@jay_s_uk no only these control the tube

Posts made by Macwolf

-

RE: Laser Outputposted in Laser Cutters

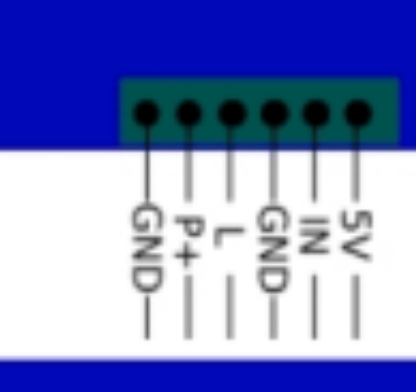

@jay_s_uk and the others there are more connections like 5v, p+ gnd ......where are these connected to the duet board?

-

RE: Laser Outputposted in Laser Cutters

@jay_s_uk yes that's true, but there is no line from the contacts to the board and I don't want to try until it works

-

RE: Laser Outputposted in Laser Cutters

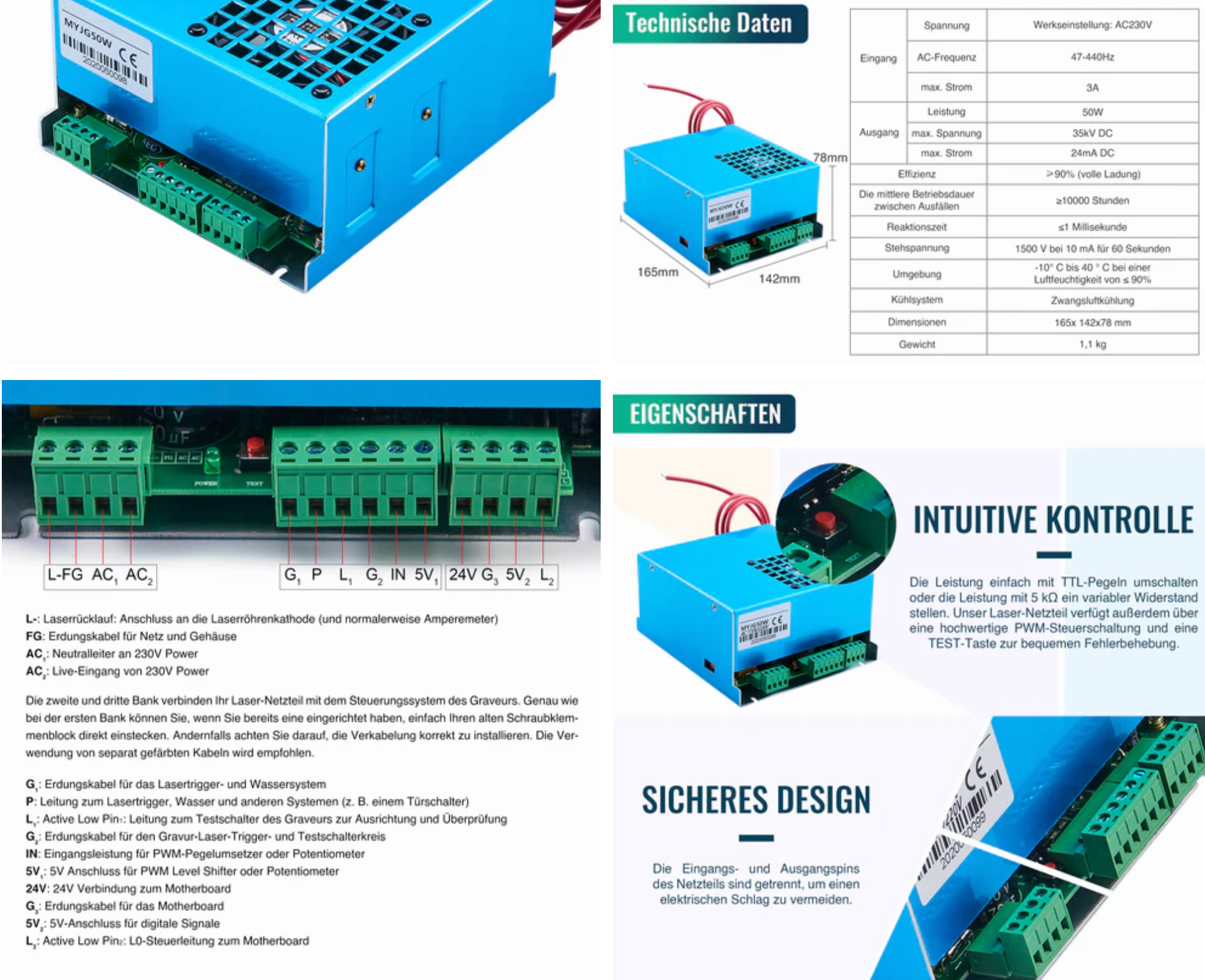

@dc42 my power supply is from the same manufacturer as the tube I have a diagram, but the description is in German

