@o_lampe

Thanks ,i will test it after work

Posts made by lui2004

-

RE: 2nd print too high and z-offset is inconsistent,config problem?posted in Tuning and tweaking

-

RE: 2nd print too high and z-offset is inconsistent,config problem?posted in Tuning and tweaking

no, i dont use babystep for the first print ,its all fine

prusa slicer start g-code:

T0 G28 XY ;Home XY M561 ; Clear any bed transform that might be in place G1 X162 Y110 ; Move Probe to middle of bed G30 ; Do a single probe G29 S1 ; Load my custom heightmap. Otherwise use G29 S1 G92 E0 ;Reset Extruder G1 Z2.0 F3000 ;Move Z Axis up M104 S[first_layer_temperature] ; set final nozzle print temp M109 S[first_layer_temperature] ; wait for the nozzle to heat up G1 X10.1 Y20 Z0.28 F5000.0 ;Move to start position G1 X10.1 Y200.0 Z0.28 F1500.0 E15 ;Draw the first line G1 X10.4 Y200.0 Z0.28 F5000.0 ;Move to side a little G1 X10.4 Y20 Z0.28 F1500.0 E30 ;Draw the second line G92 E0 ;Reset Extruderend g-code:

M106 S0 ; turn off cooling fan M104 S0 ; turn off extruder M140 S0 ; turn off bed G91 ; set to relative positioning G1 Z5 ; raise Z 5 mm G90 ; set to absolute positioning G1 X235 Y235 ; park at X0 Y0 M84 ; disable motors -

RE: 2nd print too high and z-offset is inconsistent,config problem?posted in Tuning and tweaking

Morning

the problem with the second preresist,the second print is always too high

i must shutdown the printer and then is all fine and the second print is again high

i dont know why

-

RE: 2nd print too high and z-offset is inconsistent,config problem?posted in Tuning and tweaking

no problem !

now i have follow problem, my z-offset shows me different z-offsets:

whats going wrong here ?Stopped at height 0.709 mm Stopped at height 0.729 mm Stopped at height 0.739 mm Stopped at height 0.756 mm Stopped at height 0.697 mm Stopped at height 0.696 mm Stopped at height 0.697 mm -

RE: 2nd print too high and z-offset is inconsistent,config problem?posted in Tuning and tweaking

@cosmowave said in 1st print perfect,2nd print too high,config problem ?:

M106 S0 ; turn off cooling fan M104 S0 ; turn off extruder M140 S0 ; turn off bed G91 ; relative positioning if {move.axes[2].userPosition +5} < move.axes[2].max; possible to move z+5 ? G0 Z+5; move z 5mm away from nozzle else G0 Z+{move.axes[2].max - move.axes[2].userPosition}; move z to the max possible position G90 ; set to absolute positioning G1 X235 Y235 ; park at X0 Y0 M84 ; disable motors

i got this error from prusaslicer:

G-code export to C:\Users\Lfna\AppData\Local\Temp\.2324.gcode failed due to invalid custom G-code sections: end_gcode Parsing error at line 5: Not a variable name if {move.axes[2].userPosition +5} < move.axes[2].max; possible to move z+5 ? ^ Please inspect the file C:\Users\Lfna\AppData\Local\Temp\.2324.gcode.tmp for error messages enclosed between !!!!! Failed to process the custom G-code template ... and !!!!! End of an error report for the custom G-code template ... for all macro processing errors. -

RE: 2nd print too high and z-offset is inconsistent,config problem?posted in Tuning and tweaking

@cosmowave said in 1st print perfect,2nd print too high,config problem ?:

G91 ; relative positioning if {move.axes[2].userPosition +5} < move.axes[2].max ; possible to move z+5 ? G0 Z+5 ; move z 5mm away from nozzle else G0 Z+{move.axes[2].max - move.axes[2].userPosition} ; move z to the max possible position

ok iadd this code in my Duet Stop.g

do i need to change something in my End G-Code ? -

RE: 2nd print too high and z-offset is inconsistent,config problem?posted in Tuning and tweaking

