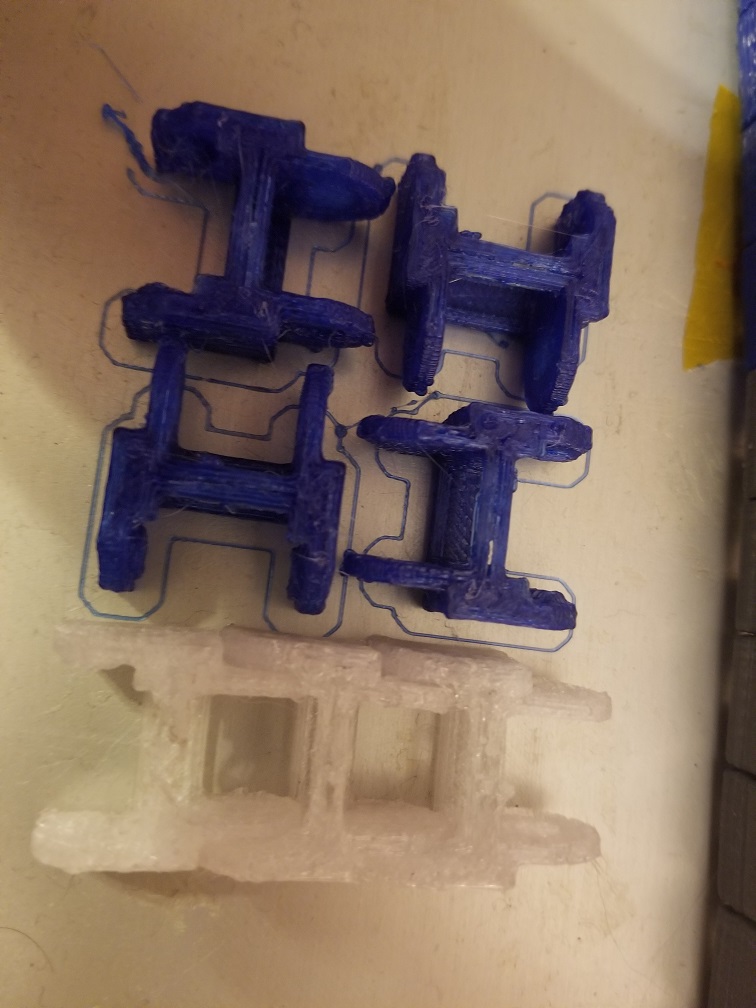

Well here's the results lol.

The blue pieces in a 'square' are made with eSUN PETG as a fast test. First print with both X and Y gantries replaced with linear guides/rails (whatever people wanna call em). So now aka Janky v4

The clear/white is Solutech PETG with the carbon fiber tubes on both X and Y gantries..... noticeable improvement... holy crap... This is basically Janky v3

The gray pieces connected together are made with Hatchbox "Silver" PETG and have been significantly 'post processed' with razors and such. Done on what was Janky v2

And finally the blue pieces connected together were made on the very first version of Janky, which was holy crap terrible... but hey, it worked! Used the completely wrong settings for EVERYTHING... 0.4mm nozzle with 0.4mm layer height, 135% layer width, yadda yadda, complete garbage.

They were printed with Hatchbox ABS, and had the least 'post processing' of anything ironically. They just snapped together, and with alittle silicone lube, work perfectly fine. They have a slight 'uphill' travel to them but hey, they work!

Anyway, this was basically just to showcase that linear guides/rails are hands down just worth the money... 23 bucks for two carbon fiber tubes, or 23 bucks for a linear guide/rail... I'll now take that rail any day... so much easier to model parts for, so much easier to work with, so much easier in actual use....

Also, as a side note:

The test print wasn't entirely successful, hence the terrible look. The extruder kept jamming every couple of minutes, so the gaps/uneven looking shells are attributed to that... Idk why it jams so much now. All I did from v2 to v3/4 was move it from one z post to the other so that the filament was easier to reach lol.

!

!

if so, then I think this is exactly what I was looking for then.

if so, then I think this is exactly what I was looking for then. If this is not currently a part of the SBC interface solution, may I ask why it has not been implemented yet? Its fully possible to do, so if it isn't, why hasn't it been?

If this is not currently a part of the SBC interface solution, may I ask why it has not been implemented yet? Its fully possible to do, so if it isn't, why hasn't it been?