-

RE: Laser Outputposted in Laser Cutters

@jay_s_uk

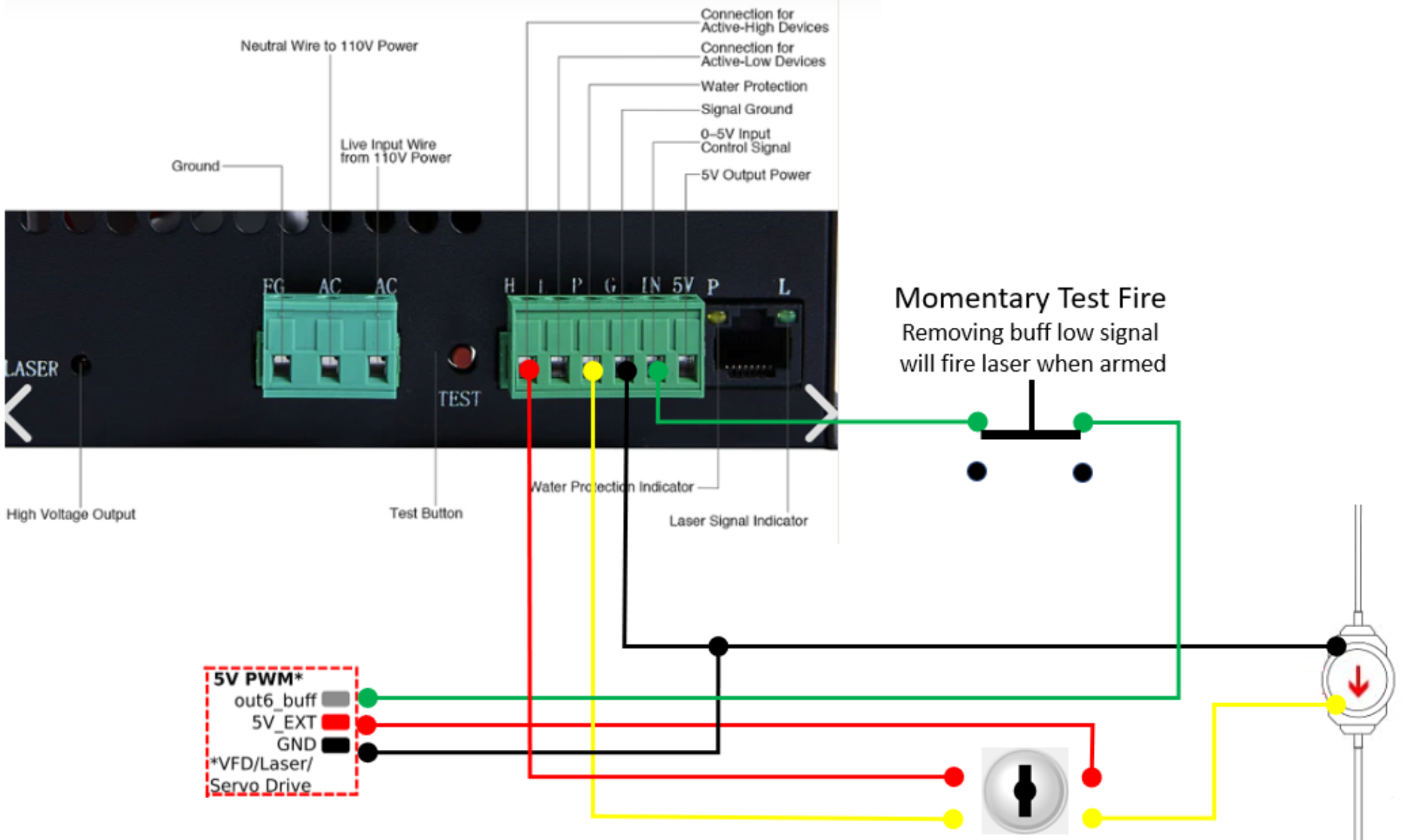

Out 1 is now the output for the laser, it doesn't deliver a negative signal, does it?further connections are needed.

-

5V for TH

-

ground

-

I simulate the cooling.

where exactly should I connect these cables to the power supply terminal

-

-

RE: Laser Outputposted in Laser Cutters

@jay_s_uk

A technical question: How much frequency does a 40W CO2 laser tube need? In your example, is the Q value 5000? Or does that not matter.

I am new to this area and am wondering whether I am implementing it technically correctly. There were no operating instructions included, neither with the power supply nor with the tube.Markus

-

RE: Laser Outputposted in Laser Cutters

@jay_s_uk

M452 C"! Laser" R255 Q500;

no change. or how to use the negative output -

RE: Laser Outputposted in Laser Cutters

the Duet board is configured, I use a CO2 tube. A "tool" is configured, see Config, but there is a problem, when I start up the machine, the laser is active!!!

I use the active high input on the laser power supply.

Markus

config.g -

RE: Laser Outputposted in Laser Cutters

@jay_s_uk Thanks, I didn't know that this source explained it.

-

Laser Outputposted in Laser Cutters

Hello, I have a Duet 3 XD and the "Laser, VFD..." connection is a mystery to me. How is this pin addressed? Is it an "OUT"? Unfortunately, it is not mentioned anywhere in the documentation.

