Fixed the problem with the end stops! Added a '!' to invert the signal and now is everything working as intended. Thanks!

Posts made by Rik Snelder

-

RE: Homing problem COREXY (H-bot)posted in General Discussion

-

RE: Homing problem COREXY (H-bot)posted in General Discussion

@Phaedrux Yea I think that that is happening in my case. It is also a really small movement only a couple of mm

-

RE: Homing problem COREXY (H-bot)posted in General Discussion

@Manfred53 It is a H-bot design, same as a coreXY just with 1 belt

-

RE: Homing problem COREXY (H-bot)posted in General Discussion

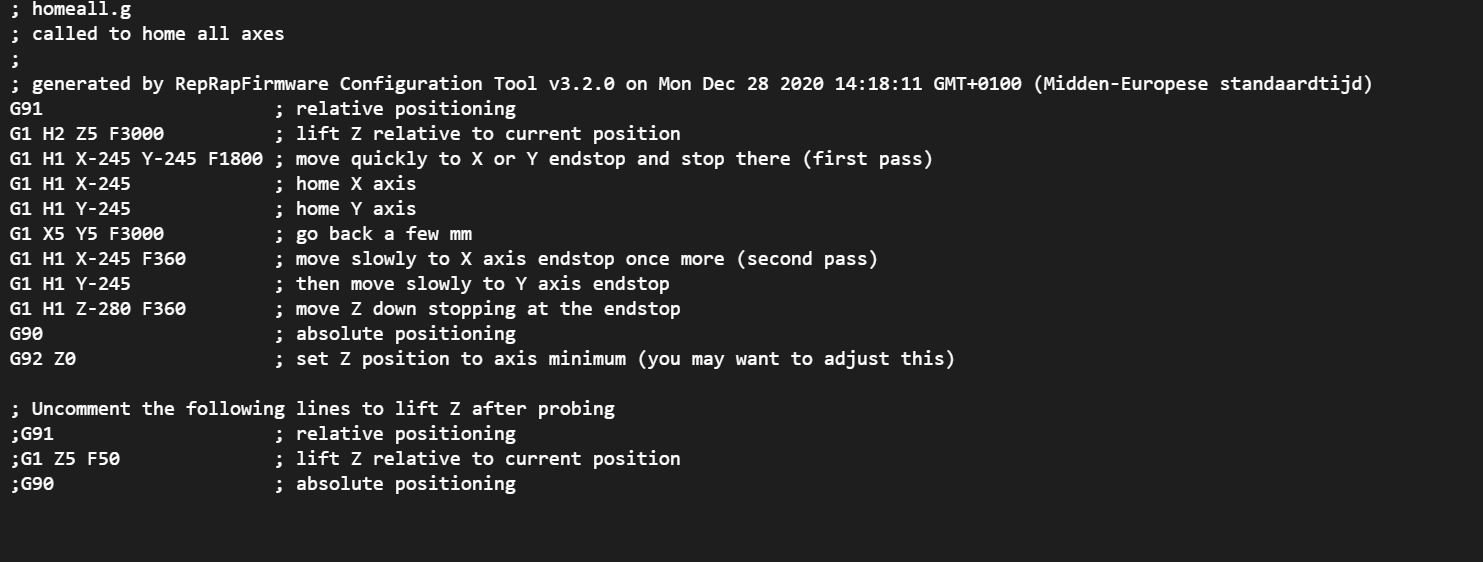

@Stephen6309 This is what my homingfile looks like, any idea what could be wrong?

-

RE: Homing problem COREXY (H-bot)posted in General Discussion

@Stephen6309 Thanks for your quick reply. When giving the M119 code I get the following;

The motors are moving the right way, only when homing they move the other way for some reason -

Homing problem COREXY (H-bot)posted in General Discussion

Hi everyone,

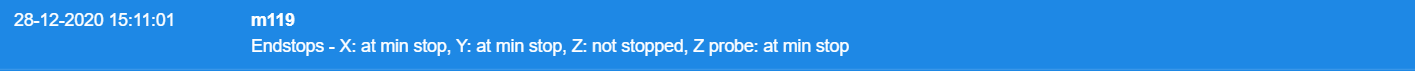

I am working on the finishing touches of a high temp printer using the CoreXY (H-bot) system. Everything appears to be working as intended however when I want to home all the axis the printhead only moves a really small amount (2 maybe 3mm) in each axis. Beacaus of this I can't home the printer, also when (trying to) homing, all the axis move in the wrong direction.

