It would be really nice if Duet Web Control could Log the temperatures and positions with timestamps that it receives from the board to a CSV locally on the machine where Duet Web Control is running in the Browser.

Best posts made by lee7670

-

Logging Temperatures and positions to CSV from Duet Web Controlposted in Duet Web Control wishlist

-

Support for BISS-C Encoders on 1HCL via IC-Haus IC-MB4 Chipposted in Firmware wishlist

Hello,

It would be extremely useful to support using an absolute linear encoder to close the position loop on BISS-C Absolute Linear encoders as the linear element in a dual loop configuration.To that end, there is a relatively (~$10USD) affordable IC that is SPI accessible that can handle 2 BISS-C/SSI encoders.

https://www.ichaus.de/product/ic-mb4/

US Sample Shop

https://us-shop.ichaus.com/ProductDetails.asp?ProductCode=iC-MB4-QFN28-5x5-SAMPLE

German Sample Shop

https://de-shop.ichaus.com/ic-mb4-qfn28-5x5.htmlIn this case, instead of using the duet magnetic encoder on the motor and a quadrature encoder on the load,

you could use either a quadrature encoder on the motor and a BISS-C Absolute linear encoder on the load.

Alternatively, the IC-MB4 supports 2 BISS-C encoders when used with external RS-422 transceivers so you could just use a second absolute Biss-C encoder on the motor itself, so you don't have to phase the motor upon power on.Examples of BISS-C encoders that are applicable to this use case

Renishaw Resolute

https://www.renishaw.com/en/resolute-encoder-series--37823

RLS LA11

https://www.rls.si/eng/la11-linear-absolute-encoder? -

TMC4671 expansion boardposted in Hardware wishlist

The TMC4671 (https://www.trinamic.com/products/integrated-circuits/details/tmc4671/) can support steppers, Three-Phase, and DC motors/voice coils all running closed loop with Field Oriented Control for steppers and three phase motors.

Having an expansion board running one or more of these of these drivers with a power stage of 4 half bridges would allow maximum flexibility for motors/feedback.

There are dual feedback inputs so you can have one feedback mechanism for commutation and one for the actual position loop. They support both incremental ABN encoders, Hall sensors, and BISS-C/SSI encoders.

This would allow you to drive essentially any motor in step/direction mode from a duet.

Sweet tiny extruder with a micro geared dc motor for the smallest direct drive possible (https://www.pololu.com/product/3055)? You got It!

Drive a linear motor for the absolute fastest speeds for benchy printing? You can do it!

Motor torque feedback for extruder pushing force tracking and grinding prevention? Totally doable.

Want to drive a voice coil optical stage that you got on ebay just because? Easy.

Got your hands on some optical scales from a CNC and never want to use limit switches again? Sure.

That's a lot of functionality for a 12USD chip...

-

M291 Image File Supportposted in Duet Web Control wishlist

It would be really interesting to support Image serving in the M291 command to better allow setup procedure to be shown that aren't easily described using text.

Use cases would be things like CNC setups, cleaning procedures, bed prep procedures, warnings to clear certain areas, etc.

I( have a couple of procedures where it would be really helpful to allow operators to check visual references against an image.

This could even be a pi exclusive feature if the Duet 3 MB6HC can't handle serving image files.

See this reference from HAAS on what this could look like. Massive Cheese warning....

https://www.youtube.com/watch?time_continue=2&v=_FxHfVKSOcs&feature=emb_logo -

RE: Using multiple outputs for single heaterposted in Firmware wishlist

I have a similar situation where this would be very useful in general for heater outputs for multi-heater beds and extruders and other things.