Thanks -

Duet 3 Scanning Z probe questionsposted in General Discussion

Hello

duet has a scanning Z probe on offer, my question about the product is, can you use it as a "Z-endstop"? otherwise there would be 2 probes on the print head. one for bed mesh and one as an end stop. -

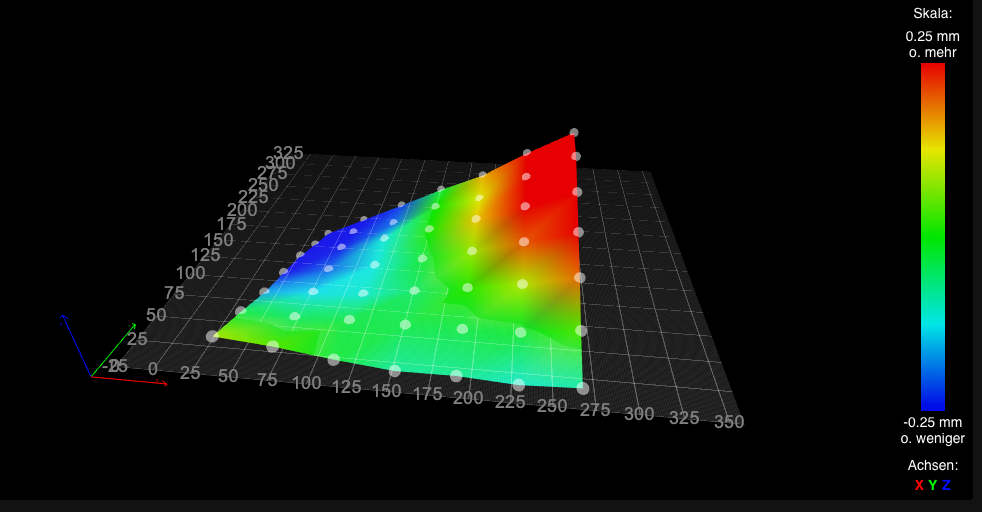

RE: is my bed crooked?posted in Tuning and tweaking

Thanks for the answers, meanwhile the highest value is 0.3mm, I drove off the top of the top plate

with a dial gauge, the Y rail is at 1-2/100. the bed is warped from the middle of 3/10.

Thanks Markus

-

RE: is my bed crooked?posted in Tuning and tweaking

@deckingman hence the question of whether the bed is crooked or something else, the Y rail (CBC) is mounted on aluminum, according to the height map the aluminum should be warped. if it's not the bed.

-

RE: is my bed crooked?posted in Tuning and tweaking

this machine is a tool changer with a 3 belt drive, the bed is 6 mm finely milled cast aluminum plate, I cannot check whether this is straight. but I think so.

to test I put a glass plate on the bed which is on 2 parallel pegs and the result is the same

that's on the borosilicate board

-

RE: is my bed crooked?posted in Tuning and tweaking

@Phaedrux

Does the order of the pivot points listed in M671 match the order of the motors listed in M584?

Yes

What results are displayed on a G32? Does it get better or worse if you do it more than once?

the result is always accurate

G32

Leadscrew adjustments made: 0.261 -0.106 0.064, points used 3, (mean, deviation) before (0.090, 0.112) after (0.000, 0.000)after

Leadscrew adjustments made: -0.020 0.035 0.036, points used 3, (mean, deviation) before (0.016, 0.017) after (0.000, 0.000)If the order doesn't match, you can actually add a twist to the bed instead of correcting it.

how does it work? -

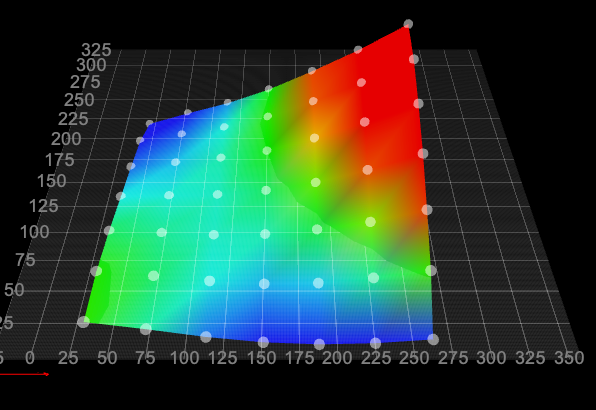

is my bed crooked?posted in Tuning and tweaking

I use three Z axes for the automatic bed alignment on my printer.

but the height map shows something strange.

I've attached the config and bed -

RE: SBC Problemposted in Duet Hardware and wiring

@Phaedrux said in SBC Problem:

You should remove the multiple values for the Z axis in all of these commands. It is set per axis. The only time multiple values are required is for extruders as they are independent axis.

Great problem solved

-

RE: SBC Problemposted in Duet Hardware and wiring

@Phaedrux said in SBC Problem:

At what point are you seeing this speed?

when homing above at "requested speed"

and of course the bed that moves in slow motion. Z also moves at 0.5mm/s when moving