I use Prusaslicer

can you check my Start G-Code and End Gcode,please ?Start G-Code:

T0 G28 XY ;Home XY M561 ; Clear any bed transform that might be in place G1 X162 Y110 ; Move Probe to middle of bed G30 ; Do a single probe G29 S1 ; Load my custom heightmap. Otherwise use G29 S1 G92 E0 ;Reset Extruder G1 Z2.0 F3000 ;Move Z Axis up M104 S[first_layer_temperature] ; set final nozzle print temp M109 S[first_layer_temperature] ; wait for the nozzle to heat up G1 X10.1 Y20 Z0.28 F5000.0 ;Move to start position G1 X10.1 Y200.0 Z0.28 F1500.0 E15 ;Draw the first line G1 X10.4 Y200.0 Z0.28 F5000.0 ;Move to side a little G1 X10.4 Y20 Z0.28 F1500.0 E30 ;Draw the second line G92 E0 ;Reset ExtruderEnd G-Code:

M106 S0 ; turn off cooling fan M104 S0 ; turn off extruder M140 S0 ; turn off bed G91 ; set to relative positioning G1 Z5 ; raise Z 5 mm G90 ; set to absolute positioning G1 X235 Y235 ; park at X0 Y0 M84 ; disable motors -

RE: 2nd print too high and z-offset is inconsistent,config problem?posted in Tuning and tweaking

rest of config looks good ?

ok,now it looks like this:

homeall.g

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.3.4 on Thu Oct 14 2021 05:57:31 GMT+0200 (Mitteleuropäische Sommerzeit) ;M913 X35 Y35 Z35 ; Reduce motor currents for homing G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X 240 F3000 ; move quickly to X axis endstop and stop there (first pass) G1 H1 Y 240 F3000 ; move quickly to Y axis endstop and stop there (first pass) G1 H2 X-5 Y-5 F6000 ; go back a few mm G90 ; absolute positioning G1 X162 Y110 F2000 ; put head over the centre of the bed, or wherever you want to probeG30 ; home Z by probing the bed M558 F600 A1 ; Dive fast once G31 P500 X-52 Y0 Z0.689 C0.0010 S20 H5 ; set Z probe trigger value, offset and trigger height G30 ; probe Z M558 F100 A10 ; Slow second dive with more accuracy G31 P500 X-52 Y0 Z0.689 C0.0010 S20 H5 ; set Z probe trigger value, offset and trigger height G30 ; probe z again G29 S1 ; Load heightmap and enable mesh grid compensation G1 X235 Y235 Z10 F6000 ; return head to park position M913 X100 Y100 Z100 ; Return motor currents to normal ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioning -

2nd print too high and z-offset is inconsistent,config problem?posted in Tuning and tweaking

Hi

my Machine:

Ender 5 + Pinda V2

Micro Swiss Direct Drive + All Metal Hotend

Board: Duet 2 WiFi

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.3 (2021-06-15)

Duet WiFi Server Version: 1.26After i set the new Z-Offset the print come out pretty perfect ,first layer all perfect.

but if i start a second print after the first one it will print too high and i dont know why ?if i run G29 it will probe the bed very slow

i will my show you my config:

