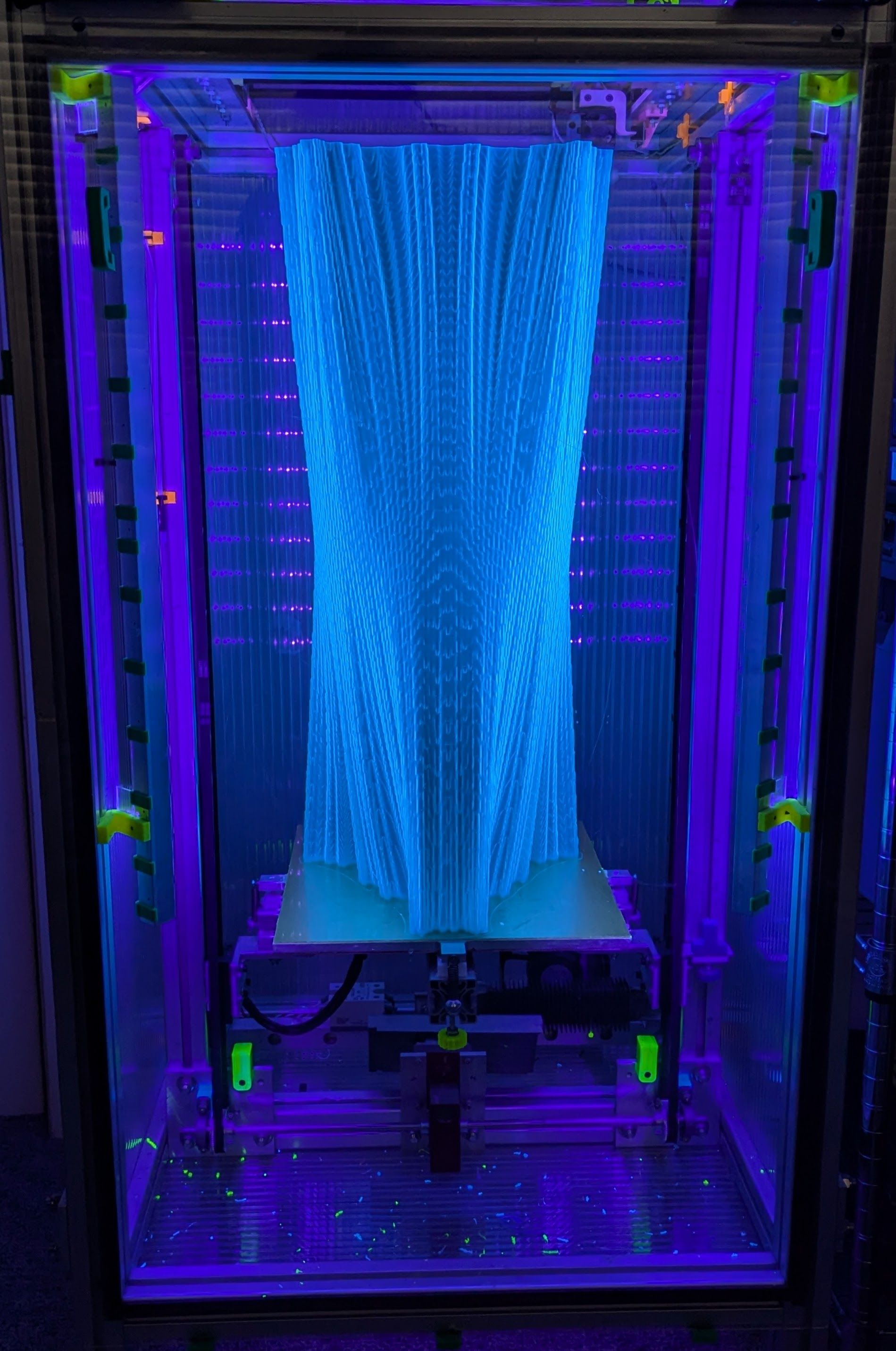

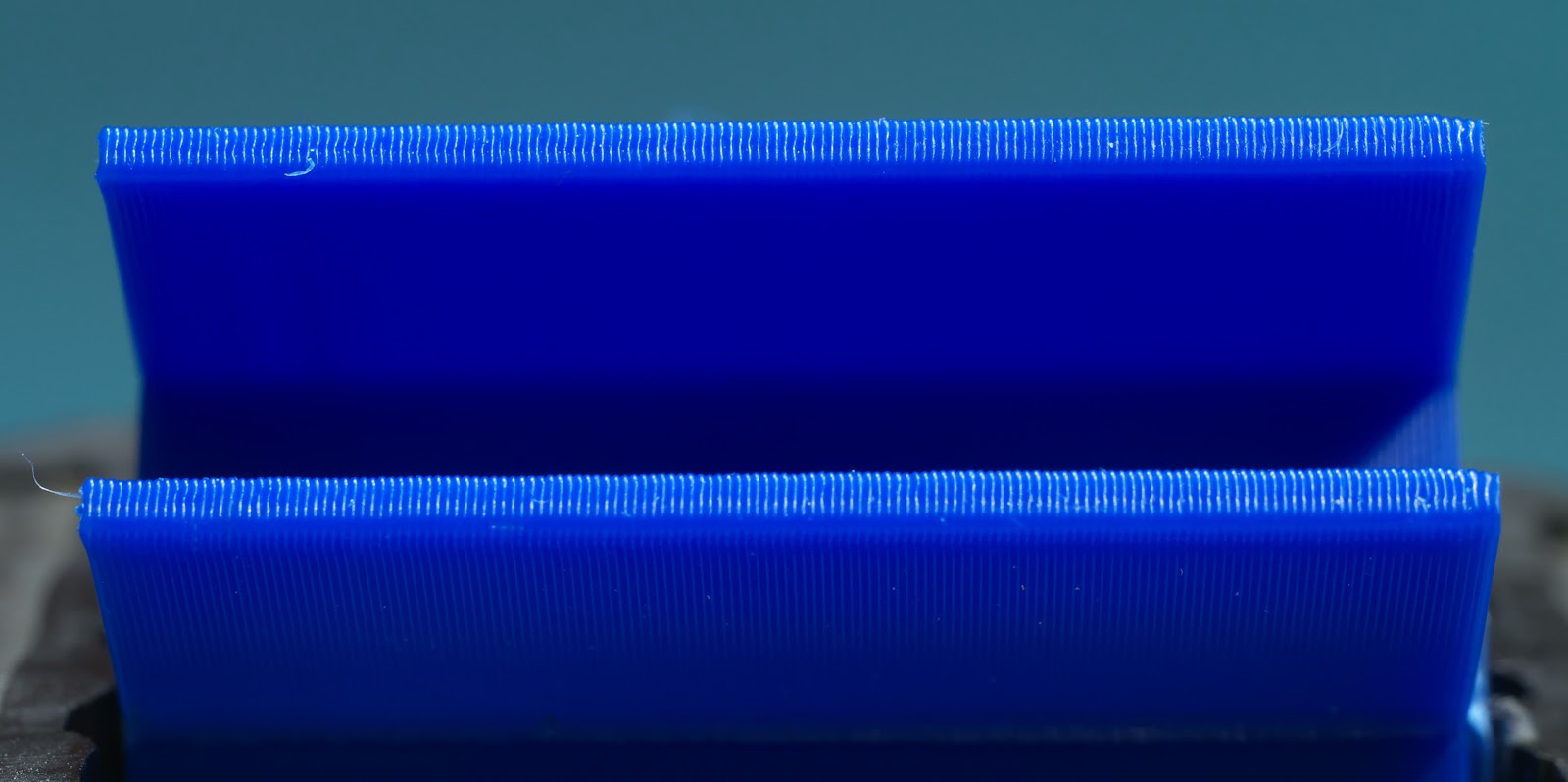

15 hours at 40 mm/sec, 1mm nozzle, 1.2 mm line width, 0.3 mm layers, vase mode in Cura, 923g of PETG filament, 638 mm tall:

It's going to become a lamp.

15 hours at 40 mm/sec, 1mm nozzle, 1.2 mm line width, 0.3 mm layers, vase mode in Cura, 923g of PETG filament, 638 mm tall:

It's going to become a lamp.

Here is Ms. Kitty enjoying my corexy sand table running a circular erase pattern at 1500 mm/sec with acceleration of 10k mm/sec^2.

The table is driven by two servomotors with a Duet2 WiFi controller.

