@ianborg I would look into possible interference somewhere but I can't suggest where to start looking.

Alternatively, as a band-aid, set your printer up to only start heating the nozzle when the bed is at temperature.

Posts made by jens55

-

RE: Heater faultposted in Tuning and tweaking

-

RE: Heater faultposted in Tuning and tweaking

@ianborg, I have similar issues with a nozzle heater. It generally boils down to poor connections either at the heater end, temperature sender end , at the controller end (rare) of either or, as in my case, a plug/socket connection in the line (so I can swap out either without a major effort).

Looking at the temperature curve can usually give you a good hint on where the fault lies. The bed can't change temperature fast so if you see a fast temperature change the issue is in the temperature sensing circuit. If it is a slooow temperature change then it's likely to be the heater.

Last but not least, at least in my case, there is a good chance the sensor itself is faulty or getting towards it's end of life.

Good luck! -

RE: Suggestions needed to fix a poor printposted in Tuning and tweaking

Just as a follow up, I am happy to report that drying the PETG helped quite a bit. While the new print isn't perfect, I can't call it a 'dogs breakfast'. Besides drying the filament, I also went with random seams as all other choices ended up putting the seams on the overhangs.

-

RE: Suggestions needed to fix a poor printposted in Tuning and tweaking

@jay_s_uk, thanks, I might give it a try if things don't improve with the dried filament. I will do another print tomorrow morning.

-

RE: Suggestions needed to fix a poor printposted in Tuning and tweaking

@jay_s_uk, I have had bad luck with beta builds before and I was waiting for 3.6. I was aware of the improvements and was looking forward to 3.6 being released to try that out.

-

RE: Suggestions needed to fix a poor printposted in Tuning and tweaking

@engikeneer, thanks for that suggestion - no the PETG was not dried and yes, I have seen the difference in print quality but for some reason it didn't occur to me to try that. I will dry it overnight and try again tomorrow.

On the ABS, I have very little (practically nil) cooling and it is an enclosed printer. I could see two sides being good and two sides being bad if it was a fan issue but why would only one side turn out nice?

I will check on the seam ... again something I didn't think of checking!

-

RE: Suggestions needed to fix a poor printposted in Tuning and tweaking

@jay_s_uk, 3.5.1 for both printers.

-

RE: Suggestions needed to fix a poor printposted in Tuning and tweaking

@jumpedwithbothfeet, thanks! I did notice the ringing but I was more concerned about the crappy three other sides. I was thinking that pressure advance would cause the ringing because that is something I have been struggling with. I can't understand how one side could be nice and crisp but the other sides are crappy. The print orientation was with the left end sitting on the build plate so I was expecting all sides to have more or less equal print quality. Also, this is the print from a second printer with the first printer producing crap on all four sides. It is likely that both printers have more or less equal settings (other than what is required for the different filaments) so I was thinking that parameters would be a better explanation.

I will verify that everything is tight. -

Suggestions needed to fix a poor printposted in Tuning and tweaking

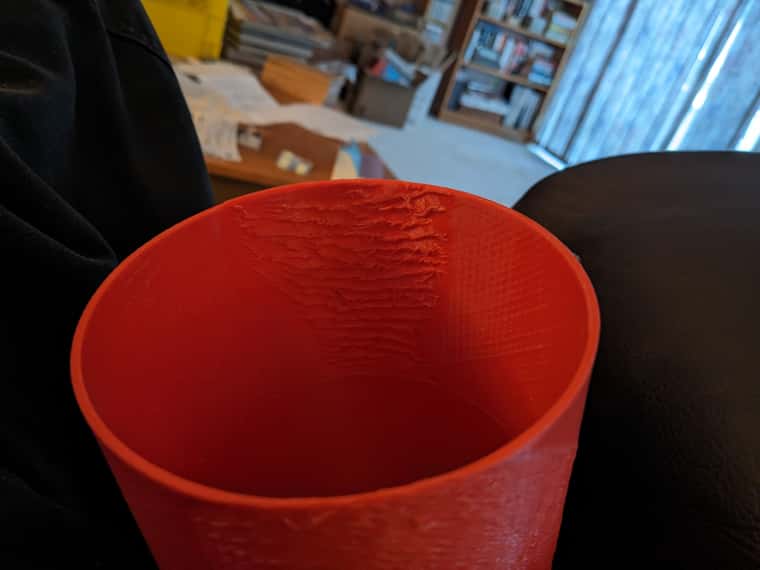

I have had some issues with print quality but they were never enough to really worry about. Yesterday I printed a particular part on my Jubilee printer in PETG and it came out very poorly. I turned around and printed the same part in ABS on a CR10 based printer. One side came out reasonable but 3 sides were crap. Here are the pictures of the ABS print of two different sides. PETG print was even rougher looking (on all 4 sides)

Off hand I have no idea of what I could try to change in my settings to improve the print quality and I could use some suggestions.

BTW, I use PrusaSlicer.2.9

-

RE: Duet Wifi - Thermistor issuesposted in Duet Hardware and wiring

@Jarery, I have had a similar situation happen once - it turned out to be a defective extruder. The extruder worked fine with no load but fed intermittently when the filament needed to pass through the nozzle. The root cause was a busted bearing.

While it may not be that, it's worth investigating (it took me a long time to find that issue) -

RE: Dual motorised nozzleposted in Duet Hardware and wiring

Just as an additional thought - how about mounting the extruders on a single plate with a swivel point in the middle. The idea is when one nozzle goes down, the second one goes up ... and vice versa. I am pretty sure that I have seen this kind of arrangement in a commercial setup before but I have no clue where I saw it. It was quite a while ago. The point being that you save some weight.

-

RE: Tracing down a bad conductorposted in General Discussion

@3DPrintingWorld, 'spiking' would imply 'going high'. A short would not do that.

If this is just a terminology issue and you are referring to a temperature DROP then I would look at two aspects. How is the heater connected to the Duet? Are you using any connectors or is the only connector at the PCB. I have had many issues with connections overheating causing poor connection which then causes heating which then causes even more issues. Look at all connections to make sure the contacts are not discoloured.

I have also run into 'gentle' temperature dropping which can be caused by a defective thermistor. Rapid changes (ie instantaneous) could indicate a bad connection someplace since the hot end can not change instantaneously.

A defective thermistor might also cause sharp drops.

I have seen a number of issues and most of them relate to either the thermistor or bad connections on either the thermistor or the heater. -

RE: DWC suddenly shows only a blank page.posted in Duet Web Control

@Crosswire, don't know if it is related but on occasion I also get a blank page. It resolves itself quickly (might take 2 or 3 reloads). Today I had a blank page that did not resolve itself but I had no trouble with the same page on another computer (it was already loaded).

-

RE: Poor overhang performanceposted in Tuning and tweaking

@MJLew, thanks again for your suggestions. This morning I collected the new print and there was only a tiny area that showed the same symptoms as the earlier print. It was a thing of (mostly) beauty!

I do not know what parameter change(s) caused the huge improvement. I forgot to mention that I had also added a tiny bit of support but that support was not in the problem areas but rather what PS felt strongly about.

I need one more of these fittings so I will get to reverse one or two of the previous changes to maybe narrow things down a bit more but my gut feeling is that reducing the speed was the cause of the improvement.

The next print will be started tonight for another overnight print. -

RE: Poor overhang performanceposted in Tuning and tweaking

@MJLew, thanks for the input. I have rotated the print and reduced the speed from 180 t0 100 mm/sec and started another print. It is a 6 hr print so it will be a while before I can see if there is a difference.

In retrospect, while PS does indeed slow down for bridges, I am not entirely sure this applies to overhangs in this part. Looking at the speed as reported by PS, it seems there was no slowdown. On the other hand, the overhang test sample did show a drastic speed reduction for the very outside filament laid down. It should be interesting to see how this next print turns out. -

Poor overhang performanceposted in Tuning and tweaking

I am trying to print a 4 inch sch 40 45 degree pipe fitting. The fitting is printed with one open end flat on the build plate. Since this is a 45 degree fitting, I was under the impression that the most overhang I would encounter would be 45 degrees. Well this seems to not be correct for some reason or other that I don't really understand. I get severe artifacts on what I would think are the highest overhang portions.

I test-printed an overhang test piece with the chosen settings using PrusaSlicer and there was no distortion on the highest angled overhang which was 70 degrees (PS automatically reduces speed and turns the part cooling fan to 100%)

I also tried slicing the part with different settings of maximum overhang to see where PS started inserting supports and that happened at 75 degrees approximately.

I have a number of questions:

Since this fitting is a 45 degree fitting of a 4" pipe, are there actual sections where the overhang is more than 45 degrees?

Is there any other way that I can print this part without using a huge amount of support material? I tried different print orientations but that didn't get me that far.

Attached are a couple of photos of the artifact which to me look like a case of not enough cooling (I printed at 205C with PLA) but printing the overhang calibration print showed no difference between 205C and 195C.

-

RE: Pause print to insert nut/washerposted in General Discussion

@Phaedrux .... or turn the part cooling fan off during the first layer

My next job that requires weight is actually going to be done with sand and I will try to remember to turn the fan off. -

RE: Duet Maestro with latest firmware and web control is sluggish.posted in Duet Web Control

@dlc60, I suspect that my closing the web control window and opening a new window does exactly the same thing that you accomplished by clearing your cache and cookies ..... but hey, it's a computer so what do I know

There is no question in my mind that there is a gremlin in the DWC system somewhere ...... -

RE: Duet Maestro with latest firmware and web control is sluggish.posted in Duet Web Control

I have a similar issue with a Duet2 WIFI and a Duet3 6HC. In my case, DWC slows down to unacceptable levels after having been run for a while (several days). In my case closing the DWC window and re-starting the web access brings speed back to normal.

This has been an issue for a very long time which has been reported in the past but no cause/fix was ever found. I have learned to live with it -

RE: many many hiccups (thousands)posted in Beta Firmware

@Phaedrux, while not impossible, I don't really know what I am doing. Could you give me a hint as to what you expect to see? There is no apparent (at least to me) difference in printer behaviour between a printer that shows hiccups vs one that doesn't produce hiccups. I don't know if maybe one would see choppy motion for example ... but there is no hint of choppiness.