@T3P3Tony Thanks, that's great, where can I get more information about them? is a brochure available?

Posts made by juliann

-

RE: 48V Duet3(4?) to complement future Duet Motors?posted in Hardware dev

-

RE: 48V Duet3(4?) to complement future Duet Motors?posted in Hardware dev

@T3P3Tony When this new Duet motors will be available?

Thanks! -

RE: [3.4.0beta6] After update: Heater 1 fault shows 409.9 °Cposted in Beta Firmware

Hi David @dc42

I am currently rewiring the the ground using a 10K resistor.

Before you send me this message I bought another Toolboard v1.1 and installed it with a new thermistor and heater, but after a few prints I got the same issue (with temp0) so I think you are right, as there is no chance to have been shorts in the installation an ESD should be the explanation.BTW I already received this morning the repaired tool board.

After finishing this installation, can I send you this second tool board to repair it as well?

Thank you!

Julián. -

RE: [3.4.0beta6] After update: Heater 1 fault shows 409.9 °Cposted in Beta Firmware

Hi @dc42

I just got you email, thank you very much for the detailed explanation.

I will recheck very carefully all the tool board wiring and send it back to you.Thanks again

Julián. -

duet 3 mini 5+ short to ground reported by driver 2posted in General Discussion

Hi

I've been using the Duet 3 mini wifi since i got without any issues and have not made any modifications lately.

But few days ago (maybe in coincidence with the 3.4.0beta6 update) it showed an error message (short to ground reported by driver 2).If I turn off/ on the printer or I press emergency stop few times sometimes the issue disappears and I am able to print again.

I already checked all the wiring many times and everything seems to be fine. Actually the printer is being working perfectly since March 2021.Duet 3 Mini 5+ Wifi V0.5 with Expansion Mini 2+, SBC and tool board v1.1

I think this is the exact same issue reported by another user here: https://forum.duet3d.com/topic/26124/duet-3-mini-5-short-to-ground-reported-by-driver-1

config.g

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"duet3" ; set printer name M669 K1 ; CoreXY G21 ; Set Units to Millimeters ; Network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet G4 S2 ;wait for expansion boards to start ; Drives M569 P0.0 S0 D3 ; physical drive 0.0 goes forwards M569 P0.1 S0 D3 ; physical drive 0.1 goes forwards M569 P0.2 S0 D3 ; physical drive 0.2 goes forwards M569 P0.3 S1 D3 ; physical drive 0.3 goes forwards M569 P0.4 S1 D3 ; physical drive 0.4 goes forwards M569 P20.0 S0 D3 ; physical drive 0.5 goes forwards M584 X0.4 Y0.3 Z0.0:0.1:0.2 E20.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation ;LGX M92 X80.00 Y80.00 Z800.00 E412.35 M906 X1200 Y1200 Z1000 E500 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M566 X600.00 Y600.00 Z60.00 E600 P1 ; set maximum instantaneous speed changes (mm/min) M203 X10800.00 Y10800.00 Z1000.00 E3600.00 ; set maximum speeds (mm/min) ;M203 X60000.00 Y60000.00 Z1000.00 E3600.00 ; set maximum speeds (mm/min) M201 X5000.00 Y5000.00 Z100.00 E3600.00 ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X500 Y500 Z500 S0 ; set axis maxima ; Endstops M574 X1 S1 P"20.io2.in" ; configure active high endstops M574 Y2 S1 P"io1.in" ; configure active high endstops M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe ;; BLTouch M950 S0 C"20.io0.out" ; Create a servo pin on io3 M558 P9 C"20.io0.in" F150 H4 R0.2 T12000 A5 B0 ; set Z probe type to unmodulated and the dive height + speeds G31 P1000 X-29.146 Y0 Z2.395 M671 X-4.5:250:504.5 Y-4.52:505:-4.52 S50 ; Define positions of Z leadscrews or bed levelling screws M557 X10:460 Y15:470 S25 ; define 5x5 mesh grid M563 P0 D0 H1 F1 ; define tool 0 ; BED HEATER M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out5 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 110C ;; BED Heater PID Tune JEN M307 H0 B0 R0.795 C325.9 D3.08 S1.00 V23.9 ; Fans M950 F0 C"20.out2" Q25000 ; create fan 0 on pin out3 and set its frequency M106 P0 C"Hotend Fan" S.5 H1 T45 ; set fan 0 name and value. Thermostatic control turned on for Hotend M950 F1 C"!20.out1+out1.tach" Q25000 ; create fan 1 on pin out4 and set its frequency M106 P1 C"Layer Fan" S0 H-1 L0.2 X0.4 ; set fan 1 name and value. Thermostatic control is turned off M950 F2 C"!out3+out3.tach" Q25000 ; create fan 1 on pin out4 and set its frequency M106 P2 C"Filter & Bottom Fans" S0 H-1 L255 ; set fan 1 name and value. Thermostatic control is turned off M950 F3 C"!out4+out4.tach" Q25000 ; create fan 1 on pin out4 and set its frequency M106 P3 C"Exhaust Fan" S0 H-1 L255 ; set fan 1 name and value. Thermostatic control is turned off M950 F4 C"out5" Q10 ; create fan 1 on pin out4 and set its frequency M106 P4 C"12vFANs" S1.0 H-1 L255 ; set fan 1 name and value. Thermostatic control is turned off ; Tools G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M308 S1 P"20.temp1" Y"thermistor" T500000 B4723 C1.196220e-7 ; PARA SLICE ENGINNERING HIGH TEMP M950 H1 C"20.out0" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S301 ; set the maximum temperature in C for heater M307 H1 B0 R2.138 C163.4:146.8 D7.88 S1.00 V23.8 ; Miscellaneous M575 P1 B57600 S1;enable panelDue UART M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set tension thresholds and actions to run on power loss M404 N1.75 D0.4 ; Filament width and nozzle diameter ;DHT Sensor on IO4 M308 S10 P"io4.out+io4.in" Y"dht22" A"Chbr Temp[C]" M308 S11 P"S10.1" Y"dhthumidity" A"Chbr Hum[%]" M591 D0 P3 C"20.io1.in" S0 R10:200 L22.00 E3.0 ; Duet3D rotating magnet sensor for extruder drive 0 is connected to E0 endstop input, enabled, sensitivity 24.8mm.rev, 70% to 130% tolerance, 3mm detection length ;Input Shaping M593 P"none" ; disable DAA ;M593 P"mzv" F34.76 ; Pressure Advance M572 D0 S0.06 ;Taper Height M376 H20 ; Set up Accelerometer M955 P20.0 I12 S1000 Q2000000 ; Accelerometer on toolboard, Enable for RRF 3.3 Stable T0m122