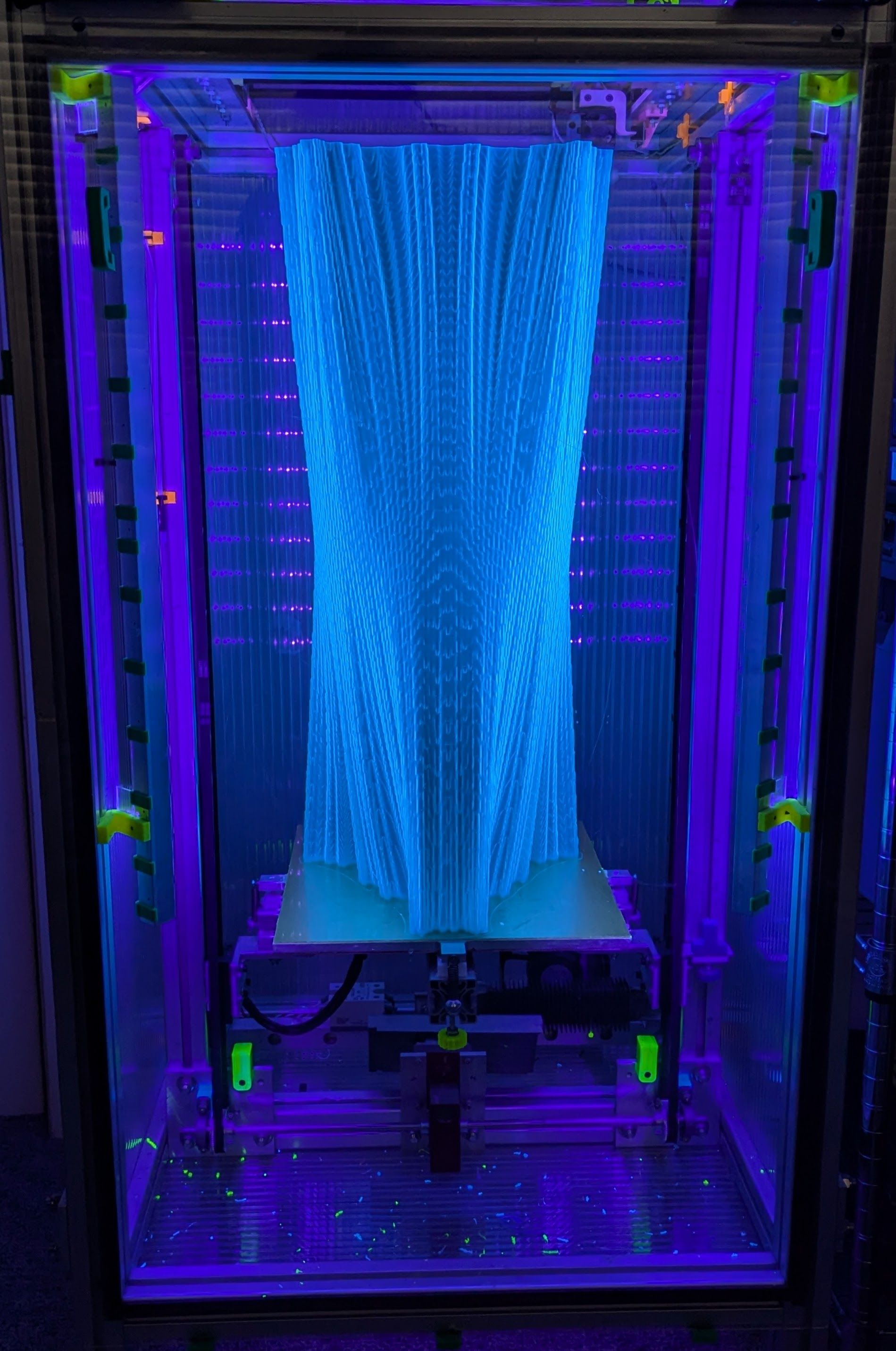

You're essentially asking about the difference between a Kelvin and a Maxwell kinematic coupling.

The "rails" have to run parallel to the direction that the plate expands, relative to the chosen reference point. The reference point location relative to the adjustments is what makes it a Kelvin or Maxwell coupling.

If you choose the reference point to be the center of the bed, the "rails" should be aligned to point at the center of the bed at all three support points because the bed expands outward in all directions from there. That's the classic Maxwell coupling.

OTOH, if you choose one of the screws to be the reference point, say one of the two along the bottom edge, that point won't need rails- just a "hole" to sit in. The rails at the other point along the bottom edge will simply be parallel to the bottom edge (in your drawing) of the plate, and the third will just support the flat bottom of the plate and is allowed to slide in X and Y. You'll adjust the bottom edge point first to set the edge of the plate parallel to printer's X axis, and then set roll using the third point to set the plate parallel to printer's Y axis. This is a Kelvin mount.

The Kelvin mount's square angles are easier to set up accurately - most machine tools are square- than the odd angles that will result if you choose the reference to be any other point (as in a Maxwell mount), and you only need "rails" at one point, not all three.

If the rails are set square to each other (Kelvin style) and the lines they define are parallel to the X and Y axes of the printer, leveling the bed is super easy because a) you'll only need to adjust two leveling points and b) when you make the adjustments all tilting will be in the directions of the X and Y axes of the printer.

I used a Kelvin mount in my printer, with the reference being a point on one of the "ears" on the plate:

In the Maxwell mount, every leveling adjustment, tilts the bed in X and Y, so tramming isn't quite as simple. Also, every tramming adjustment moves the reference point vertically, so you have to adjust the Z=0 position once the bed is level. It's only a Maxwell mount if you accurately aim the rails at the reference point. Any error will cause the bed to tilt and move up and down a bit as it heats up.

With the Kelvin mount, the reference point doesn't move vertically when you tram the bed, and each adjustment (provided you adjust pitch first, then roll) only tilts the bed along one axis. That means that when you adjust roll, it doesn't affect the pitch adjustment.

Of course, if you use auto tramming and zeroing, difficulties in adjustment shouldn't matter...

My coffee table, aka Arrakis 2.0, is a servomotor powered coreXY mechanism that is normally used to magnetically drag a steel ball to create pretty patterns in sand. My cat enjoys chasing the ball, especially when the table is running a spiral erase pattern at 1000 mm/sec.

I decided to try to create patterns that she might like, so I wrote a spreadsheet that generates random motion of the type that attracts her attention. I enter the table dimensions, the desired speed range, and desired dwell time range and the spreadsheet creates gcode that causes the ball to move in random directions at random speeds and then stops for a random amount of time, before darting away, sort of like a small animal might behave. Ms. Kitty loves it!

The spreadsheet generates 500 lines of gcode that typically take about 16 minutes to run on the table, about 3x longer than Ms. Kitty's attention span.

