@dc42 What is considered an acceptable amount of deviation?

Posts made by kjiwa

-

RE: T3P3 Mini Kosselposted in My Duet controlled machine

-

RE: T3P3 Mini Kosselposted in My Duet controlled machine

@dc42 Thank you! G32 reports a deviation of 0.066mm. I am using a v2 Smart Effector.

-

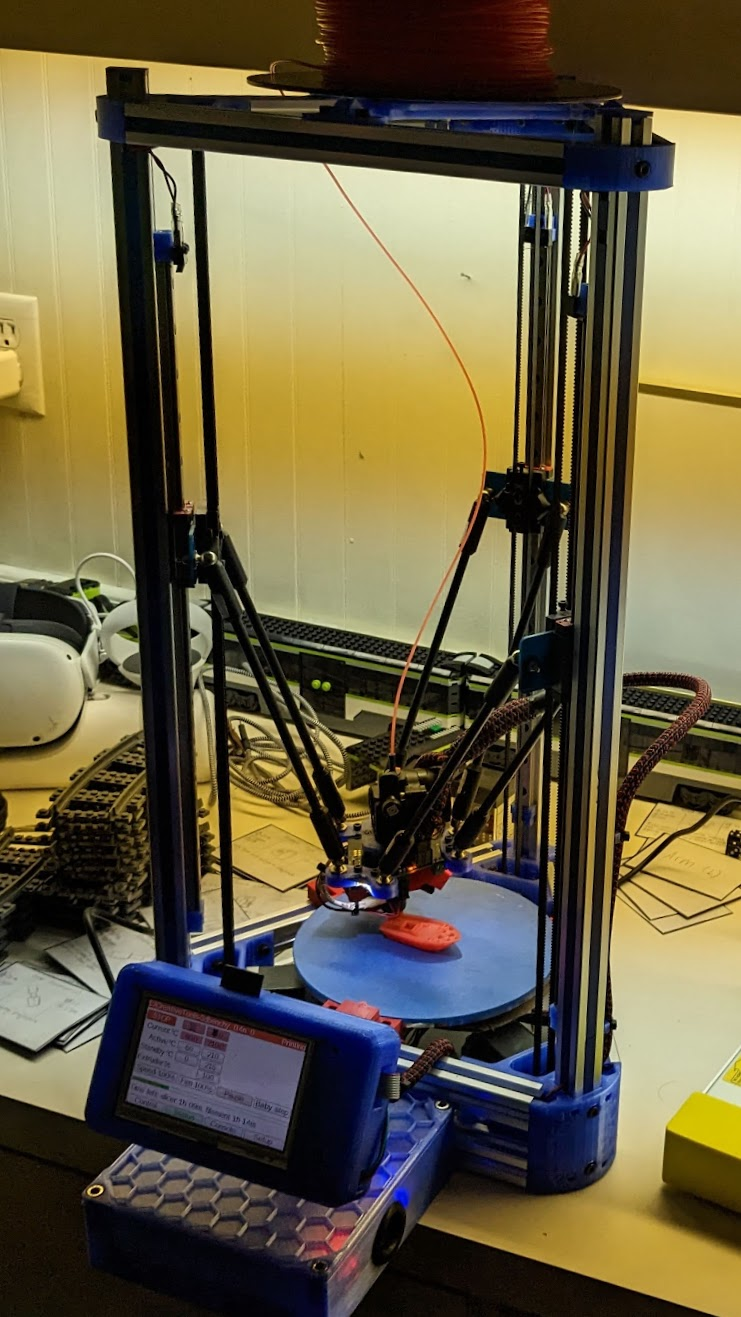

T3P3 Mini Kosselposted in My Duet controlled machine

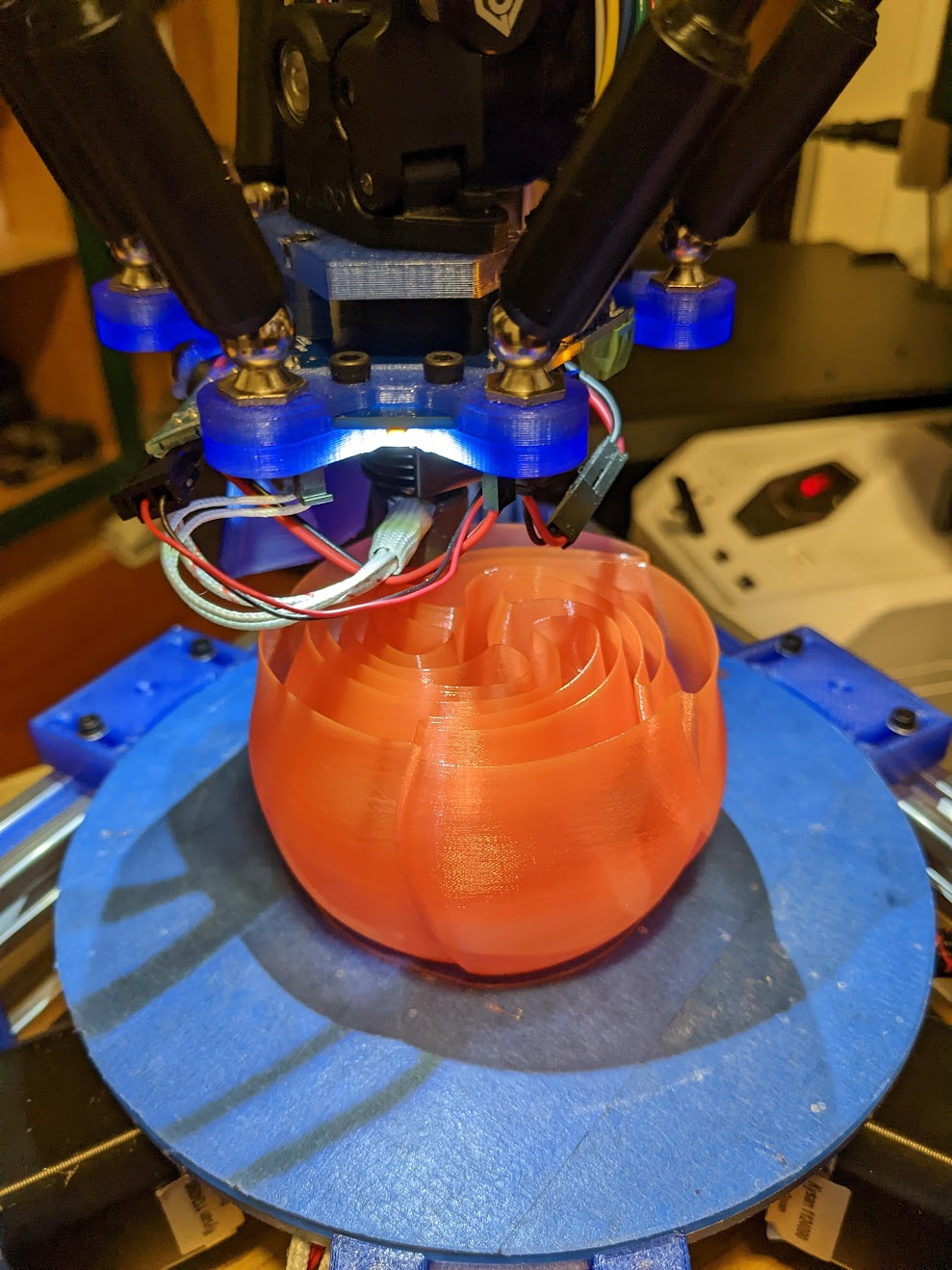

This is my first working delta build [1]. I learned a ton, but it is by no means a perfectly precise build, despite my best efforts. However, it does work, so I'll take it as a win.

The T3P3 kits are no longer available, so I sourced all of the parts independently, and upgraded parts where and when I thought appropriate. So this build has:

- A Duet 2 WiFi with 4.3" PanelDue

- Haydn Huntley's magball arms

- An Orbiter 2.0 extruder

- A 24V heated bed

- An E3D Revo Micro hotend

[1] My first actual build was based on Johann's original design with 1515 extrusions. I met him several years ago and he gave me a box of loose parts, most of which came from an incomplete OpenBeam kit. I eventually completed the build (that being my first substantial electronics project), but my first 4-5 layers came out very poorly. Despite replacing nearly every component in the build, I never did figure out what was causing the problem and eventually abandoned the build and started over.

-

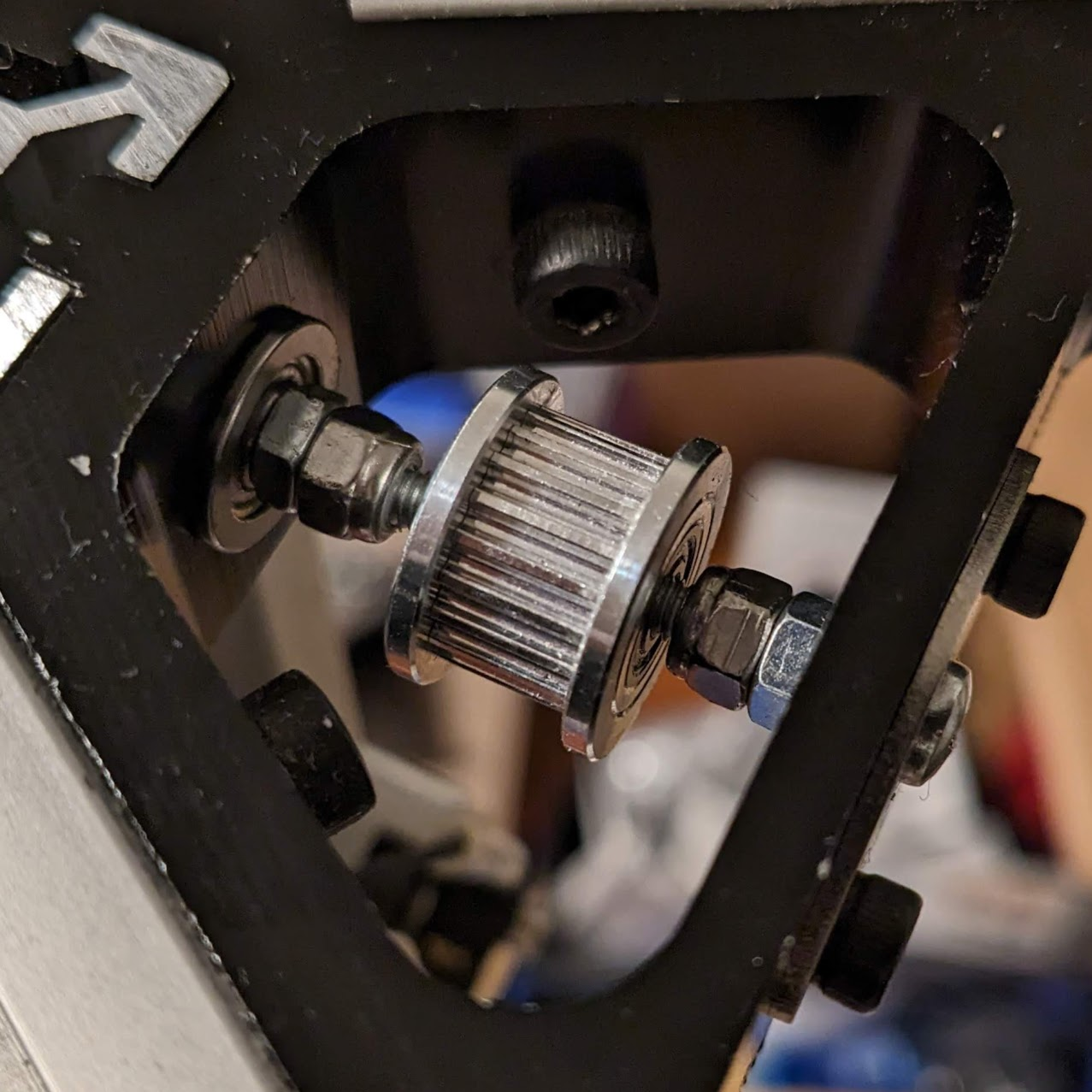

Delta idler positionposted in 3D Printing General Chat

I'm starting a new delta build and I'm curious about how to best determine the position of my idlers. In his "Precision Kossel build" blog post, dc42 suggests adjusting nylock nuts to keep the idler pulley in place. Does the exact position of the idler matter? If so, how can I determine where on the screw the idler should sit?

On a tangent, I've noticed some threads where folks have recommended the use of shoulder bolts. These bolts are unthreaded, so what is the preferred way to position idlers on shoulder bolts? Should I print some spacers? And if so, how can I determine the length of the spacers so that the idler is correctly positioned?