-

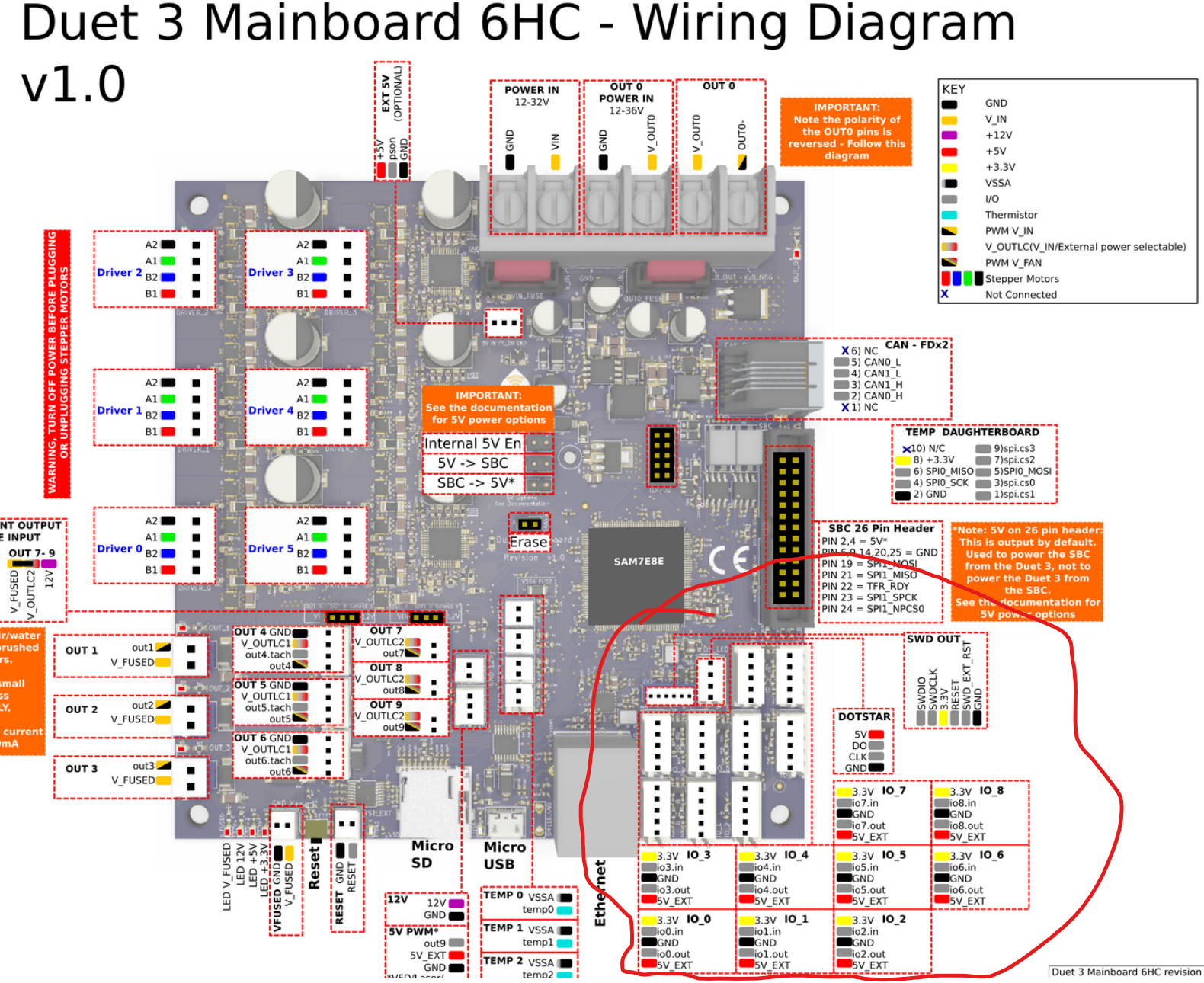

RE: Wiring a 3 pin end-stop switch a Duet3 6HCposted in General Discussion

You'll want to use the general IO headers for this.

Choose one, I usually start with IO_1.

Connect 5V_ext to V+.

Connect Ground to Ground.

Connect the Signal pin to IO_X.in

Latest posts made by lee7670

-

Support for BISS-C Encoders on 1HCL via IC-Haus IC-MB4 Chipposted in Firmware wishlist

Hello,

It would be extremely useful to support using an absolute linear encoder to close the position loop on BISS-C Absolute Linear encoders as the linear element in a dual loop configuration.To that end, there is a relatively (~$10USD) affordable IC that is SPI accessible that can handle 2 BISS-C/SSI encoders.

https://www.ichaus.de/product/ic-mb4/

US Sample Shop

https://us-shop.ichaus.com/ProductDetails.asp?ProductCode=iC-MB4-QFN28-5x5-SAMPLE

German Sample Shop

https://de-shop.ichaus.com/ic-mb4-qfn28-5x5.htmlIn this case, instead of using the duet magnetic encoder on the motor and a quadrature encoder on the load,

you could use either a quadrature encoder on the motor and a BISS-C Absolute linear encoder on the load.

