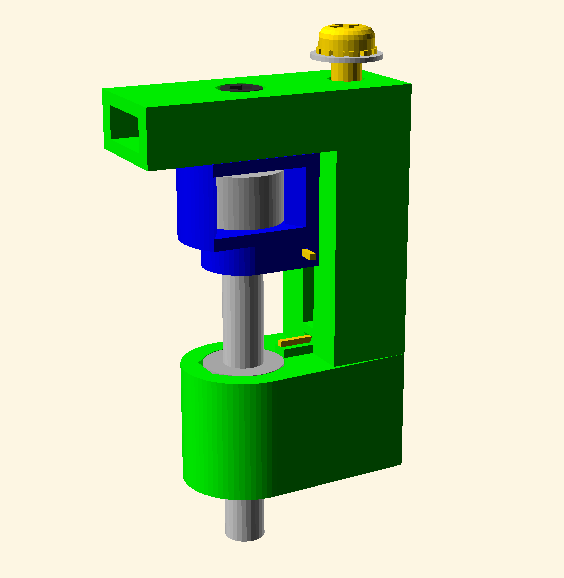

I have added the Model to NopSCADlib if anybody needs an OpenSCAD model.

I have added the Model to NopSCADlib if anybody needs an OpenSCAD model.

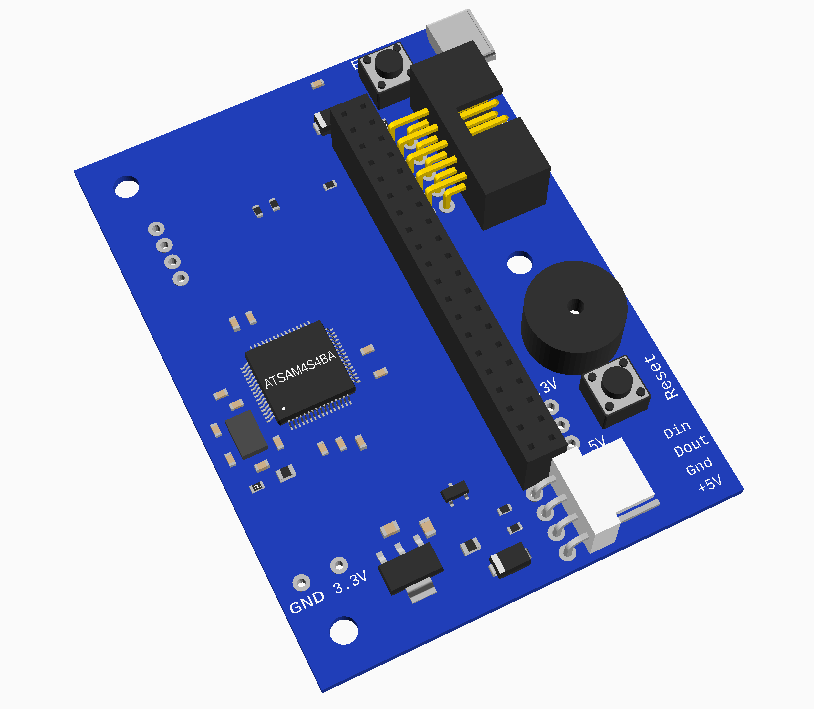

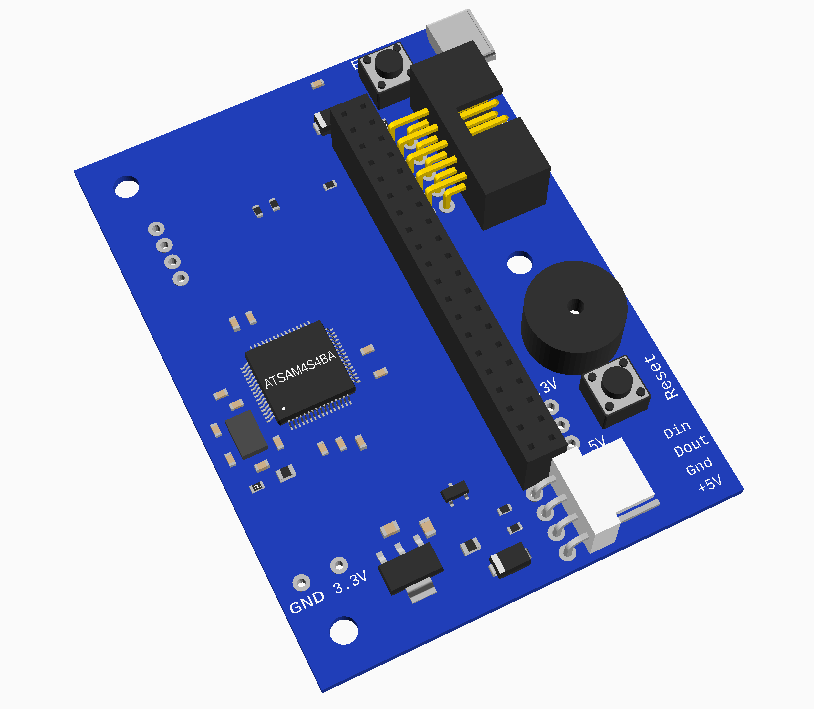

I can't find the design files for the Panel Due v3.0a PCB that I have. I would like to model the board in OpenSCAD and having the Gerber files saves a lot of time.

Are the available on github?

R in the equation is the resistance of the thermistor at temperature T, they are the variables. A, B, C are constants for a given thermistor.

