Jerk settings and curve print speeds / quality

-

Yet another jerk and speed topic....

Anyhow, as I was performing some flow testing last night I came to a halt when I could not raise speed higher than 350mm/s on a 200mm single wall cylinder in vase mode.Observations

- My settings were:

Duet2 Wifi + Duex5 RRF2.05.1Accel: X - 20,000 Y - 20,000 E - 3000 Z - 200Jerk: X - 700 Y - 700 E - 1000 Z - 50Starting from 300mm/s and up I could see that some section of the perimeter were being performed at different speed and some vibration was occurring.

The DWC speed indicators were also witnessing that speed variation.

I then tried to raise speed again, but nothing would happened, it was in a lock.Surface finish was like if the tiny segments from the GCode were amplified.

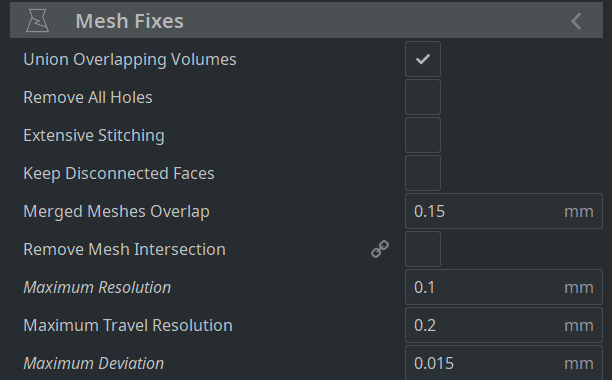

- Here are my resolution settings from Cura (I know 0.1mm resolution might be aggressive):

I then tried something....

I bumped jerk all the way to:Jerk: X - 3000 Y - 3000Magic! speed went up well passed 500mm/s and surface finish was back to normal~ish.

Assumption

Since the GCode little segments are requiring direction change that are so small, the acceleration settings are not used, but jerk is instead.Question

Is there a way to maintain speed on curves without having to bump jerk? Anything higher than 650-700 triggers step skipping at those accel and speed value.

And the 20000 accel is what allows me to print fast without skipping. Not that fast, but the max I can go with this issue for now: https://youtu.be/ZZDuX6hcd28?t=294Thank you

Olivier -

This is just exactly the way jerk works. Segments you were printing had sufficient angle between them to cause the instantaneous speed change to take effect, and the print head would slow down to (some proportion) of the "jerk" speed between the segments. Your high acceleration allowed for a lot of speed to be reached in a small distance, hence the odd seeming behaviour.

When you increased the jerk speed, it no longer had to slow down so much for those segments. You will notice, though, that sharp corners have lots of ringing now.

Decreasing the acceleration would have had a similar effect, but backwards: the print head would not be able to speed up as much between the vertices, so the negative effects would have been slightly mitigated -- though, the print speeds would be much slower.

Don't worry about it, though. Very smart people are at work planning an improved motion system for RRF.