Alternatively, the IC-MB4 supports 2 BISS-C encoders when used with external RS-422 transceivers so you could just use a second absolute Biss-C encoder on the motor itself, so you don't have to phase the motor upon power on.Examples of BISS-C encoders that are applicable to this use case

Renishaw Resolute

https://www.renishaw.com/en/resolute-encoder-series--37823

RLS LA11

https://www.rls.si/eng/la11-linear-absolute-encoder? -

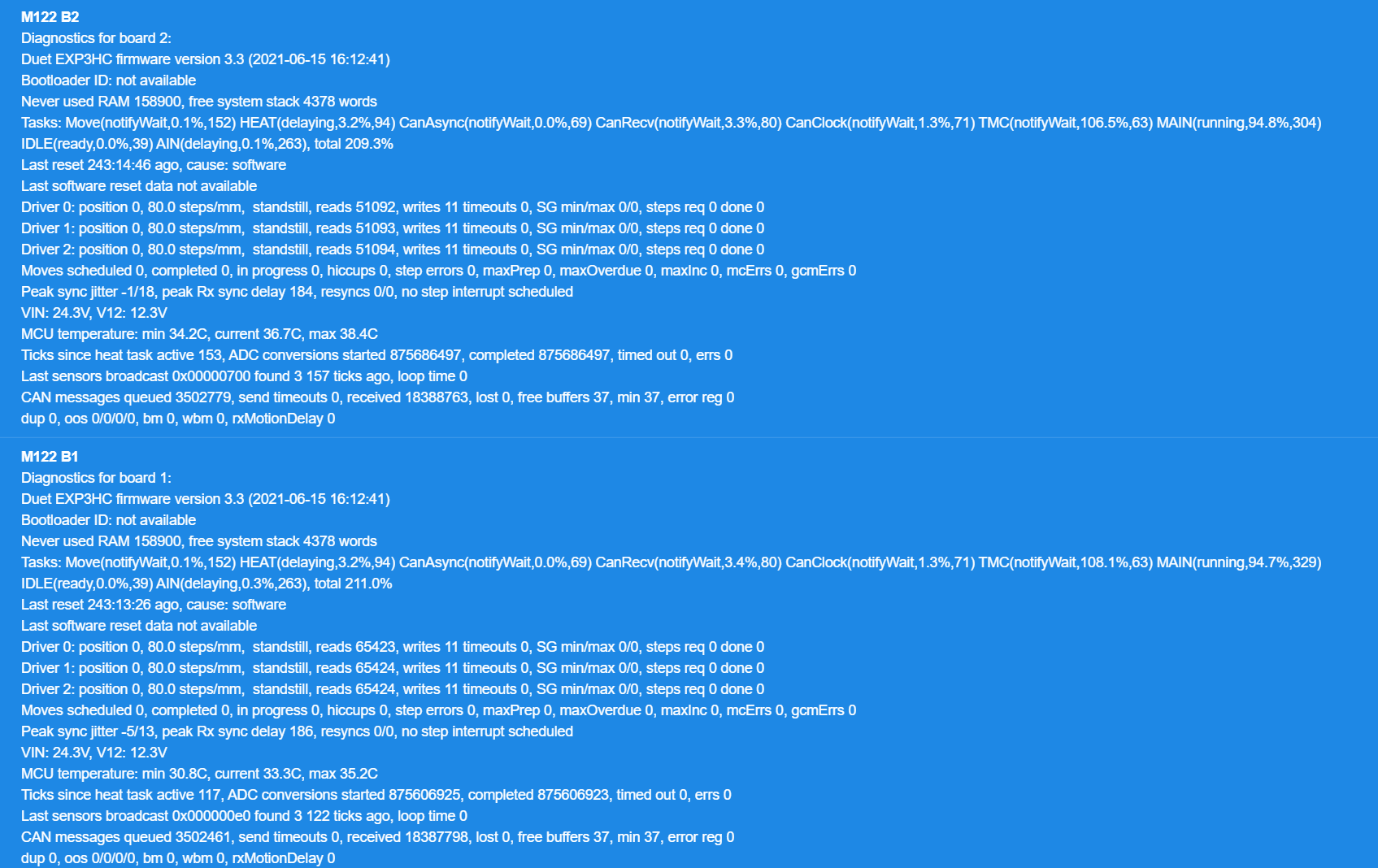

RE: Temperature duplication on Expansion board sensors on 3.3 stableposted in Using Duet Controllers

@t3p3tony Running in standalone mode.

