Depends. If you will make a panel with steel on both sides, then you will have better results with the lighter insulation.

That way you really decouple the sheets, if you use a stiffer one it could happen that you transfer the sound from inside to outside.

You can also benefit if you put thinner sheet metal on inside (or outside). The difference in the natural frequency helps dampening.

Posts made by OBELIKS

-

RE: Building a Sound Dampening Enclosureposted in My Duet controlled machine

-

RE: V-Core Pro lives again (-:posted in My Duet controlled machine

Maybe, with a different cable. It would need to be shielded

-

RE: V-Core Pro lives again (-:posted in My Duet controlled machine

I am still hunting for a durable surface that would work with IR-probe.

I have some black copy of Buildtack, but it holds too much and even a slight hit with hot hotend runis the surface.But the V-Core pro is great!

-

RE: Purge macro prusaslicer issues.posted in Tuning and tweaking

Is this the whole start code?

Because you are completely missing the temperatures.I would put this before G32

M104 S{first_layer_temperature[0]-40} ; set extruder temp M140 S[first_layer_bed_temperature] ; set bed temp M190 S[first_layer_bed_temperature] ; wait for bed temp M109 S{first_layer_temperature[0]-40} ; wait for extruder tempThis way you avoid runny extruder while printer is running mesh procedure.

Then add this before ; Purge extruder

M104 S[first_layer_temperature] ; set extruder temp M109 S[first_layer_temperature] ; wait for extruder temp -

RE: Slicing G-Code curves from solid (not mesh) geometry.posted in General Discussion

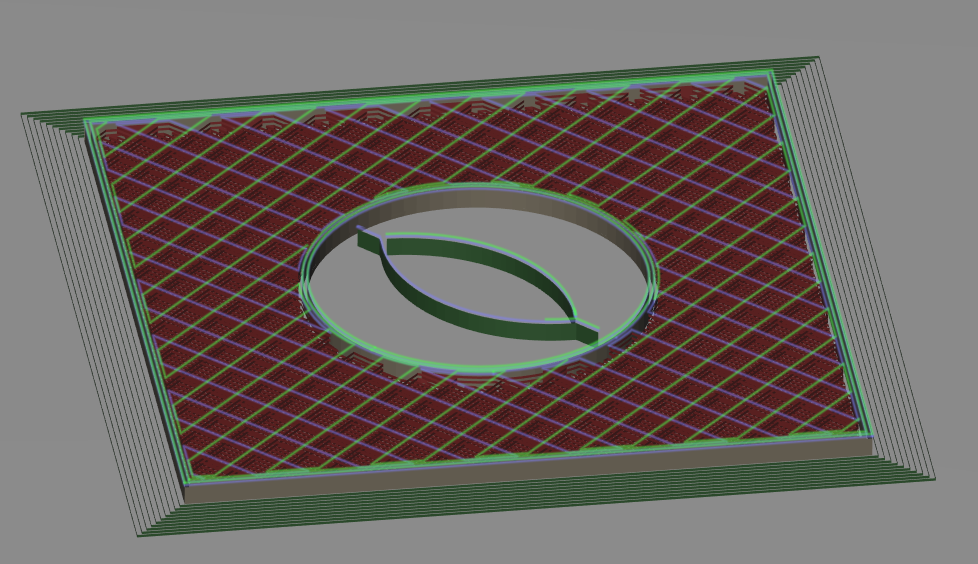

In this case it is trying to support the circle above with minimal waste. It is looking at bridges and making them shorter than a value.

-

RE: Slicing G-Code curves from solid (not mesh) geometry.posted in General Discussion

Interesting and they added 3mf export (unfortunately only in the Manufacturing space)!

And I like this support structure:

-

RE: Print quality issueposted in Tuning and tweaking

WOW

Can you make a picture with M3 bolt in the cheap idler? Is the gap visible? -

RE: New repository for machine configuration filesposted in General Discussion

Ah, that makes sense.

-

RE: New repository for machine configuration filesposted in General Discussion

Would it make sense to remove the values from M143, M906 and M208 and put them to the comment for these lines?

