@mintytrebor yes you right, lts just stick with the normal way. And nowdays everthing is connected to the internet even my refrigerator (which a sbit concerning by the way) so it should be fine for the duet, too

Posts made by jrentschler01

-

RE: How To write a plugin for DWCposted in Plugins for DWC and DSF

-

RE: How To write a plugin for DWCposted in Plugins for DWC and DSF

@mintytrebor said in How To write a plugin for DWC:

(This is why I tell users to ensure they have an internet connection when installing the plugin in my wiki)

Ahh okay, that is what I missed! Now I got it how it works. But do you see a way that we can tell webpack to bundle this packages into the plugin files? So that it works without an internet connetion?

But this is not critical now for me just would be a nice to have

And Thanks for your fast response!

-

RE: How To write a plugin for DWCposted in Plugins for DWC and DSF

@MintyTrebor I looked also in your plugin and I see you use some dependencies they are not installed in DWC but where did you tell webpack to pack them into your plugin?

I see you have plugin.json in your /dist folder with a webpack config but I'm not sure where to put this in the DWC that it will be used for the build process?

and did you install your libraries that you use normally with npm into DWC to deveolpe and build it?

-

RE: How To write a plugin for DWCposted in Plugins for DWC and DSF

@mintytrebor Omg so simple sure it works. I don't know why I didn't try this. Thank you

-

RE: How To write a plugin for DWCposted in Plugins for DWC and DSF

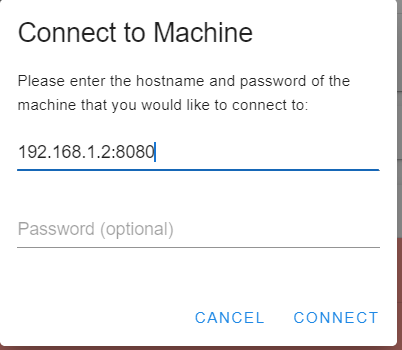

I'm able to build and run the DWC but I'm not able to connect to the Board I always get:

Failed to connect to 192.168.1.2:8080

Network errorIs there a password needed? Is the port 8080 correct?

The onboard DWC with 192.168.1.2 works normal.

I added also the M586 C"*" to my config. -

RE: How To write a plugin for DWCposted in Plugins for DWC and DSF

Thank you guys, I already got the envirement setup and it looks doable.

-

How To write a plugin for DWCposted in Plugins for DWC and DSF

Is there any guide, documentation how to write a plugin for DWC? Example Project?

or could have somebody answers to this questions:

Which envirement is used to do that ?

where can I find the plugin system API?

which dependecies are neccearry? -

RE: Found issues using duet as CNC controllerposted in CNC

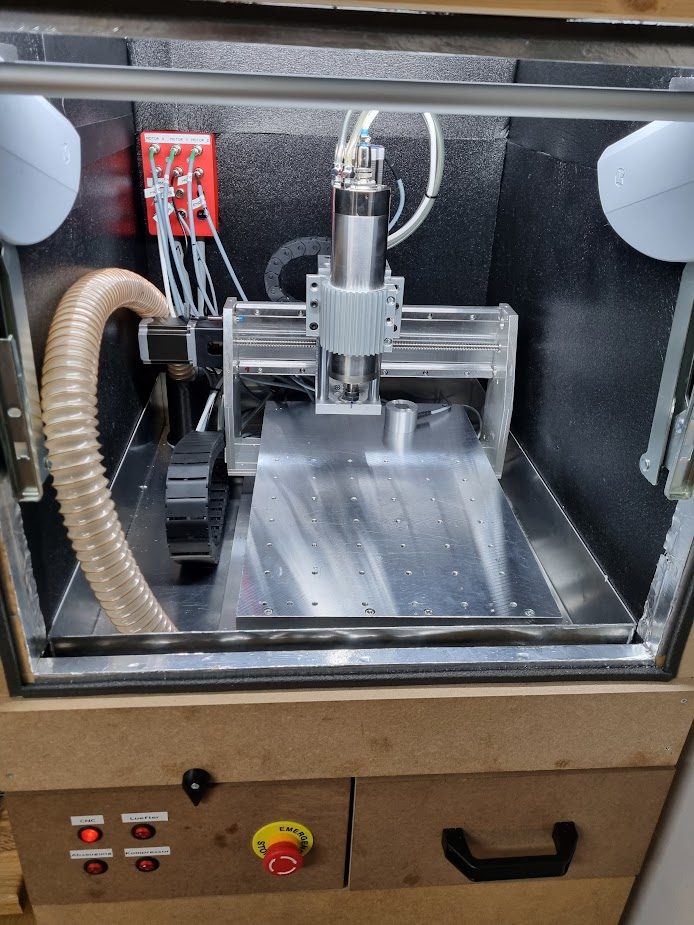

just for who is curious wht kind of CNC I have here a picture to have idea of it:

It's nothing Special, but it works precise and fine with milling aluminium. The Axis motors could be a bit bigger to go faster, but thats fot the next step.

-

RE: Found issues using duet as CNC controllerposted in CNC

@jay_s_uk okay did it:

5.11.2021, 19:38:57 M669

Kinematics is Cartesian, 1 segments/sec, min. segment length 1.00mm, matrix:

1.00 0 0

0 1.00 0

0 0 1.00I'm not exactly sure what itr should do? I read the documentation and I guess it helps if more Movement commands in the buffer but if you have an long onging movement like 100mm it sill will not stop until this is done. I tryed it with M0

-

RE: Found issues using duet as CNC controllerposted in CNC

@pcr said in Found issues using duet as CNC controller:

stopping can be quick If you Play with the segment paramter

can you tell me a bit more about that? or tell me where this is documented?

-

RE: Found issues using duet as CNC controllerposted in CNC

@pcr said in Found issues using duet as CNC controller:

Try using

G10 L2 P1 X50 Y50

Then G54

Okay you right I was missing G54, so this is solved now. Thank you!

-

RE: Found issues using duet as CNC controllerposted in CNC

@pcr I already cleared the cache and also tryed it in edge, when it is loading you can see for a sec the printer conrols then they disapear. Thats it

you can choose the CNC from the settings. Try toggle IT.

Where which setting do you mean?

-

RE: Feature Request - workpiece angle compensation CNCposted in Firmware wishlist

@dc42 I tested now with G1 the same wy with drawing a simple rectangle and it worked so far, I assume G2&G3 as well. Thank you a lot.

I'm continue getting a macro ready to probe the workpice and calulate the angle like @jay_s_uk mentioned.It would be great if we could visualize it after that somehow.

-

RE: Found issues using duet as CNC controllerposted in CNC

@pcr said in Found issues using duet as CNC controller:

@jrentschler01

The CNC is now in DWC 3.4 Beta 5. You have to Just Install it. You Always have to Install the RRF and Same DWC VersionG68 is Just implemented. But still Testing.