m122 === Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.4.0beta6 (2021-11-06 11:39:32) running on Duet 3 Mini5plus WiFi (SBC mode) Board ID: BJHV4-F396U-D65J0-40KML-NT03Z-74PH4 Used output buffers: 1 of 40 (20 max) === RTOS === Static ram: 103876 Dynamic ram: 99104 of which 0 recycled Never used RAM 38732, free system stack 194 words Tasks: SBC(resourceWait:,3.1%,478) HEAT(notifyWait,0.0%,344) Move(notifyWait,0.0%,361) CanReceiv(notifyWait,0.0%,772) CanSender(notifyWait,0.0%,372) CanClock(delaying,0.0%,337) TMC(notifyWait,1.2%,105) MAIN(running,94.8%,507) IDLE(ready,0.1%,29) AIN(delaying,0.8%,264), total 100.0% Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:19:08 ago, cause: software Last software reset at 2021-11-29 18:25, reason: User, GCodes spinning, available RAM 34916, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task SBC Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 MCU revision 3, ADC conversions started 1149342, completed 1149342, timed out 0, errs 0 Step timer max interval 1477 MCU temperature: min 29.9, current 30.1, max 42.9 Supply voltage: min 23.9, current 24.0, max 24.0, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Driver 0: pos 0, standstill, SG min 2, read errors 0, write errors 1, ifcnt 30, reads 38880, writes 12, timeouts 0, DMA errors 0 Driver 1: pos 0, standstill, SG min 2, read errors 0, write errors 1, ifcnt 30, reads 38880, writes 12, timeouts 0, DMA errors 0 Driver 2: pos 0, standstill, SG min 2, read errors 0, write errors 1, ifcnt 30, reads 38880, writes 12, timeouts 0, DMA errors 0 Driver 3: pos 0, standstill, SG min 2, read errors 0, write errors 1, ifcnt 30, reads 38879, writes 12, timeouts 0, DMA errors 0 Driver 4: pos 0, standstill, SG min 2, read errors 0, write errors 1, ifcnt 30, reads 38880, writes 12, timeouts 0, DMA errors 0 Driver 5: pos 0, standstill, SG min 0, read errors 0, write errors 1, ifcnt 19, reads 38883, writes 9, timeouts 0, DMA errors 0 Driver 6: pos 0, standstill, SG min 0, read errors 0, write errors 1, ifcnt 19, reads 38883, writes 9, timeouts 0, DMA errors 0 Date/time: 2021-11-29 18:44:22 Cache data hit count 2676970072 Slowest loop: 11.55ms; fastest: 0.10ms === Storage === Free file entries: 10 SD card 0 not detected, interface speed: 0.0MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1, chamber heaters -1 -1, ordering errs 0 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === Filament sensors === Extruder 0: no data received === CAN === Messages queued 10337, received 23491, lost 0, longest wait 2ms for reply type 6049, peak Tx sync delay 272, free buffers 17 (min 16), ts 5745/5744/0 Tx timeouts 0,0,0,0,0,0 === SBC interface === Transfer state: 4, failed transfers: 0, checksum errors: 0 RX/TX seq numbers: 45390/45390 SPI underruns 0, overruns 0 State: 5, disconnects: 0, timeouts: 0, IAP RAM available 0x0f120 Buffer RX/TX: 0/0-0 === Duet Control Server === Duet Control Server v3.4-b6 Code buffer space: 4096 Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0 Full transfers per second: 39.56, max wait times: 69.7ms/14.6ms Codes per second: 0.07 Maximum length of RX/TX data transfers: 3596/832M122 b20

M122 b20 Diagnostics for board 20: Duet TOOL1LC rev 1.1 or later firmware version 3.4.0beta6 (2021-11-06 11:56:11) Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1) Never used RAM 2124, free system stack 2762 words Tasks: Move(notifyWait,0.0%,153) HEAT(notifyWait,0.2%,111) CanAsync(notifyWait,0.0%,64) CanRecv(notifyWait,0.0%,77) CanClock(notifyWait,0.0%,64) ACCEL(notifyWait,0.0%,61) TMC(delaying,3.0%,57) MAIN(running,91.8%,350) IDLE(ready,0.0%,27) AIN(delaying,4.9%,142), total 100.0% Last reset 00:25:20 ago, cause: software Last software reset data not available Driver 0: pos 0, 412.4 steps/mm,standstill, SG min 0, read errors 0, write errors 1, ifcnt 27, reads 39441, writes 12, timeouts 0, DMA errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter -2/9, peak Rx sync delay 211, resyncs 0/0, no step interrupt scheduled VIN voltage: min 24.3, current 24.4, max 24.4 MCU temperature: min 47.8C, current 47.9C, max 50.5C Last sensors broadcast 0x00000002 found 1 237 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 31124, send timeouts 0, received 13686, lost 0, free buffers 37, min 37, error reg 110000 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 Accelerometer detected: yes, status: 00 I2C bus errors 0, naks 3, other errors 0 === Filament sensors === Interrupt 4 to 8us, poll 6 to 738us Driver 0: pos 208.12, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0Thank you!

Regards

Julián. -

RE: duet 3 mini 5+ short to ground reported by driver 1posted in General Discussion

I am experiencing the exact same problem in my case with driver 2.

What can I do to solve it?Thanks in advance

Regards

Julián. -

RE: [3.4.0beta6] After update: Heater 1 fault shows 409.9 °Cposted in Beta Firmware