2 boards were showing the error when I checked for you. Here's the M122 output.

M105 doesn't output anything because we have no heaters set up. -

RE: Temperature duplication on Expansion board sensors on 3.3 stableposted in Using Duet Controllers

@droftarts Tried fixing that, no change, running config.g manually reports no errors.

-

RE: Temperature duplication on Expansion board sensors on 3.3 stableposted in Using Duet Controllers

@dc42

Errors persist for a couple of minutes at a time.

They display temperatures of other sensors on the same expansion board, it is intermittent though.

The main board has never had any duplication -

Temperature duplication on Expansion board sensors on 3.3 stableposted in Using Duet Controllers

I have a temperature sensor array using 1 duet 3 main board and 4 exp3hc boards with PT1000 sensors hooked up to all ports.

Temperature sensors on the expansion boards only (not the main board) seem to duplicate the value of other ports on that board even though they are at very different temperatures.

This seems to be a per expansion board thing so the 3 temperature sensors per board will only seem to sporadically duplicate sensors on the same board.

All boards are on 3.3 stable. I have tried other versions and they seem to do the same thing.

Also, is it possible to have the change the graph temperature range?

Config is below.

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"manytempsensors" ; set printer name ; Network M551 P"" ; set password M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S1 ; enable FTP M586 P2 S1 ; enable Telnet ;RTDs M308 S1 P"temp0" Y"pt1000" A"RTD1" R2200 M308 S2 P"temp1" Y"pt1000" A"RTD2" R2200 M308 S3 P"temp2" Y"pt1000" A"RTD3" R2200 M308 S4 P"temp3" Y"pt1000" A"RTD4" R2200 M308 S5 P"1.temp0" Y"pt1000" A"RTD5" R2200 M308 S6 P"1.temp1" Y"pt1000" A"RTD6" R2200 M308 S7 P"1.temp2" Y"pt1000" A"RTD7" R2200 M308 S8 P"2.temp0" Y"pt1000" A"RTD8" R2200 M308 S9 P"2.temp1" Y"pt1000" A"RTD9" R2200 M308 S10 P"2.temp2" Y"pt1000" A"RTD10" R2200 M308 S11 P"3.temp0" Y"pt1000" A"RTD11" R2200 M308 S12 P"3.temp1" Y"pt1000" A"RTD12" R2200g M308 S13 P"3.temp2" Y"pt1000" A"RTD13" R2200 M308 S14 P"4.temp0" Y"pt1000" A"RTD14" R2200 M308 S15 P"4.temp1" Y"pt1000" A"RTD15" R2200 M308 S16 P"4.temp2" Y"pt1000" A"RTD16" R2200Ex. 2 different sensors with very different temperatures, but they read the same.

-

RE: Manually provide the number of steps to be executed by a drive?posted in Firmware developers

Just set steps per unit to1?

-

RE: FEED HOLD (Stop Motion)posted in General Discussion

@dc42 is there more detail on how segmentation works? If I pause mid move with segmentation on, move a motor, G92 a couple axes and then resume, will it resume mid segment?

-

Logging Temperatures and positions to CSV from Duet Web Controlposted in Duet Web Control wishlist

It would be really nice if Duet Web Control could Log the temperatures and positions with timestamps that it receives from the board to a CSV locally on the machine where Duet Web Control is running in the Browser.

-

How to get new M307/M301 to applyposted in General Discussion

Hi, I'm trying to tune a pesky unstable heater. Autotuning is unstable for various reasons, so I am having to tune M307/M301 Parameters by hand.

Do I need to turn off the heater to change the heater model/PID parameters or can I change them on the fly? It's hard to tell whether the new parameters have taken effect.

If I run a M301 to try some Legacy PID parameters and I want to switch back to an M307 heater model afterwards do I need to reset the board before doing that to remove the overrides or can I just send an M307?