Hello I just bought a wifi duet for my ender 3, this printer comes with 24v hot bed, can I connect directly to the duetwifi without any mosfet?

Posts made by IvanG

-

hot bed without mosfet ender 3posted in Duet Hardware and wiring

-

RE: Corexy 3 lead screws problem with heightposted in Duet Hardware and wiring

Sorry but I have them connected in series in ZA and ZB I do not know why I put it in parallel, I really have it connected in series, I do not understand why every time you go up and down the bed it stays at a different height, especially when I turn off and turn on the printer is a disaster the lead screw connected to the ZB is 5mm lower than the ZA and the spindle connected to the Extruder is 7 or 8 mm lower, although I raise them manually and the level again happens the same, my screws advance and nuts are from T8x8

-

RE: Corexy 3 lead screws problem with heightposted in Duet Hardware and wiring

I have manually leveled with the printer off and the problem remains exactly the same, I think I am going to try to put 2 advance screws instead of 3

-

RE: Corexy 3 lead screws problem with heightposted in Duet Hardware and wiring

The engines for z are these:

https://www.amazon.es/gp/product/B06XQWMDWT/ref=oh_aui_detailpage_o04_s00?ie=UTF8&psc=1

The maximum current they support is 1.7A

-

RE: Corexy 3 lead screws problem with heightposted in Duet Hardware and wiring

An image of the result of my bltouch probe

-

RE: Corexy 3 lead screws problem with heightposted in Duet Hardware and wiring

Thanks for your help my config.g is the following

; Configuration file for Duet WiFi (firmware version 1.20 or newer)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Sun Apr 08 2018 20:13:54 GMT+0200 (Hora de verano romance); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder movesM667 S1 ; Select CoreXY mode

; Network

M550 PD-BOT ; Set machine name

M552 S1 ; Enable network

;*** Access point is configured manually via M587

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S0 ; Drive 0 goes forwards

M569 P1 S0 ; Drive 1 goes forwards

M569 P2 S0 ; Drive 2 goes backwards

M569 P3 S0 ; Drive 3 goes backwards

M584 X0 Y1 Z2:3 E4 ; Apply custom drive mapping

M350 X16 Y16 Z16 E16 I1 ; XYZ and E0 microstepping

M92 X100 Y100 Z400 E420 ; Set steps per mm

M566 X900 Y900 Z12 E120 ; Set maximum instantaneous speed changes (mm/min)

M203 X6000 Y6000 Z200 E1200 ; Set maximum speeds (mm/min)

M201 X500 Y20 Z250 E250 ; Set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; Set axis minima

M208 X300 Y260 Z450 S0 ; Set axis maxima; Endstops

M574 X1 Y2 S0 ; X home to min. Y and Z home to max. Normally Closed limit switches.

M574 Z2 S2 ; Define Z to use Probe. Home to Min; Z-Probe

M558 P9 X0 Y0 Z2 H5 F100 T4000 A10 R0.5 S0.008 ;Set Z probe type/mode 5. H=Dive Height. F=Speed the bed moves

G31 X-19 Y-37 Z1.52 P25 ; Z probe trigger value, offset in relation to nozzle. And trigger height adjustment

M557 X15:280 Y15:245 S30 ; Define mesh grid

M376 H20 ;

M375 ; Load heightmap.csv; Heaters

M301 H0 S1.00 P10 I0.1 D200 T0.4 W180 B30 ; Use PID on bed heater (may require further tuning)

M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S280 ; Set temperature limit for heater 1 to 280C

; BLTouch - Heaters

M307 H7 A-1 C-1 D-1 ; Disable the 7th Heater to free up PWM channel 5 on the Duex board.; Fans

M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 I0 F500 H1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic saving after power loss is not enabled

; Custom settings are not configured

-

RE: Corexy 3 lead screws problem with heightposted in Duet Hardware and wiring

Hello when it is off if I can move them to level them, but every time I go up and under the bed each one is always at a different height, I am not using the automatic leveling of the bed, I understand that for this function the 3 advance screws they have to be connected in different divers, I use 2 in parallel.

-

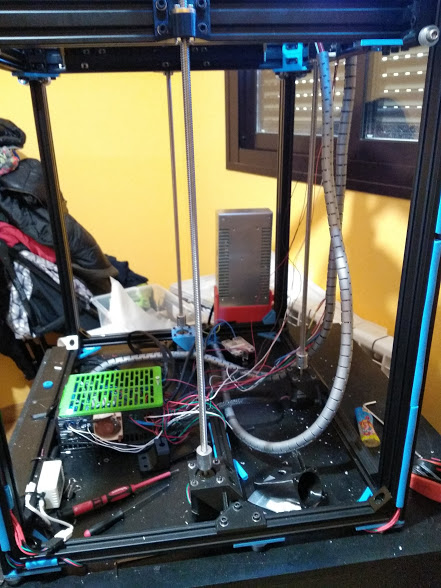

Corexy 3 lead screws problem with heightposted in Duet Hardware and wiring

Hello I have a problem with my corexy printer I am using 3 lead screw 2 screws in parallel connected to the Z and 1 screw connected to the extruder, the spindles move up and down without problem, what happens when I do z homing each screw is at a height different, is there any way to solve this problem?

I am using the duetwifi plate

-

RE: Bltouch goes down fastposted in IR Height Sensor

@dc42 said in Bltouch goes down fast:

@ivang said in Bltouch goes down fast:

@dc42 said in Bltouch goes down fast:

If the problem is that the pin is dropping too fast after the probe triggers, either increase the travel speed (T parameter in M558), or change to P9 in the M558 command (which needs firmware 1.21 to work).

Thank you try it, I have another problem that I just saw, when the XY axes move the 3 axes Z also turn very very slowly, because can this be ??

That's normal if you have bed compensation enabled.

I just want to use Bltouch to create the mesh at the time of printing, the strange thing is that if I move with the X axis 100mm the z axes also start moving, as I can disable so that the Z axes do not move when I move them. X and Y axes

-

RE: Bltouch goes down fastposted in IR Height Sensor

@dc42 said in Bltouch goes down fast:

If the problem is that the pin is dropping too fast after the probe triggers, either increase the travel speed (T parameter in M558), or change to P9 in the M558 command (which needs firmware 1.21 to work).

Thank you try it, I have another problem that I just saw, when the XY axes move the 3 axes Z also turn very very slowly, because can this be ??

-

RE: Bltouch goes down fastposted in IR Height Sensor

@shadowx said in Bltouch goes down fast:

M558 P5 H5 F600

I just tried to get down to F100 and F200 but it keeps hitting on the bed when it goes down, I'll have to adjust the speed of raising and lowering the bed on M203 X6000 Y6000 Z160 E1200; Set maximum speeds (mm / min) ???

-

Bltouch goes down fastposted in IR Height Sensor

I have a problem, when I do homing in Z or a G29 my bed goes up and it hits the probe correctly, but when I lower my bltouch bed it hits the bed again when it goes down, there is some way so that the pin does not go down so fast and Do not hit my hot bed 2 times?

; Drives

M569 P0 S0 ; Drive 0 goes forwards

M569 P1 S0 ; Drive 1 goes forwards

M569 P2 S0 ; Drive 2 goes backwards

M569 P3 S0 ; Drive 3 goes backwards

M584 X0 Y1 Z2:3 E4 ; Apply custom drive mapping

M350 X16 Y16 Z16 E16 I1 ; XYZ and E0 microstepping

M92 X100 Y100 Z400 E420 ; Set steps per mm

M566 X900 Y900 Z12 E120 ; Set maximum instantaneous speed changes (mm/min)

M203 X6000 Y6000 Z160 E1200 ; Set maximum speeds (mm/min)

M201 X500 Y20 Z250 E250 ; Set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; Set axis minima

M208 X300 Y260 Z450 S0 ; Set axis maxima; Endstops

M574 X1 Y2 S0 ; X home to min. Y and Z home to max. Normally Closed limit switches.

M574 Z2 S2 ; Define Z to use Probe. Home to Min; Z-Probe

M558 P5 H5 F600 T4000 X0 Y0 Z2 ; Set Z probe type/mode 5. H=Dive Height. F=Speed the bed moves

G31 P25 X-24 Y35 Z1.52 ; Z probe trigger value, offset in relation to nozzle. And trigger height adjustment

M557 X15:280 Y15:245 S30 ; Define mesh grid

M375 -

RE: How to create a mesh for Bltouchposted in Firmware installation

@t3p3tony said in How to create a mesh for Bltouch:

@ivang from a noise perspective running x16 interpolated to 256 and running x256 is functionally the same. The only difference is that the driver is generating the intermediate steps. I could not tell a noise difference between the two during testing.

I think maybe you do not have I1 in you M350 command ?

Also note that interpolation only works on x16 (not for example x32 and x64)

He is right I just put the end I1 and the noise is almost nonexistent, thank you very much.

-

RE: How to create a mesh for Bltouchposted in Firmware installation

So for the moment the only solution is to run X16 the steps of the engine? I buy a duetwifi for the X256 and for the little noise that engines make but if I have to run to X16 it makes the same noise as my mks gen

-

RE: How to create a mesh for Bltouchposted in Firmware installation

@phaedrux said in How to create a mesh for Bltouch:

@dc42 said in How to create a mesh for Bltouch:

M350

Does your M350 command have I1?

But I do not understand why with the configuration of X16 interpolated steps if it works correctly but when I change it to interpolated X256 the G29 command does not work

-

RE: How to create a mesh for Bltouchposted in Firmware installation

Hello I have changed it to x16 interpolated and now if it works correctly, although the noise from the engines is annoying, is there any way to work it to x256 interpolated?

-

RE: HOT BED 220V DUETWIFI RESETposted in Duet Hardware and wiring

Thanks for the answers, I think I will buy this rele ssr in Amazon, what do you think?

https://www.amazon.es/gp/product/B0716RTYMD/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1

-

RE: HOT BED 220V DUETWIFI RESETposted in Duet Hardware and wiring

@mike said in HOT BED 220V DUETWIFI RESET:

@ivang Don't use that! It's a mechanical relay that's only rated for 12V. Running 220V at the output is dangerous and has probably just fried the contacts. I'd advise you to get a DC/AC Solid State Relay. I don't know where you are, but you can easily get those off Amazon and e-bay. Just make sure it's the DC/AC type.

You mean that the connectors on the board broke? I had connected it before but when I saw it did not work, I removed it.

-

RE: How to create a mesh for Bltouchposted in Firmware installation

@dc42 said in How to create a mesh for Bltouch:

-

Send M557 without parameters and review the response, to check that the mesh parameters you set in config.g have been accepted.

-

After you run G29 and it stops, check the GCode Console page of Duet Web Control for error messages.

When I send the M557 command, the following message appears:

M557

Grid: X15.0:205.0, Y15.0:245.0, radius -1.0, X spacing 30.0, Y spacing 30.0, 56 pointsAfter sending G29 there is no error message or anything, the printer moves a little and stops, the status of the printer is always busy and nothing else I can give emergency stop or turn off the duertwifi and turn it on current.

-