Thank you @t3p3tony

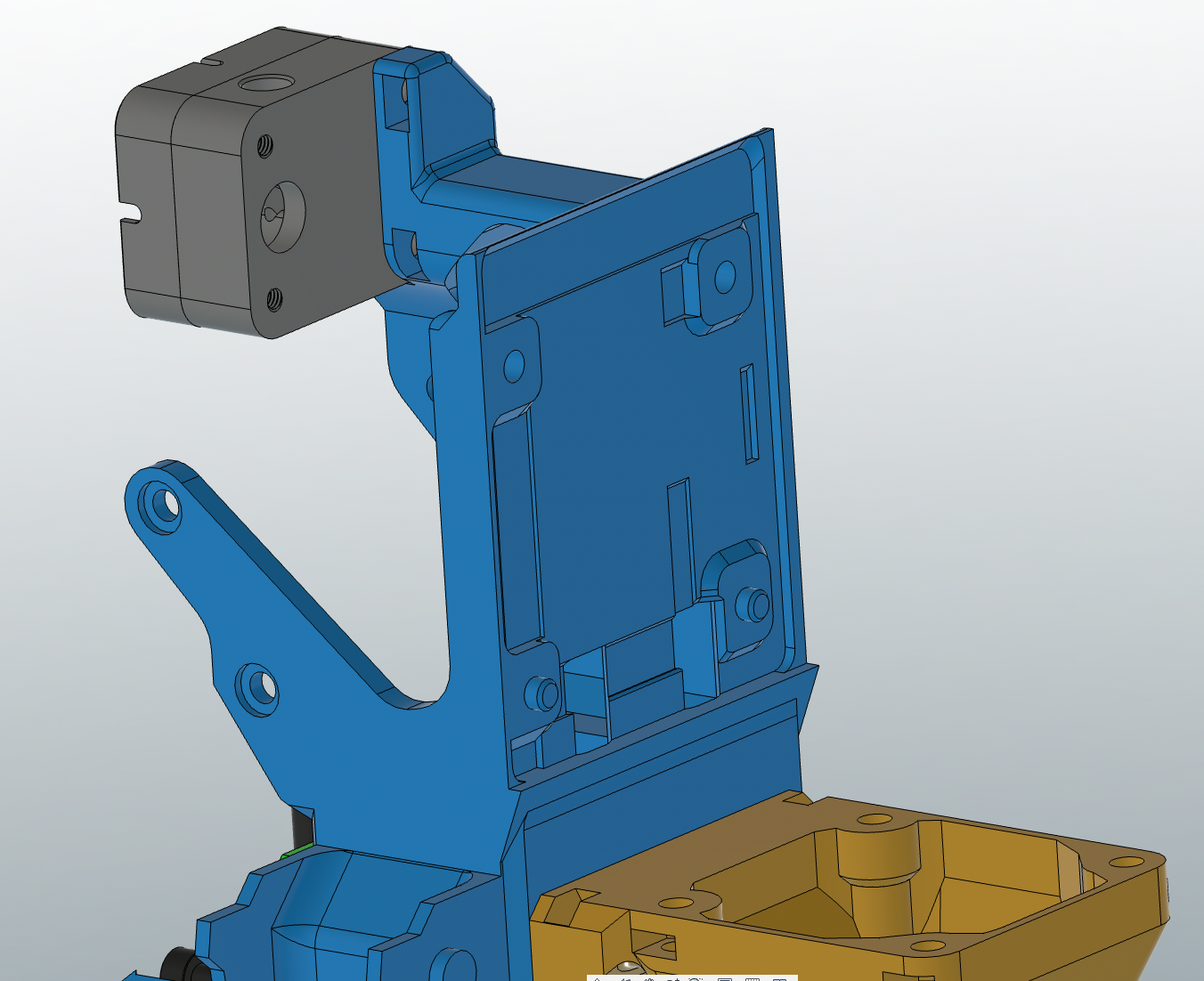

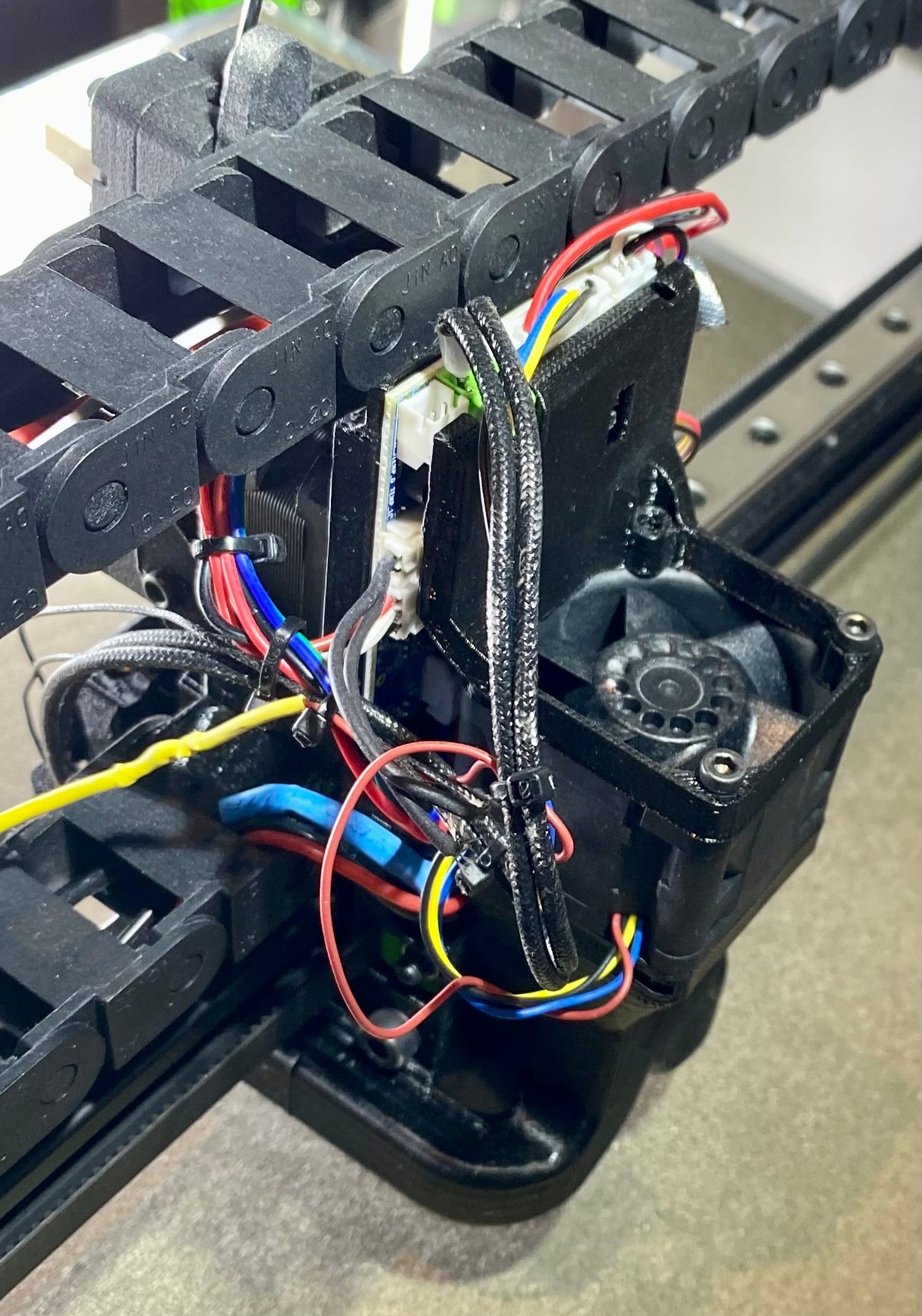

All the parts in contact with the tool board are plastic, just two screws are used to mount it. At this moment I am using the temp1 of the tool board without issues (same way as I did before with the previous one).

If I switch back to temp0 the problem persists.As I just replaced the tool board the current wiring is not organised, I just put a coupe of ties to keep cables in a safe position.

Please let me know if you need more photos/ information.

-

RE: [3.4.0beta6] After update: Heater 1 fault shows 409.9 °Cposted in Beta Firmware

Hi @dc42

Sorry, the problem persists.

I received the Toolboard replacement and worked perfect during the first 5 prints.