Live coordinates you can See with the DWC CNC

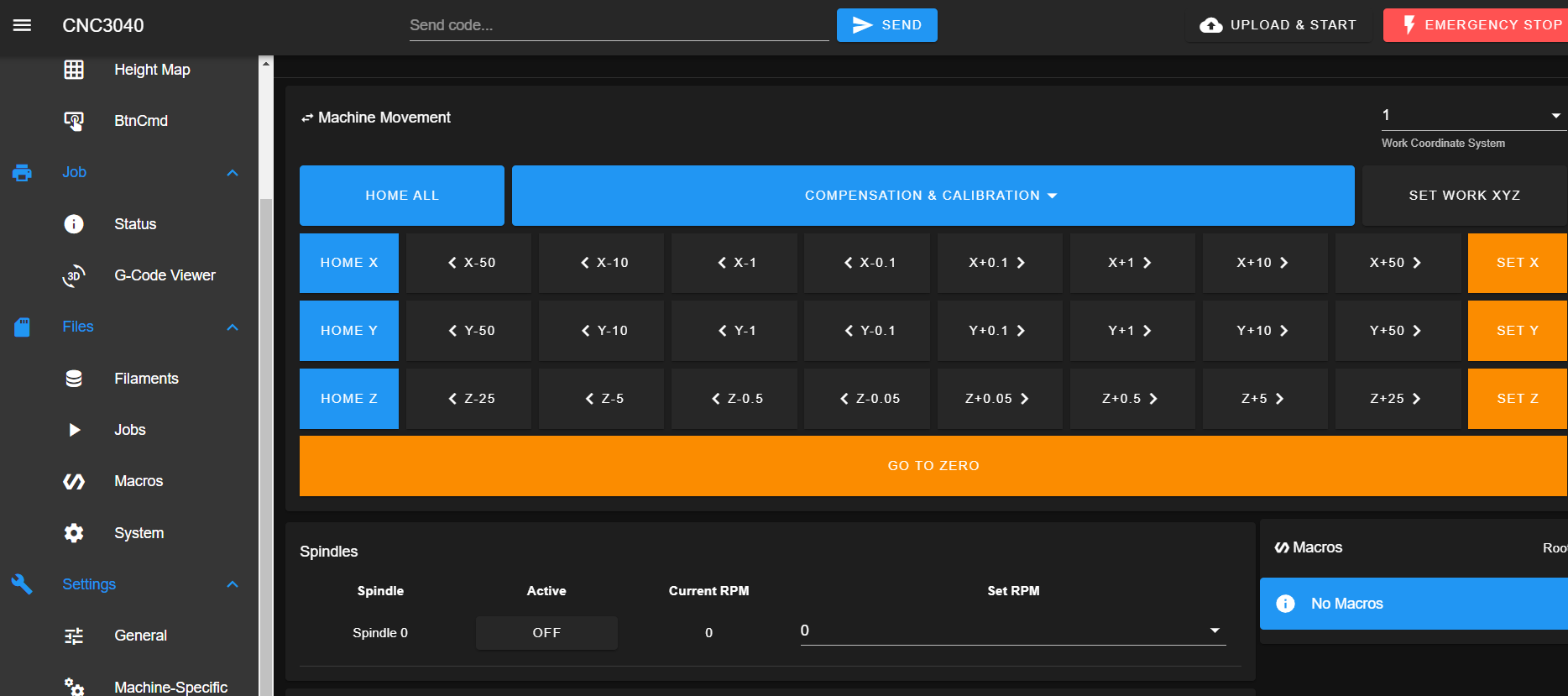

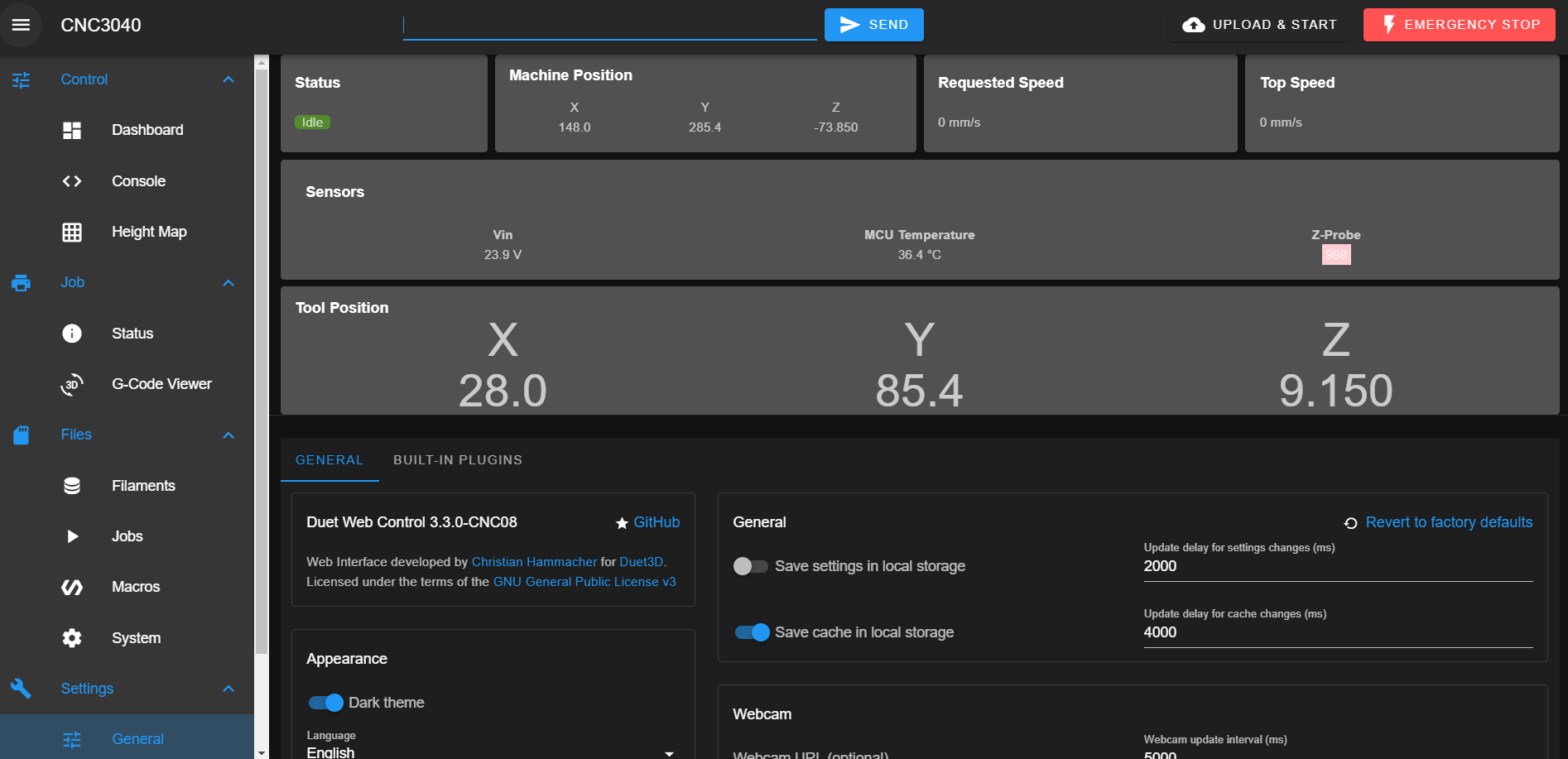

I tryed the DWC3.4 Beta 5 as well.. the same no CNC Conrols visible nowhere:

(I'm using the M453 in the config.g)

At DWC 3.3.-CNC08 they are visible:

Btw I use Chrome as Browser.

-

RE: Feature Request - workpiece angle compensation CNCposted in Firmware wishlist

@dc42 okay great let me know if I can do something to help

-

Found issues using duet as CNC controllerposted in CNC

First of all this is not a negative criticism. I just want to write about some experience I made so far when I was setting up the Duet as a cnc controller and to address this or get some feedback on what could be the solution.

-

Wiring Information / Pin usage:

Connecting stuff for a 3d printer is well documented but connecting things for CNC I needed to go through a lot of different posts here and get different information. Also which pin (gpio) could be used freely to switch relays and so on. -

Work coordinates and machine min/max:

I have setup my machine like this: M208 X0:258 Y0:350 Z-105:0 but if you set your work coordinates for example to G10 L2 X50 Y50 it doesn't allow you to go G1 X-5 but it should

because typically the work coordinates are used for the workpiece which is mostly never at machine zero coordinates. And because I set the work coordinates to X50 it should allow me to drive to min X-50 this will be the machine limit then.

If you do a surface milling you always start outside the workpiece in negative values. So what I did now to change the Maschine limits like this:

M208 X-100:258 Y-100:350 Z-105:100

but now it allows me to drive outside the machine boundaries if I'm not careful. -

Stopping:

I found no way to stop a job or movement immediately without Emergency Stop (M112) but this is sometimes absolutely necessary at CNC milling and you don't want to lose your positions and coordinate systems every time. If you just pause you never know when it stops because you don't know how much movement is still in the buffer. -

Actual Position:

I didn't found a way to get the current position during a movement, just the position that is commanded to move to. I know it's not a closed loop system but anyway the RRF commands the step pulses to the driver so it should know where it should be all the time.

Will this change with using the closed loop system on duet3? -

Workpiece angle correction (G68)

There is already a separate thread to this. Feature Request - workpiece angle compensation CNC

Until know i was not able to get it working. But for me this one of the most important thing. If you have to mill your workpiece from different sides you need to know exactly how it is placed on the machine table and a placement with a perfect precise alignment is not always possible. -

Postprocessor (F360)

I found a lot of postprocessors for fusion 360 made from several persons they all kind of work more or less but all of them has some issues where i had to edit the G Code manually afterwards but they are close to what we need. And this point I can fix by myself to edit the post processor that it will work for my cnc. But it would be nice if there would be an official post development on the duet3d github. -

DWC

This was the most reason for me to use the duet as CNC controller because of the web control and for 3d printing I love to use it. But to use it for a CNC is not this good yet. I know there are special versions for CNC and I looked into that but I read that the DWC-CNC is discontinued and integrated into the standard DWC in the current release so I used the latest release 3.3.0 but even when set to CNC Mode (M453) it looked not like I already saw on some screenshots (no XYZ Position display, G-Code Viewer was not working and so on) basically just the Extruder and heating stuff disappeared.

But then I installed the latest Release of the discontinued DWC-CNC and it worked. But still there are some things missing to get a good use for a CNC. If It is wanted I could write more about this.

Conclusion:

The duet and RRF are great and I already use 2 of duet wifi at my 3d Printers but to become a good cnc controller I guess there is still some way to go.I'm using a Duet Wifi with RRF 3.4.0beta5+1 (2021-10-28)

-

-

RE: Feature Request - workpiece angle compensation CNCposted in Firmware wishlist

@jay_s_uk do you think you can help in this?