That way there would be no way of someone running an incompatible config. Mistakes happen, you can miss something and get in to trouble. -

RE: Print quality issueposted in Tuning and tweaking

@Dkos it's a longshot. Can you try to slice again as you did and then export to .obj and open that in Blender. It will probably not show anything out of order, but still worth a shot.

-

RE: Print quality issueposted in Tuning and tweaking

I don't know if the real problem was already discovered and fixed, but here is the "official" reply from one of the developers (Vojtech Bubnik):

There are multiple effects in play, therefore some of your prints may show a different effect than the prints from the others. Ideally we would compare apples to apples, we would work with Slic3r's 3MF files that contain all the modifiers and parameters, so we can keep track of most of the variables in play.

First, the Slic3r's logic to extend the solid infill is there to anchor the solid top infill into the sparse infill. The logic is sound, but it has its drawbacks as you guys found out, it consumes material , it adds to the print time, and currently it is not configurable in Slic3r. Cura and S3D just do not extend the infill, thus you may see gaps at the bottom of your boxes as you already have found out as well. In the future versions of Slic3r, we may make the extension into the solid infill configurable.

In addition, Slic3r applies perimeter-infill overlap to close some of the gaps between the solid infill and inner perimeters, which it may have a negative effect on the accuracy of the outer wall. You may try to decrease the overlap number with the risk of getting some gaps in solid infill, the config parameter is available to you.

Then there is sometimes an effect of thin walls being extruded with just perimeters with no infill, and it may happen, that the wall thickness is not an integer multiple of the extrusion width (this is again a bit complicated by the fact, that Slic3r calculates the wall width as the tangent width giving the "corrugated iron sheet" surface of printed vertical walls, you will find a "recommended object thin wall thickness" hint at the Print Settings -> Layers and perimeters page for a given integer number of perimeters), so Slic3r will produce some overlap of the inner most perimeters to fill in the space completely, if the "Detect thin walls" feature is disabled. If you enable the "Detect thin walls", then Slic3r will fill in the remainder inside the inner most perimeter with a single line. Unfortunately the "Detect thin walls" feature currently may produce some unwanted single line extrusions at sharp protrusions of a model, therefore we have it disabled by default in our profiles. In the future, we will split the "Detect thin walls" to "Thin walls inside / Thin walls inside and outside" the way it has been done recently in S3D. By the way, S3D's recent implementation most likely copied from the initial gap fill algorithm implemented some 3 years ago in the original Slic3r, as it manifests the same behavior including the negative artifacts (read bugs).

Lastly, it is the physics as others noted. Plastics, if extruded first from pellets into a filament, and then from filament into a very thin rectangular extrusion, will behave neither as a liquid, nor as a solid. The stretching of the plastic will align the long molecular chains of the polymer, introducing internal stresses to the extrusion. This internal stress will pull the extrusion together if not cooled quickly enough. Indeed, as many of you found out, in a cool basement the effects are more pronounced, also on my MK2 the 3D Benchy has the line more pronounced at the side away from the cooling fan.

So, it is "just" physics, and it will be very difficult to compensate for the internal stresses and cooling effects of the filament IMHO, one of the reasons being the viscoelastic behavior of the molten plastics, and the dependence of the plastic behavior on its composition, temperature, hydrolisis of the polymer molecular chains if the filament is not 100% dry (polyesters - PLA & PET are sensitive to hydrolisis, hydrolised filament contains shorter polymer chains, thus being less viscous), effectivity of the cooling, reflections of the cooling air from the already printed objects etc.