-

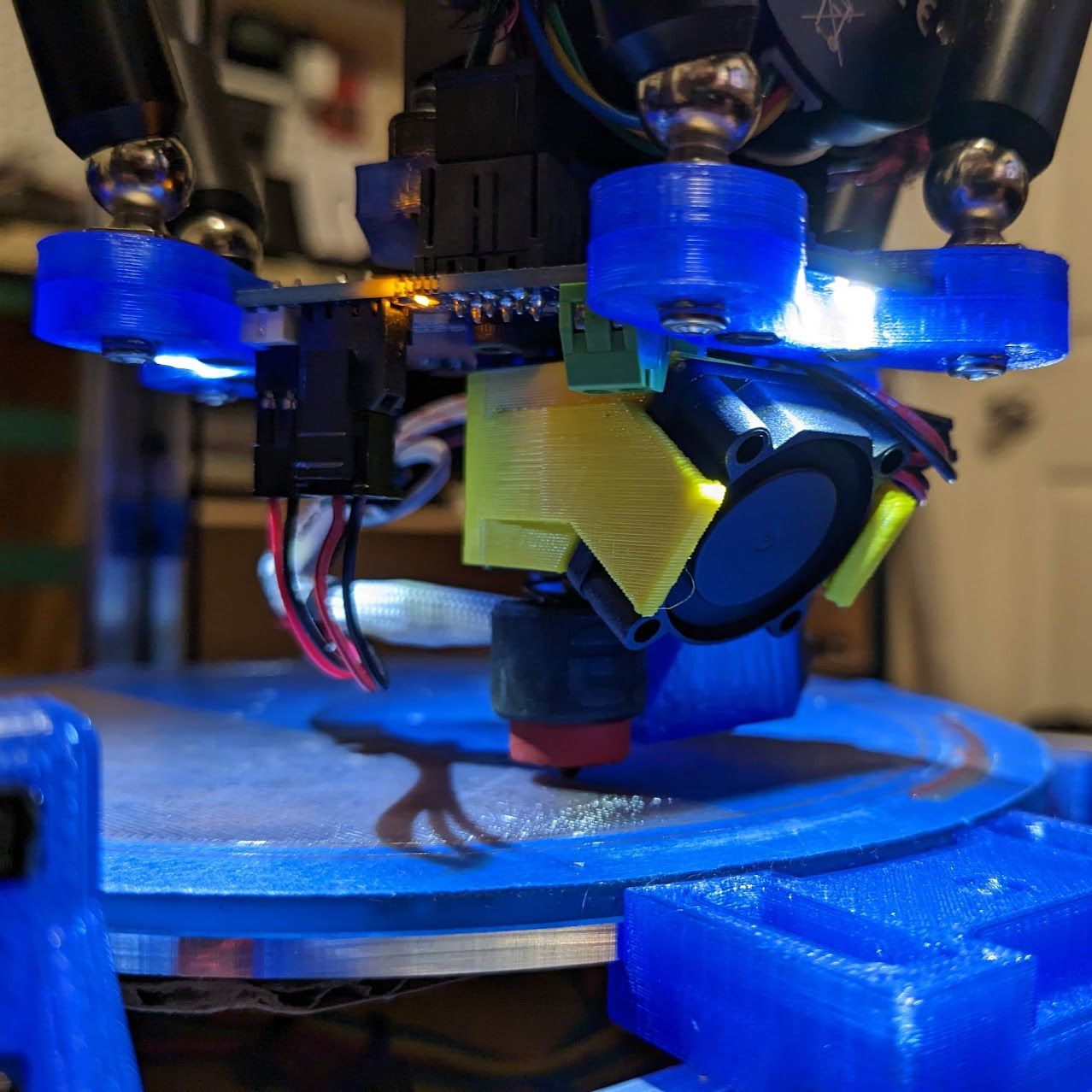

RE: SE and "Revo" hotend?posted in Smart effector for delta printers

@aerouta I use a 3510 fan for the print fan and a 2510 fan for the hotend fan. I was able to make a 40mm fan work for the print fan, but the clearance was too close for comfort. I find 35mm works nicely. I also replaced the 5V stock Revo fan with a 25mm 24v fan. 25mm was the smallest size I could find that operated on 24v.

Hotend Fan

Print Fan

The models are parametric, so they can be made to fit other fan sizes. I'm happy to share them if anybody is interested.

-

RE: Delta printer twisting beginning of printposted in Tuning and tweaking

Thanks @giostark.

Frame alignment: When I disassembled the printer and began reassembling it, I checked for alignment on the top and bottom frames. I also tightened them down with belt clamps. I think they are in good shape.

Rod length: I'm beginning to suspect my rods more and more. Currently the measuring tools I have can only give me accuracy to within +/- 0.2 mm, so I don't think I can detect errors to the degree stated in the post you linked.

I did not get them from China, but when I inspected them more closely I found one that had a loose ball joint and another one that had the ball joint glued in at a slight angle. When I repaired them, I measured them all to be the same to within that 0.2 mm margin, but I'm guessing that perhaps that is too wide of a margin for accuracy.

BLTouch: I'm not using a BLTouch.

