@dc42 Thanks for confirmation that current thing on z axis.

Just totally missed that "speed factor" setting both web control and duetpanel. Very nice that be there

@Phaedrux There is about 10mm space between under pcs --> printed mount. I know this kind of IC:s (stepper ic:s) cooled otherside to board, but do this solution because i have very low currents (900mA~ per driver) and i have quite powerfull active cooling with fan, what is always full power when my atx power is on. Of course if want update something can printed that mount again with 20-30mm supports to give little more airspace under to pcb, but not know is that necessery.

Yeah that wifi placement is other thing what i thinked before, but wire management is so good with this solution i think to try how Wifi works. Now seems that gives me about 60db values when i couple times checked that on console command. Maybe some day i move my printer different room what is little bit longer distance my wifi point. Read somewhere @dc42 text where he talked something to external antenna on Duet2, but is that possible add diy, or is that different wifi module totally? Now printer works very good and no disconnects, but when but that longer distance that wifi point maybe some problems then.

Little bit more updates to machine and new X garriage almost ready, (looks quite heavy, but not be). Induction sensor place is now intecrated that near hotend than possible, "wind tunnel" is bigger to cool hotend cool sink, same time fan updated 40mm version Noctua, part cooling fan updated Sanyo Denki good quality radial fan and new better nozzle is designed too.

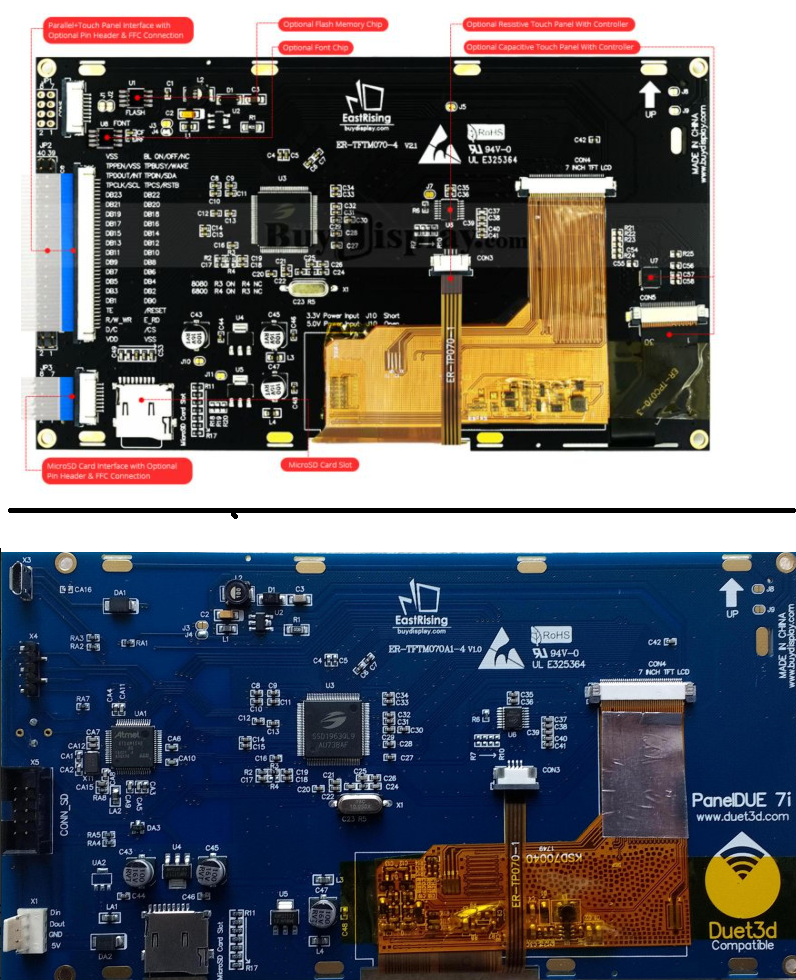

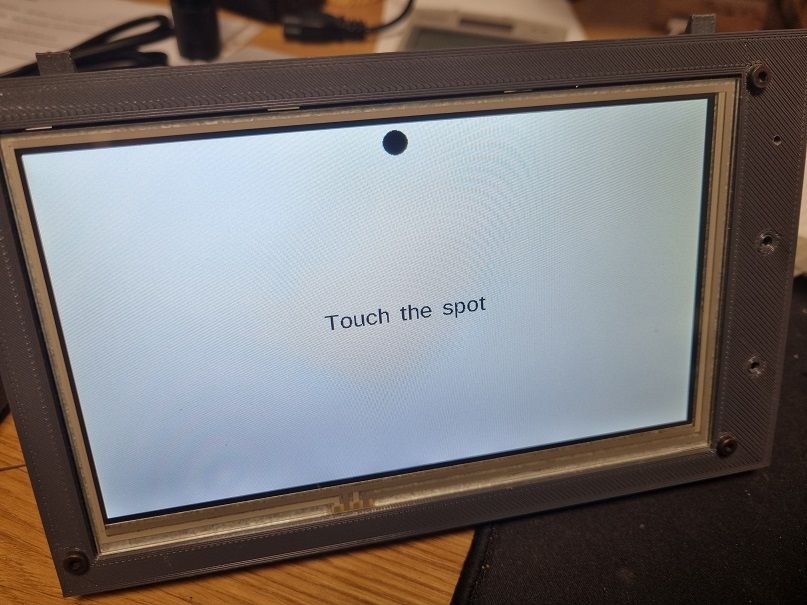

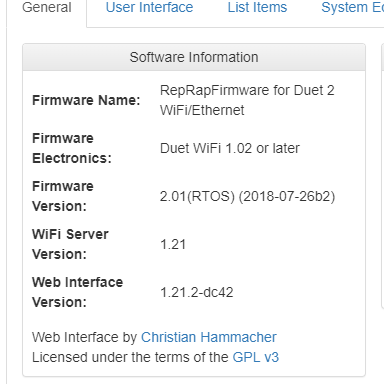

Have some problems to get macros show on Paneldue when started printer. Check forum and finded that is allready fixed bug and first time update firmware to panel. Thinked panel can be updates same way like Duet firmware, but need that extra software (Bossa) and usb cabel. Still no problem quite easy update and now have newest software inside Paneldue.

Printer mount paneldue to printer and design fast remove/attach system to get panel easily remove to printer and get more space if need update printer or service that. Same time i added hardwired Button to E0 endstop and configured that Emernency stop for now. Think to change that maybe "Pause" button or something, but now that is attached and wired to printer and easy to do what ever command to that button. I try one time that "pause" button on webcontrol. Works otherwise ok but when but resume and z axle drive 10mm down and continue printing. Extruder extrude filament that time when z axle going that 10mm down. But i think i find answer that inside resume.g or pause.g files.