-

RE: Print quality issueposted in Tuning and tweaking

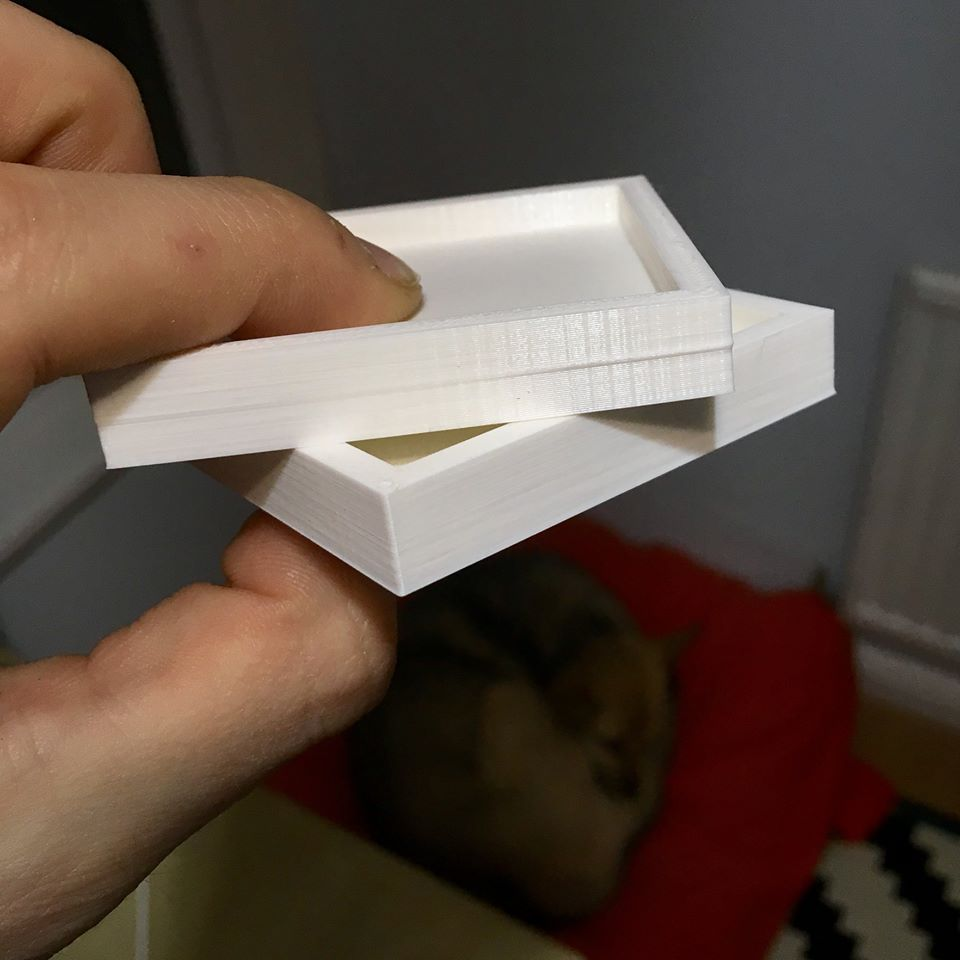

Especially if the issue is present when you transition from a solid infill/top layer to empty space as it is seen on last picture.

-

RE: Print quality issueposted in Tuning and tweaking

Ah yes, private group for Prusa printers.

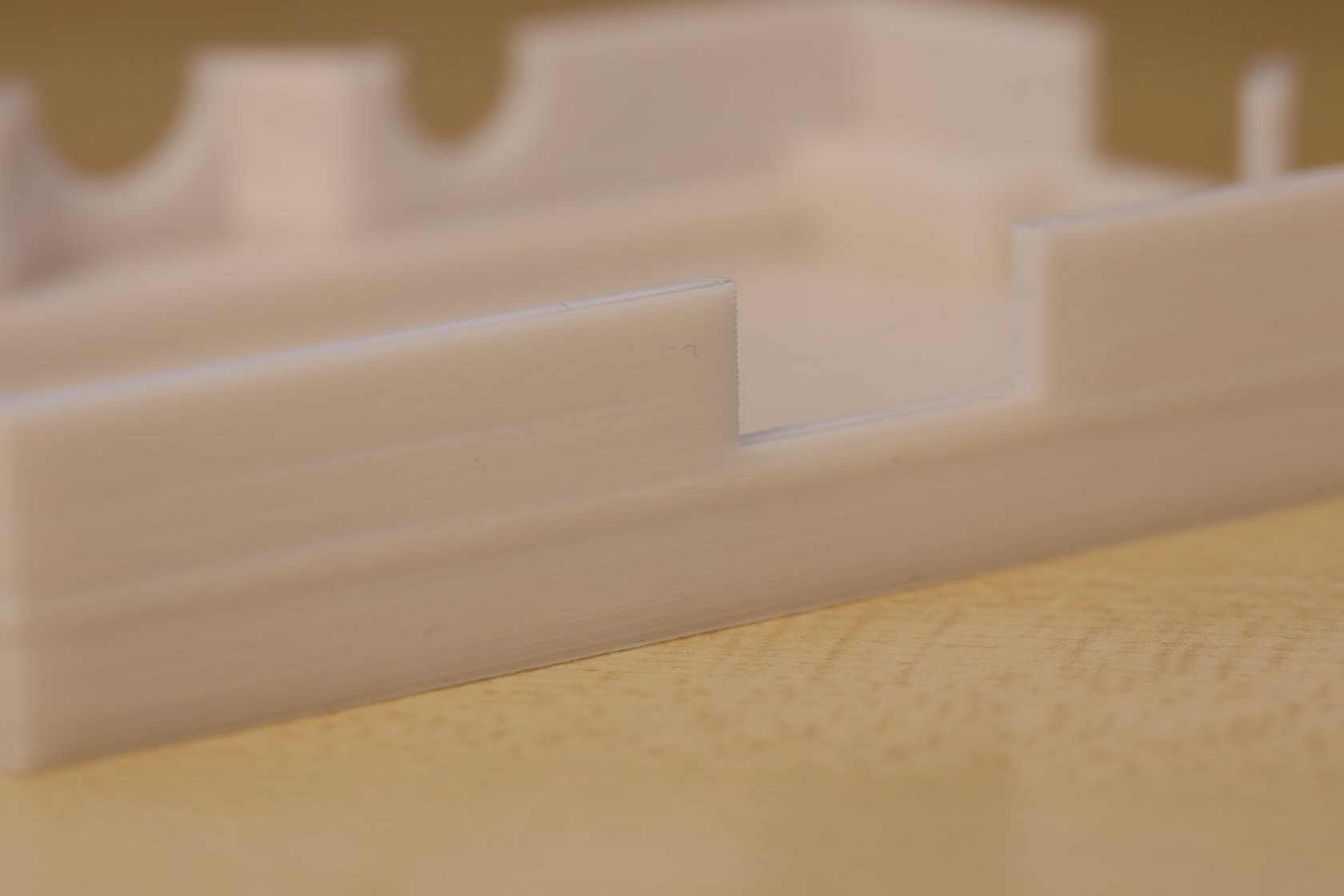

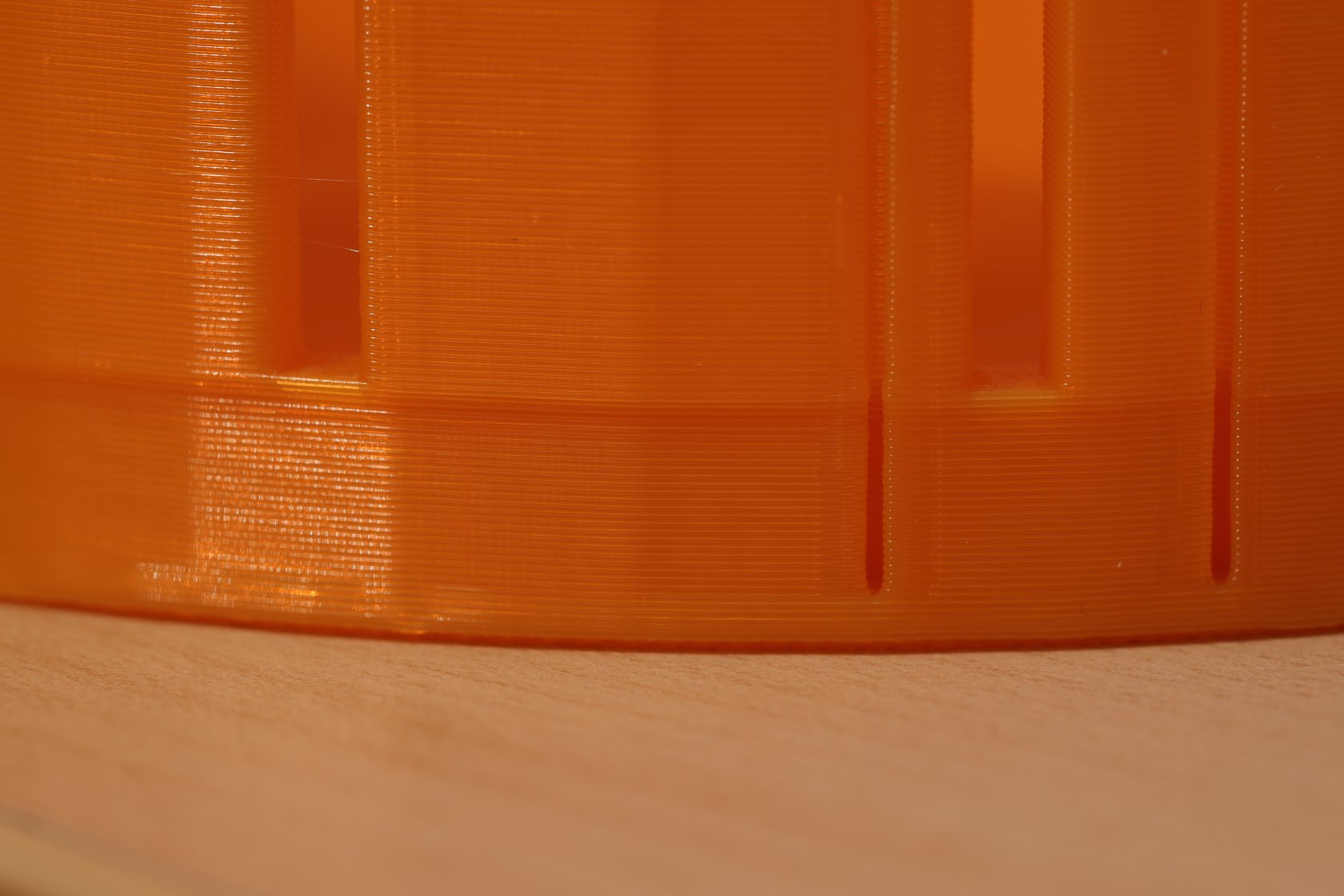

Some of the prints that are there:

While it could be unrelated, it's a good idea to first check a different slicer. -

RE: Print quality issueposted in Tuning and tweaking

First try a different slicer. It could be this https://m.facebook.com/groups/675831176090951?view=permalink&id=1183905701950160

-

RE: Blobs with PA and w/oposted in Tuning and tweaking

It could be you still have the issue and it is only hidden in the seam. On the first pictures the slicer was "hiding" the seam on the corners (either the X or Y letter or the corner of the cube).

-

RE: Blobs with PA and w/oposted in Tuning and tweaking

Is the line on the left of Y the seam? Did you change the Start Points setting on Layer tab? Because in the first prints the start points were in the corners and in the ones where you have no issues they are in a line.

I am asking, because I need to tune the settings to get rid of the same issues. -

RE: Pressure Advance seems to not be working.posted in Tuning and tweaking

@oliof said in Pressure Advance seems to not be working.:

Supermerill's Slic3r++ fork includes looping seam hiding as well, but I haven't tried it yet (the latest build crashes at launch and I haven't tried to figure out why).

He has a fix on the releases page. "You have to remove creality.ini and basic.ini from resources/profiles because they have duplicate lines."

I also need to try it. -

RE: Some infill not reaching walls ?posted in Tuning and tweaking

See here: https://forum.duet3d.com/topic/6698/pressure-advance-calibration/136

The bottom test piece in first picture PA goes from 0 to 1 and you can see that you get gaps on the change from slow to fast movement when you come close to 1. You could have the same issue.

-

RE: Some infill not reaching walls ?posted in Tuning and tweaking

20mm/s on Volcano is OK if you have a decent extruder and extruder motor.

PA of 0.8 is on the high side and it can give you problems on infill. What are your retraction settings?But I would try a different slicer, just to eliminate the possibility of wrong settings.

-

RE: Some infill not reaching walls ?posted in Tuning and tweaking

Also check coasting, there is no need for that when using PA.