More: blog post

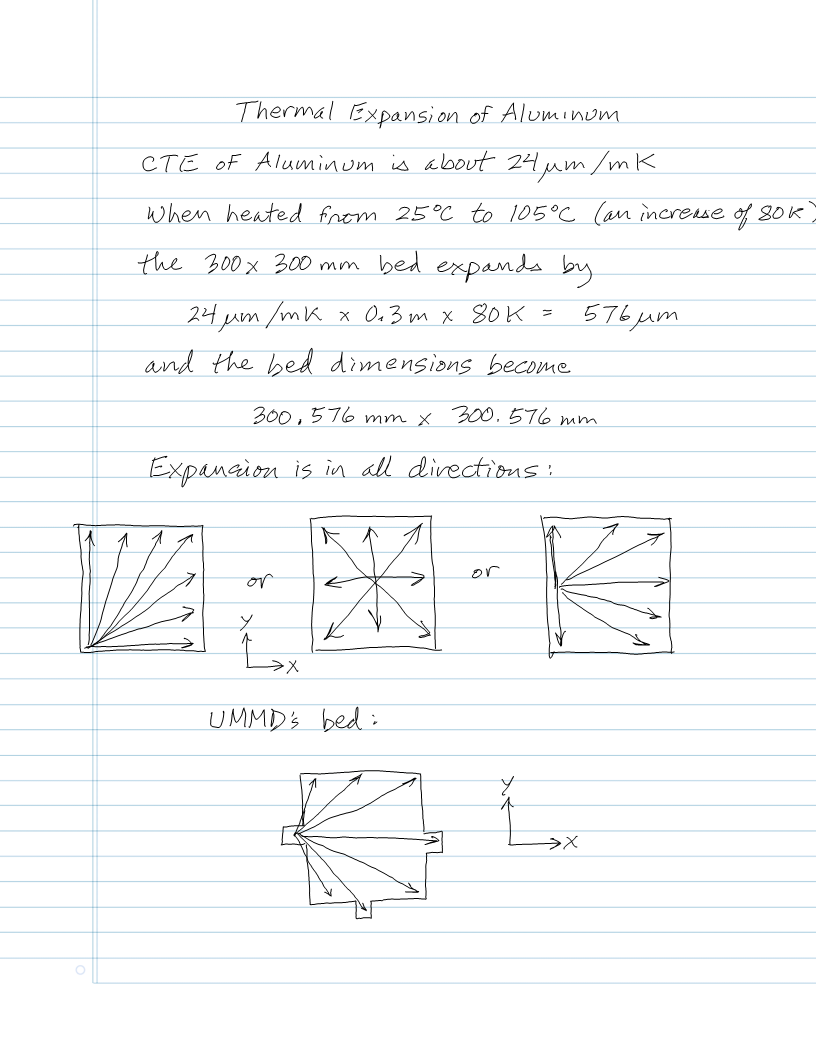

I recently installed opto endstops in my corexy printer and ran some tests of their precision.

In the X and Y axes I ran two identical prints with the first homing normally at the start of the print and the second rehoming X and Y after each layer change. The result is that the prints are barely distinguishable under high magnification and are essentially identical without magnification, indicating that the precision of the optical endstops is very high. Here are two photos of the prints that contain the largest visible difference between them:

Why would anyone want to home a print at every layer change? MarkForged printers use that feature to automatically detect and stop layer-shifted prints. If you are printing expensive material such as PEEK, PEKK, Ultem, etc., you want the print to stop pretty quickly if there's a problem like layer shifting. I'm thinking about how to program a macro that will detect layer shifting in printers running Duet controllers.

I also tested the Z axis opto endstop. I mounted a digital gauge on the printer's frame with the probe contacting the bed, then homed the machine and zeroed the gauge. I moved the bed down random amounts and rehomed 10 times to see if the bed would return to the same position as indicated by the gauge. 8 out of 10 times it went to 0.00 mm and the other 2 times it went to 0.01 mm. The Z axis in my printer is configured for 16:1 ustepping, interpolation on, and 800 steps/mm.

Video here: Z axis homing precision test

The typical way to adjust the Z=0 position is to use a screw to bump a microswitch. The problem with that is when you're zeroing the Z axis you need to be able to make very small adjustments to the home position of the bed/extruder. If you use an M4x0.7 screw, one turn of the screw moves the home position by 700 um- that's more than 3 full 200 um print layers. If you need to move the home position 30 um, that's 1/23 of a turn - not too easy to do without overshooting.

I designed a differential screw adjuster to go with the optical endstop in the Z axis. It uses a M5x0.8 screw with the end 20 mm or so turned down to 4 mm and rethreaded with a M4x0.7 mm die. The result is an adjuster that moves the home position of the bed by 100 um for each full turn of the adjuster, making it very easy to make small adjustments.

While I was running the other tests I checked the adjuster, too. The result- about 100 um per turn of the adjuster, as expected.

Video: Differential screw Z=0 adjuster test

One of the best things about opto endstops is the cost. 3 for $10. They work fine with the 3.3V that the Duet supplies. They also don't seem to mind the 50C temperature inside my printer's enclosure when I'm printing ABS. These endstops have LEDs that light up when they are triggered, making the Z=0 position adjustment easy because you don't have to check the control panel of the printer - just turn the adjuster until the light comes on.

More here:

https://drmrehorst.blogspot.com/2020/03/a-new-z-axis-optical-endstop-design-for.html

https://drmrehorst.blogspot.com/2020/03/testing-ummds-xy-optical-endstops.html

https://drmrehorst.blogspot.com/2020/03/testing-ummds-new-z-axis-optical.html

I occasionally see people posting about using servomotors here. One thing you should know about them is that they can wipe out your controller board, power supply, and any other connected electronics if you are not very careful in their use. I was uncareful and learned this the hard way when I was building the Arrakis sand table.

I had slightly reduced the size of the corexy mechanism, but failed to update the travel limits in the config.g file. I then ran an old pattern file that was generated at the original, larger size on the new, smaller mechanism. I think all this happened before I had my morning coffee. The machine homed itself then took off at 1500 mm/sec and promptly slammed into the physical end of the Y axis, bringing the servomotors to an abrupt halt. That caused a voltage surge on the power supply line that destroyed the Duet2 WiFi controller board, the power supply, and some buck converters that were used to power LED strips.

Someone pointed me at an app note on the Gecko Drives web site that will protect from exactly this sort of problem (and mechanical failures like seized bearings, or someone/something (cats?) blocking the mechanism. This is the circuit:

I designed a PCB, ordered parts, and after waiting months for backordered connectors, decided not to wait any more. I built a couple boards and ran a test of the circuit prior to installing the servomotors in my 3D printer. The protection circuit appears to work as expected. The abruptly stopped motor generates a voltage spike that gets dissipated in the 33 Ohm 10W resistor and the spike is never seen by the power supply.

@MartinNYHC said in Belt tension:

Just finished my BLV mgn cube build and now need to fine tune all the stuff. I'm wondering what the right belt tension is. Are there any rules of thumb?

There are just two rules of thumb for corexy machine belt tension:

If the belts are too tight, you'll be putting a lot of force on the pulley and motor mounts, and if they are stacked belt type that stand up like a fence post, they are liable to flex inward. The mechanism may not move smoothly and may bind depending on the type of linear bearings and the design of the pulley mounts. If you see pulleys tilting inward, you're putting too much tension on the belts (or you need to redesign motor or pulley mounts).

