I recognize an RC is out, and should update to that. Error here may already be solved in future builds, but wanted to post anyways.

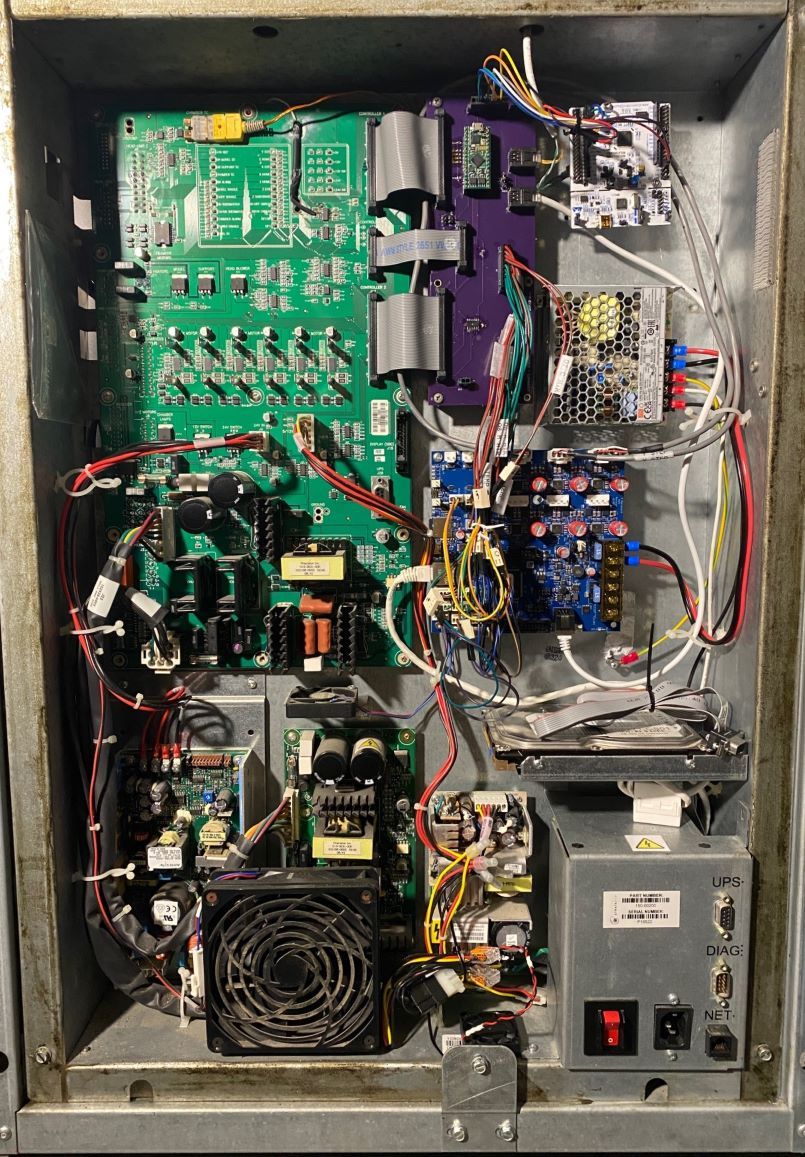

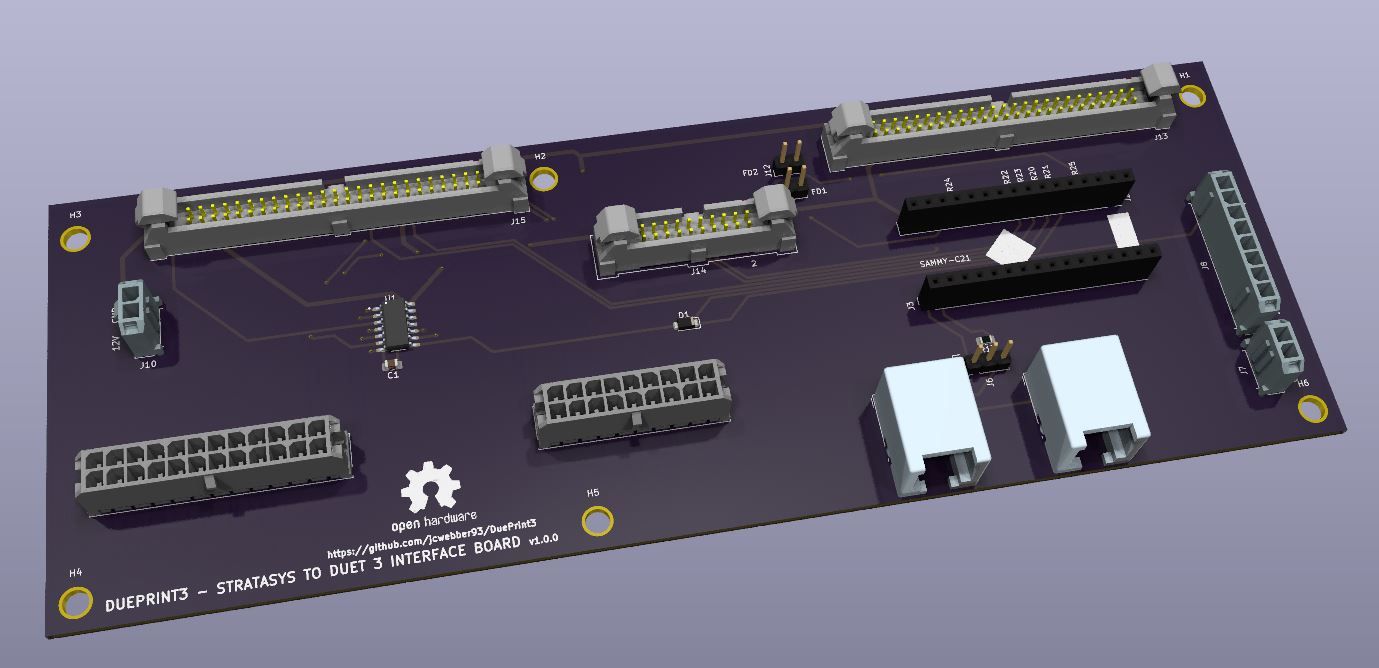

Commissioning a 'new' build - 6HC, Sammy-C21 as an expansion driving an external extruder motor. Walked up to the printer and witnessed the halt in real time.

Paused in layer 86 of the attached print file: CFFFP_3DBenchy.gcode

Error: Movement halted because a step timing error occurred on drive 0 (code 2). Please reset the controller.

Error: Extra info=-9.765625e-4

M122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.6.0-beta.3+1 (2025-01-20 20:04:23) running on Duet 3 MB6HC v1.02b or later (standalone mode)

Board ID: 08DJM-9P63L-DJMSS-6J1D8-3SD6T-9VDZ8

Used output buffers: 1 of 40 (33 max)

=== RTOS ===

Static ram: 136892

Dynamic ram: 129160 of which 0 recycled

Never used RAM 76300, free system stack 130 words

Tasks: NETWORK(1,ready,33.1%,180) ETHERNET(5,nWait 7,0.1%,316) HEAT(3,nWait 6,0.0%,323) Move(4,invalid,0.5%,215) TMC(4,nWait 6,3.0%,341) CanReceiv(6,nWait 1,0.0%,769) CanSender(5,nWait 7,0.0%,327) CanClock(7,delaying,0.0%,341) MAIN(1,running,63.3%,440) IDLE(0,ready,0.0%,29) USBD(3,blocked,0.0%,149), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:56:44 ago, cause: software

Last software reset at 2025-03-28 16:39, reason: User, Gcodes spinning, available RAM 76492, slot 2

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

