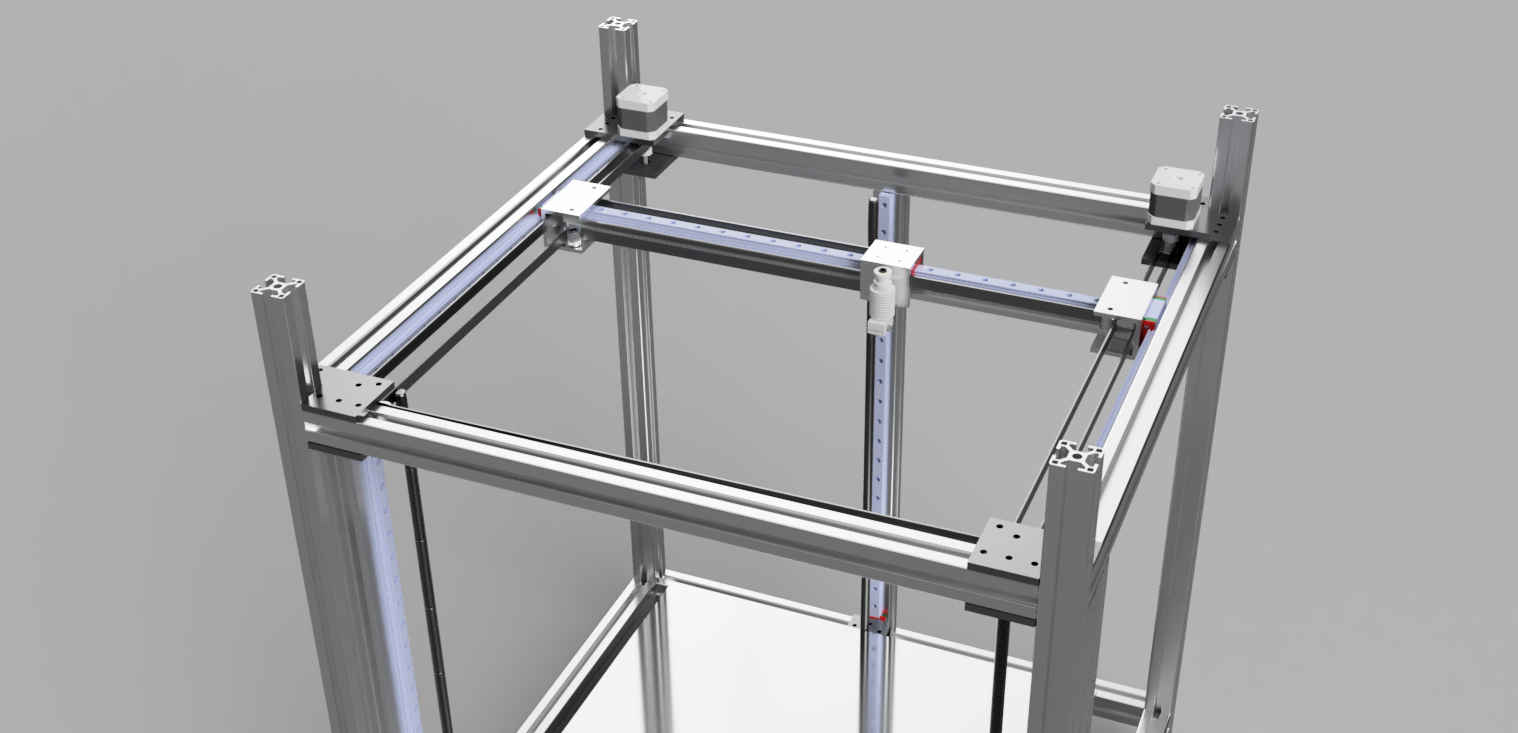

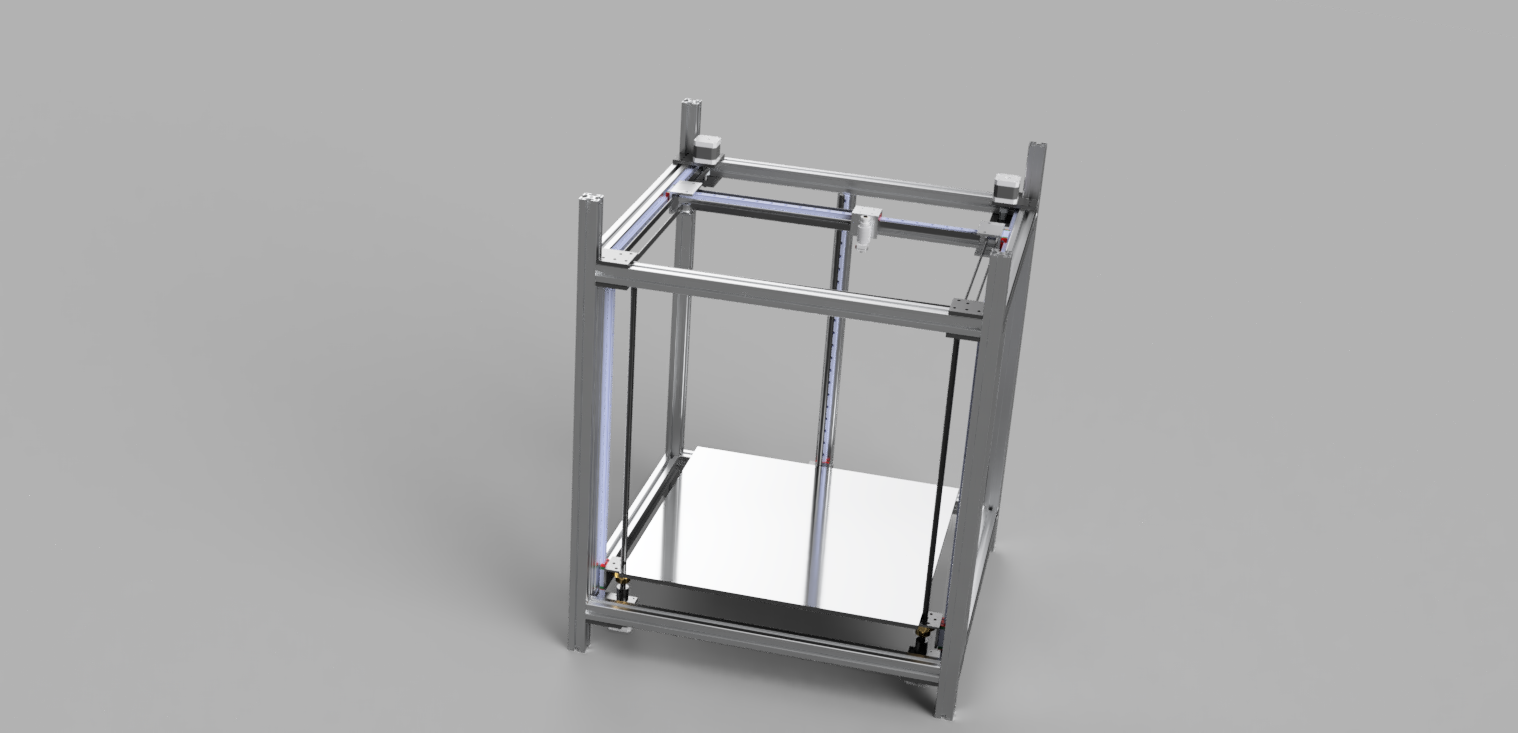

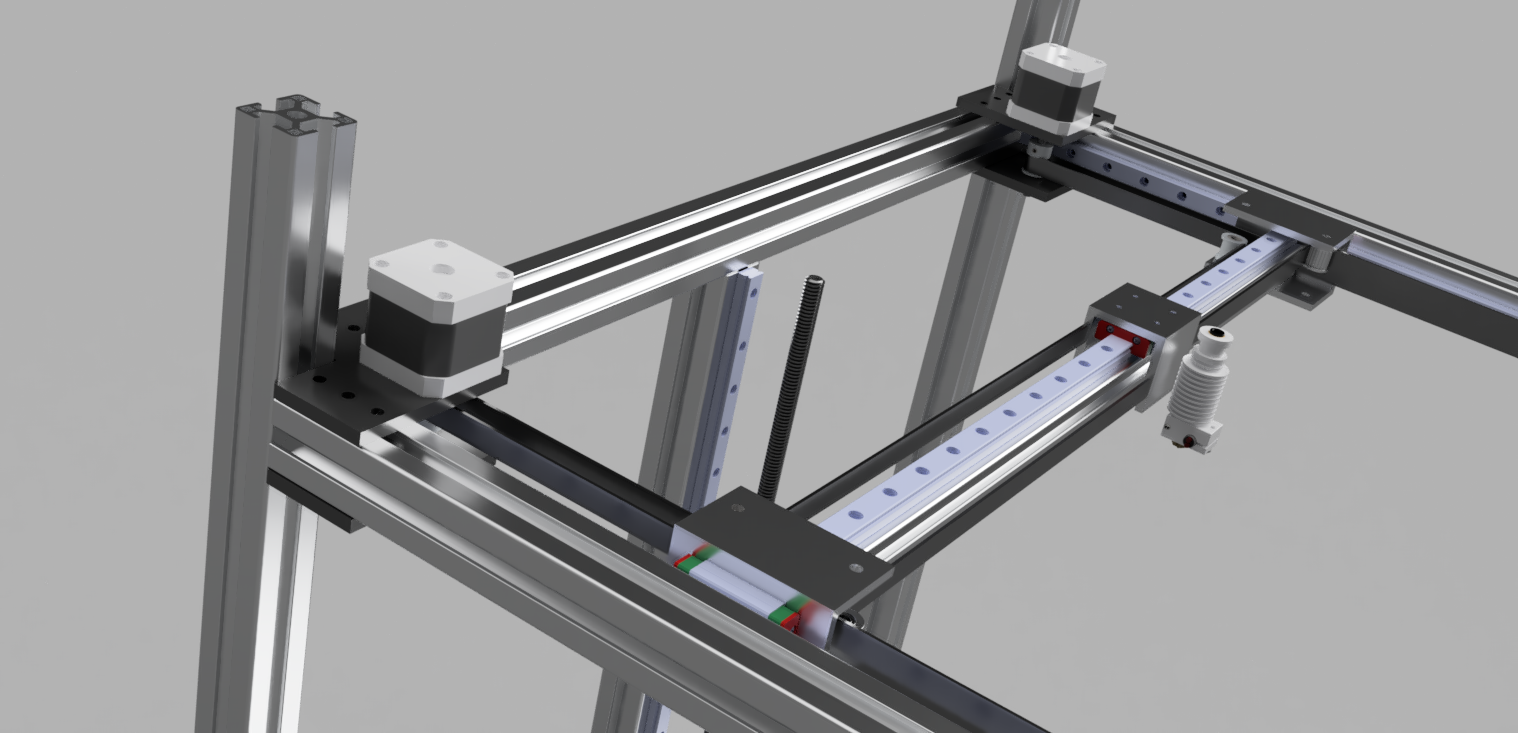

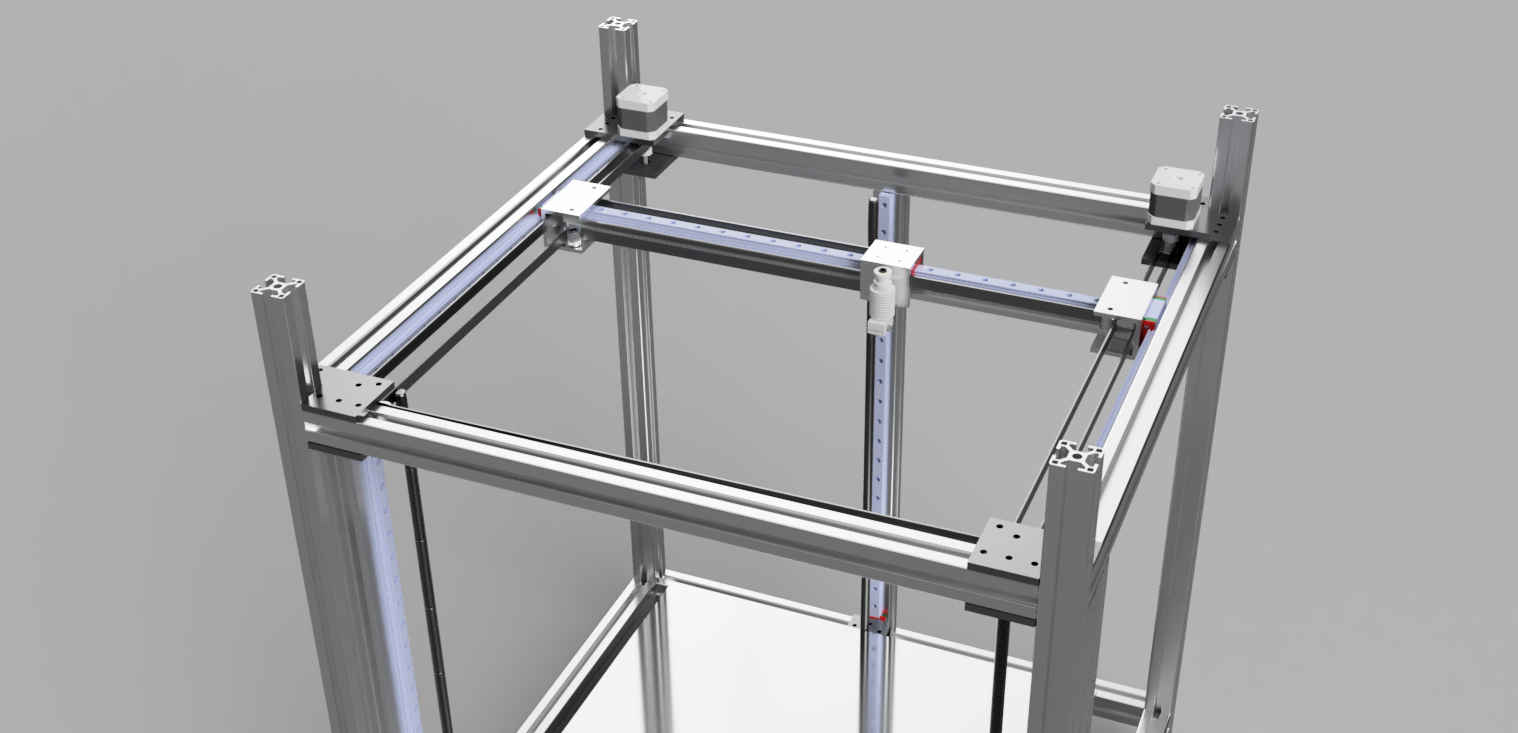

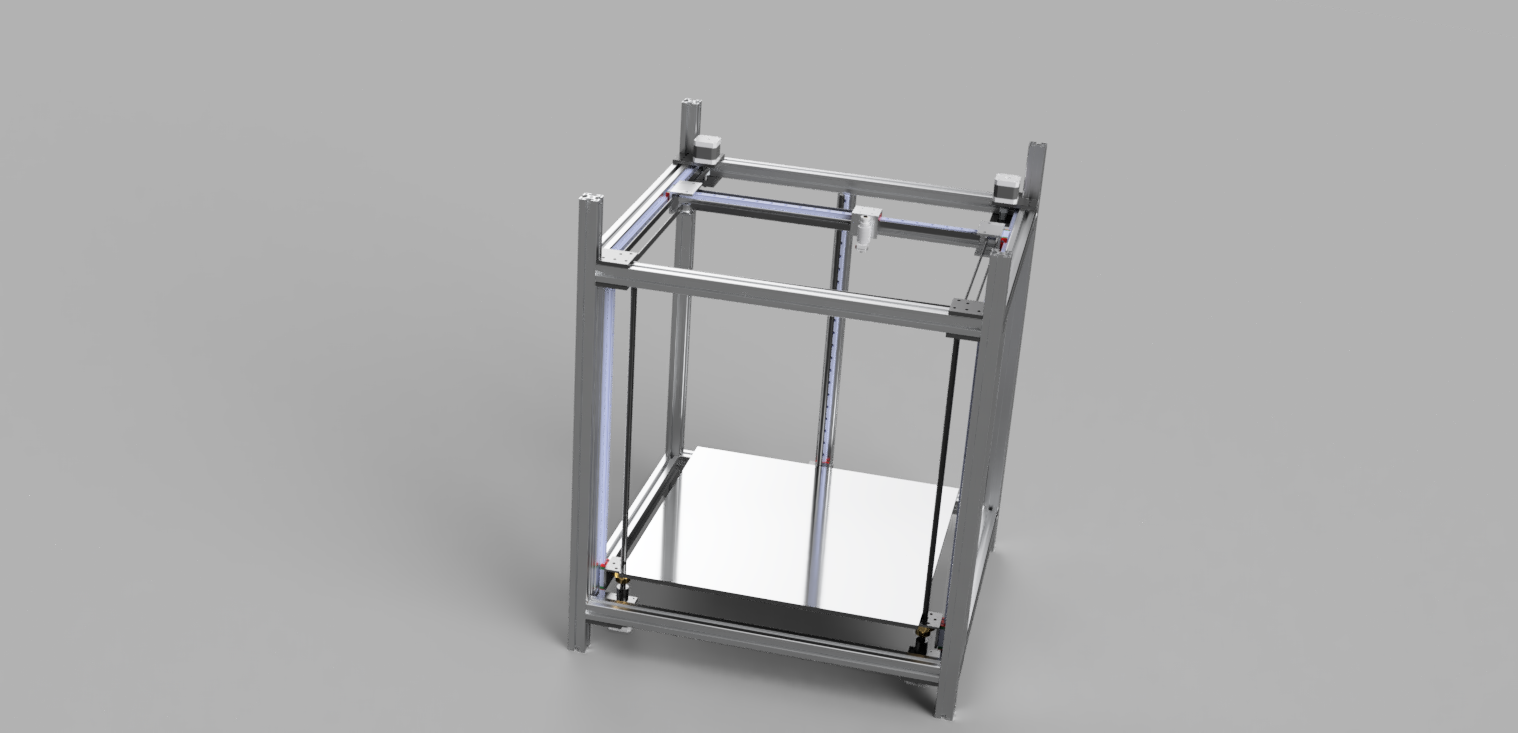

To give some perspective, the extrusions are 30x30mm and the aluminium bed measures 500x500 (printable area ca 400x400mm)

I wont take credit for the design, it's heavily inspired by 3d distributed [3ddistributed.com] but I also looked at railcore, BLV-Cube etc. for inspiration.

Any opinions, really don't want to make any rookie mistakes since it's my first build.

Thoughts and questions:

-

Belt path? I chose to place the 9mm GT2 belts inside the frame (instead of the more common approach to put it above the frame) for two reasons - easier to enclose, and primarily because I imagine it will be more rigid since all moving parts are in the same plane (?) The cost is of cause a bit of print are. Would any other belt path design be more rigid?