If the belts are too loose they may slip on the drive pulleys - that's MUCH too loose. If they are so tight that the mechanism won't move smoothly, they are too tight. You want them to be somewhere between those extremes, and just about anywhere between those extremes will work fine.

Before you tension the belts, the X and Y axes should be square. When you tension the first belt, they X and Y axes will usually be pulled out of square an amount that will vary depending on the flexibility of the X axis assembly, the type of bearings and guide rails used, and the absolute tension applied.

When you tension the second belt, it will also increase tension on the first belt that you already tensioned, so when you tension the first belt, leave it a little looser than you feel is sufficient. Then, when you tension the second belt, the first one will tighten up. You are done adjusting tension when the X and Y axes are square and the belts are tight but not too tight. Usually, the belts will be close to equal tension when you're done, but getting the axes square is the final indicator, not equal belt tension.

If the belt tension varies as you move the extruder carriage around, the pulleys guiding the belts are not positioned correctly, and a major redesign is in order.

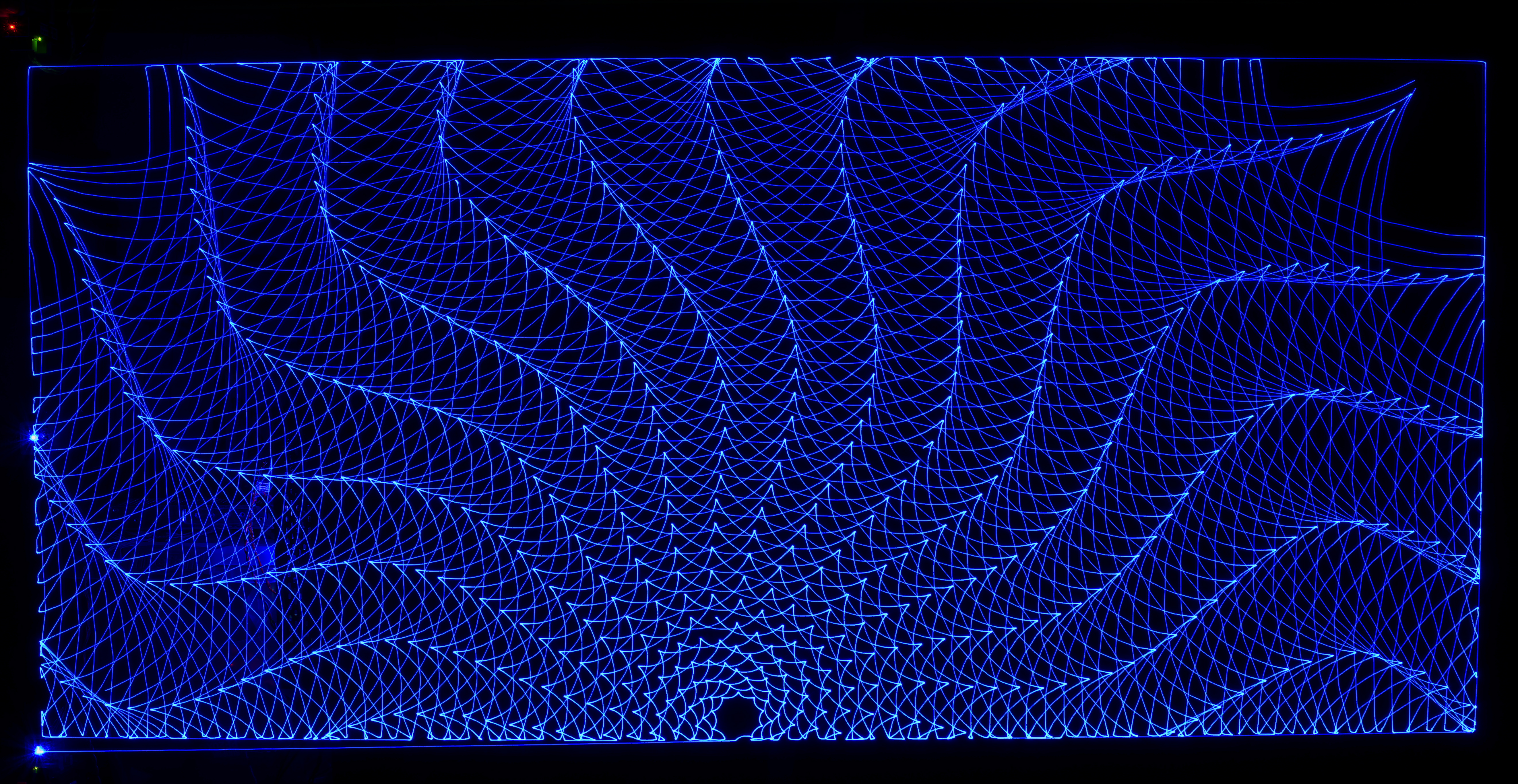

I put an LED and coin cell battery in the magnet holder, turned the table on its side, and ran a pattern. The result:

It took about 5 minutes with the speed at 2000, accel at 10k, and jerk at 12000.

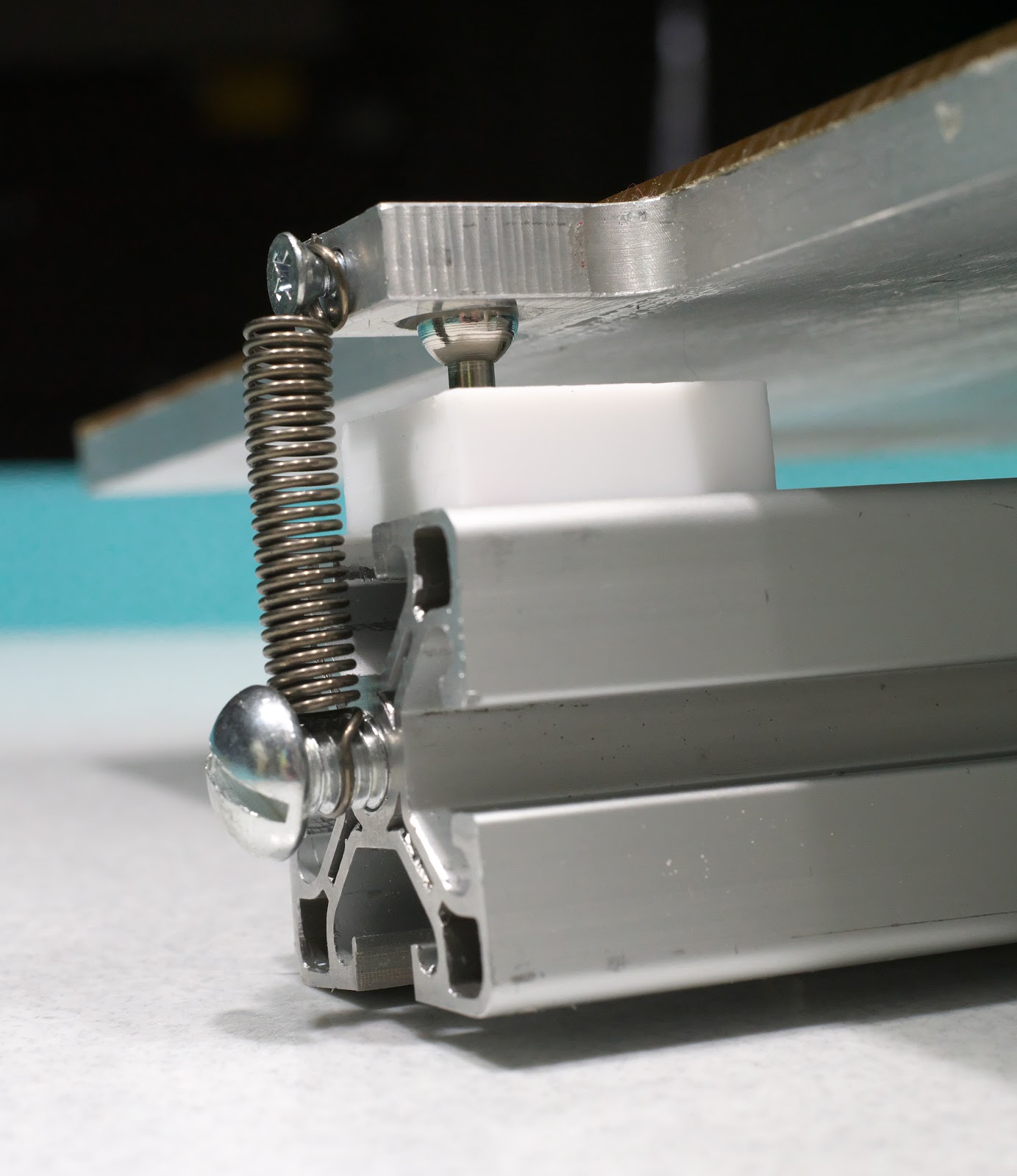

This may be of interest to those who still use endstop switches to set Z=0 in their printer. I was using a lever/cam with a clicky microswitch to set the Z=0 position in my printer, but it developed a problem so I decided to work on a replacement. I changed to an opto endstop that has an LED that lights when the beam is broken. But that's not the interesting part. I made a differential screw driven adjuster for the flag that breaks the light beam. The differential screw moves the flag 100 um per rev so it is very easy to make small adjustments without over adjusting. The differential screw assembly mounts on the bed support that moves up and down and the opto endstop mounts of the printer's frame:

The screw was made by turning the end of an M5x0.8 screw down to 4 mm on a lathe and then threading it for M4x0.7. When you turn the screw 1 rev, it moves 0.8 mm up, while the M4 nut (and the flag) move up 0.1 mm. It has about 2mm of adjustment range, so you get it close by moving the opto endstop on the frame, and make fine adjustment with the screw.

More: https://drmrehorst.blogspot.com/2020/03/a-new-z-axis-optical-endstop-design-for.html

This post is going to touch on a lot of topics previously discussed. I'm slowly sorting through the extrusion tuning posts and keep running into mentions of setting the extruder acceleration/jerk high so that among other things, the extruder doesn't limit the XY motion speeds.

What are good numbers to start with/use for extruder acceleration and jerk assuming one is going to turn on and tweak nonlinear extrusion and pressure advance? How would you actually test it to determine the limits? The firmware controls the extruder based on XY motion so there's no direct manipulation of the extrusion, other than to insert M201 statements into the gcode file (would that work?). Maybe print a line at some moderate speed/acceleration (well below the mechanism's limits) at some specific acceleration for E, then do it again and again stepping up the E acceleration until the extruder motor starts skipping? Does the Duet report extruder motor skipping, or am I listening to the extruder to determine when it skips?

Has anyone put together a compendium that goes through a step by step process for tuning the extruder/printer that includes nonlinear extrusion and pressure advance? There seems to be an awful lot of interacting variables.

Right now I'm thinking the sequence would be something like this:

If you change nozzle size or heater block/heater, go back to step 4 and do it all again.

I put the sandbox back on the table and ran some tests aimed at finding the upper limits of speed and acceleration for drawing patterns in the sand. I failed ... to find the limits!

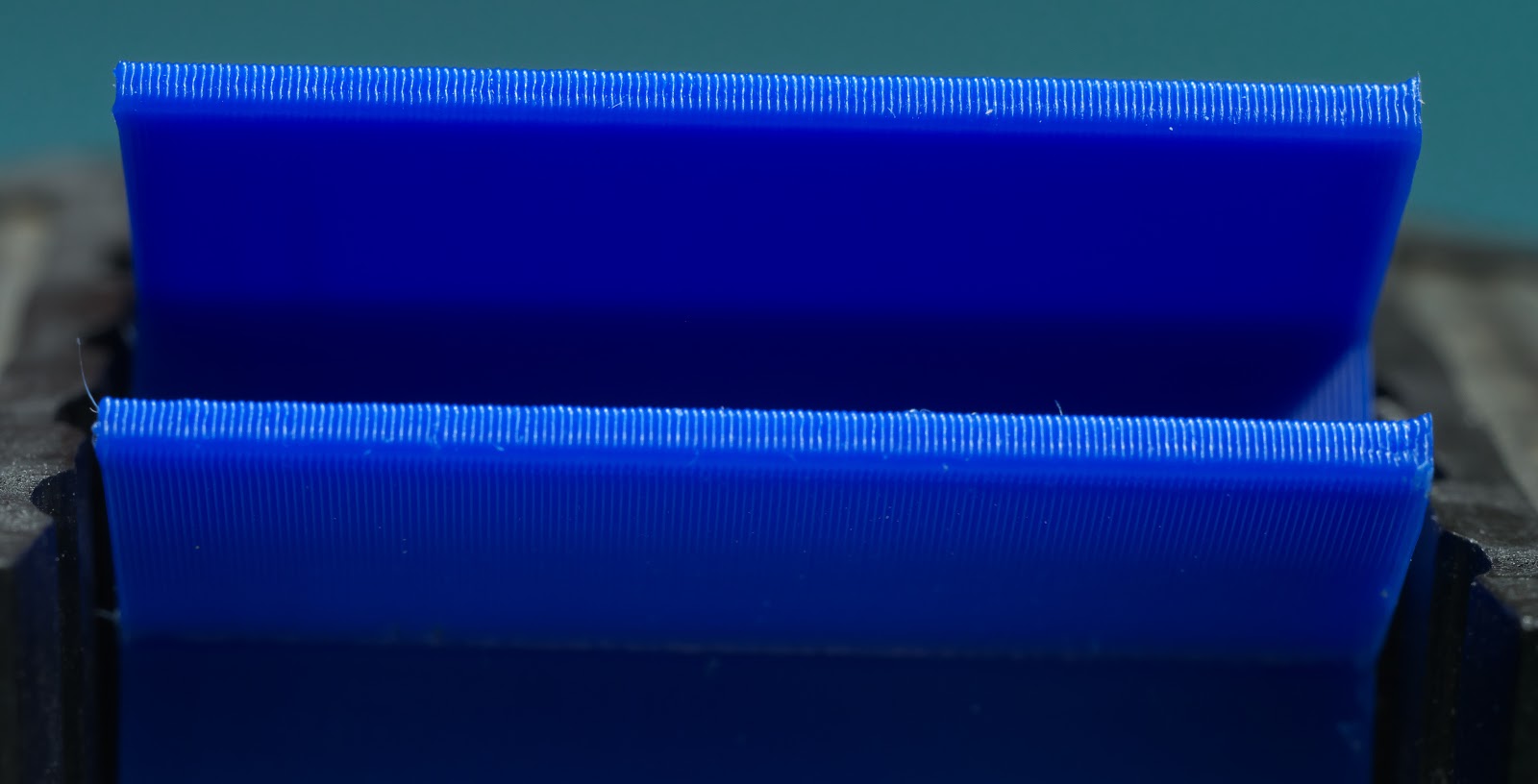

@giostark I don't know of any bed kits that are kinematic, but it isn't too had to DIY.

Start with 3 point support for bed plate- two ball head screws (or acorn nuts), and one "normal" screw:

Put one of the ball heads in a chamfered hole in the plate- this will be the reference adjuster:

And put the other ball head in a chamfered slot. This will be the pitch adjuster. Don't worry, they don't have to be milled- the slot can be cut with a saw and then filed a little to make a smooth edge for the ball to sit in. The plate is going to expand less than 1 mm, so the slot doesn't need to be long.

The third screw, the roll adjuster- just contacts the smooth underside of the plate.

At each screw the plate is free to tilt when you're leveling the bed. At the slot the plate is free to expand in the direction away from the reference screw, and tilt as needed while leveling the bed.

At the roll screw the plate is free to expand in X and Y.

Springs hold the plate down on the support.

See: https://drmrehorst.blogspot.com/2017/07/ultra-megamax-dominator-3d-printer-bed.html

and https://drmrehorst.blogspot.com/2019/04/more-changes-to-ummds-z-axis.html

Once you understand the basic concept, you can create this type of mount in many different ways. The slot doesn't have to be milled into the plate- it can be two parallel metal bars that are screwed to the plate. You can also invert the mount and put the ball head screws in the plate and the hole and slot on the support.

Leveling is easy. Adjust pitch, then roll. Done. If the assembly is solid, you won't have to do it again.

At 500mm/sec it is silent. At 1000 mm/sec it is very quiet.

It uses a mostly 3D printed corexy mechanism driven by servomotors. The controller is a Duet2 WiFi board with the expansion board to provide enable/step/direction for the integrated servomotors. Patterns are generated using Sandify.

A few minor changes yet to come- it needs a hair cut inside the sandbox- I don't like the fur peeking out under the cover, there's too much baking soda in there- it's a little too deep, and I'll be sealing the glass with a bead of silicone in case some doofus like me spills a drink on it (it's a coffee table...).

I'll be finishing a blog post on it soon and will post a link when its done.

It depends on what you're interested in. If you just want a machine that prints with minimal effort and you have the funds, buy a proven machine/kit.

If you're interested in the details of how the machines work and maximizing some specific types of performance, I would design and build from scratch. It takes time but you learn a lot along the way, including modeling in CAD, mechanical design, machining, where to buy parts, etc.

I am referring to AC servomotors used in place of steppers, not hobby servos used to change tools, etc.

I have been using iHSV servomotors in my new sand table build and was forced to make some mods to the mechanism which reduced its size in X and Y slightly. When I put it back together and ran a test file, not even thinking about the smaller dimensions, the mechanism ran into the end of an axis and promptly blew a power supply and Duet board up.

The servomotors will suck a lot of current to keep up with the input signal and in this case I think that when the mechanism hit the end of the axis, there was probably a large current spike as the motor tried to keep moving, which would have shut down the power supply, but it was moving very fast at the time, and shutting down the power supply would maybe have generated a large voltage spike on the supply line due to back EMF from the motor. I think... Whatever happened, it blew both the Duet board and power supply.

I tried replacing the voltage regulator chip but the Duet board was still dead, so I assume that a lot more than just the regulator chip bit the dust. I ordered a replacement board.

The 24V power supply is also dead- the output voltage has dropped to around 12V and bounces up and down a couple volts. I ordered a replacement.

I will be powering the Duet board from its own supply going forward. That should isolate it from the motor power lines and protect against similar mishaps.

I use a Duet wifi card in my sand table. Right now I can program playlists using the M98 command, but it would be nice if there was some means to randomly select pattern files to run from among any gcode file stored in a specific directory on card 0 or card 1. It would be especially nice if I could call a single gcode macro file upon power-up that would then randomly select pattern files to run and just keep doing that until the machine is powered off (maybe days or weeks later). That would require some looping capability, I imagine.

It would be especially nice if the random function were seeded by a real time clock or other means so that when I power up the table, the random sequence that it plays would be different every time (or almost every time).

CPAP blowers are not always easy to get or inexpensive if you buy them, so I designed a printable blower that uses a motor from a HDD which most people can get for free. About $3 worth of filament and $5 for a BLDC motor driver via ebay and you can move a lot of air quietly. Printed centrifugal blower/compressor.

I haven't tested it pushing air through a small tube like the Berdair thing. Maybe I'll get a chance in the next couple days.

https://www.filabot.com/blogs/news/57233604-the-misleading-biodegradability-of-pla

" The reality however, is that this process will take several hundred years in a typical landfill. To biodegrade, PLA requires a laundry list of conditions to effectively break down. Specifically - oxygen, a temperature of 140+ degrees, and a 2/3 cocktail of organic substrate. Collectively, these are absent in any scenario outside of industrial composting facilities. This means that PLA plastic will sit in that landfill right alongside ABS and other plastics for a very long time."

A perfect corexy mechanism really should have the same steps/mm in X and Y because of the symmetry of the construction and the way the motion works. Both motors turn for movement in either X or Y. Only one motor turns in each direction when you print a cube rotated 45 degrees. In your rotated print you're getting a 1 mm difference between the two motors that should not be there, implying that there may be something wrong with the printer geometry.

First things first- check the drive pulleys- are they securely attached to the motor shafts? Are motor mounts and and all pulleys solidly anchored? Everything should be rigid. They should not wobble at all when printing. Pulley axes should not be tilted inward by the belt tension.

What are you using for guide rails in X and Y? If you're using the v-slot wheel type construction, the printer's frame needs to be perfectly square. Check it by measuring diagonals. If you use end supported round guide rails, they can flex and be out of parallel. Are the Y axis guide rails parallel? Check by measuring diagonals. Can you post a picture of the printer, looking down from the top so we can see the belt paths? Are the belts stacked or on the same level? While you're at it, post a picture or two of the calibration prints...

Are the belts parallel to the guide rails? If they are not, the print geometry will be distorted in XY, and the distortion will vary depending on the print's location on the bed. If the printer's XY geometry is right, printing two cubes, one at the center and one near a corner of the bed, should yield identical results.

Calibrate the extruder before you start tweaking the XY steps/mm. The extruder should produce the line width you set in the slicer. Line width error won't be 0.3 mm, but it can contribute to the problem. Measure the filament diameter in 20-30 places, calculate an average value, and use that value when you slice to print the calibration cubes. Print an object with zero infill and 3 perimeters with line width set to the nozzle diameter (don't let the slicer set the line width for you), and layer thickness set to 50% of the nozzle diameter. Set the seam to "aligned" so all the start/stop problems end up in one corner of the print. Measure the print walls, avoiding areas of ringing, and away from the corners. Tweak the extruder steps/mm to get the correct wall thickness before you start messing with XY calibration.

I know it's called a "calibration cube", but a 20mm cube is too small to calibrate anything. There are too many potential distortions in the print because of thermal properties of the plastic and extrusion problems. If you use a small cube to calibrate steps/mm, when you print something larger, the absolute error from the calibration will get multiplied. If you use a large print to calibrate, when you print something smaller, the absolute error from the calibration will get divided. If you print a 100 mm cube to calibrate, you'll be able to measure the diagonals with a 6" caliper.

Print XY calibration parts with "random" seam position set in the slicer. If you use the "aligned" option, one corner of the print will have all the layer start/stop extrusion problems piled into it. That can lead to errors in the measured dimensions.

Check for squareness by measuring the diagonals of the cube. If the axes are square the diagonals should be the same. Make the measurements at least a few mm above the bottom of the print.