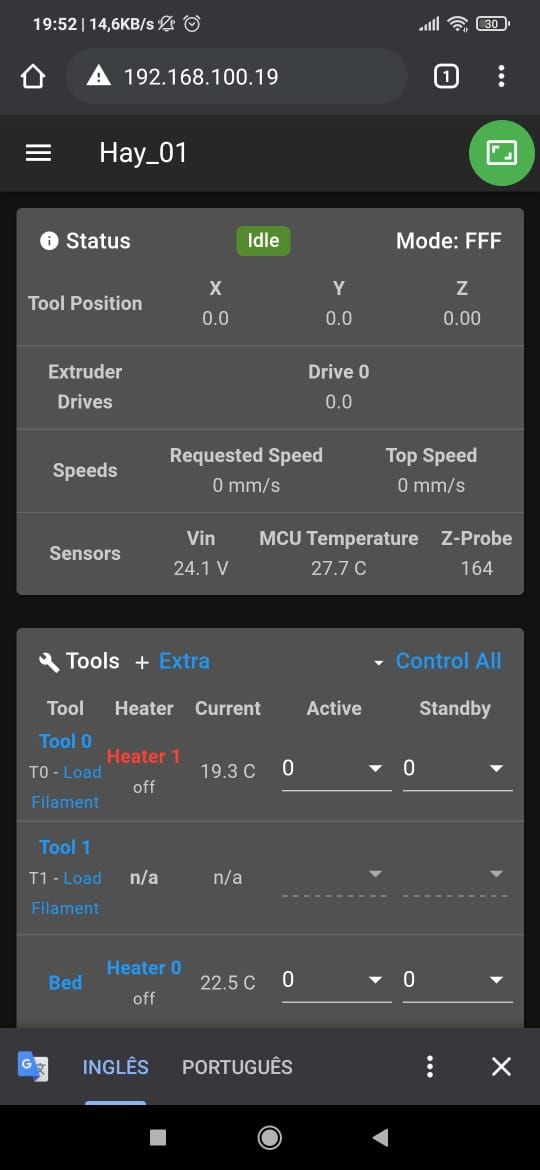

@whopping-pochard yes ... on my web duet is showing this

Posts made by herlander

-

RE: IR-Prome not workingposted in Duet Hardware and wiring

-

IR-Prome not workingposted in Duet Hardware and wiring

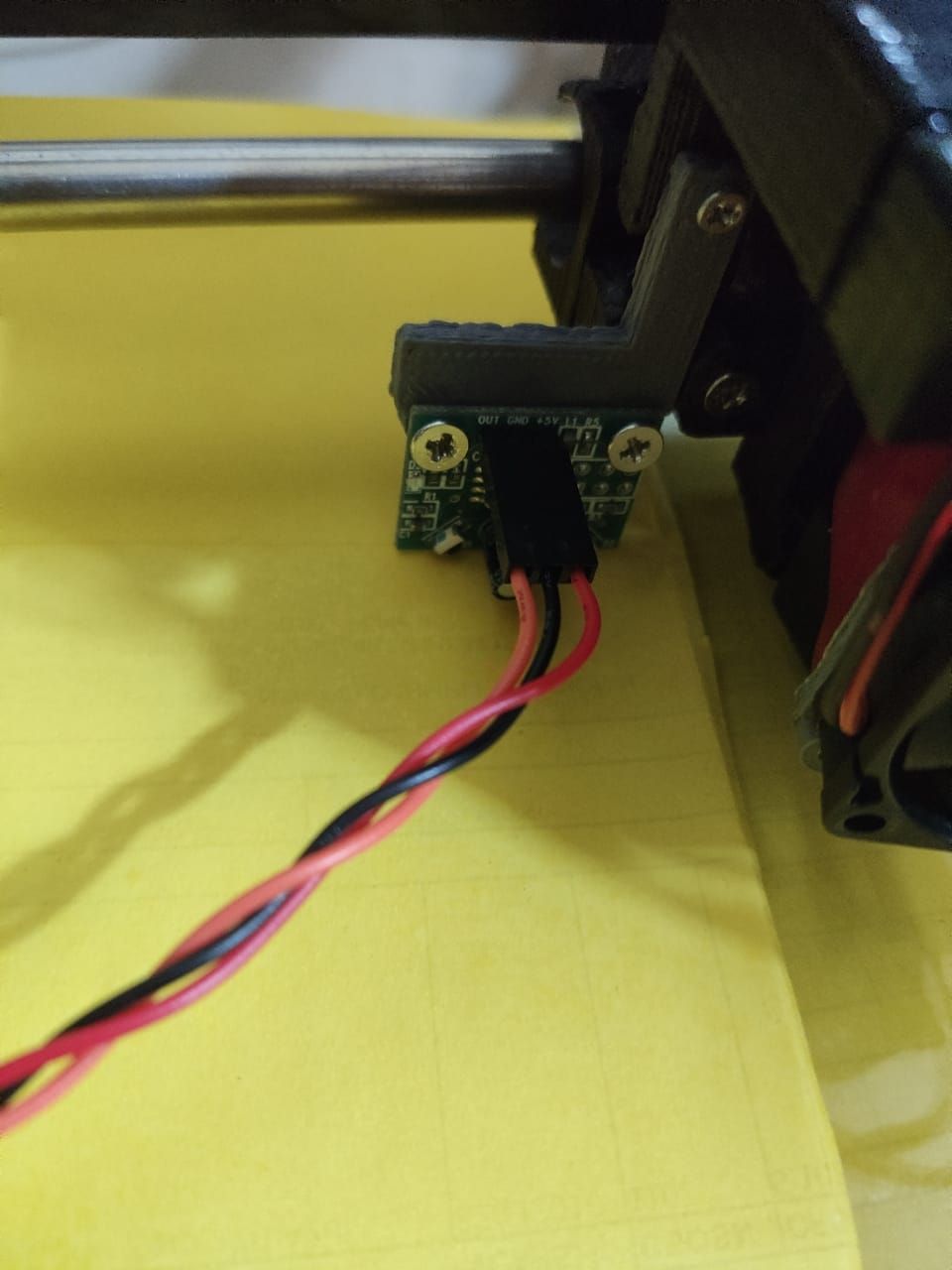

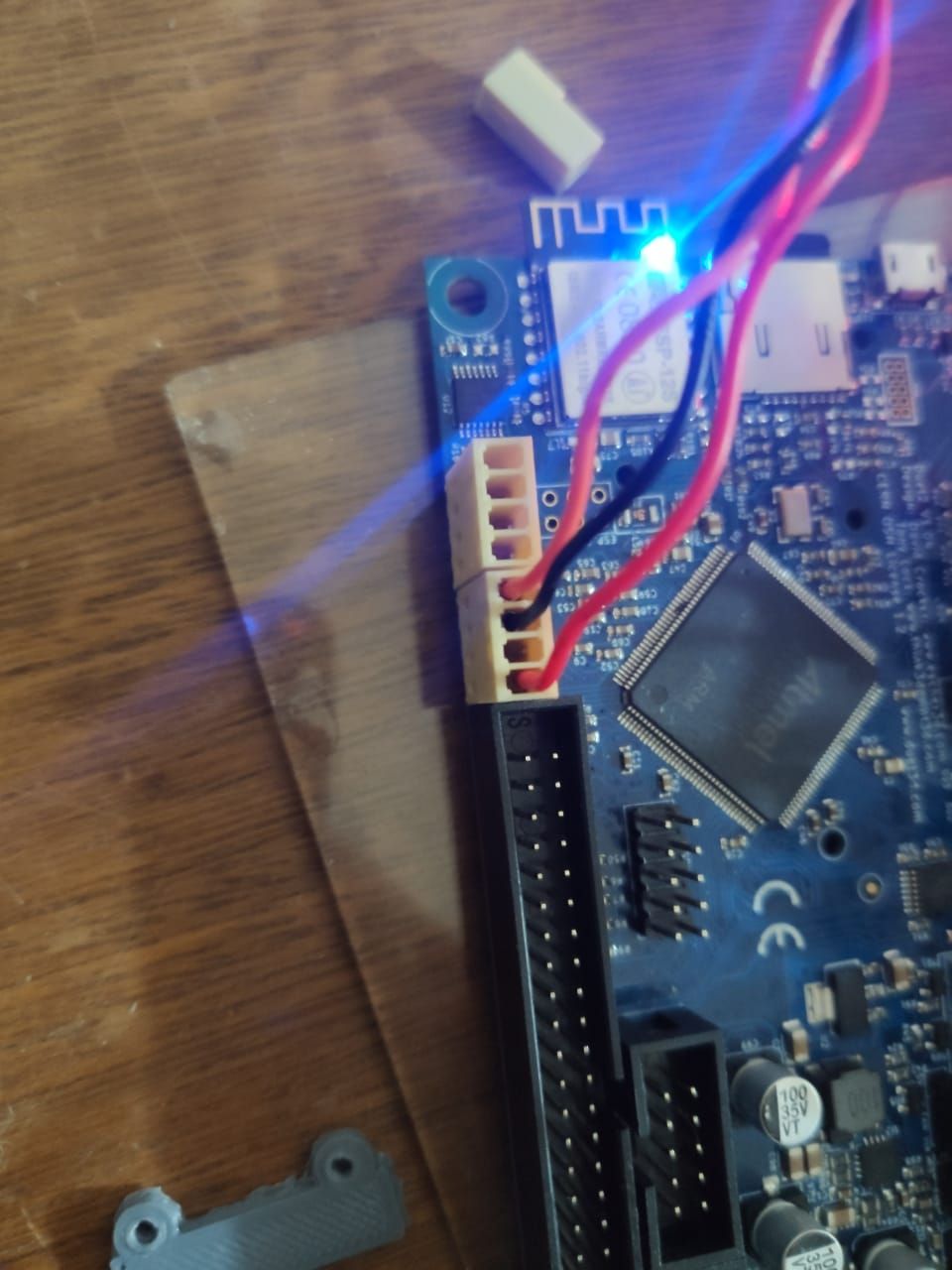

Today I went to install my IR-probe, however it doesn't work ... I've tried everything I validated more than 50 times the pinout and it should work, or at least give a sign of life ...

Board: Duet 2 WiFi (2WiFi)

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.1.1 (2020-05-19b2)

Duet WiFi Server Version: 1.23bed.g

; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Sat Sep 12 2020 13:13:28 GMT-0300 (Brasilia Standard Time) ;G28 ; home ;M401 ; deploy Z probe (omit if using bltouch) ;G30 P0 X20 Y100 Z-99999 ; probe near a leadscrew, half way along Y axis ;G30 P1 X180 Y100 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors ;M402 ; retract probe (omit if using bltouch) M561 ; clear any bed transform G28 ; home all axis G29 ; probe the bed and enable compensationconfig.g

; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S0 ; physical drive 2 goes backwards M569 P3 S0 ; physical drive 3 goes backwards M569 P4 S0 ; physical drive 4 goes backwards M584 X0 Y1 Z2:4 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z1600.00 E495.35 ; set steps per mm M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z180.00 E1500.00 ; set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z100.00 E10000.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent ;M92 X80.00 Y80.00 Z1600 E785.60 ; set steps per mm ;M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min) ;M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) ;M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) ;M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X300 Y330 Z200 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S1 P"zstop+e1stop" ; configure active-high endstop for low end on Z via pin zstop ; Z-Probe ;M558 P1 C"zprobe.in" H5 F120 T6000 ; Set endstops controlled by probe M558 P1 C"zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X35:265 Y35:265 P2 ; Define mesh grid (for glass bed 4 points are more than enough) ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 A108.4 C588.7 D0.4 S1.00 V22 B0 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M308 S2 P"drivers" Y"drivers" A"DRIVERS" ; configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet M308 S3 P"mcu-temp" Y"mcu-temp" A"Duet Board" ; Configure MCU sensor ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 C"Part Fan" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 C"Hotend Fan" S1 H1 T40 ; set fan 1 name and value. Thermostatic control is turned on M950 F2 C"fan2" Q500 ; Define Fan_2 for use - Duet board cooling - PWM fan M106 P2 H2:3 T15:70 C"Duet Fan" ; Set fan 2. Manages Duet board fan. ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 D0 F-1 ; define tool 2 G10 P1 X0 Y0 Z0 ; set tool 2 axis offsets G10 P1 R0 S0 ; set initial tool 2 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss