@phaedrux Bad wire confirmed. I ordered a new one, hooked it up and no more problems. Thank you!

Posts made by hbrownell

-

RE: Warning: motor phase B may be disconnectedposted in Duet Hardware and wiring

-

Dual Z doesn't come out level.posted in Duet Hardware and wiring

Is there a way to adjust either side of the dual Z setup? I found that I'm off by quite a bit. Thanks!

-

RE: Warning: motor phase B may be disconnectedposted in Duet Hardware and wiring

@dc42 Okay, so this was the latest error I got today

M0 H1

Warning: motor phase B may be disconnected reported by driver(s) 3Which motor should I consider suspect?

-

Warning: motor phase B may be disconnectedposted in Duet Hardware and wiring

I get this warning when my machine is working. It just started and I have no idea why.

Warning: motor phase B may be disconnected reported by driver(s) 3

-

Failed print using latest cura and 3.2posted in Tuning and tweaking

I was able to print a tiny robot perfectly with no supports last night. I tried to print a part I created and, again, with no supports it printed okay but the thinner portions failed at the top of the print where they had succeded before. I then tried it with supports but it failed misserably. This causes me to think of another calibration model I tried with a hole on the side and a relatively thin wall. The wall was fine up to the hole and then where the nozzle started to print again, the model failed at that point for a few mm and when the flow seemed to kick up again it resumed normal print.

Was there a change in the new Cura that might explain this? I tried a fresh profile to see if something might be different in Cura, but it had the same result. When I did a test extrusion, I noticed that I got a really thick stream of filament coming out of the nozzle, so I'm not sure where the problem lies at this point. Up until the power outtage a couple of weeks ago this printer was top-notch. I'm using PLA from Eryone and I've had great success with their products before and this spool has been the same up till now. I'm rather lost at this point. And for the record, all axis including the extruder are properly calibrated.

-

G32 tries to go negative on X axisposted in Gcode meta commands

Thanks for the help folks, moving on to the next round, G32. It does the first probe just fine, but then X tries to go negative and rubs the belt (that da-da-da-da-da sound) but then continues on to the rest. I can't find where the odd plot number is..

config.g

; Axis Limits

M208 X20 Y-19 Z0 S1 ; set axis minima

M208 X230 Y215 Z200 S0 ; set axis maximabed.g

; called to perform automatic bed compensation via G32

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun May 16 2021 20:01:34 GMT-0500 (Central Daylight Time)

M561 ; clear any bed transform

;G29 ; probe the bed and enable compensation

;Dual Z bed.g

G28 ; home

G30 P0 X20 Y105 Z-99999 ; probe near a leadscrew, half way along Y axis

G30 P1 X180 Y105 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors

G28 Z -

RE: Error M280posted in Firmware installation

@hbrownell Never mind. I just needed to update the firmware to 3.22.. it was still on 2.05.

-

Error M280posted in Firmware installation

So, I just did the update to 3.2 and my BL Touch is not connecting apparently.

Error: M280: Invalid servo index 0 in M280 commandFrom config.g

; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P25 X29 Y-6.5 Z1.2 ; set Z probe trigger value, offset and trigger height

M557 X20:180 Y20:180 S80 ; define mesh grid; deployprobe.g

; called to deploy a physical Z probe

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun May 16 2021 20:01:35 GMT-0500 (Central Daylight Time)

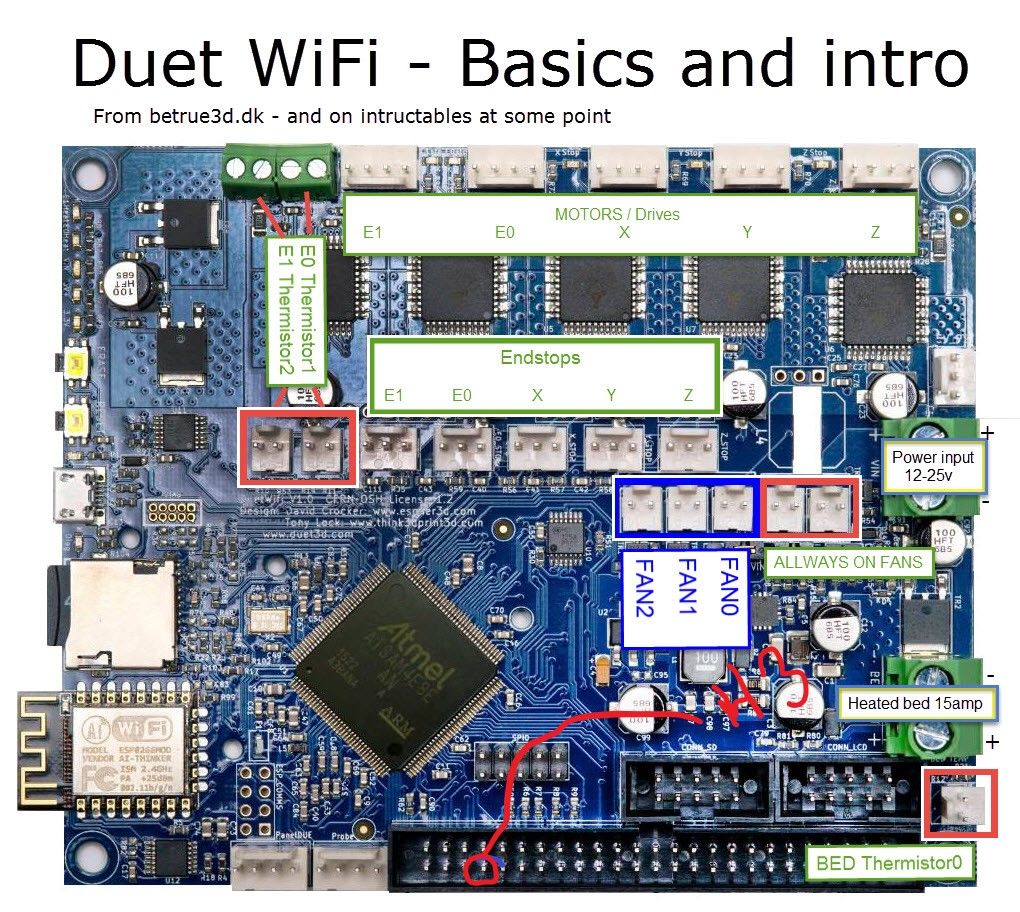

M280 P0 S10 ; deploy BLTouchI followed this image to make my connections.

-

RE: Upgrading to 3.2, need a once over on code.posted in Firmware installation

@phaedrux Last question (Hopefully) I erased the old drive but there were several folders and one zip file on it. The new build has but 2 folders sys and www. Do I need any other files to make this work or just plug it in and go?

-

RE: Upgrading to 3.2, need a once over on code.posted in Firmware installation

@phaedrux Got it, but I think I caught another error. I'm missing M671 no? and M584 should be ;

M584 X0 Y1 Z2:4 E3 yes? Because Z is running 2 and 4? -

RE: Upgrading to 3.2, need a once over on code.posted in Firmware installation

@phaedrux Awesome! I'll plug this in right away! Out of curiosity, what command SHOULD I run to do the dual z leveling? I've just been using G29 and leveling the bed from the data. I also have to manually level the x gantry which is a headache and I'd like to be done doing that.

-

RE: Upgrading to 3.2, need a once over on code.posted in Firmware installation

" I would also uncomment out the M561 at the start of bed.g (and add it in to your homing files too). That way you know for sure that mesh compensation is deactivated whilst homing and running bed leveling. "

So, to be clear add this to homeall, homex, homey, homez files?

M561 ; clear any bed transform -

RE: Upgrading to 3.2, need a once over on code.posted in Firmware installation

@hbrownell

I set my PWM to heater 3 and here's where the pin is so I'm hoping I'm right.

image url)

image url) -

RE: Duet 3D Wifi error 99posted in My Duet controlled machine

@phaedrux

I did check my extrusion calibration and it's spot on. I tried with a couple of prints I found on thingaverse and got some okay prints but near the hole and starting the next layer it was under extruding. On one of my own prints (Which I've done many times before) about 2-3mm up and it just disintegrates (under extrudes). I'm currently working my way through upgrading to 3.2 so I don't know if this conversation would be mute anyway.. I'd say just mark this one as solved since the network was back up and running. -

Upgrading to 3.2, need a once over on code.posted in Firmware installation

Here is my new config;

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun May 16 2021 20:01:34 GMT-0500 (Central Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"3DPrinter" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S0 ; physical drive 3 goes backwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X99.9 Y100.25 Z400.207 E412.70 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E110.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z4000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X1100 Y1100 Z1100 E850 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X0:220 Y-15:210 Z200 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P25 X29 Y-6.5 Z1.2 ; set Z probe trigger value, offset and trigger height