During the last one, a heater 0 fault suddenly appeared interrupting the printing (while reading 241°).

After pressing emergency stop, the temperature reading went to 980° (just the reading, not actual temp).

The ambient reading now is 280° no matter if I reset of turn off/on the printer.So I did the same as before, I changed the temp port in the toolboard and now in the temp1 it seems to work again. Any ideas?

Thanks again

Julián. -

RE: [3.4.0beta6] After update: Heater 1 fault shows 409.9 °Cposted in Beta Firmware

Sorry I forgot to mention, there is no possible contact in the back of the toolboard everything is plastic and it is correctly protected to avoid issues.

-

RE: [3.4.0beta6] After update: Heater 1 fault shows 409.9 °Cposted in Beta Firmware

@dc42 said in [3.4.0beta6] After update: Heater 1 fault shows 409.9 °C:

https://duet3d.dozuki.com/Wiki/Calibrating_thermistor_and_PT1000_readings

Yes, I am using exactly the same M308 parameters.

When I try to run the semi-automatic calibration procedure (I already tried with both beta firmwares) I get this message (with all temp sensors unplugged):

M308 S1 H999

Error: M308: Computed correction is not valid. Check that you have disconnected the thermistor.Anyway the temp 0 always shows between 200 and 410 °C which it depend if the thermistor is plugged or unplugged.

Thanks!

Julián. -

RE: [3.4.0beta6] After update: Heater 1 fault shows 409.9 °Cposted in Beta Firmware

Thank you @dc42

I did it but the problem persist, this is the temp 0 with the beta 5:

09/11/2021, 12:42:35 m122 b20 Diagnostics for board 20: Duet TOOL1LC rev 1.1 or later firmware version 3.4.0beta5 (2021-10-12 13:59:06) Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1) Never used RAM 3032, free system stack 2789 words Tasks: Move(notifyWait,0.0%,153) HEAT(notifyWait,0.1%,115) CanAsync(notifyWait,0.0%,64) CanRecv(notifyWait,0.0%,77) CanClock(notifyWait,0.0%,64) ACCEL(notifyWait,0.0%,61) TMC(notifyWait,2.9%,67) MAIN(running,92.1%,440) IDLE(ready,0.0%,27) AIN(delaying,4.9%,148), total 100.0% Last reset 00:00:03 ago, cause: software Last software reset time unknown, reason: AssertionFailed, available RAM 3392, slot 2 Software reset code 0x0120 ICSR 0x00000000 SP 0x2000415c Task Freestk 129 bad marker Stack: 00000544 00022ffc 00019b65 20003134 00016cff 20003134 000163d1 20000ed0 00000000 00000001 00008275 200071c8 200071c8 200071e0 00000000 20000f50 00011647 000223b8 00022474 00021ac8 00019b05 200071c8 200071c8 20000f50 000083ed 200071d8 000009c7 Driver 0: pos 0, 80.0 steps/mm, standstill, SG min/max 0/0, read errors 0, write errors 1, ifcnt 49, reads 1870, writes 9, timeouts 0, DMA errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter -2/5, peak Rx sync delay 564, resyncs 0/0, no step interrupt scheduled VIN voltage: min 24.0, current 24.0, max 24.0 MCU temperature: min 35.4C, current 35.4C, max 35.4C Last sensors broadcast 0x00000000 found 0 42 ticks ago, loop time 0 CAN messages queued 59, send timeouts 0, received 45, lost 0, free buffers 37, min 37, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 Accelerometer detected: yes, status: 00 I2C bus errors 0, naks 3, other errors 0 -

RE: [3.4.0beta6] After update: Heater 1 fault shows 409.9 °Cposted in Beta Firmware

It seems to be something related to the tool board temp sensor 0 port, I moved the thermistor to temp 1 and now the temperature is normal again.

Is the temp 0 port on the tool board faulty or a bug in this release?

-

RE: [3.4.0beta6] After update: Heater 1 fault shows 409.9 °Cposted in Beta Firmware

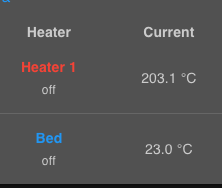

If I remove the thermistor connector from the tool board the temperature decreases to 203 °C.

-

[3.4.0beta6] After update: Heater 1 fault shows 409.9 °Cposted in Beta Firmware

Hi All,

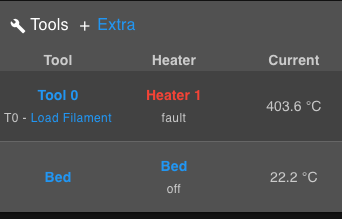

After update to [3.4.0beta6] I am stuck with the following error:

- permament "Heater 1 fault 409.9 °C" (So I can't print since this update) The heater is actually off (cold).

- Warning: M307: Heater 0 appears to be over-powered. If left on at full power, its temperature is predicted to reach 284C

I tried resetting the faulty heater, restarting, power off/on the machine and every time I get the same error.

I am using the a Slice Eng HT heater and a Slice Eng HT thermistor.

With the previous beta5 it worked fine.

Any suggestions?

Thank you!

