Yet another jerk and speed topic....

Anyhow, as I was performing some flow testing last night I came to a halt when I could not raise speed higher than 350mm/s on a 200mm single wall cylinder in vase mode.

Observations

Duet2 Wifi + Duex5

RRF2.05.1

Accel:

X - 20,000

Y - 20,000

E - 3000

Z - 200

Jerk:

X - 700

Y - 700

E - 1000

Z - 50

Starting from 300mm/s and up I could see that some section of the perimeter were being performed at different speed and some vibration was occurring.

The DWC speed indicators were also witnessing that speed variation.

I then tried to raise speed again, but nothing would happened, it was in a lock.

Surface finish was like if the tiny segments from the GCode were amplified.

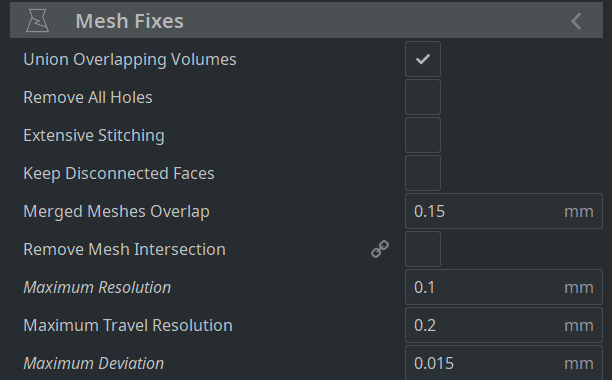

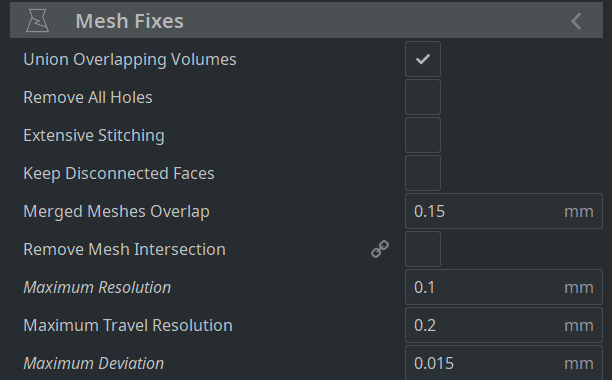

- Here are my resolution settings from Cura (I know 0.1mm resolution might be aggressive):

I then tried something....

I bumped jerk all the way to:

Jerk:

X - 3000

Y - 3000

Magic! speed went up well passed 500mm/s and surface finish was back to normal~ish.

Assumption

Since the GCode little segments are requiring direction change that are so small, the acceleration settings are not used, but jerk is instead.

Question

Is there a way to maintain speed on curves without having to bump jerk? Anything higher than 650-700 triggers step skipping at those accel and speed value.

And the 20000 accel is what allows me to print fast without skipping. Not that fast, but the max I can go with this issue for now: https://youtu.be/ZZDuX6hcd28?t=294

Thank you

Olivier