Bed: This was previously an issue, but I've since fixed the bed mounting and the glass is very secure and level on the frame now.

-

RE: Delta printer twisting beginning of printposted in Tuning and tweaking

I think the next thing I'm going to try is a new set of arms. It seems like the preassembled rods on AliExpress are about the same as the cost of materials, so I'm going to give them a shot as well as making some new ones of my own. I'll update the thread once they arrive (which will not likely be any time soon given lead times from China these days).

-

RE: Delta printer twisting beginning of printposted in Tuning and tweaking

@dc42 Thank you. I also replaced and tightened down the pulleys. They seem firm and in the right positions.

-

RE: Delta printer twisting beginning of printposted in Tuning and tweaking

Just to close out this thread... since this is not a Duet-related issue I've moved the thread to the deltabot forums on Google Groups: https://groups.google.com/forum/#!msg/deltabot/MKpY_hvHnLE/vij7Q4LOAwAJ.

Thanks again for all of the suggestions here.

-

RE: Delta printer twisting beginning of printposted in Tuning and tweaking

I was a bit premature in declaring victory. I continue to have issues with layer shifting and autocalibration. At this point I've tried almost everything except replacing the steppers. I've taken everything apart, measured parts to ensure they are sized accurately, and replaced the timing belts, pulleys, and idlers. Still, no improvement to the layer shifting.