MCU temperature: min 41.2, current 42.3, max 42.6

Supply voltage: min 47.5, current 48.0, max 48.3, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.1, current 12.3, max 12.5, under voltage events: 0

Heap OK, handles allocated/used 99/8, heap memory allocated/used/recyclable 2048/156/40, gc cycles 0

Events: 0 queued, 0 completed

Date/time: 2025-03-28 17:36:38

Slowest loop: 211.09ms; fastest: 0.07ms

USB interrupts 2

=== Storage ===

Free file entries: 19

SD card 0 detected, interface speed: 25.0MBytes/sec

SD card longest read time 2.8ms, write time 70.4ms, max retries 0

=== Move ===

Segments created 71, maxWait 485690ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00/53.45ms), max steps late 1, ebfmin 0.00, ebfmax 0.00

Pos req/act/dcf: 483.00/384/1.00 1953.00/2046/-1.00 11564.00/11564/-0.00

next step interrupt due in 214 ticks, disabled

Driver 0: standstill, SG min 0, mspos 648, reads 58364, writes 65 timeouts 3

Driver 1: standstill, SG min 0, mspos 24, reads 58364, writes 65 timeouts 3

Driver 2: standstill, SG min 0, mspos 696, reads 58364, writes 65 timeouts 3

Driver 3: standstill, SG min n/a, mspos 8, reads 58385, writes 44 timeouts 3

Driver 4: standstill, SG min n/a, mspos 8, reads 58385, writes 44 timeouts 3

Driver 5: standstill, SG min n/a, mspos 8, reads 58385, writes 44 timeouts 3

Phase step loop runtime (us): min=0, max=501, frequency (Hz): min=672, max=10416

=== DDARing 0 ===

Scheduled moves 55178, completed 55119, LaErrors 0, Underruns [0, 0, 0]