config.g

; Configuration file for Duet WiFi (firmware version 1.21) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2 on Tue May 07 2019 23:06:50 GMT+0100 (British Summer Time) ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Network M550 P"Ender 5" ; Set machine name M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P0 S0 ; Physical drive 0 goes forwards M569 P1 S0 ; Physical drive 1 goes forwards M569 P2 S0 ; Physical drive 2 goes backwards M569 P3 S1 ; Physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z800.00 E272.00 ; set steps per mm M566 X800.00 Y800.00 Z60.00 E3000.00 ; Set maximum instantaneous speed changes (mm/min) M203 X12000.00 Y12000.00 Z900.00 E6000.00 ; Set maximum speeds (mm/min) M201 X6000.00 Y6000.00 Z200.00 E6000.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E1400 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X220 Y220 Z300 S0 ; set axis maxima ; Endstops ;M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop ;M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 X2 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y2 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ;Filament Sensors ;M591 D0 P2 C"!e0_stop" S1 ;Extruder 1(0) ; PINDA2 M558 P8 C"^zprobe.in" H5 F1000 T6000 A20 S0.005 ; set Z probe type to effector and the dive height + speeds, max number of probes per point, tolerance(MM) M308 S2 P"e1temp" A"Pinda V2" Y"thermistor" T100000 B3950 ; temperature of PINDA2 G31 P500 X-52 Y0 Z0.689 C0.0010 S20 H5 ; set Z probe trigger value, offset and trigger height ;M557 X10:168 Y10:200 P2 ; zum leveln aktivieren M557 X0:220 Y0:220 S20 ;M671 X28.8:198.8:198:28.8 Y24:24:194:194 P0.5 ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S280 ; set temperature limit for heater 1 to 300C M307 H1 B0 S1.00 ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 ; Define tool 0 S3D G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Automatic saving after power loss is not enabled ; Custom settings are not configured M575 P1 S1 B57600 ; enable support for PanelDue ;M572 D0 S0.1 ; Pressure Advance PETG ;M572 D0 S0.095 ; Pressure Advance PLA M572 D0 S0.025 ; Pressure Advance PLA M207 S0.80 R0 F1800 T1800 Z0 ; Firmware Retraction M204 P600 T2000 ;set print and travel accellerations T0 ; Sets Tool0 as default M501config-override.g

; config-override.g file generated in response to M500 at 2021-10-21 11:41 ; This is a system-generated file - do not edit ; Heater model parameters M307 H0 R0.236 C467.211:467.211 D10.35 S1.00 V24.2 B0 I0 M307 H1 R2.289 C148.192:133.205 D5.09 S1.00 V24.3 B0 I0 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 G10 L2 P9 X0.00 Y0.00 Z0.00homeall.g

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.3.4 on Thu Oct 14 2021 05:57:31 GMT+0200 (Mitteleuropäische Sommerzeit) M913 X35 Y35 Z35 ; Reduce motor currents for homing G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X 240 F3000 ; move quickly to X axis endstop and stop there (first pass) G1 H1 Y 240 F3000 ; move quickly to Y axis endstop and stop there (first pass) G1 H2 X-5 Y-5 F6000 ; go back a few mm G90 ; absolute positioning G1 X162 Y110 F2000 ; put head over the centre of the bed, or wherever you want to probeG30 ; home Z by probing the bed M558 F600 A1 ; Dive fast once G30 ; probe Z M558 F100 A10 ; Slow second dive with more accuracy G30 ; probe z again G29 S1 ; Load heightmap and enable mesh grid compensation G1 X235 Y235 Z10 F6000 ; return head to park position M913 X100 Y100 Z100 ; Return motor currents to normal ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioninghomex.g

; homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v3.3.4 on Thu Oct 14 2021 06:02:43 GMT+0200 (Mitteleuropäische Sommerzeit) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X240 F1800 ; move quickly to X axis endstop and stop there (first pass) G1 H2 X-5 F6000 ; go back a few mm G1 H1 X240 F360 ; move slowly to X axis endstop once more (second pass) G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioninghomey.g

; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v3.3.4 on Thu Oct 14 2021 06:04:12 GMT+0200 (Mitteleuropäische Sommerzeit) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 Y240 F1800 ; move quickly to Y axis endstop and stop there (first pass) G1 H2 Y-5 F6000 ; go back a few mm G1 H1 Y240 F360 ; move slowly to Y axis endstop once more (second pass) G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioninghomez.g

; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Jul 28 2020 08:52:37 GMT+0200 (Mitteleuropäische Sommerzeit) M913 X35 Y35 Z35 ; Reduce motor currents for homing G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G90 ; absolute positioning G1 X162 Y110 ; Move Probe to middle of bed G30 ; Do a single probe M913 X100 Y100 Z100 ; Return motor currents to normalheightmap.csv

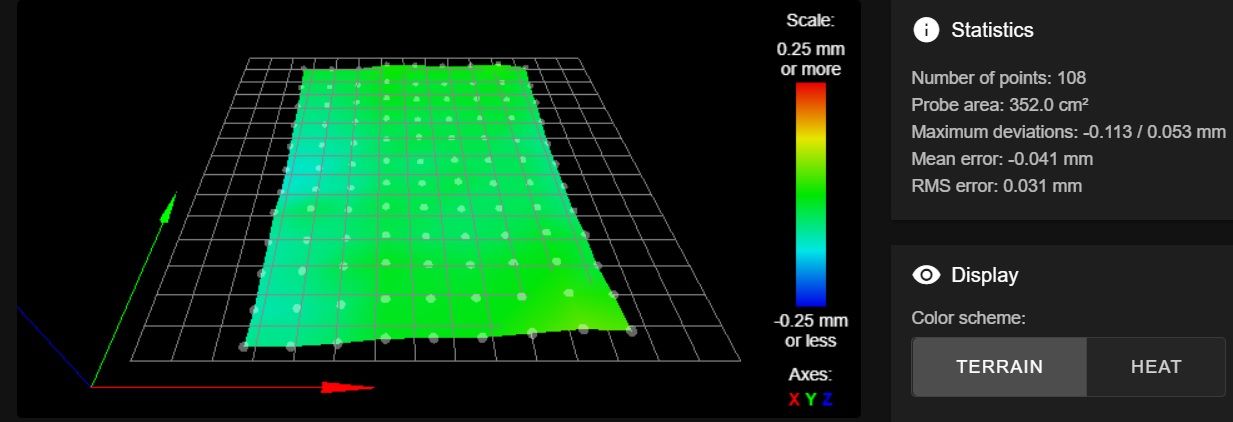

RepRapFirmware height map file v2 generated at 2021-10-25 16:36, min error -0.113, max error 0.053, mean -0.041, deviation 0.031 axis0,axis1,min0,max0,min1,max1,radius,spacing0,spacing1,num0,num1 X,Y,0.00,220.00,0.00,220.00,-1.00,20.00,20.00,12,12 -0.073, -0.073, -0.050, -0.014, -0.010, -0.007, 0.024, 0.053, 0.040, 0, 0, 0 -0.097, -0.086, -0.061, -0.019, -0.017, -0.013, -0.005, 0.020, 0.010, 0, 0, 0 -0.088, -0.070, -0.038, -0.014, -0.024, -0.028, -0.015, -0.004, -0.032, 0, 0, 0 -0.091, -0.074, -0.062, -0.040, -0.048, -0.050, -0.042, -0.022, -0.035, 0, 0, 0 -0.073, -0.048, -0.059, -0.035, -0.041, -0.052, -0.048, -0.042, -0.064, 0, 0, 0 -0.110, -0.093, -0.082, -0.047, -0.048, -0.037, -0.050, -0.046, -0.070, 0, 0, 0 -0.113, -0.104, -0.075, -0.052, -0.060, -0.045, -0.048, -0.045, -0.072, 0, 0, 0 -0.095, -0.090, -0.074, -0.046, -0.032, -0.037, -0.037, -0.054, -0.077, 0, 0, 0 -0.079, -0.077, -0.058, -0.032, -0.042, -0.040, -0.032, -0.030, -0.058, 0, 0, 0 -0.069, -0.062, -0.041, -0.012, -0.021, -0.020, -0.018, -0.023, -0.041, 0, 0, 0 -0.048, -0.048, -0.033, -0.010, -0.025, -0.025, -0.021, -0.015, -0.039, 0, 0, 0 -0.017, -0.023, -0.018, 0.010, 0.006, 0.001, 0.003, 0.015, -0.009, 0, 0, 0

first print:

second print:

-

RE: problems with Stringingposted in Tuning and tweaking

cheap ? 1 plated copper nozzle arround 17€

-

RE: problems with Stringingposted in Tuning and tweaking

i can see the differences between 0 and 4mm on retraction

-

problems with Stringingposted in Tuning and tweaking

Hi

Ender5

Micro Swiss Direct Drive

All Metal Hotend genuine with 0.4 Nozzle

Extruder Motor: Compact But Powerful motor 0.9°Filament:

its new filament i have buy it yesterday

sunlu

Petg 1.75

Temp: 235°C , Bed: 70°CI have try to reduce stringing with retract from 1.0 to 3.5 but nothing always stringing.

i use the firmware retract and also for test retraction with Prusaslicer alway the same result.

if you need something like config or other please tell me i will repost it

thanks

-

RE: Config for the Pinda v2 ,need help!posted in Tuning and tweaking

Thanks ,i will give it a try!

Other question when print is finished my z axis at 0 what i can do that the z-axis goes u after print?

-

RE: Config for the Pinda v2 ,need help!posted in Tuning and tweaking

Hi

Is there a how to ,to set z offset on different temperature? Like in marlin?

-

RE: Config for the Pinda v2 ,need help!posted in Tuning and tweaking

This is my actuall config.g

; Configuration file for Duet WiFi (firmware version 1.21) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2 on Tue May 07 2019 23:06:50 GMT+0100 (British Summer Time) ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Network M550 P"Ender 5" ; Set machine name M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P0 S1 ; Physical drive 0 goes forwards M569 P1 S1 ; Physical drive 1 goes forwards M569 P2 S0 ; Physical drive 2 goes backwards M569 P3 S1 ; Physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E288.30 ; set steps per mm M566 X600.00 Y600.00 Z60.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z600.00 E6000.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E1400 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X235 Y235 Z250 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ;Filament Sensors M591 D0 P2 C"!e0_stop" S1 ;Extruder 1(0) ; PINDA2 ;M558 P5 C"^zprobe.in" H1.5 F1000 T12000 A3 ; set Z probe to PINDA2 M558 K0 P8 C"^zprobe.in" I1 H2 F1000 T6000 A20 S0.005 ; set Z probe type to effector and the dive height + speeds, max number of probes per point, tolerance(MM) M308 S2 P"e1temp" A"Pinda V2" Y"thermistor" T100000 B3950 ; temperature of PINDA2 G31 P500 X52.7 Y18 Z1.775 ; set Z probe trigger value, offset and trigger height M557 X10:210 Y10:210 S20 ; define mesh grid ;M557 X41.2:219 Y15:195 S20 ;M671 X28.8:198.8:198:28.8 Y24:24:194:194 P0.5 M557 X10:220 Y10:220 S20 ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S280 ; set temperature limit for heater 1 to 300C M307 H1 B0 S1.00 ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 ; Define tool 0 S3D G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Automatic saving after power loss is not enabled ; Custom settings are not configured M575 P1 S1 B57600 ; enable support for PanelDue M572 D0 S0.05 ; Pressure Advance PLA ;M572 D0 S0.08 ; Pressure Advance PLA M207 S1.50 R0 F2100 T2100 Z0 ; Firmware Retraction P0 S0.45 R0 F2100 T2100 Z0 ; Firmware Retraction M204 P500 T2000 T0 ; Sets Tool0 as default M501homeall.g