What's really confusing me is why the autocalibration gives me such wild results between runs. Here is the output from the last few invocations of G32:

Diagonals 215.000:215.000:215.000, delta radius 105.620, homed height 236.757, bed radius 70.0, X 1.482°, Y 0.880°, Z 0.000° Diagonals 215.000:215.000:215.000, delta radius 110.722, homed height 237.256, bed radius 70.0, X -14.987°, Y -7.550°, Z 0.000° Diagonals 215.000:215.000:215.000, delta radius 106.415, homed height 236.746, bed radius 70.0, X 1.289°, Y 0.492°, Z 0.000° Diagonals 215.000:215.000:215.000, delta radius 105.221, homed height 236.595, bed radius 70.0, X -1.524°, Y -0.171°, Z 0.000° Diagonals 215.000:215.000:215.000, delta radius 106.281, homed height 236.804, bed radius 70.0, X 1.278°, Y 0.430°, Z 0.000° Diagonals 215.000:215.000:215.000, delta radius 106.814, homed height 236.817, bed radius 70.0, X 0.138°, Y 1.348°, Z 0.000° Diagonals 215.000:215.000:215.000, delta radius 106.660, homed height 236.546, bed radius 70.0, X 0.512°, Y -0.868°, Z 0.000°This is just a sample from today. There are times when the control board detects nearly 0 degree offsets, but most of the time it's something like 0.5 degrees. The second one you see is a bit crazy though -- it thinks my build has a nearly -15 degree angle! This is my first ever build, so I may not have done a great job, but I can assure you that nothing about my build is this inaccurate. I have also watched every moving part very closely, but my eye is unable to detect any sort of wobbling or movement.

@dc42 You mentioned two things that I thought might be the culprit: my belts and the diagonal arms. I tested the arms and they are all the same size (measured as best as I could with my tools). I also wondered if I had abused my belts, so I replaced them in case there was any stretch or wear.

Any other suggestions? Could it be my linear rails? Or might the motors have some issues?

-

RE: Delta printer twisting beginning of printposted in Tuning and tweaking

I put some more work into my build and managed to get rid of the twist. My prints are coming out very nicely now. Thank you everyone for the help.

I believe my issues came from two major areas:

-

I mentioned earlier that my bed had some tilt to it. I was aware of the tilt, but I was under the impression that the Duet controller could compensate for it. The documentation states that a level bed "isn't essential, because RepRapFirmware can compensate for [it]." Anyway, I redesigned my bed mounting parts and gave the bed a lot more support.

-

I am using FSRs, but I had not done a great job of calibrating them. This meant that in some cases the nozzle had to depress the bed a lot to generate a reading. When I redesigned the bed mounts, I also used the opportunity to calibrate the FSRs and to make sure that their ambient resistance was in a range where they would be sensitive enough to detect approximately 500g of mass.

I still have some other settings to dial in now, but at least I can move on from worrying about the straightness of my prints. Thanks again!

-

-

RE: Delta printer twisting beginning of printposted in Tuning and tweaking

Thanks for the tips @giostark. But as discussed earlier, I'm fairly certain the rod length is accurate, and as I had mentioned, I was able to make good quality prints before when I was using the RAMPS board.

We're at a point where the twist is gone from my prints. It is a small print, but this indicates that my towers are likely straight, and not bowed or highly angled.

The issue I am seeing now is with layer shifting in the calibration cube where the letters begin and end. What could be causing that? There are entire sections of the print that are straight. It's only when there is a change in the object that the layers shift a little bit.

-

RE: Delta printer twisting beginning of printposted in Tuning and tweaking

Unfortunately I did not make a note of those values.

-

RE: Delta printer twisting beginning of printposted in Tuning and tweaking

The Marlin config is in my GitHub. A diff from the default settings is here: https://github.com/kjiwa/Marlin/commit/c0d4e67b1c7fc02f868063cb9aff10a0eb38b81c.

With the Marlin firmware I had the tower motors configured with the following values:

- max speed 500 mm/s

- max acceleration 9000 mm/s^2

- default acceleration 3000 mm/s^2

- default jerk 10 mm/s^3

Other than that, geometry and other settings are mostly unchanged between what I had set with the RAMPS board vs what I have set with the Duet.