Segments left 1, axes/extruders owned 0x80000007, drives owned 0x80000007

Code queue is empty

=== DDARing 1 ===

Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0]

Segments left 0, axes/extruders owned 0x00000000, drives owned 0x00000000

Code queue is empty

=== Heat ===

Bed heaters -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters 0 -1 -1 -1 -1 -1 -1 -1, ordering er=== GCodes ===

Movement locks held by null, null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is doing "G1 X19.803 Y1.127 E0.01883" in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

File2 is idle in state(s) 0

Queue2 is idle in state(s) 0

=== CAN ===

Messages queued 80102, received 27247, lost 0, ignored 0, errs 2684, boc 0

Longest wait 1ms for reply type 6018, peak Tx sync delay 46148, free buffers 50 (min 49), ts 16135/16132/0

Tx timeouts 0,0,2,0,0,0 last cancelled message type 30 dest 127

=== Network ===

Slowest loop: 204.57ms; fastest: 0.03ms

Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0)

HTTP sessions: 2 of 8

= Ethernet =

Interface state: active

Error counts: 0 0 0 1 0 0

Socket states: 6 2 2 2 2 0 0 0 0

=== WiFi ===

Interface state: disabled

Module is disabled

Failed messages: pending 0, notrdy 0, noresp 0

Socket states: 0 0 0 0 0 0 0 0

=== Multicast handler ===

Responder is inactive, messages received 0, responses 0

M122 B124

Diagnostics for board 124:

Duet SAMMYC21 firmware version 3.6.0-beta.3+1 (2025-01-20 20:01:57)

Bootloader ID: not available

All averaging filters OK

Never used RAM 9444, free system stack 71 words

Tasks: Move(3,nWait 7,0.2%,86) HEAT(2,nWait 6,0.1%,128) CanAsync(5,nWait 4,0.0%,66) CanRecv(3,nWait 1,0.1%,70) CanClock(5,nWait 1,0.0%,58) MAIN(1,running,98.3%,436) IDLE(0,ready,0.0%,26) AIN(2,delaying,1.3%,120), total 100.0%

Owned mutexes:

Last reset 01:11:39 ago, cause: software

Last software reset data not available

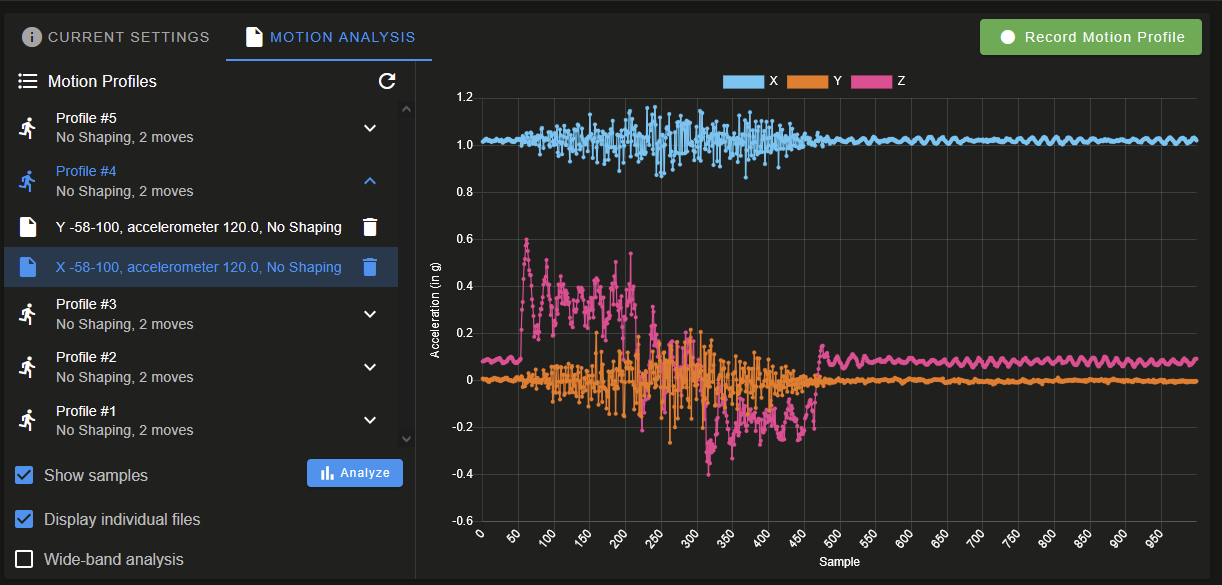

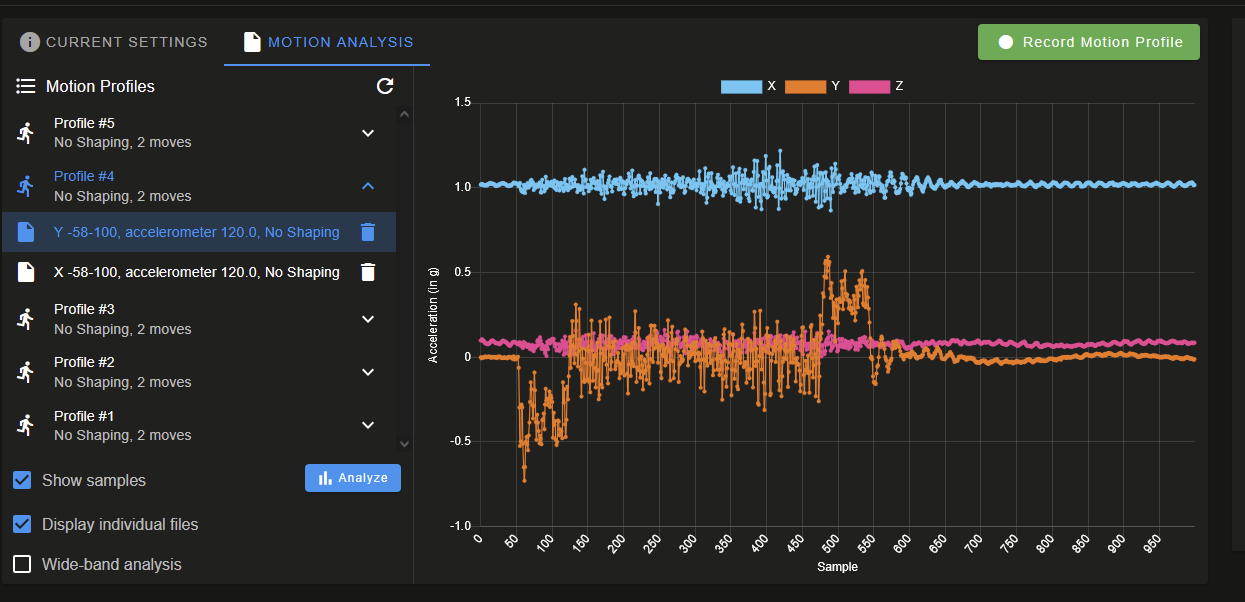

Moves scheduled 50341, hiccups 697 (53.45/53.45ms), segs 23, step errors 0 (types 0x0), maxLate 0 maxPrep 272, ebfmin 0.00 max 0.00

Peak sync jitter 3/8, peak Rx sync delay 293, resyncs 0/0, no timer interrupt scheduled, next step interrupt due in 3582982220 ticks, disabled

MCU temperature: min 39.0C, current 39.2C, max 39.8C

Driver 0: pos 9953144, 3230.8 steps/mm

Last sensors broadcast 0x00000000 found 0 6 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 34423, send timeouts 0, received 87925, lost 0, ignored 0, errs 0, boc 0, free buffers 18, min 18, error reg 0

dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 466, adv 35536/47502

Accelerometer: none

Inductive sensor: not found

I2C bus errors 0, naks 0, contentions 0, other errors 0

config.g

; Default config.g template for DuetPi

; Replace this with a proper configuration file (e.g from https://configtool.reprapfirmware.org)

; Display initial welcome message

;M291 P"Please go to <a href=""https://www.duet3d.com/StartHere"" target=""_blank"">this</a> page for further instructions on how to set it up." R"Welcome to your new Duet 3!" S1 T0

; Enable network

if {network.interfaces[0].type = "ethernet"}

M552 P192.168.100.56 S1

else

M552 I1 S1

M552 I1 S1 ; enable wifi

G4 S2 ;wait for expansion boards to start

; Drives

M569 P0 S1 ;physical drive 0 goes backwards, X-Axis

M569 P1 S0 ;physical drive 1 goes forwards, Y-Axis

M569 P2 S1 ;physical drive 2 goes forwards, Z-Axis

M569 P124.0 S0 T0:0:0:0 ;external driver on sammy

M584 X0 Y1 Z2 E124.0 ;set drive mapping

M350 X16 Y16 Z16 E16 I1 ;configure microstepping with interpolation

M92 X53.33 Y134 Z629.864 E3230.77 ;set steps per mm was 1011.99 then 1594.6, then 642.61