When T is 25C then R will be the thermistor's nominal resistance, e.g. 100K.

@Nuramori Ha, Skeinforge has had that option for about 10 years I think.

@zapta said in Duet 3 first-generation prototype giveaway:

@nophead said in Duet 3 first-generation prototype giveaway:

No it doesn't because motion planning does not depend on real time input,

How do you handle motion related configurations that are done at the printer's level? E.g. from config.gcode? Do you feed them to the off line planner?

Sorry I missed this question a month ago.

My machine specific configuration is simply expressed in Python files, rather than encoded into dozens of cryptic gcodes. When I process the machine agnostic g-code tool path from the slicer I apply the machine and filament specific speeds, accelerations and temperatures, etc, before sending binary packets to the actual machine.

I never modify anything on the fly though. I have never felt the need. When I start a print job it is usually from another room. I tend to look via camera to see if the first layer looks sane and then I wait for it to finish. I don't interact with my machines other than to clear the bed ready for the next job, or change the filament. I run a separate python script to do the latter.

As well as the spring effect of filament and motor there is also backlash if using gearing or a Bowden tube that has to be slightly bigger diameter than the filament. @dc42 does the pressure advance separate these two effects and compensate for them independently? I.e. to get over backlash you would want a very fast movement and then a slower accelerating speed once the filament is engaged.

@robm If the lines are aligned vertically they are related to stepper position. I don't see how varying speed or acceleration would change the position of the lines, just perhaps their severity if they are due to resonance.

On a delta the motor positions don't map linearly to object position, breaking alignment, but on a Cartesian machine there is no way to break the alignment.

@jens55 said in Can 'pressure advance' cause negative filament feed ?:

negative feed doesn't make sense

It does if the line segment is a very short part of a decelerating sequence as dc42 explained. During deceleration the pressure has to be reduced and that means feeding less filament in than is coming out. The amount extruded during the line should always be positive and proportional to its length but that isn't the same as what is feed into the extruder while accelerating and decelerating with pressure advance.

However, in any sequence of segments from a start to a stop the total fed in should equal the total out, so that should always be positive and match the sum of the E values in the G-code.

This is what I use on one of my machines.

It is a 4mm rod that runs in an LM4UU bearing and is held above the nozzle by a magnet. When I remove a print I manually deploy it by pulling it down away from the magnet. It then closes two gold contacts together and hangs below the nozzle.

When I start the next build my host software checks the contacts are closed and prompts me if I have forgotten to deploy it. It then probes the bed using successive approximation to find the z microstep where the contacts just open.

When it has finished probing it lowers Z axis until the probe is attracted to the magnet, which lifts it clear of the nozzle.

Is it too simple?

Note that 220V AC has a peak of 331V, so you shouldn't really use a 220V DC relay, even with a bridge.

The label says "5-220 VDC", so It looks like a DC relay to me. Probably a MOSFET which will have a body diode across it which will always conduct when the polarity is reversed. So when off you get half wave rectified mains, when on you will get full AC.

This is why I use flat ribbon cables on my 3D printers with lots of wires in parallel to handle the current. The bend radius you need for thicker wires is surprisingly large.

3D printers tend to make a very large number of moves compared to other CNC machines. I have thick cables in cable chains on my router but, being mainly 2D, it simply doesn't have the mileage my 3D printers get.

The graph looks like heater lost its connection and regained it rather than a sensor fault.

If its a moving head machine how are you getting wires to the head? Moving wiring tends to break unless you take precautions to ensure a minimum bend radius compatible with the wire.

@singhm29 No I mean't repeating a print. Does it come out exactly the same or are the blobs in different places?

If your extruder motor can't handle the speed, acceleration or jerk you have specified it is likely to show up when doing retracts because it moves much faster then. It gives exactly those symptoms if it sometimes stalls on retract and sometimes on un-retract. It would also probably come out different when the print was repeated if it was only occasionally stalling.

@singhm29 If you print the same object twice is it consistent?

Is it possible your extruder motor is stalling? That causes those sorts of symptoms because if it stalls on retract but not un-retract you get too much filament, but vice versa you get too little.

@deckingman Well the fix is simple. You just accumulate the E steps converting them from relative to absolute, like the other axes and then you don't lose anything as each move is rounded to the nearest microstep but the total stays accurate.

Or alternatively carry forward the rounding errors:-

0.4 no step, carry 0.4.

0.8 step, carry -0.2

0.2 no step, carry 0.2

0.6 step, carry -0.4

0.0 no step carry 0.0

repeat, so every five 0.4 steps we should move two microsteps.

I have always found .local hit and miss with any device but my router names hosts it gives DHCP leases to .lan. So machinename.lan works for me and doesn't require anything on the client side.

@deckingman said in What does x256 interpolation mean ?:

So if it's say 0.4 of a micro step, then that will get rounded down to 0 resulting in no movement. On the other hand, if the required extrusion amount resulted in 0.6 of a micro step, that would get rounded up to 1 micro step.

Is this really the case? The firmware should keep track of the fractions and add them to the next step. So if you do 0.4 of step it will not move but after a second one it will and not on the third, and so on. So the amount deposited would still be correct when averaged over the path. If it really rounds a sequence of 0.4 steps always to zero that it a bug.

@thomas_rudloff NTCs are fine for beds. I use 1% Epcos B57861S104F40 epoxy bead thermistors that come with PTFE covered leads. I attach them with JB-Weld.

At typical bed temperatures 1% is only a degree or so so I don't see any point in being more accurate. It would be a good bed that has less temperature difference across its surface.