Julián.config.g

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"duet3" ; set printer name M669 K1 ; CoreXY G21 ; Set Units to Millimeters ; Network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet G4 S2 ;wait for expansion boards to start ; Drives M569 P0.0 S0 D3 ; physical drive 0.0 goes forwards M569 P0.1 S0 D3 ; physical drive 0.1 goes forwards M569 P0.2 S0 D3 ; physical drive 0.2 goes forwards M569 P0.3 S1 D3 ; physical drive 0.3 goes forwards M569 P0.4 S1 D3 ; physical drive 0.4 goes forwards M569 P20.0 S0 D3 ; physical drive 0.5 goes forwards M584 X0.4 Y0.3 Z0.0:0.1:0.2 E20.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation ;LGX M92 X80.00 Y80.00 Z800.00 E408.23 M906 X1200 Y1200 Z1000 E500 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M566 X600.00 Y600.00 Z60.00 E600 P1 ; set maximum instantaneous speed changes (mm/min) M203 X10800.00 Y10800.00 Z1000.00 E3600.00 ; set maximum speeds (mm/min) ;M203 X60000.00 Y60000.00 Z1000.00 E3600.00 ; set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z100.00 E3600.00 ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X500 Y500 Z500 S0 ; set axis maxima ; Endstops M574 X1 S1 P"20.io2.in" ; configure active high endstops M574 Y2 S1 P"io1.in" ; configure active high endstops M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe ;; BLTouch M950 S0 C"20.io0.out" ; Create a servo pin on io3 M558 P9 C"20.io0.in" F150 H4 R0.2 T12000 A5 B0 ; set Z probe type to unmodulated and the dive height + speeds G31 P1000 X-29.146 Y0 Z2.440 M671 X-4.5:250:504.5 Y-4.52:505:-4.52 S50 ; Define positions of Z leadscrews or bed levelling screws M557 X10:460 Y15:470 S25 ; define 5x5 mesh grid M563 P0 D0 H1 F1 ; define tool 0 ; BED HEATER M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out5 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 110C ;; BED Heater PID Tune JEN M307 H0 B0 R0.795 C325.9 D3.08 S1.00 V23.9 ; Fans M950 F0 C"20.out2" Q25000 ; create fan 0 on pin out3 and set its frequency M106 P0 C"Hotend Fan" S.5 H1 T45 ; set fan 0 name and value. Thermostatic control turned on for Hotend M950 F1 C"!20.out1+out1.tach" Q25000 ; create fan 1 on pin out4 and set its frequency M106 P1 C"Layer Fan" S0 H-1 L0.2 X0.45 ; set fan 1 name and value. Thermostatic control is turned off M950 F2 C"!out3+out3.tach" Q25000 ; create fan 1 on pin out4 and set its frequency M106 P2 C"Filter & Bottom Fans" S0 H-1 L255 ; set fan 1 name and value. Thermostatic control is turned off M950 F3 C"!out4+out4.tach" Q25000 ; create fan 1 on pin out4 and set its frequency M106 P3 C"Exhaust Fan" S0 H-1 L255 ; set fan 1 name and value. Thermostatic control is turned off M950 F4 C"out5" Q10 ; create fan 1 on pin out4 and set its frequency M106 P4 C"12vFANs" S1.0 H-1 L255 ; set fan 1 name and value. Thermostatic control is turned off ; Tools G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M308 S1 P"20.temp0" Y"thermistor" T500000 B4723 C1.196220e-7 ; PARA SLICE ENGINNERING HIGH TEMP M950 H1 C"20.out0" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set the maximum temperature in C for heater M307 H1 B0 R2.138 C163.4:146.8 D7.88 S1.00 V23.8 ; Miscellaneous M575 P1 B57600 S1;enable panelDue UART M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set tension thresholds and actions to run on power loss M404 N1.75 D0.4 ; Filament width and nozzle diameter ;DHT Sensor on IO4 M308 S10 P"io4.out+io4.in" Y"dht22" A"Chbr Temp[C]" M308 S11 P"S10.1" Y"dhthumidity" A"Chbr Hum[%]" M591 D0 P3 C"20.io1.in" S0 R10:200 L22.00 E3.0 ; Duet3D rotating magnet sensor for extruder drive 0 is connected to E0 endstop input, enabled, sensitivity 24.8mm.rev, 70% to 130% tolerance, 3mm detection length ;Input Shaping M593 P"none" ; disable DAA ;M593 P"mzv" F34.76 ; Pressure Advance M572 D0 S0.06 ;Taper Height M376 H20 ; Set up Accelerometer M955 P20.0 I12 S1000 Q2000000 ; Accelerometer on toolboard, Enable for RRF 3.3 Stable T0config-override.g

; config-override.g file generated in response to M500 at 2021-10-06 12:42 ; Heater model parameters M307 H0 R0.795 C325.900:325.900 D3.10 S1.00 V23.9 B0 M307 H1 R2.138 C163.400:146.800 D7.90 S1.00 V23.8 B0 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 G10 L2 P9 X0.00 Y0.00 Z0.00m122

m122 === Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.4.0beta6 (2021-11-06 11:39:32) running on Duet 3 Mini5plus WiFi (SBC mode) Board ID: BJHV4-F396U-D65J0-40KML-NT03Z-74PH4 Used output buffers: 2 of 40 (20 max) === RTOS === Static ram: 103876 Dynamic ram: 99104 of which 0 recycled Never used RAM 38732, free system stack 196 words Tasks: SBC(ready,3.0%,489) HEAT(notifyWait,0.0%,356) Move(notifyWait,0.0%,361) CanReceiv(notifyWait,0.0%,772) CanSender(notifyWait,0.0%,372) CanClock(delaying,0.0%,346) TMC(notifyWait,1.2%,105) MAIN(running,94.6%,507) IDLE(ready,0.3%,29) AIN(delaying,0.8%,264), total 100.0% Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:04:30 ago, cause: power up Last software reset at 2021-11-08 17:41, reason: User, GCodes spinning, available RAM 38732, slot 2 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00446000 BFAR 0xe000ed38 SP 0x00000000 Task SBC Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 MCU revision 3, ADC conversions started 270594, completed 270594, timed out 0, errs 0 Step timer max interval 1473 MCU temperature: min 28.1, current 30.1, max 30.8 Supply voltage: min 23.9, current 24.0, max 24.0, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Driver 0: pos 0, standstill, SG min 0, read errors 0, write errors 0, ifcnt 12, reads 24569, writes 12, timeouts 0, DMA errors 0 Driver 1: pos 0, standstill, SG min 0, read errors 0, write errors 0, ifcnt 12, reads 24569, writes 12, timeouts 0, DMA errors 0 Driver 2: pos 0, standstill, SG min 0, read errors 0, write errors 0, ifcnt 12, reads 24568, writes 12, timeouts 0, DMA errors 0 Driver 3: pos 0, standstill, SG min 0, read errors 0, write errors 0, ifcnt 12, reads 24568, writes 12, timeouts 0, DMA errors 0 Driver 4: pos 0, standstill, SG min 0, read errors 0, write errors 0, ifcnt 12, reads 24569, writes 12, timeouts 0, DMA errors 0 Driver 5: pos 0, standstill, SG min 0, read errors 0, write errors 0, ifcnt 9, reads 24572, writes 9, timeouts 0, DMA errors 0 Driver 6: pos 0, standstill, SG min 0, read errors 0, write errors 0, ifcnt 9, reads 24571, writes 9, timeouts 0, DMA errors 0 Date/time: 2021-11-08 17:48:47 Cache data hit count 623931007 Slowest loop: 8.65ms; fastest: 0.07ms === Storage === Free file entries: 10 SD card 0 not detected, interface speed: 0.0MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1, chamber heaters -1 -1, ordering errs 0 === GCodes === Segments left: 0 Movement lock held by null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === Filament sensors === Extruder 0: no data received === CAN === Messages queued 2354, received 5239, lost 0, longest wait 2ms for reply type 6049, peak Tx sync delay 5, free buffers 17 (min 16), ts 1353/1352/0 Tx timeouts 0,0,0,0,0,0 === SBC interface === Transfer state: 4, failed transfers: 0, checksum errors: 0 RX/TX seq numbers: 10530/10530 SPI underruns 0, overruns 0 State: 5, disconnects: 0, timeouts: 0, IAP RAM available 0x0f14c Buffer RX/TX: 0/0-0 === Duet Control Server === Duet Control Server v3.4-b6 Code buffer space: 4096 Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0 Full transfers per second: 13.00, max wait times: 36.4ms/11.9ms Codes per second: 0.11 Maximum length of RX/TX data transfers: 3392/928m122 b20