Let me know if you you guys need more information or anthing I should test.I knkow i needed quite some time to get ready but I'm not sure how long I keep this setup with the duet because this will be one of the essential functions I need and some other issues that I faced with using RepRap for CNC. I might moving on to linuxcnc soon.

-

RE: Feature Request - workpiece angle compensation CNCposted in Firmware wishlist

After days of reading through this forum I managed now to get my machine wokring somehow but there are still a lot off issues that i found with using the duet as CNC Controller. But I guess I should put this in a seperate thread, right?

@t3p3tony But now I was able to test the angle compensation, I was a little confused with the other threads that I thought you will do it differently then the G68 command that's why I asked for the procedure.

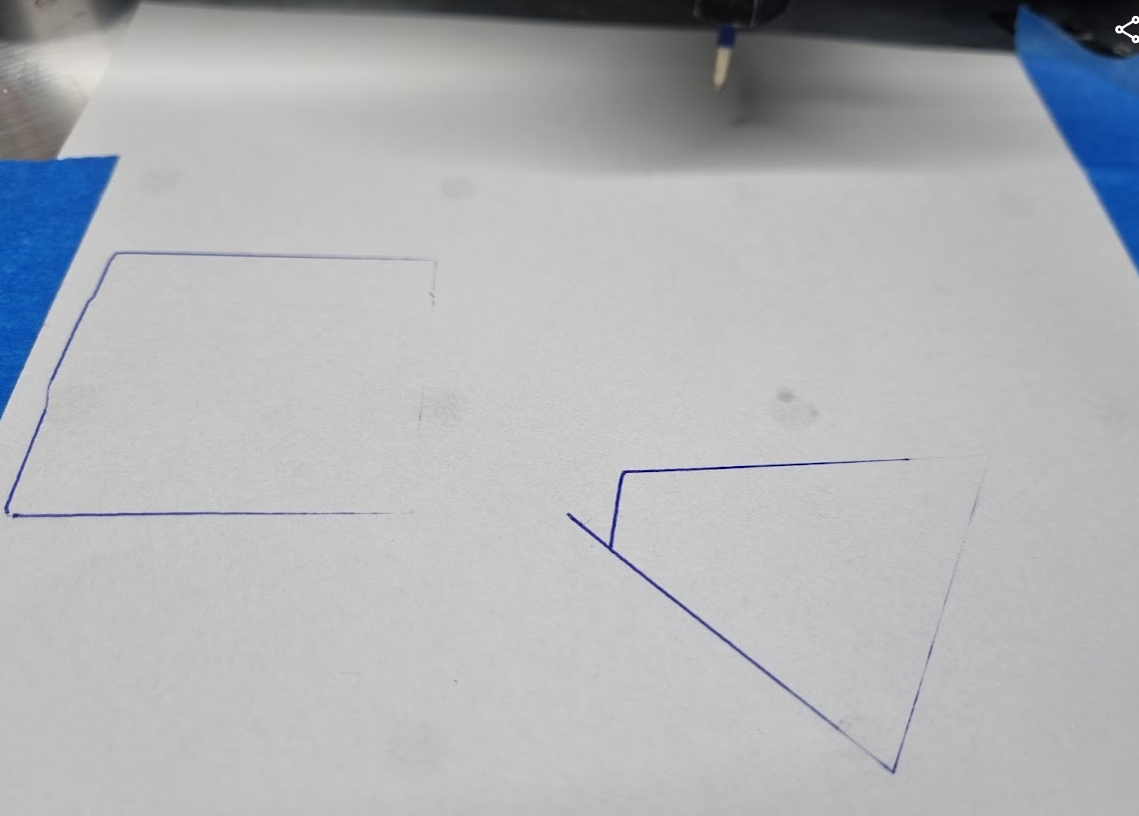

I tryed it with the RRF 3.4b5 in the link and the G68 command but it was a fail. Here is what I did:I drawed a simple rectangle with this G-Code

;simple rectangle for test G90 G21 G1 F500 G1 X50 G1 Y50 G1 X0 G1 Y0Then I just moved the X Work offset +70 and entered

G68 A0 B0 R45

and run the same G-Code again but the result was far away from what I expected:

the left rectange is normal without G68 and the right one is with the 68.I think just the first move looks right with the 45° angle. What could be the Problem?