M566 X600 Y600 Z60 E3000 ;set jerk

M203 X30000 Y18000 Z1200 E1800.00 ;set max speeds (mm/min)

M201 X2500 Y3500 Z2000 E3000 ;set max accelerations (mm/s^2)

M201.1 X750 Y750 Z2000 E3000 ;max special acceleration move (homing)

M906 X1800 Y2600 Z2600 I30 ;set motor currents (mA) and motor idle percent

M84 S30 ;set idle timeout

M208 X-138.3 Y-137.5 Z-2 S1 ;set axis minima

M208 X160.4 Y178.5 Z325.116 S0 ;set axis maxima

; Toggle nozzle min - -163.2 , 206 max

; X EOT toggles at 181.2

; Y EOT at 182.4

;purge bucket near middle - x162.5, y155.5

;z probe left toggle -136.5

;z probe right toggle 197.5

;from build plate center, model (right) offset x=+20.8 (too far right), support is +40.8

;from build plate center, Y offset = -23 (too far forward)

;Z bottom (EOT) 325.1

;Endstops

M574 X1 S1 P"!io0.in" ; X home limit (low side)

M574 Y1 S1 P"!io1.in" ; Y home limit (low side, toward front of printer

M574 Z2 S1 P"!io6.in" ; assign Z EOT to x endstop on high side

; Z-Probe

M558 P5 H5 F1200:200 T5000 C"!io2.in" ; Z probe, set dive height, probe speed and travel speed

;G31 P1000 X-46 Y-74 Z0.896

G31 P1000 X-24 Y-73 Z1.365

;G31 P1000 X24 Y96 Z0.896 ; set Z probe trigger value, offset and trigger height

M557 X-135:135 Y-135:65 P5:5 ; define mesh grid. The whole bead cannot be probed due to the position of the probe.

; Head Blower Fan

M950 P0 C"!out4"

M42 P0 S0 ; enable blower

; Extruder Motor Enable

M950 P1 C"!out5"

M42 P1 S0

; Touch Power Enable

M950 P2 C"!out6"

M42 P2 S0

; Door Enable

M950 P3 C"io6.out"

M42 P3 S0

; LED Lights Enable

M950 P4 C"io2.out"

M42 P4 S1 ;S1 to turn on!

; Gecko Reset

M950 P5 C"io0.out"

M42 P5 S0

; Thermocouples

M308 S0 A"Chamber Test" P"temp0" Y"linear-analog" F0 B-42 C113

M308 S1 A"Model Test" P"temp1" Y"linear-analog" F0 B12.5 C328

M308 S2 A"Support Test" P"temp2" Y"linear-analog" F0 B12.5 C328

; Heaters

M140 H-1 ;Disable bed heater

M950 H0 C"!out7" T0 ; chamber, sensor 0

M141 H0 ; map chamber to heater 0

M143 H0 S85 ; set temperature limit for heater 0 to 85C

M570 H0 P30 T10 ; Increase fault delay to 30s, decrease temperature fault to 10c

M950 H1 C"!out8" T1 ; model, sensor 1

M143 H1 S320

M570 H1 P30 ; set fault time delay to 30s for heater 1

M950 H2 C"!out9" T2 ; support, sensor 2

M143 H2 S320 ; set temperature limit for heater 1 to 320C

M570 H2 P30 ; set fault time delay to 30s for heater 2

; Tools

M563 P0 S"Model" D0 H1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures

M563 P1 S"Support" D0 H2 ; define tool 1

G10 P1 X-20 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures

; Gecko Error In

M950 J0 C"124.pa04" ;gecko error in

; Head Thermostat Status

M950 J1 C"124.pa05"

; Door In

M950 J2 C"124.pa06"

; Print Head Support Toggle

M950 J3 C"124.pa07"

; Print Head Model Toggle

M950 J4 C"124.pa19"

; X-axis EOT

M950 J5 C"!io3.in"

; Y-axis EOT

M950 J6 C"!io4.in"

; Z-axis Home

M950 J7 C"!io5.in"

; Z-axis EOT

;M950 J8 C"!io6.in"

; Print Head Temp Alarm

M950 J9 C"!io7.in"

; Chamber Temp Alarm

M950 J10 C"!io8.in"

;M581 Tx P5:6:7:8

M501 ;config g

M302 S200 R200

M98 P"globals.g"

!

!

). I can try and find where the orientation is defined later.

). I can try and find where the orientation is defined later.