M557 X20:180 Y20:180 S80 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H T45 ; set fan 0 value. Thermostatic control is turned on

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M501 ; load saved parameters from non-volatile memoryOld Config;

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2 on Fri May 24 2019 20:44:40 GMT-0500 (Central Daylight Time); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves; Network

M550 P"3DPrinter" ; Set machine name

M552 S1 ; Enable network

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S1 ; Physical drive 0 goes forward X Drive

M569 P1 S0 ; Physical drive 1 goes Backwards

M569 P2 S1 ; Physical drive 2 goes forwards

M569 P3 S0 ; Physical drive 3 goes forwards;current settings

M584 X0 Y1 Z2:4 E3; two Z motors connected to driver outputs Z and E1

M671 X-81.5:291.5 Y110:110 S2 ; leadscrews at left (connected to Z) and right (connected to E1) of X axisM350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X99.9 Y100.25 Z400.207 E412.70 ; Set steps per mm (E100.7-bowden)

M566 X900.00 Y900.00 Z12.00 E110.00 ; Set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z4000.00 E1200.00 ; Set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; Set accelerations (mm/s^2)

M906 X1100.00 Y1100.00 Z1100.00 E850.00 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits old

;M208 X20 Y0 Z0 S1 ; Set axis minima

;M208 X230 Y210 Z200 S0 ; Set axis maxima;New Settings

M208 X0:220 Y-15:205 ; X carriage moves from 0 to 220, Y bed goes from 0 to 220; Endstops

M574 X1 Y1 S1 ; Set active high endstops; Z-Probe

M574 Z1 S2 ; Set endstops controlled by probe

M307 H3 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch

M307 H1 A309.8 C176.8 D3.7 S1.00 V12.0 B0 ; New PID Settings 08/25/2020; new suggested settings

M558 P9 H5 F120 T6000 A5 T0.0 ; Set Z probe type to bltouch and the dive height + speeds (F100 T2000 original settings)

;M558 P9 H10 F500 T4000 X0 Y0 Z1 ; Set Z probe type to bltouch and the dive height + speeds (F100 T2000 original settings)

G31 P25 X29 Y-6.5 Z1.2 ; Set Z probe trigger value, offset and trigger height (+=down -=Up) (.75 bowden)(x34.82)(y=-8)---------------------------

M557 X0:200 Y20:200 S50 ; Define mesh grid

M564 H0; Heaters

M305 P0 T100000 B4138 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S280 ; Set temperature limit for heater 1 to 280C; Fans

M106 P0 S0 I0 F500 H T45 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic saving after power loss is not enabled

; Custom settings are not configured

; Miscellaneous

M501 ; Load saved parameters from non-volatile memoryNew Bed.g

; bed.g

; called to perform automatic bed compensation via G32

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun May 16 2021 20:01:34 GMT-0500 (Central Daylight Time)

;M561 ; clear any bed transform

;G29 ; probe the bed and enable compensation

;Dual Z bed.g

G28 ; home

;M401 ; deploy Z probe (omit if using bltouch)

G30 P0 35Y105 Z-99999 ; probe near a leadscrew, half way along Y axis

G30 P1 X205 Y105 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors

;M402 ; retract probe (omit if using bltouch)Old bed.g

;Suggested settings from the Duete3D Dozuki.com

G28 ; home

;M401 ; deploy Z probe (omit if using bltouch)

G30 P0 X35 Y105 Z-99999 ; probe near a leadscrew, half way along Y axis

G30 P1 X205 Y105 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors

;M402 ; retract probe (omit if using bltouch) -

RE: Duet 3D Wifi error 99posted in My Duet controlled machine

@phaedrux It certainly fixed the network issue though the prints are terrible now.

Very under extruded and I'm at a loss for why that is.

Very under extruded and I'm at a loss for why that is. -

RE: Duet 3D Wifi error 99posted in My Duet controlled machine

@hbrownell Okay, so I found another thread that had the similar issue. I had to rebuild the network connection. It lives again, and I'm assuming updated to the latest software.

-

RE: Duet 3D Wifi error 99posted in My Duet controlled machine

M115

FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 2.05.1 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2020-02-09b1

ok -

RE: Duet 3D Wifi error 99posted in My Duet controlled machine

@hbrownell Scratch that. I used YAT and got wifi moduel is bein started ok