-

RE: Delta printer twisting beginning of printposted in Tuning and tweaking

@dc42 I do not believe I am using steel-cored belts. When you say the that one of my towers is not moving linearly, are you suggesting that there is some curvature to its movement?

In terms of its assembly, I measured the distance between each pair of towers at the top, middle, and bottom, and the horizontal distances were all identical to within 0.5 mm over height of the printer. So this leads me to believe that the towers are fairly parallel to each other. The angular offset should be no more than 0.05 degrees, if even that much.

I once again measured each of the diagonal rods and they were all close to 215 mm, but I measured them while the machine was assembled, so my confidence in them being exactly the same is reduced. That said, the rods (and towers) were cut and provided to me by Johann R, who designed the Mini Kossel, so I expect they were measured and cut precisely.

I want to note that I didn't have these problems with my RAMPS board, and nothing else about the printer has changed since the upgrade to the Duet 2 WiFi. Here's a sample print from when I still had the RAMPS board on: https://imgur.com/a/L1Hyo4S. I had also printed a 3DBenchy and it came out really nicely.

-

RE: Delta printer twisting beginning of printposted in Tuning and tweaking

Thank you @bot. I tried four-factor calibration and confirmed that the tower angular offsets remained 0. Doing this got rid of the twist that I was seeing at the start of my prints, so thank you for suggesting that!

Here is how the print looks now: https://imgur.com/a/tJZK2xa. It's much more straight, but you'll notice that there is still some layer shifting occurring where the letters begin and end. The first and last layers also seem to have some additional shift. The last photo in that album shows the effect well.

I've tried using different temperature settings to see how that affects the first layer and the overall print smoothness, but those settings didn't seem to help remove the layer shifting.

-

RE: Delta printer twisting beginning of printposted in Tuning and tweaking

Thanks for the suggestions. I tried as you stated, to use the calibration results and to set the angular offsets to 0, but this leads to prints that don't adhere to the bed surface in all places. The bed does have a slight tilt to it.

As for the diagonal rods, I had measured them each as best as I could from the bearing centers. They each measured very close to 215 mm.

-

RE: Delta printer twisting beginning of printposted in Tuning and tweaking

Here are the results:

G32 Calibrated 6 factors using 6 points, deviation before 2.437 after 0.000 M665 Diagonals 215.000:215.000:215.000, delta radius 107.333, homed height 247.759, bed radius 70.0, X 0.043°, Y -0.594°, Z 0.000° M666 Endstop adjustments X0.11 Y0.46 Z-0.58, tilt X0.00% Y0.00% -

RE: Delta printer twisting beginning of printposted in Tuning and tweaking

Hi @bot. Thanks for your response.

I am not using mesh compensation. Before each print I run a 6-factor automatic calibration. The calibration probes six points around the edge of the bed and also the center point.

My config.g is here: https://pastebin.com/WgQBag6r.

-

Delta printer twisting beginning of printposted in Tuning and tweaking

I recently replaced a RAMPS board on my Mini Kossel with a Duet 2 WiFi and have been slowly been dialing in the print settings. I'm at a point where I'm pretty happy with the print quality, but I'm seeing some layer shifting and a small amount of twisting right at the beginning of the print. There are some photos on imgur: https://imgur.com/a/Bo7vGKK.

The shift occurs at the layer when the letters first appear. Could it be high acceleration or jerk causing this? My acceleration is set to 1000 mm/s^2 and each motor is set to receive 1 A (they are 1.8 deg motors rated for 1.5 A). I used the stepper motor speed worksheet that I found linked on your website and set my print speed to 30 mm/s -- a value that I considered conservative. I also enabled jerk control in my slicer, which I believe is supposed to reduce the jerk, but this setting appeared to have no effect.

As for the initial twist, I'm not sure what could be causing that. My belts seem to have good tension, and I checked that the towers are straight and have even spacing. It's just the first part of the print that has that twist, so I'm not sure where to begin with this one. I find it strange that the print begins to straighten when the letters are being printed.

Thank you.