Diagnostics for board 20: Duet TOOL1LC rev 1.1 or later firmware version 3.4.0beta6 (2021-11-06 11:56:11) Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1) Never used RAM 2124, free system stack 2762 words Tasks: Move(notifyWait,0.0%,153) HEAT(notifyWait,0.2%,115) CanAsync(notifyWait,0.0%,64) CanRecv(notifyWait,0.0%,77) CanClock(notifyWait,0.0%,64) ACCEL(notifyWait,0.0%,61) TMC(notifyWait,3.0%,57) MAIN(running,91.9%,350) IDLE(ready,0.0%,27) AIN(delaying,4.9%,142), total 100.0% Last reset 00:06:08 ago, cause: power up Last software reset time unknown, reason: AssertionFailed, available RAM 3392, slot 2 Software reset code 0x0120 ICSR 0x00000000 SP 0x2000415c Task Freestk 129 bad marker Stack: 00000544 00022ffc 00019b65 20003134 00016cff 20003134 000163d1 20000ed0 00000000 00000001 00008275 200071c8 200071c8 200071e0 00000000 20000f50 00011647 000223b8 00022474 00021ac8 00019b05 200071c8 200071c8 20000f50 000083ed 200071d8 000009c7 Driver 0: pos 0, 408.2 steps/mm,standstill, SG min 0, read errors 0, write errors 0, ifcnt 12, reads 53093, writes 12, timeouts 0, DMA errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter -3/7, peak Rx sync delay 207, resyncs 0/0, no step interrupt scheduled VIN voltage: min 24.2, current 24.3, max 24.3 MCU temperature: min 41.3C, current 41.5C, max 41.7C Last sensors broadcast 0x00000002 found 1 138 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 7271, send timeouts 0, received 3241, lost 0, free buffers 37, min 37, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 Accelerometer detected: yes, status: 00 I2C bus errors 0, naks 3, other errors 0 === Filament sensors === Interrupt 4 to 8us, poll 6 to 546us Driver 0: pos 0.00, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 -

RE: Unreliable Z height calibration on V-Core 3 w/BLtouch & Mini 5+posted in Tuning and tweaking

Hi

@nurgelrot!

Good catch! yes, that was wrong for sure. Thank you very much!@dc42 @fcwilt @PCR

Thank you very much for the additional tests, clearly I had something wrong in my original config, everything is still working fine by the moment.Julián.

-

RE: Bondtech LGX owners what are your settings?posted in Tuning and tweaking

Hi @nightlonk42

I have these settings in my RatRig V-Core 3 500mm (Duet 3 Mini5+ & Toolboard v1.1)

M92 X80.00 Y80.00 Z800.00 E408.23 M906 X1200 Y1200 Z1000 E500 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M566 X600.00 Y600.00 Z60.00 E600 P1 ; set maximum instantaneous speed changes (mm/min) M203 X60000.00 Y60000.00 Z1000.00 E3600.00 ; set maximum speeds (mm/min) M201 X3500.00 Y3500.00 Z100.00 E3600.00 -

RE: Unreliable Z height calibration on V-Core 3 w/BLtouch & Mini 5+posted in Tuning and tweaking

Hi Frederick! @fcwilt

Very good news, you found the solution!

I applied your suggestions and now the issue is totally fixed!Thank you so much for all the help provided.

Julián.

-

RE: Unreliable Z height calibration on V-Core 3 w/BLtouch & Mini 5+posted in Tuning and tweaking

Hi Frederick & sinneD & @T3P3Tony @fcwilt @sinned6915

Sorry for the delay in my response.

I rechecked everything in my printer included mechanical and the frame assembly as well.

Everything seems to be fine, no issues found.Frederick @fcwilt

I did several tests following your instructions but I am afraid the behaviour is always de same I described before:- The printer is already calibrated and all previous prints were perfectly fine.

- Power off and power on the printer.

- I try to print anything and the first layer is much more closer to the bed that usual.

- Cancel that print (Emergency stop on DWC) and clean the bed

- Then I print again the same file without touching any setting and now the first layer is perfect again.... (and of course I can continue printing without issues).

I am attaching "30 mm cube.gcode " file.

@sinned6915

Thank you very much for taking the time analysing my problem. Please see below my answers

-

After rechecking the frame, belts, carriage many times I can confirm you that there is no problem there.

Just to clarify, I think the issue I am experiencing is not precisely what you are suggesting, please see the behaviour I mentioned before.

I mean, I am able to get perfectly fine prints, first layer included but always considering the behaviour/ issue I previously described. -

To be honest, it is probably inexperience from my side :-)... I am still new in 3d printing and many of my settings are there just for someone's advice.

If you know a better way to do that I will appreciate if you share it with me.

I am printing PETG-CF, that temp is working very well to me. -

Done! thanks so much for this, it seems to be better now.

-

I did that but the results are conditioned by the behaviour I described before.

After powering on the printer the nozzle is very close to the bed, so if I do this test I probably scratch the bed.

but...

if I press emergency stop then the test result is perfectly fine (and of course any print I do) -

I did it, same results as response 4.

-

Pressing emergency stop after powering on and then printing w/o heightmap I got the expected results based on the height map showed in DWC.

If I don't press the emergency stop after power on, the nozzle is too close to the bed (with or without heightmap).

If press emergency stop and then I print with the heightmap the print is perfectly fine. -