Does someone have an idea why this happens? I have attached the config.g and all the homing files. Also a picture of the H-bot setup.!

homez.g homey.g homex.g homeall.g config.g -

RE: DIY high temp printer buildposted in My Duet controlled machine

@kstra It uses the CoreXY motion system from e3d

unfortunately still waiting for some parts so it might take a while for it to be finished

unfortunately still waiting for some parts so it might take a while for it to be finished -

RE: DIY high temp printer buildposted in My Duet controlled machine

@jens55 Yes, they will be lasercut and bend by a local company!

There is guide on the Dyze Design website about installing them (https://docs.dyzedesign.com/liquid-cooling.html#liquid-cool-your-extruder) it is just attached to the outside of the motor, so no need to take it apart

-

RE: DIY high temp printer buildposted in My Duet controlled machine

@jens55 Jup, heavy it wil be

around 80kg according to SolidWorks...

around 80kg according to SolidWorks...

No probs, the cooling blocks seem well engineered. Can't wait to try it out, when all the other parts are here. (still waiting on all the sheet metal parts and some electronics) -

RE: DIY high temp printer buildposted in My Duet controlled machine

@jens55 The inside wall of the build chamber is made of stainless steel (2mm) then there is a 30mm layer of rockwool followed up by a outer layer of 2 mm aluminium. So there is hopefully not a hole lot of heat losses.

Both the hotend and extruder are watercooled with the cooling blocks from dyze

-

RE: DIY high temp printer buildposted in My Duet controlled machine

@Phaedrux It sure is! using 3030 aluminium profiles with 2 mm aluminium and stainless plates on all sides. Should weigh around 80 kg

-

RE: DIY high temp printer buildposted in My Duet controlled machine

Planning on printing the high temp stuff, PEEK, PEKK, PPSU etc.

Will print at slow speeds, 30-40 mm/s probaly, just have to do some test to find the optimal!Yes 500c is a really high temp, but that is just what the hotend is capable of (dyze end pro). Won't run it near that temeprature so no worries!

-

RE: DIY high temp printer buildposted in My Duet controlled machine

@Veti No, the entire motion system is outside the build chamber (using high quility kevlar bellows for the XY motion). So there is no need for it, the hotend and extruder however are water cooled!

-

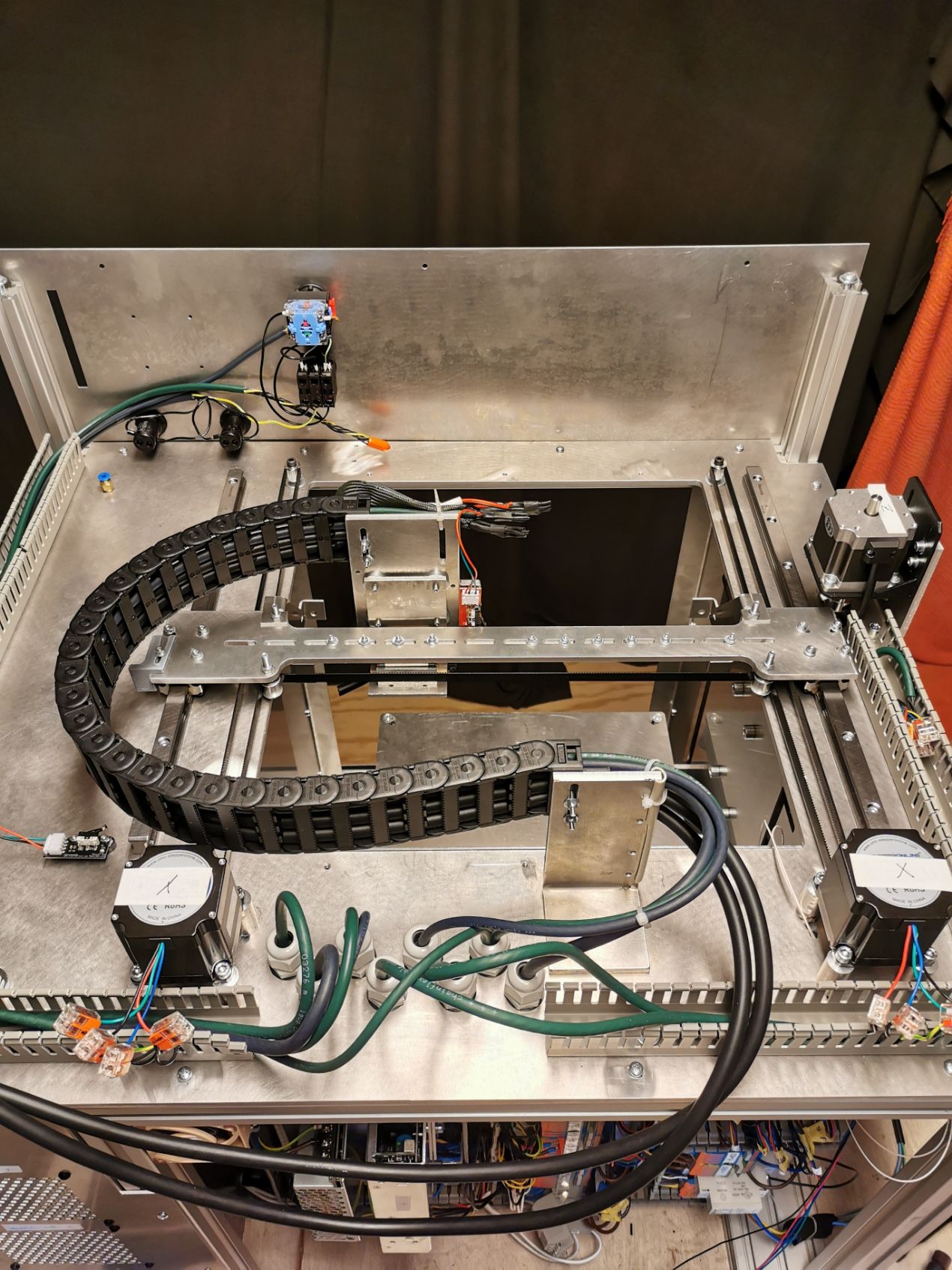

DIY high temp printer buildposted in My Duet controlled machine

Hi everyone, just wanted to introduce the project that I am working on, a DIY high temperature 3d printer. I have been working on it for a couple of months now, and the design is almost finished. It features all high quality parts from dyzedesign, Bosch Rexroth, Duet3d, alphacool and many others!

The finished design will have a build volume of 240x240x275mm, 500c watercooled hotend, 200c capable bed, heated build chamber and filament chamber.

For the heated chamber I will be using 3 200 watt ptc heaters with a fan slowly blowing hot air in the chamber, with this I hope to be able to reach a chamber temp of around 100-120c. The render below is an indication of the design, there have already been some changes to it

Now it is just waiting on the last parts to start the construction, the frame is already standing as can be see. I am also working on a website for this project, so that should be up and running in the next couple of weeks!

Will keep this post updated on any further process made!

Regards,

Rik -

Hotend keeps heetingposted in Duet Hardware and wiring

I connected a hotend to my duet 2 wifi. If I say in the web control to heat the hotend to a certain temperature, the hotend starts heating but if it reaches the target temperature it doesn't stop heating. Also the max. temperature in the config files(see enclosed file) is 450 degrees celcius but the software gives an error at 250 degrees celcius. Does anyone know how to fix this?[0_1598350426651_config 3.zip](Uploading 100%)