@oliof Yeah I figured that was going to be the best answer. Thanks for the reply

Posts made by Hytek

-

RE: Not a Duet question, large print surface questionposted in General Discussion

-

RE: Not a Duet question, large print surface questionposted in General Discussion

Magnetic print surface arrived today, looks good except for the damaged corner from shipping. It was packaged well so I guess one of the handlers thought it was a giant frizbee

Once I get this straightened out (no pun intended) I have a decision to make, which I would appreciate any advice. Right now I have an 8mm aluminium bed with a buildtak surface on. The buidtak surface is in good condition except a small chip which I normally dodge in the slicer. Can't decide if I should say goodbye to the buildtak surface and apply the magnetic sticker directly to the aluminium plate or attach it to a piece of glass. Any thoughts?

Thanks in advance

-

RE: Paneldue going blackposted in General Discussion

Well....this is gonna hurt. I did it! It was my fault. When I disassembled the module from the back of the display I realized I had forgotten to fit the 3v jumper. After installing the jumper I left the printer on for the day, ran a couple of prints and no issues. Considering the purpose of the jumper I guess I should consider myself lucky, didn't fry the screen.

Anyway, figured accept responsibility for my error and post it so I may save someone else the issues

-

RE: Paneldue going blackposted in General Discussion

@Phaedrux Thanks for the reply. Is there any particular part of the board you want to see?

-

Paneldue going blackposted in General Discussion

Hi all, I am currently having an odd issue with my 7" paneldue. Quite often, and for no apparent reason, the display goes black. This has happened on initial boot up, sitting idle for a short period of time and part way through a print. So no rhyme nor reason to its behavior.

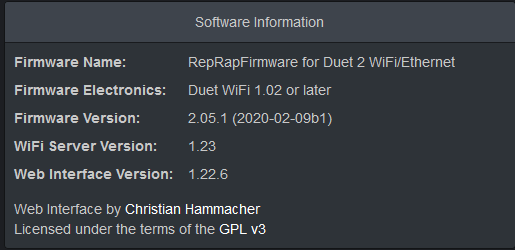

I have also noticed when the display goes black the buttons and audible confirmations are still active. To get the display active again I have to cycle the power off & on, sometime a couple of times. If I see the splash screen I know we're good.Current firmware:

It's the earlier 7" panel with separate module that plugs into the back. Current panel firmware is 1.24

Any help would be much appreciated as this is becoming quite frustrating

-

RE: Not a Duet question, large print surface questionposted in General Discussion

@Corexy 500x500 seems not TOO hard to find, even Wham Bam has a 500 available. Over that is a PITA to find anything for, especially if you don't want to pay $500

-

RE: Not a Duet question, large print surface questionposted in General Discussion

@Corexy As soon as I have a chance to test it I will update the post. Options seem to be pretty limited for larger format printers at the moment. Kind of a case of take what you can get.

-

RE: Question about significance of height map.posted in My Duet controlled machine

@fcwilt Is this last map done at printing temp?

-

RE: Question about significance of height map.posted in My Duet controlled machine

@fcwilt Considering the height map shows front left, front right & rear right pretty much level I wouldn't imagine this to be a result of the rear left adjustment. Winding the rear left to compensate would drop the front right. You mentioned the 3 adjustment points are near perfect, everything outside of those areas can't be adjusted without adversely effecting somewhere else. So if you are showing a dip in the rear left corner without a countering rise in the front right I would say there is a dip. One thing I have noticed is the height map seems a little exaggerated. This might be a minor dip in reality.

My bad, I should have been clearer when I said checked it manually. I mean with a paper test or dial indicator if you have one.

-

RE: Question about significance of height map.posted in My Duet controlled machine

It looks like you have set it to check only 4 points, while this is fine for initial 'course' setting. You're best results will come from selecting more points. The purpose of generating the height map is to give mesh compensation an idea of your bed's levelness as well as overall flatness at a given temperature.

Was this map generated at printing temp? Things can change at different temperature settings.

Have you checked it manually to confirm?

Are your first layers printing good?

-

RE: Not a Duet question, large print surface questionposted in General Discussion

Just an update on this topic. The only place I have had any luck so far is on AliExpress. Though they do not list the size I required they were more than happy to accommodate. The process to finally order is a bit of a PITA as it is not a stock line in their store.

https://a.aliexpress.com/_dSRK8LJ?spm=a2g0s.imconversation.0.0.209a3e5fIe2hQc

I ended up purchasing 3 of these to get one complete set plus a spare print surface. This came to round figures $200 AUD which I think equates to $4 USD

Anyway, hope this will help someone else who has a large printer

-

RE: High Temperature printingposted in General Discussion

Yes, depending on the length, diameter & inertia force applied in the change of direction the lead screw can flex. In a slight case these 'flexes' will show up in the print surface. In heavier cases can cause unwanted noise, vibrations and shorten component life.

I'm not saying lead screws can't be used, just suggesting there are things to consider when making that choice. -

RE: High Temperature printingposted in General Discussion

Depending on the travel length and desired print speed lead screws or ball screws may suffer whip. Unless of course you compensate by increasing the diameter, which in turn increases weight & load on the drive motor to change direction. A balancing act for sure.

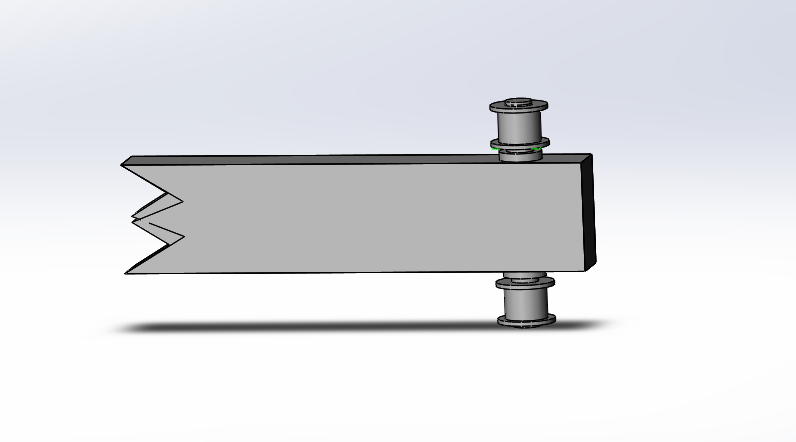

One possible suggestion for passing belt drive through the sealed enclosure might be a thru axle. Please excuse my rough pic

You get the idea tho

-

RE: Odd behavior of Stepper motors on Duet 3.posted in Duet Hardware and wiring

@R3D Have you tested any of the failed stepper motors back in a known good source, i.e. the other printer you mentioned. This is just a precautionary measure before the next suggestion in case the stepper has taken damage.

If you plug your Z stepper/s into X or Y driver do they become active?

Sorry I can't help on the firmware side, I'm new to Duet myself

-

RE: Odd behavior of Stepper motors on Duet 3.posted in Duet Hardware and wiring

@R3D I can't see anything to suggest you have done this so...

Can you operate a stepper off the suspect drive on the bench? For clarity, that would be a different stepper motor/s with new wiring loom and no load.Also, bare in mind I haven't seen your build so I don't know how feasible this suggestion is. But if you send a move command to the problem stepper/s and manipulate the wiring harness, particularly near corners, is there any change?

-

RE: Brave Browserposted in Duet Web Control

I ended up using Firefox. I set the web interface as my home page and that's all I use Firefox for. Seems wasteful but....

-

RE: Not a Duet question, large print surface questionposted in General Discussion

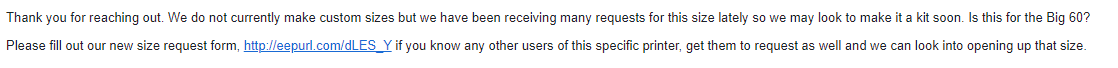

@chas2706 Yes, about a month ago I contacted Wham Bam and they said:

Their system sounds good & well priced comparatively. Unfortunately they still don't offer any bigger than 500x500

-

RE: Not a Duet question, large print surface questionposted in General Discussion

I'll send them an email tomorrow. Could end up back to Buildtak, they do a 609x609. Not gonna cry for 1x1mm

-

RE: Not a Duet question, large print surface questionposted in General Discussion

I use a BLtouch at the moment, would have chose matt black option anyway.

Just looked again and only goes to 500x500, might have sold out of larger sizes

-

RE: Not a Duet question, large print surface questionposted in General Discussion

O.o that's the exact site I looked up. Got to 500x500 then went round. Might have to Email them.

Thanks a lot for the advice before I forget again