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Jul 28 2020 08:52:12 GMT+0200 (Mitteleuropäische Sommerzeit) G91 ; relative mode G1 H2 Z4 F200 ; raise head 4mm G1 H1 X-240 Y-240 F3000 ; move up to 240mm in the -X and -Y directions until the homing switches are triggered G1 H2 X4 Y4 F600; move slowly 6mm in +X and +Y directions G1 H1 X-10 Y-10 ; move up to 10mm in the -X and -Y directions until the homing switches are triggered G90 ; back to absolute mode G1 X57.3 Y92 F2000 ; put head over the centre of the bed, or wherever you want to probe G30 ; lower head, stop when probe triggered and set Z to trigger height; homex.g

; homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v2 on Tue May 07 2019 23:06:50 GMT+0100 (British Summer Time) G91 ; relative mode G1 H2 Z4 F200 ; raise head to avoid dragging nozzle over the bed G1 H1 X-240 F3000 ; move up to 240mm in the +X direction, stopping if the homing switch is triggered G1 X-4 F600 ; move slowly 4mm in the -X direction G1 H1 X10 ; move slowly 10mm in the +X direction, stopping at the homing switch G1 H2 Z-4 F200 ; lower the head again G90 ; back to absolute modehomey.g

; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v2 on Tue May 07 2019 23:06:50 GMT+0100 (British Summer Time) G91 ; relative mode G1 H2 Z4 F200 ; raise head to avoid dragging nozzle over the bed G1 H1 Y-240 F3000 ; move up to 240mm in the -X direction, stopping if the homing switch is triggered G1 X4 F600 ; move slowly 4mm in the +X direction G1 H1 X-10 ; move slowly 10mm in the -X direction, stopping at the homing switch G1 H2 Z-4 F200 ; lower the head again G90 ; back to absolute modehomez.g

; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Jul 28 2020 08:52:37 GMT+0200 (Mitteleuropäische Sommerzeit) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G90 ; absolute positioning G1 X57.3 Y92 F6000 ; go to first probe point G30 ; home Z by probing the bedthanks for help

-

RE: Config for the Pinda v2 ,need help!posted in Tuning and tweaking

I bought a new surface !

what is important to calibrate the pinda V2 ?

-

RE: Config for the Pinda v2 ,need help!posted in Tuning and tweaking

aluminium bed with pei

this is my heightmap:

RepRapFirmware height map file v2 generated at 2021-10-12 14:59, min error -0.093, max error 0.125, mean 0.003, deviation 0.049 axis0,axis1,min0,max0,min1,max1,radius,spacing0,spacing1,num0,num1 X,Y,10.00,220.00,10.00,220.00,-1.00,20.00,20.00,11,11 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0 0, 0, 0, 0.008, -0.000, 0.091, 0.057, -0.005, 0.050, 0.050, 0.007 0, 0, 0, -0.000, -0.025, 0.082, 0.087, 0.050, 0.032, 0.091, -0.009 0, 0, 0, -0.018, 0.025, 0.116, 0.125, 0.012, 0.007, 0.082, -0.025 0, 0, 0, -0.025, 0.016, 0.116, 0.125, -0.018, 0.032, -0.005, -0.050 0, 0, 0, -0.043, -0.025, 0.041, 0.025, -0.009, -0.018, 0.025, -0.084 0, 0, 0, -0.050, -0.075, -0.034, -0.018, -0.000, -0.000, -0.000, -0.059 0, 0, 0, -0.050, -0.038, -0.034, -0.021, -0.018, -0.018, 0.037, -0.059 0, 0, 0, -0.055, -0.050, -0.043, 0.025, -0.018, -0.034, -0.055, -0.093 0, 0, 0, -0.063, -0.034, 0.032, 0.025, 0.016, -0.009, 0.020, -0.050 0, 0, 0, -0.030, -0.025, 0.007, -0.000, 0.025, 0.025, 0.050, 0.041 -

RE: Config for the Pinda v2 ,need help!posted in Tuning and tweaking

the pinda wont trigger because i have a pei surface.

i have insert some Aluminum foil under the pei i now it will work.

which surface is good without Aluminum foil under pei ?