-

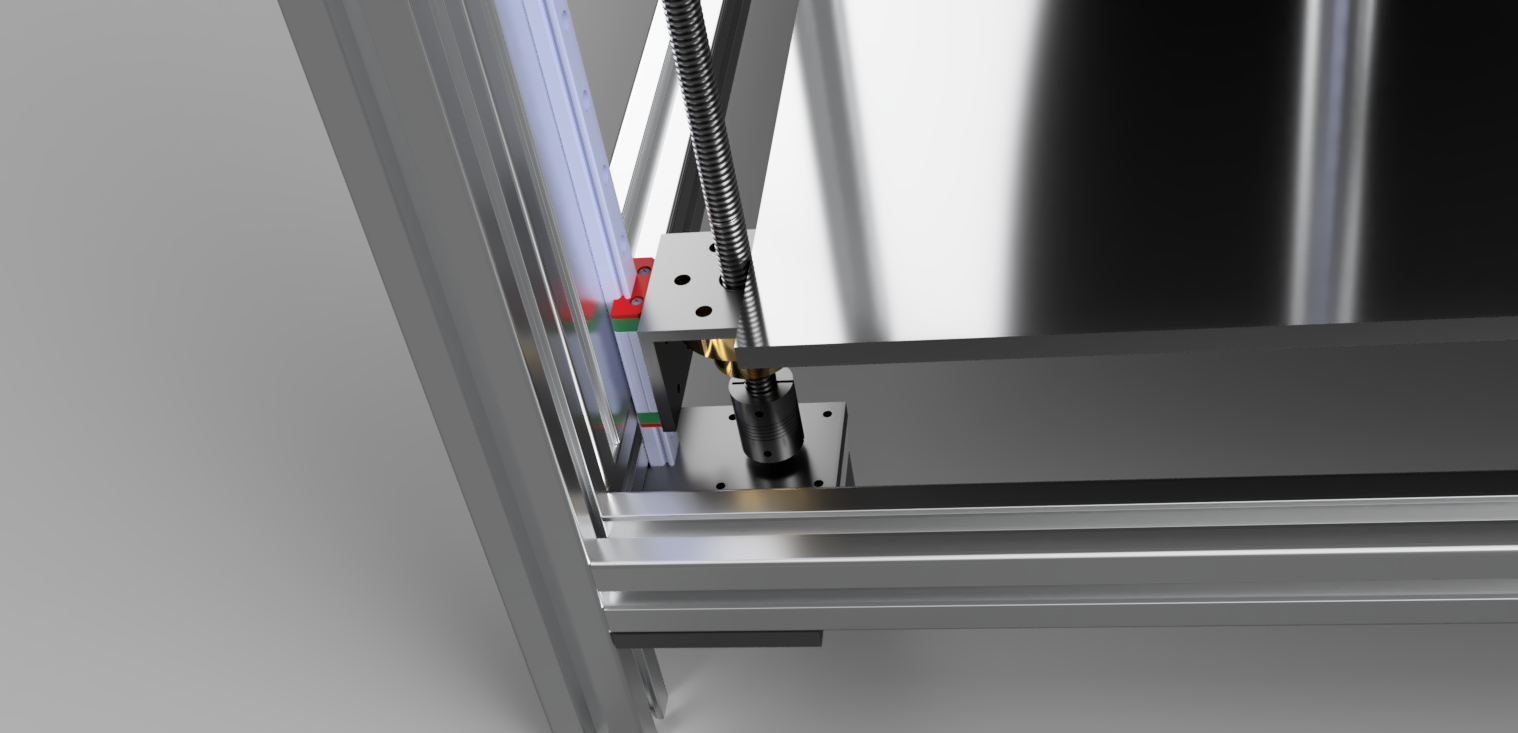

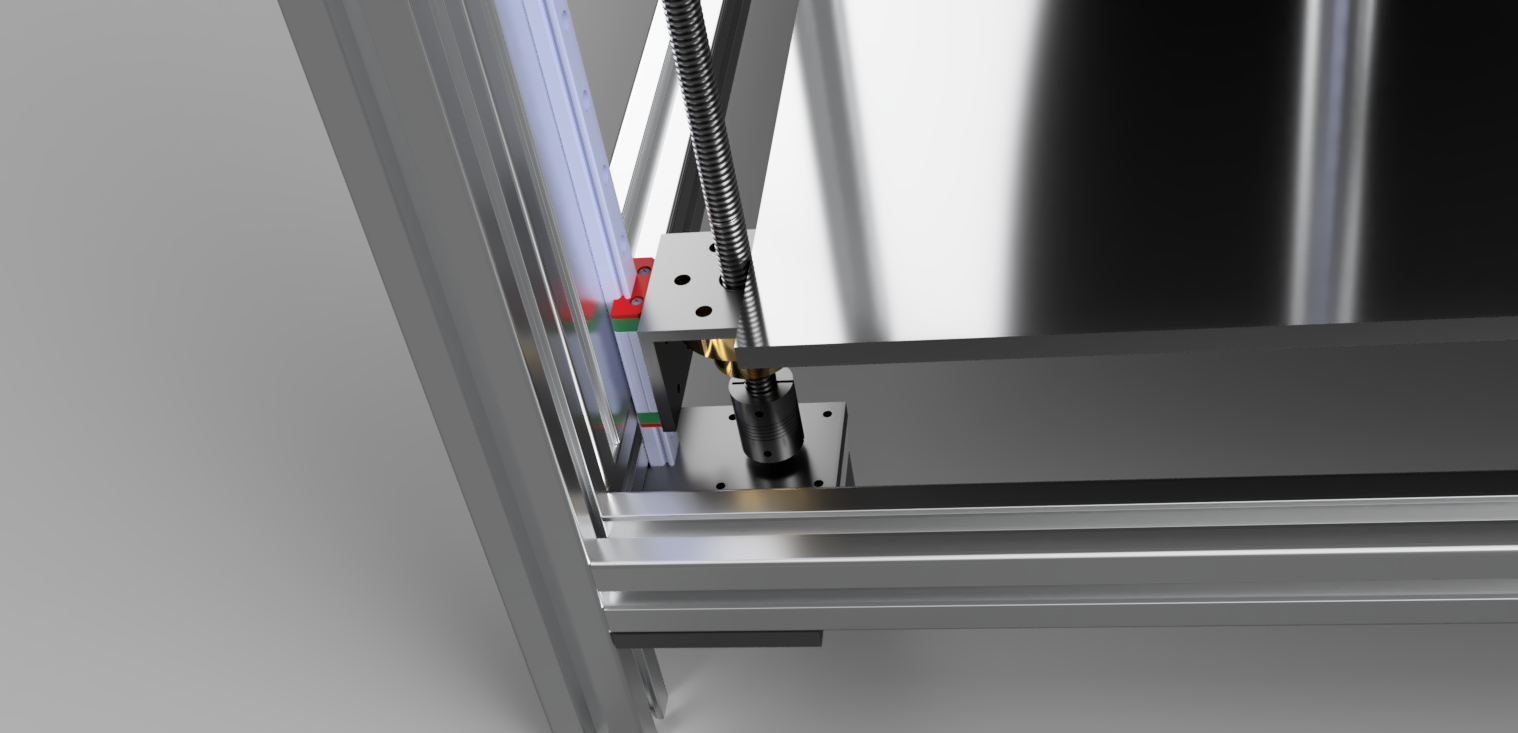

Z-axis mount? How would you fasten the aluminium tool plate in the angle mounts? I'm thinking of placing a spring washer or a short spring between the screw and the mount to allow some movement for heat expansion and allow the independent Z axis motors to do their job.Would that be sufficent? Is it preferable to have the linear guide and lead screw in axis as on the pictures, or should them be placed side by side or any other way?

-

Torque? Im planning on using these 59Ncm steppers, but with a custom ordered longer shaft so I can fit the big pulleys and a bearing supporting the long shaft [www.omc-stepperonline.com]

How much does the pulley weight affect the speed/acceleration/quality? Lighter is better ofc, I've looked at the Zesty Nimble as a extruder, but how much would 150g stepper motor affect the performance?

-

I'm planning on running the Duet3 on 32v to give the steppers voltage to overcome the EMF at high speeds. Is that a bad idea? Would this require active stepper cooling? How do I feed 24v to the hotend, buck-converter or separate power supply?

-

Rigidity? The motor and idler-mounts will reinforce the corners, and I will also add corner brackets on the outside and the enclosure will also provide some rigidity. the motor mounts are 6mm and the U-profile used for the gantry is 4mm. Is that enough?

Do you see any design flaws?

What would you say the "weakest link" in the design is?

Please let me know what you think and please ask questions if the renderings are unclear (I haven't placed out all the screws etc. yet).