SuperSlicer_config_bundle.ini & 30 mm cube.gcode

[print:JEN 0.4 PETG Filamentive Carbon F] allow_empty_layers = 0 avoid_crossing_not_first_layer = 1 avoid_crossing_perimeters = 1 avoid_crossing_perimeters_max_detour = 0 bottom_fill_pattern = rectilinear bottom_solid_layers = 6 bottom_solid_min_thickness = 0 bridge_acceleration = 0 bridge_angle = 0 bridge_flow_ratio = 60% bridge_overlap = 145% bridge_speed = 15 bridge_speed_internal = 15 bridged_infill_margin = 200% brim_ears = 0 brim_ears_detection_length = 1 brim_ears_max_angle = 125 brim_ears_pattern = concentric brim_inside_holes = 0 brim_offset = 0 brim_width = 0 brim_width_interior = 0 clip_multipart_objects = 0 compatible_printers = compatible_printers_condition = complete_objects = 1 complete_objects_one_brim = 0 complete_objects_one_skirt = 1 complete_objects_sort = object curve_smoothing_angle_concave = 0 curve_smoothing_angle_convex = 0 curve_smoothing_cutoff_dist = 2 curve_smoothing_precision = 0 default_acceleration = 0 dont_support_bridges = 1 draft_shield = 0 duplicate_distance = 6 enforce_full_fill_volume = 1 ensure_vertical_shell_thickness = 0 exact_last_layer_height = 0 external_infill_margin = 150% external_perimeter_cut_corners = 0% external_perimeter_extrusion_spacing = external_perimeter_extrusion_width = 0.45 external_perimeter_overlap = 100% external_perimeter_speed = 50% external_perimeters_first = 0 external_perimeters_hole = 1 external_perimeters_nothole = 1 external_perimeters_vase = 0 extra_perimeters = 1 extra_perimeters_odd_layers = 0 extra_perimeters_overhangs = 0 extruder_clearance_height = 20 extruder_clearance_radius = 20 extrusion_spacing = extrusion_width = 0.45 fill_angle = 45 fill_angle_increment = 0 fill_density = 0% fill_pattern = gyroid fill_smooth_distribution = 10% fill_smooth_width = 50% fill_top_flow_ratio = 125% first_layer_acceleration = 0 first_layer_extrusion_spacing = first_layer_extrusion_width = 0.42 first_layer_flow_ratio = 100% first_layer_height = 0.25 first_layer_infill_speed = 15 first_layer_min_speed = 0 first_layer_size_compensation = -0.2 first_layer_size_compensation_layers = 1 first_layer_speed = 10 gap_fill = 1 gap_fill_last = 1 gap_fill_min_area = 25% gap_fill_overlap = 100% gap_fill_speed = 20 gcode_comments = 0 gcode_label_objects = 0 hole_size_compensation = 0 hole_size_threshold = 100 hole_to_polyhole = 0 hole_to_polyhole_threshold = 0.01 hole_to_polyhole_twisted = 1 infill_acceleration = 0 infill_anchor = 600% infill_anchor_max = 50 infill_connection = connected infill_connection_bottom = connected infill_connection_solid = connected infill_connection_top = connected infill_dense = 1 infill_dense_algo = enlarged infill_every_layers = 1 infill_extruder = 1 infill_extrusion_spacing = infill_extrusion_width = 0.42 infill_first = 0 infill_only_where_needed = 0 infill_overlap = 35% infill_speed = 20 inherits = interface_shells = 0 ironing = 0 ironing_angle = -1 ironing_flowrate = 15% ironing_spacing = 0.1 ironing_speed = 15 ironing_type = top layer_height = 0.2 max_print_speed = 20 max_volumetric_speed = 0 milling_after_z = 200% milling_extra_size = 150% milling_post_process = 0 milling_speed = 30 min_skirt_length = 20 min_width_top_surface = 100% model_precision = 0.0001 no_perimeter_unsupported_algo = none notes = only_one_perimeter_first_layer = 0 only_one_perimeter_top = 1 only_one_perimeter_top_other_algo = 0 only_retract_when_crossing_perimeters = 1 ooze_prevention = 0 output_filename_format = [input_filename_base].gcode over_bridge_flow_ratio = 125% overhangs_reverse = 0 overhangs_reverse_threshold = 250% overhangs_speed = 10 overhangs_width = 50% overhangs_width_speed = 1% perimeter_acceleration = 0 perimeter_bonding = 0% perimeter_extruder = 1 perimeter_extrusion_spacing = perimeter_extrusion_width = 0.45 perimeter_loop = 0 perimeter_loop_seam = rear perimeter_overlap = 100% perimeter_round_corners = 0 perimeter_speed = 20 perimeters = 3 post_process = print_extrusion_multiplier = 100% print_retract_length = -1 print_retract_lift = -1 print_settings_id = print_temperature = 0 raft_layers = 0 resolution = 0.002 seam_angle_cost = 100% seam_position = aligned seam_travel_cost = 100% single_extruder_multi_material_priming = 1 skirt_brim = 0 skirt_distance = 3 skirt_distance_from_brim = 1 skirt_extrusion_width = 0 skirt_height = 1 skirts = 2 slice_closing_radius = 0.049 small_perimeter_max_length = 20 small_perimeter_min_length = 10 small_perimeter_speed = 15 solid_fill_pattern = rectilineargapfill solid_infill_below_area = 70 solid_infill_every_layers = 0 solid_infill_extruder = 1 solid_infill_extrusion_spacing = solid_infill_extrusion_width = 0.42 solid_infill_speed = 20 solid_over_perimeters = 2 spiral_vase = 0 standby_temperature_delta = -5 support_material = 0 support_material_angle = 0 support_material_auto = 1 support_material_buildplate_only = 1 support_material_contact_distance_bottom = 0.2 support_material_contact_distance_top = 0.2 support_material_contact_distance_type = plane support_material_enforce_layers = 0 support_material_extruder = 1 support_material_extrusion_width = 0.35 support_material_interface_contact_loops = 0 support_material_interface_extruder = 1 support_material_interface_layers = 3 support_material_interface_pattern = rectilinear support_material_interface_spacing = 0 support_material_interface_speed = 100% support_material_pattern = rectilinear support_material_solid_first_layer = 0 support_material_spacing = 2.5 support_material_speed = 15 support_material_synchronize_layers = 0 support_material_threshold = 0 support_material_with_sheath = 1 support_material_xy_spacing = 50% thin_perimeters = 1 thin_perimeters_all = 0 thin_walls = 0 thin_walls_merge = 1 thin_walls_min_width = 33% thin_walls_overlap = 50% thin_walls_speed = 10 threads = 8 top_fill_pattern = monotonic top_infill_extrusion_spacing = top_infill_extrusion_width = 0.4 top_solid_infill_speed = 20 top_solid_layers = 6 top_solid_min_thickness = 0 travel_acceleration = 1500 travel_speed = 300 travel_speed_z = 0 wipe_tower = 0 wipe_tower_bridging = 10 wipe_tower_brim = 150% wipe_tower_no_sparse_layers = 0 wipe_tower_rotation_angle = 0 wipe_tower_width = 60 wipe_tower_x = 180 wipe_tower_y = 140 xy_inner_size_compensation = 0 xy_size_compensation = 0 [filament:V-CORE 3 Carbon F] bed_temperature = 80 bridge_fan_speed = 100 bridge_internal_fan_speed = -1 chamber_temperature = 0 compatible_printers = compatible_printers_condition = compatible_prints = compatible_prints_condition = cooling = 1 disable_fan_first_layers = 1 end_filament_gcode = "" external_perimeter_fan_speed = 20 extrusion_multiplier = 0.81 fan_always_on = 0 fan_below_layer_time = 60 filament_colour = #29B2B2 filament_cooling_final_speed = 3.4 filament_cooling_initial_speed = 2.2 filament_cooling_moves = 4 filament_cooling_zone_pause = 0 filament_cost = 0 filament_density = 0 filament_deretract_speed = 50 filament_diameter = 1.75 filament_dip_extraction_speed = 70 filament_dip_insertion_speed = 33 filament_enable_toolchange_part_fan = 0 filament_enable_toolchange_temp = 0 filament_load_time = 0 filament_loading_speed = 28 filament_loading_speed_start = 3 filament_max_overlap = 100% filament_max_speed = 0 filament_max_volumetric_speed = 0 filament_max_wipe_tower_speed = 0 filament_melt_zone_pause = 0 filament_minimal_purge_on_wipe_tower = 15 filament_notes = "" filament_ramming_parameters = "120 100 6.6 6.8 7.2 7.6 7.9 8.2 8.7 9.4 9.9 10.0| 0.05 6.6 0.45 6.8 0.95 7.8 1.45 8.3 1.95 9.7 2.45 10 2.95 7.6 3.45 7.6 3.95 7.6 4.45 7.6 4.95 7.6" filament_retract_before_travel = nil filament_retract_before_wipe = nil filament_retract_layer_change = nil filament_retract_length = 0.3 filament_retract_lift = nil filament_retract_lift_above = nil filament_retract_lift_below = nil filament_retract_restart_extra = nil filament_retract_speed = 60 filament_seam_gap = nil filament_settings_id = "" filament_shrink = 100% filament_skinnydip_distance = 31 filament_soluble = 0 filament_spool_weight = 0 filament_toolchange_delay = 0 filament_toolchange_part_fan_speed = 50 filament_toolchange_temp = 200 filament_type = PET filament_unload_time = 0 filament_unloading_speed = 90 filament_unloading_speed_start = 100 filament_use_fast_skinnydip = 0 filament_use_skinnydip = 0 filament_vendor = (Unknown) filament_wipe = nil filament_wipe_advanced_pigment = 0.5 filament_wipe_extra_perimeter = nil filament_wipe_speed = nil first_layer_bed_temperature = 80 first_layer_temperature = 267 full_fan_speed_layer = 0 inherits = max_fan_speed = 15 max_speed_reduction = 90% min_fan_speed = 15 min_print_speed = 10 slowdown_below_layer_time = 5 start_filament_gcode = "; Filament gcode\nG1 X250 Y250 \nG30\n\nM290 R0 S0.09 \n\nG29 S1\n" temperature = 262 top_fan_speed = 15 [printer:V-CORE 3 Frederick] bed_custom_model = bed_custom_texture = bed_shape = 0x0,500x0,500x500,0x500 before_layer_gcode = ; 0.2mm layer, 8 bands 5mm each, total height 40mm\n;{if layer_num== 1}M572 D0 S0.13\n;{elsif layer_num== 20}M572 D0 S0.14\n;{elsif layer_num== 40}M572 D0 S0.15\n;{elsif layer_num== 60}M572 D0 S0.16\n;{elsif layer_num== 80}M572 D0 S0.17\n;{elsif layer_num== 100}M572 D0 S0.18\n;{elsif layer_num== 120}M572 D0 S0.19\n;{elsif layer_num== 150}M572 D0 S0.20\n;{endif} between_objects_gcode = color_change_gcode = M600 cooling_tube_length = 5 cooling_tube_retraction = 91.5 default_filament_profile = default_print_profile = deretract_speed = 50 end_gcode = M104 S0 ; turn off temperature\nM140 S0 ; turn off bed\nG28 X0 ; home X axis\nM84 ; disable motors\nM999 extra_loading_move = -2 extruder_colour = "" extruder_fan_offset = 0% extruder_offset = 0x0 extruder_temperature_offset = 0 fan_kickstart = 0 fan_percentage = 0 fan_speedup_overhangs = 1 fan_speedup_time = 0 feature_gcode = gcode_filename_illegal_char = gcode_flavor = reprapfirmware gcode_precision_e = 5 gcode_precision_xyz = 3 high_current_on_filament_swap = 0 host_type = octoprint inherits = layer_gcode = machine_limits_usage = time_estimate_only machine_max_acceleration_e = 10000,5000 machine_max_acceleration_extruding = 1500,1250 machine_max_acceleration_retracting = 1500,1250 machine_max_acceleration_travel = 1500,1250 machine_max_acceleration_x = 9000,1000 machine_max_acceleration_y = 9000,1000 machine_max_acceleration_z = 500,200 machine_max_feedrate_e = 120,120 machine_max_feedrate_x = 500,200 machine_max_feedrate_y = 500,200 machine_max_feedrate_z = 12,12 machine_max_jerk_e = 2.5,2.5 machine_max_jerk_x = 10,10 machine_max_jerk_y = 10,10 machine_max_jerk_z = 0.2,0.4 machine_min_extruding_rate = 0,0 machine_min_travel_rate = 0,0 max_gcode_per_second = 1500 max_layer_height = 0.3 max_print_height = 200 milling_diameter = milling_toolchange_end_gcode = milling_toolchange_start_gcode = milling_z_lift = min_layer_height = 0.07 min_length = 0.035 nozzle_diameter = 0.4 parking_pos_retraction = 92 pause_print_gcode = M601 print_host = printer_model = printer_notes = printer_settings_id = printer_technology = FFF printer_variant = printer_vendor = printhost_apikey = printhost_cafile = printhost_port = remaining_times = 0 retract_before_travel = 3 retract_before_wipe = 0% retract_layer_change = 0 retract_length = 0.3 retract_length_toolchange = 10 retract_lift = 0 retract_lift_above = 0.3 retract_lift_below = 0 retract_lift_first_layer = 0 retract_lift_top = "All surfaces" retract_restart_extra = 0 retract_restart_extra_toolchange = 0 retract_speed = 60 seam_gap = 15% silent_mode = 1 single_extruder_multi_material = 0 start_gcode = G28 ; home all axes\nG1 Z5 F5000 ; lift nozzle\n start_gcode_manual = 0 template_custom_gcode = thumbnails = 0x0,0x0 thumbnails_color = #018aff thumbnails_custom_color = 0 thumbnails_with_bed = 1 time_estimation_compensation = 100% tool_name = 0 toolchange_gcode = use_firmware_retraction = 0 use_relative_e_distances = 0 use_volumetric_e = 0 variable_layer_height = 1 wipe = 0 wipe_advanced = 0 wipe_advanced_algo = linear wipe_advanced_multiplier = 60 wipe_advanced_nozzle_melted_volume = 120 wipe_extra_perimeter = 0 wipe_speed = 0 z_offset = 0 z_step = 0.005 [physical_printer:Printer 1] host_type = duet preset_name = VCoreNeu - PrusaSlicer_config_bundle.ini print_host = duet.fritz.box printer_technology = FFF printhost_apikey = vcore2019 printhost_authorization_type = key printhost_cafile = printhost_password = printhost_port = printhost_user = [presets] print = JEN 0.4 PETG Filamentive Carbon F sla_print = - default - sla_material = - default - printer = V-CORE 3 F filament = V-CORE 3 Carbon F physical_printer =Thank you very much!

Julián.